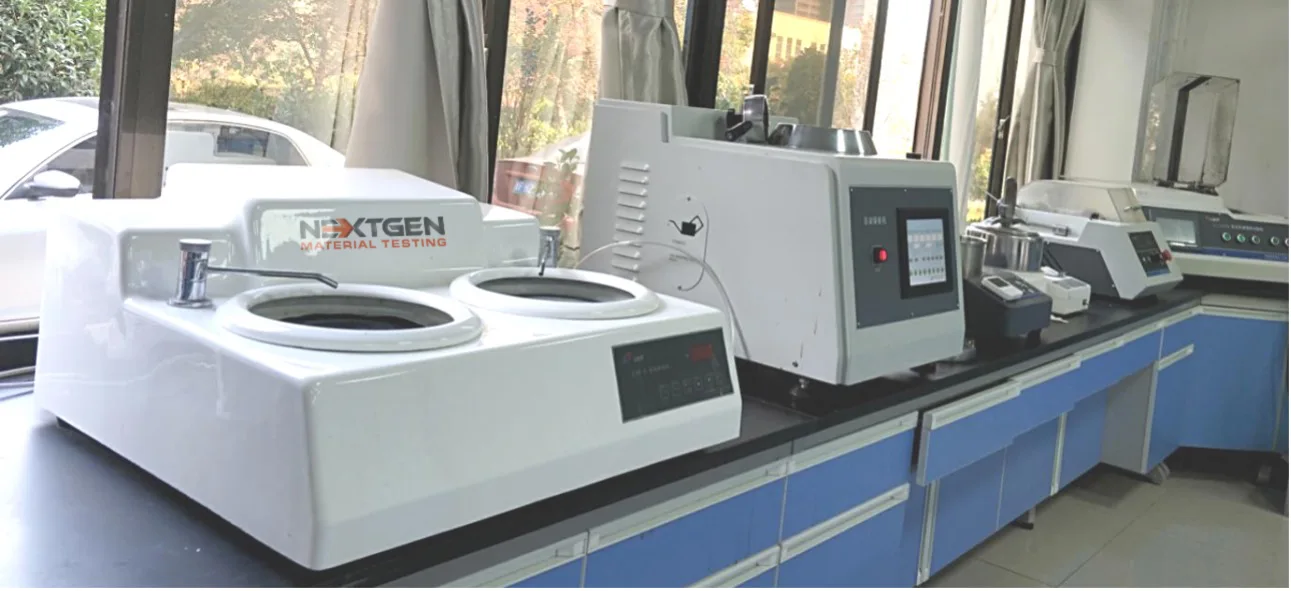

Metal Testing Equipment

Description

NextGen's MFA Series - Fully Automatic Mounting Presses for Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material samples. The fully automatic mounting press system is controlled with a 7” touch screen controller where the parameters for heating, cooling and timing can all be adjusted and saved. GenPress - automatic hot mounting press can store up to 100 operator created programs which can be easily selected and repeated. The GenPress MFA system frees the operator to perform other tasks in the laboratory during the cycle and sounds an alarm when the cycle is completed. More in our MEGA blog!

The MFA series - mounting presses has an integrated hydraulic system to apply the necessary compression to form quality samples. The unit is conveniently sized to be configured for any laboratory or production setting. Sample sizes are available in 1”, 1.25”, 1.5”, 1.75”, 2" as well as 25mm, 30mm, 40mm and 50mm. With the use of optional sample spacers, the MFA series - hot mounting presses can prepare one to two mounted samples in a single cycle. This state-of-the-art automatic mounting press provides a cost-effective option for a fully automatic metallography mounting press.

Fully Automatic Mounting Press Standard Configuration

-

Mounting Press

-

Mold Assembly (please identify which size of mold assembly upon ordering)

-

Powder Spoon

-

Funnel

-

Water Inlet Pipe

-

Drain Pipe

-

Cleaning Brush

-

Dual Spacer

-

Operation Manual

GenPress MFA Features

-

High Quality ABS Shell allowing for a modern appearance with ease of cleaning and maintenance

-

Touch Screen Control – 7” User Friendly Interface

-

Precision Hydraulic Operated Cycles with Silent Operation

-

Closed Loop Fully Automatic Process

-

Integrated Cooling System allows for more efficient sample preparation times

-

Molds can be customized depending on your size requirements

-

Operated Manually or Automatically – depending on your requirements

-

Up to 100 Sets of Cycle Memory

-

Up to 2 samples can be produced in one cycle

Fully Automatic Mounting Press Technical Specifications

|

Model |

GenPress MFA |

|

Mold Diameter |

Standard Ø40mm (option:Ø22/25/30/45/50mm) |

|

Mosaic programming |

Programmable database with the ability to store over 100 programs |

|

System Pressure |

0-300Bar |

|

Pressure Setting Range |

0-60Bar |

|

Heater Power |

2KW |

|

Mosaic temperature Range |

0 - 200℃ adjustable |

|

Mosaic time Range |

0-99min |

|

Cooling Down Time Range |

0-99min |

|

Pressure Loading |

Automatic loading pressure (by hydraulic system) |

|

Cooling |

Water cooling (Chiller available as an optional purchase) |

|

Mounting Program |

Can edit and save over 100 mounting programs |

|

Operation and Display |

7" touch screen |

|

Working mode |

Automatic and/or Manual Operation |

|

Total Power |

2.2KW |

|

Power supply |

AC220V 50/60Hz |

|

Dimension & Weight |

18” x 24” x 20”; 143lbs / 460 x 600 x 500mm; 65kg |

FAQs

In order to provide service in environments where space is at a premium, the GenPress MFA HYD - Fully Automatic Hydraulic Mounting Press is specifically designed with dimensions of 460mm x 600mm x 500mm (or 18" x 24" x 20" in imperial measurements) to provide service in environments who have a limited amount of space. Its compact footprint makes it an ideal choice for smaller laboratories or facilities where space optimization is crucial. Despite its modest size, the machine does not compromise functionality or efficiency.

It is this combination of compactness and capability that makes the GenPress MFA HYD one of the most popular devices among professionals working in small labs and confined spaces. That's a testament to the thoughtful engineering that has gone into the design of a mounting press that is capable of fitting seamlessly into a compact area while still delivering top-notch performance.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press boasts dimensions of 460mm in width, 600mm in depth, and 500mm in height. For those more accustomed to imperial measurements, these dimensions translate to approximately 18 inches wide, 24 inches deep, and 20 inches high. Considering the weight of the machine, it is estimated that it weighs 65 kilograms, which is approximately 143 pounds.

In addition to the dimensions and weight of the GenPress MFA HYD, its compact yet robust design makes it suitable for use in both laboratory and industrial environments, thanks to its compact yet robust design. As a result of its relatively moderate size, it isn't likely to occupy a great deal of space, while its weight underlines its durability and stability during operation. It is important for users to allocate sufficient space for this equipment, both in terms of its dimensions and weight, to ensure that they are able to use it safely and efficiently.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD - Fully Automatic Hydraulic Mounting Press requires a power supply of AC220V with a frequency of either 50Hz or 60Hz in order to operate properly. The following specification identifies the standard voltage and frequency at which the device is designed to operate in a safe and efficient manner.

It is typical for many laboratory and industrial equipment to require a power supply of this type. The device's AC220V input ensures robust performance for its operations. The dual-frequency compatibility (50Hz and 60Hz) ensures flexibility to be used in various regions with different power standards without experiencing any issues. There are certain requirements that must be met by the power source before the GenPress MFA HYD can be installed or used for the first time. It will ensure that the device will have optimal functionality as well as a long lifespan.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press is designed with a power-efficient system, having a total power consumption of 2.2KW. The power rating of this device ensures that it can efficiently mount while at the same time maintaining its optimal performance. It is due to the 2.2KW total power consumption of the machine that it has been able to achieve the perfect balance between performance and energy efficiency.

Having a clear understanding of a machine's power consumption is crucial for laboratory and industrial setups. It allows for appropriate electrical planning, ensures operations safety, and can save money over time. The GenPress MFA HYD offers robust functionality while at the same time keeping energy consumption at a minimum thanks to it's 2.2KW rating. As a result, this is an advantage for environments aiming for productivity and sustainability at the same time.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD - Fully Automatic Hydraulic Mounting Press employs an advanced automatic loading pressure mechanism which is operated by the integrated hydraulic system in the press. By making use of this technology, the machine will be able to consistently apply the necessary pressure to mount samples, so that each time a sample is mounted, it will result in a uniform and quality finish.

In addition to providing greater precision and stability, the hydraulic system also reduces the chances of errors or inconsistencies occurring during the mounting process as a result of using hydraulics. It offers the benefit of automatically adjusting and delivering the required pressure without manual intervention, which can be crucial for achieving optimal sample preparation.

Furthermore, the hydraulic pressure loading feature ensures that the machine operates smoothly and efficiently, reducing wear and tear and increasing longevity. By automating this critical step, the GenPress MFA HYD increases productivity and maintains sample integrity.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press offers an adjustable temperature range from 0 to 200℃. This variety of temperature settings is essential for metallographic sample preparation.

As a result of the mounting press's ability to adjust between such a wide temperature range, it is able to cater to different types of samples, each of which has unique temperature requirements to ensure optimal processing. GenPress MFA HYD is capable of handling both low and high-temperature needs with precision, starting at room temperature and extending up to 200°C.

This flexibility in temperature control is pivotal for ensuring that each sample is processed under optimal conditions, preserving its structural integrity and characteristics. Whether the sample requires just slight heating or needs to be processed closer to the upper limit, the GenPress MFA HYD provides consistent and reliable temperature settings. This is to meet the exact requirements of each procedure.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press comes equipped with a heater with 2KW. The robust heating capabilities of the mounting press ensure that sample preparation materials can be heated efficiently and quickly during the mounting process.

A 2KW heater power allows the GenPress MFA HYD to reach desired temperatures swiftly, reducing wait times. It's essential for the integrity and quality of metallographic samples that the temperature be controlled and consistent. Whether the samples require a moderate or high level of heat during the mounting process, the 2KW heater ensures the temperature remains stable throughout.

It is due to the existence of such a powerful heating system in the GenPress MFA HYD that metallographic sample preparation is both efficient and of the highest quality possible. Professionals in this field will be able to benefit from this service since it caters to their needs.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press has a pressure setting range from 0 to 60 bar. This adjustable range provides users with the flexibility to select the optimal pressure setting based on the specific requirements of their samples and the mounting procedure they are undertaking.

This range ensures that the mounting process can be tailored to accommodate different materials, each with unique properties and mounting needs. By operating at the lower end of the spectrum, delicate or sensitive samples can be treated with the necessary care, ensuring their preservation. Conversely, for materials that require a higher level of pressure, higher settings can be employed.

Flexibility is vital in metallographic sample preparation, where diverse materials are often encountered. The ability to precisely set the desired pressure within the 0-60 bar range allows for consistent and high-quality sample mounting, making the GenPress MFA HYD an indispensable tool for laboratories and production environments alike.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press boasts a system pressure range from 0 to 300 bar. This comprehensive range indicates the machine's capability to handle a multitude of tasks. It is adaptable to diverse material samples and mounting demands.

For delicate samples, the machine can operate at the lower end, ensuring specimen integrity. Conversely, for more robust or dense materials that necessitate greater force for effective mounting, the machine can be adjusted to function at higher pressures. This adaptability ensures that whether one is dealing with fragile materials or more resilient materials, the GenPress MFA HYD remains a reliable tool.

In various laboratory or production settings, the need for a mounting press that caters to a broad spectrum of requirements is essential. The GenPress MFA HYD, with its extensive system pressure range, stands out as a versatile, efficient, and invaluable asset for metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press offers a dual mode of operation, catering to varied user needs and preferences. Users can choose between a manual or an automatic operational mode. The manual mode provides hands-on control, allowing operators to directly intervene and adjust settings as per the specific requirements of the sample or task. This mode is particularly beneficial for unique or one-off tasks where close monitoring and manual adjustments might be necessary.

On the other hand, the automatic mode is suitable for standardized procedures where consistent replication of conditions is desired. Once the parameters are set, the machine can run without constant oversight, streamlining the process and freeing the operator to attend to other tasks. This is especially advantageous in busy labs or industrial settings where efficiency and throughput are crucial.

The GenPress MFA HYD offers flexibility in operation, ensuring that both experts and novices can use the equipment effectively. This is whether they prefer direct control or automation.

Click here to learn more about the product or here to receive a personalized quote.

Recognizing that different applications and samples require different sizes, the machine allows for the customization of molds based on the specific size requirements of the user. This feature is particularly advantageous for laboratories or industries that work with a diverse range of sample sizes and shapes. By offering customizable mold options, the GenPress MFA HYD ensures precise and consistent results for each specimen, irrespective of its dimensions.

Furthermore, using this method does not require the purchase of multiple machines or additional equipment in order to accommodate varying sample sizes. As a result, cost savings are achieved as well as efficient space utilization is achieved. By offering the option of customizing molds, the press becomes more versatile and adaptable in terms of its capabilities and potential. In this way, it can be used for a wide variety of metallographic preparations, therefore it is a very suitable choice.

Click here to learn more about the product or here to receive a personalized quote.

The High Quality ABS Shell featured in the GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press offers multiple advantages. Firstly, the ABS material gives the machine a modern and sleek appearance. This ensures that it functions optimally and complements contemporary laboratory or production environments. Additionally, ABS' inherent properties make it robust and durable, ensuring the machine remains protected from external factors and prolonging its lifespan.

Moreover, one of the standout features of this shell is its ease of cleaning and maintenance. Unlike some materials that stain, corrode, or degrade over time, ABS remains resilient. Its smooth surface means that dust, dirt, and residues can be easily wiped away. This maintains the machine's clean look and ensures no contaminants interfere with its operation. In the long run, this ease of maintenance can lead to reduced downtime and costs, as well as consistent and reliable performance from the machine. Overall, the High Quality ABS Shell is an essential component that combines form with function, ensuring the GenPress MFA HYD looks as good as it performs.

Click here to learn more about the product or here to receive a personalized quote.

The standard configuration of the GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press is thoughtfully designed to cater to a wide range of metallographic sample preparation needs. At the core of this configuration is the mounting press itself, which serves as primary equipment for compression mounting of material samples. To complement this, a mold assembly is provided. However, it's crucial for users to specify the desired size upon ordering to ensure accurate shaping of samples during mounting.

For accurate measurement and transfer of mounting powders, the configuration includes a powder spoon. Additionally, a funnel is integrated into the system to guide materials or fluids precisely, minimizing wastage. The water inlet pipe ensures the machine has a consistent water supply, crucial for cooling operations. In addition, the drain pipe plays a crucial role in discharging used water and maintaining system efficiency.

Regular maintenance is facilitated by a cleaning brush, essential for machine longevity and optimal performance. The dual spacer is a versatile component, allowing one or two samples in a single cycle. Lastly, an operation manual is provided, offering users detailed guidance on machine operation, troubleshooting, and maintenance.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press is equipped with a feature that allows the use of optional sample spacers. These spacers play an important role in enhancing press operational efficiency and flexibility.

Primarily, sample spacers enable the press to accommodate and process multiple samples at once. By using these spacers, the MFA series can prepare one to two mounted samples within a single operational cycle. This dual-sample capability significantly increases the mounting press throughput, reducing sample preparation time and increasing overall laboratory productivity.

Furthermore, the flexibility to mount either one or two samples offers operators the versatility to customize their sample preparation. This is based on the specific requirements of their analysis or study. For tasks where rapid processing of multiple samples is essential, the dual-mounting feature proves invaluable. On the other hand, for specialized or singular analyses, the machine can be easily adjusted to process a single sample without compromising on mount quality.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press is designed with adaptability and flexibility at its core, as evidenced by its convenient sizing and the diverse range of sample sizes it supports.

Firstly, the press's compact and adaptable dimensions make it an ideal fit for various settings, from compact laboratories to expansive production environments. Its convenient size ensures that it doesn't occupy excessive space, allowing for optimal workspace organization and efficient movement within the setting. Moreover, the press's design makes it easy to integrate into existing workflows or adjust placements when laboratory or production layouts change.

Secondly, the wide range of supported sample sizes, from 1” to 2" and 25mm to 50mm, is crucial in ensuring the machine's applicability across a broad range of metallographic analysis tasks. Different analyses and studies might require samples of varying sizes, and the GenPress MFA HYD's ability to accommodate these diverse sizes ensures that the machine remains relevant and useful for multiple applications. Furthermore, this range caters to both standard industry requirements and specific, niche analytical needs.

Click here to learn more about the product or here to receive a personalized quote.

The integrated hydraulic system in the GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press serves a critical function in metallographic sample preparation.

The hydraulic system provides consistent and precise compression during the mounting process. Compression is a vital aspect of forming samples, ensuring they are shaped accurately, uniformly, and free from defects or inconsistencies. The hydraulic system facilitates force application in a controlled manner. This is essential for high-quality samples that yield accurate analytical results.

Hydraulic systems offer advantages over mechanical methods. It allows for fine-tuning and adjustments, enabling the operator to set the desired pressure levels based on the specific requirements of each sample. This adaptability ensures optimal outcomes across a range of materials and sample types.

The hydraulic system's inherent design minimizes wear and tear on the machine, prolonging its lifespan and reducing maintenance needs. It also enhances the safety quotient, as it reduces the risk of abrupt mechanical failures or over-pressurizing that can damage the samples or the equipment.

Click here to learn more about the product or here to receive a personalized quote.

The automation and alarm features of the GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press play a crucial role in terms of both maximizing productivity and ensuring precision in metallographic sample preparation.

Automation of the mounting press system brings two benefits. Firstly, it ensures a standardized and consistent preparation process, reducing human error. With the press automatically managing the mounting cycle, inconsistencies or irregularities are minimized. This is crucial for accurate and repeatable metallography results.

A second benefit of full automation is that it allows operators to multitask. Instead of being tethered to the machine, monitoring each phase of the process, laboratory personnel can divert their attention to other essential tasks. This optimizes lab time and resource utilization. This multipronged approach to work increases throughput and operational efficiency.

The inclusion of an alarm system complements this automated process by alerting the operator once the cycle has concluded. This ensures timely intervention, be it for sample retrieval or initiating a subsequent cycle, eliminating unnecessary wait times and bolstering workflow. Together, these features make the GenPress MFA HYD an exemplar of modern design, balancing automation with user-centric functionality.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press's ability to store up to 100 operator-created programs is a testament to its advanced design, aimed at facilitating streamlined and efficient metallographic sample preparation. This feature is particularly beneficial for labs and institutions that handle diverse materials, each requiring distinct mounting conditions.

By allowing operators to save their customized programs, the machine offers a quick and seamless way to shift between different sample preparation protocols. This means that, once an optimal setting for a particular material type is discovered, it can be stored and recalled automatically in the future, eliminating the need to manually re-input parameters every time.

With the capacity to save 100 such programs, operators can cater to an extensive range of materials. The easy selection and repetition of these programs ensure consistent and accurate results for every sample, minimizing human error and variability. In essence, this storage capability significantly enhances the press's adaptability and efficiency, making it an indispensable tool for busy laboratories and production settings.

Click here to learn more about the product or here to receive a personalized quote.

The 7” touchscreen controller integrated into the GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press plays an important role in optimizing and simplifying the sample preparation process. This user-friendly interface offers a visual and intuitive method for operators to fine-tune the machine's parameters, including heating, cooling, and timing.

Such precision ensures that materials undergo the exact conditions needed for ideal mounting, guaranteeing consistency across samples. The ability to adjust and save these parameters directly translates to a more customized preparation process for diverse materials. Furthermore, with the save feature, users can establish specific presets, making it easier to replicate conditions for similar sample types in the future.

As a result of the touchscreen controller, the machine's interface has been modernized and its efficiency and precision have been increased. By ensuring that the mounting process can be easily adapted to different materials, users can be assured that every mounting cycle will produce high-quality results, regardless of the material.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press is designed to provide an efficient and streamlined solution for metallographic sample preparation. As a fully automatic mounting press, its primary role is to compress material samples, ensuring they are appropriately prepared and shaped for further analysis or display.

A key feature of this machine is its 7” touchscreen controller, allowing users to adjust and monitor settings such as heating, cooling, and duration. These settings are crucial for ensuring sample integrity and consistency. With its ability to store up to 100 customized user programs, repetitive processes become simplified, ensuring each sample is prepared under identical conditions.

The GenPress MFA HYD offers precision, consistency, and efficiency. It streamlines the material sample preparation process, freeing operators to handle other tasks and ensuring samples are of the highest quality. This is not just a piece of machinery but a vital tool for labs and research facilities that require accurate and reliable sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA DUAL HYD Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material samples

GenPress MFA MOT - Fully Automatic Motorized Mounting Press – Motor Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA MOT mounting press system frees the operator to perform other tasks in the laboratory during the cycle allowing better efficiency

GenVac MP3 Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

Experience our enhanced version of the GenVac MP Series. Our user-friendly touch screen interface along with automatic unit conversion and memory modes holds the title of one of the most advanced systems in the marketplace.

GenVac MP Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

GenVac MP2 - Vacuum Impregnator is designed for precision sample impregnation for porous materials. Common applications for vacuum impregnation systems include rocks and minerals, ceramics, electronic circuit boards and other composite materials.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.