Metal Testing Equipment

Standards

ASTM D412, ASTM E8, ISO 7500-1, ASTM E4, ISO 527, ISO 604, ISO 1184, ISO 37, ASTM D638, ISO 6892-1, ASTM E21

Description

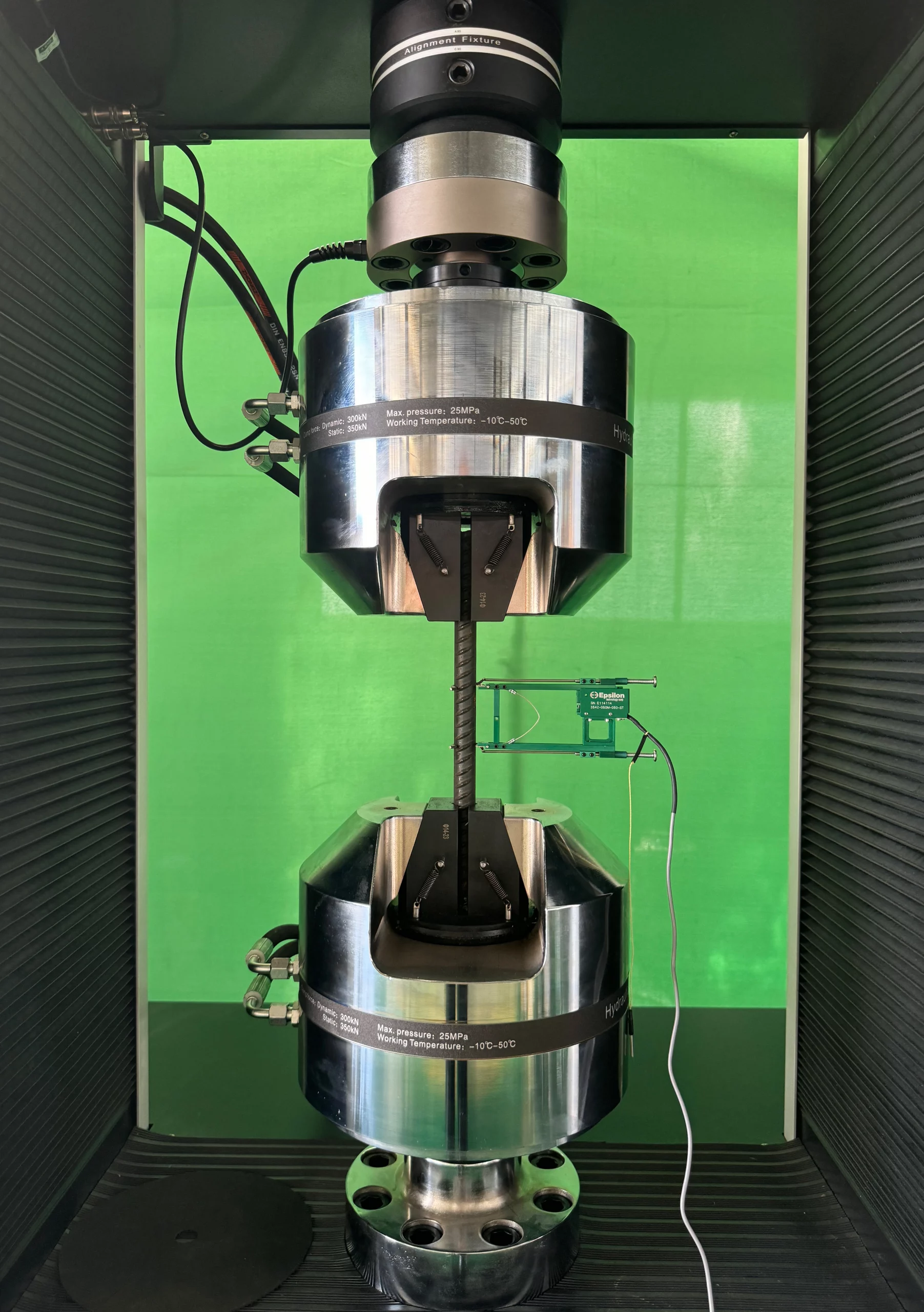

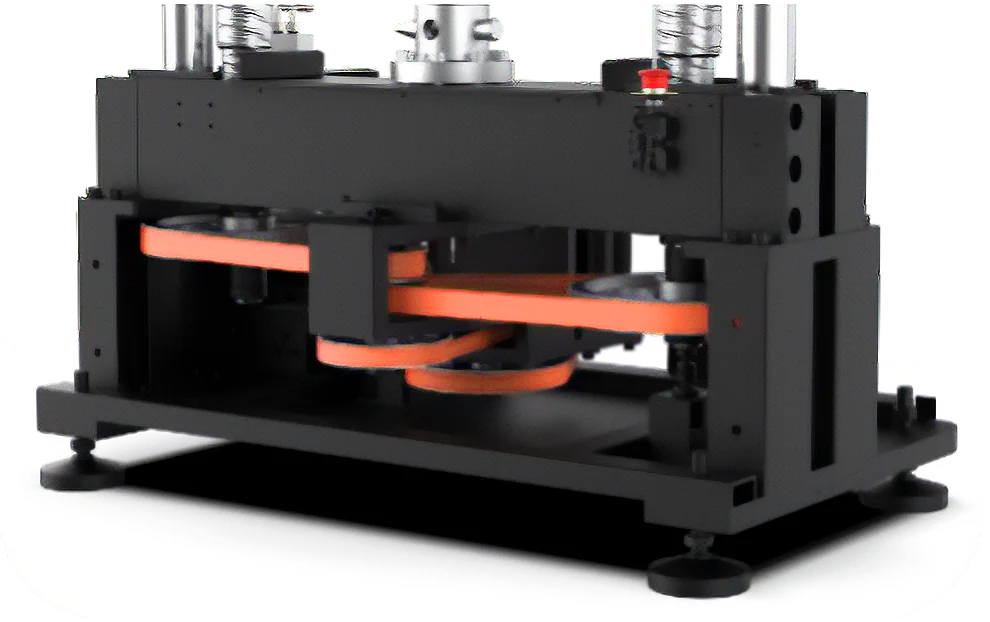

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN) is a heavy-duty electromechanical system developed to meet the increasing demands of testing high-strength steels, advanced composites, high-temperature alloys, and other challenging materials. This system is optimized for both standardized testing and complex research environments requiring maximum stiffness, accuracy, and test stability. The system features a dual-column floor-standing frame, optimized by finite element analysis (FEA), with reinforced guidance columns and preloaded precision assemblies that ensure exceptional mechanical rigidity and alignment. The high-rigidity synchronous belt drive and servo direct-drive architecture allow for low-noise, high-speed, and backlash-free performance during tensile, compression, and flexural testing. High precision is maintained even under extreme test conditions, with a minimum testing speed of 0.00005 mm/min and a sampling frequency of up to 1200 Hz. The system supports intelligent waveform generation, strain rates down to 0.00007/s, and provides collision protection, overload safety, and adaptive closed-loop control.- Force Capacity Options: 50 kN, 100 kN, 200 kN, 300 kN, 500 kN, 600 kN, 1000 kN (11240 – 224800 lbf)

- Frame Configuration: Dual-column, floor-standing electromechanical frame with servo direct-drive and synchronous belt transmission

- Test Space: Available in single-space and dual-space configurations; extended-travel models offered for long specimens or specialized fixtures

- Typical Applications: Suited for high-strength metal testing, composite development, material fatigue studies, thermal testing, and advanced quality control in aerospace, automotive, manufacturing, and research laboratories

Typical Specimens

Designed for high-precision testing of advanced and high-strength materials, the NG-EML Series D system supports a broad range of specimen types, including:- Rubber, elastomers, and soft polymers (ASTM D412, ISO 37)

- Engineering plastics and reinforced composites (ASTM D638, ISO 527, ISO 604)

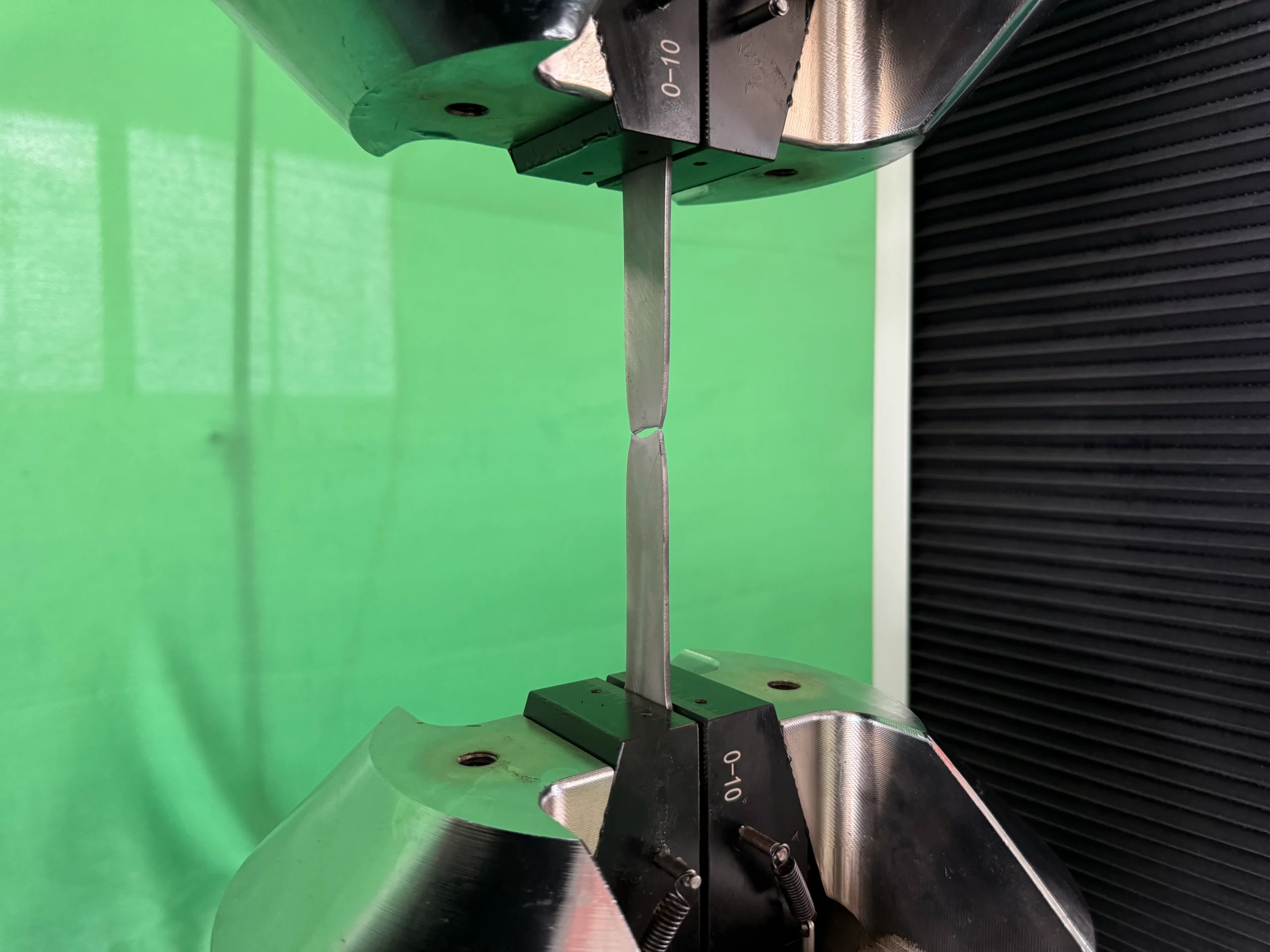

- Metal sheets, rods, and wires including high-strength steels (ASTM E8, ISO 6892-1, GB/T 228)

- High-temperature alloys and prepregs (ASTM E21, ISO 7500)

- Biodegradable plastics and flexible polymers (ISO 1184)

- Flexible electronics and printed substrates

- Structural materials and components tested at elevated loads and temperatures

- Samples requiring advanced strain-rate control or waveform-driven testing procedures

Key Features of the NG-EML Series D UTM

The NG-EML Series D is designed to address the high-performance requirements of contemporary materials testing. Its main features include:- Floor-standing dual-column configuration: Engineered for high stiffness and stability, optimized through FEM analysis. Equipped with robust guidance columns and additional linear guides to ensure accurate crosshead alignment and minimize vibration.

- Direct-drive servo system with synchronous belt transmission: Replaces traditional gear reducers to deliver high-speed motion, minimal vibration, and enhanced energy efficiency. Offers fast acceleration response and higher test stability across a broad range of materials.

- Pre-loaded precision ball screws: Enhances load transmission consistency and reduces mechanical backlash, ensuring reliable results during cyclic or high-force testing.

- Photoelectric encoder-based position measurement: Integrated within the servo system, supports precise displacement tracking with micro-resolution (as low as 0.0095 µm depending on model), ensuring high fidelity in measurement and strain-rate control (as low as 0.00007 s−1).

- Closed-loop control and high-speed data acquisition: 1200 Hz sampling and control frequency, 6-channel 24-bit AD acquisition, and 3-channel digital acquisition (up to 4 MHz). Supports waveform generation including sine and trapezoidal forms.

- Built-in intelligent safety features: Includes overload protection (103% of rated force), mechanical stroke limiters, software-defined safety thresholds, and real-time collision mitigation based on force change detection.

- GenTest™ software platform: Preloaded with ASTM, ISO, GB/T, and EN standard methods. Offers step-by-step workflows, recalculation features, customizable reports, multi-language support, voice broadcasting, and smart accessory control integration.

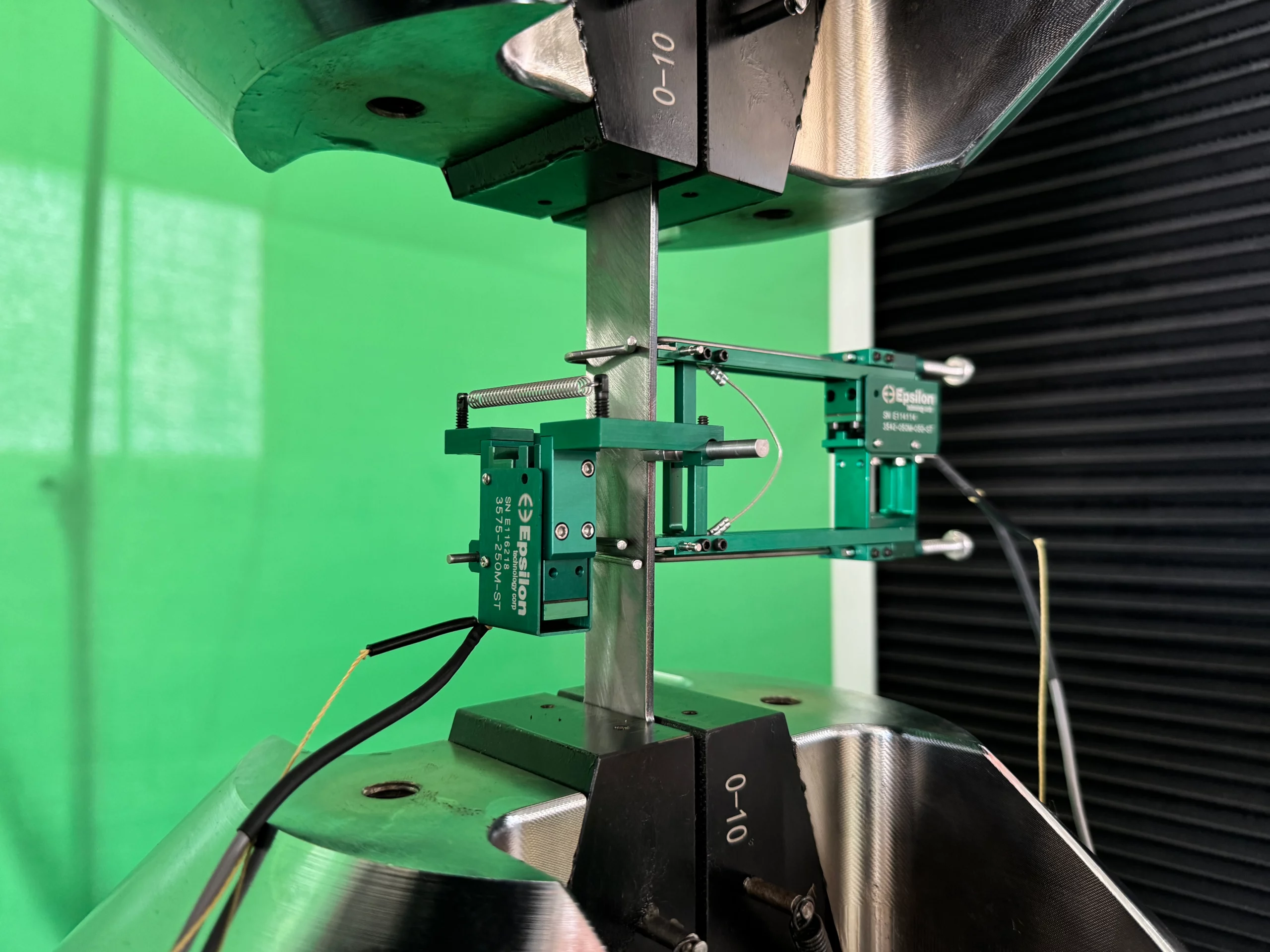

- Flexible system integration: Compatible with extensometers, video extensometers, high/low temperature chambers, pneumatic grip modules, strain gauges, and more. Analog signal output and Ethernet/USB interfaces support external DAQ systems.

- Handset with 3.5” touchscreen: Provides magnetic mounting, real-time data display, crosshead jog, fine-tuning, grip control, and return-to-origin functionality. Dual communication modes with both controller and PC.

Control System

The NG-EML Series D Universal Testing Machine integrates a high-performance digital control architecture designed to deliver precision test execution, high-speed communication, and system-wide integration.- Alternative Connectivity – Ethernet & USB: In addition to USB connectivity, the system supports Ethernet (TCP/IP) communication via a dedicated high-speed chip with integrated hardware logic for complex protocol handling. This provides stable, low-latency data transmission for remote control, lab networking, or distributed acquisition environments.

- Sampling and Signal Acquisition: The controller supports up to 1200 Hz closed-loop control frequency and 1200 Hz real-time sampling, ensuring accurate synchronization of force, position, and extensometer signals. It features a 6-channel 24-bit AD analog measurement system, plus 3-channel high-speed digital input capable of acquiring orthogonal pulse signals (e.g., encoder, grating ruler) at up to 4 MHz.

- Integrated Hardware Safeguards: Embedded firmware constantly monitors voltage, current, overload, motor temperature, and displacement limits. Both hardware- and software-level emergency stop logic are in place to safeguard the system during abnormal conditions.

- Handheld Remote Console (Standard): The system includes a 3.5-inch color touchscreen handset with tactile silicone buttons and a precision rotary control wheel. It supports:

- Crosshead movement (up/down)

- Test start/stop

- Return-to-origin with memory function

- Grip open/close (if equipped)

- Specimen protection logic (to avoid overloading during setup)

Optimized Structural Rigidity

The NG-EML Series D – Floor Standing Universal Testing Machine is built around a dual-column frame architecture that delivers outstanding stiffness, alignment stability, and mechanical durability. Its structure is optimized using finite element analysis (FEA) to minimize frame deflection and mechanical backlash under full load conditions. The system features:- Robust guidance columns with self-lubricating design, ensuring high lateral stiffness and straight crosshead travel.

- Preloaded precision ball screws for consistent axial force transmission and minimal mechanical clearance.

- Integrated servo motor encoder system with high-resolution position tracking.

Advanced Direct-Drive Servo Actuation

The NG-EML Series D – Floor Standing machine features a servo direct-drive transmission system that replaces traditional gear reducers with a high-rigidity synchronous belt mechanism. This architecture improves mechanical efficiency, reduces transmission backlash, and enhances energy efficiency across all test conditions. Key performance benefits include:

Key performance benefits include:

- High-speed crosshead movement: Up to 850 mm/min (for 50–100 kN models) and up to 300 mm/min (for 1000 kN model) depending on frame capacity.

- Fast return speeds: Up to 1200 mm/min, minimizing idle time between tests.

- Ultra-low minimum test speed: Down to 0.00005 mm/min, enabling precise control for tests requiring low strain rates, including high-temperature tensile strain rates as low as 0.00007 s⁻¹.

- Smooth acceleration profiles: Enhanced for dynamic responsiveness during ramp, hold, and waveform-based testing.

Intelligent Safety and Control Architecture

The NG-EML Series D UTM integrates a multi-layered safety and intelligence framework designed to safeguard equipment, test specimens, and operators during all stages of material testing.- Real-Time Collision Detection: The system monitors abnormal force changes in real time. If force exceeds a preset threshold (e.g., specimen break or obstruction), crosshead movement is automatically stopped, preventing damage to the load cell and specimen.

- 103% Overload Protection: The machine features built-in software-configurable overload limits that stop the test once the applied load exceeds 103% of rated capacity.

- Dual Position Limit Safeguards: Both mechanical limit switches and software-defined stroke boundaries are included to prevent overtravel during operation.

- Emergency Stop System: The control unit is equipped with emergency stop circuitry, allowing operators to immediately halt all motion in critical situations.

- Sensor Range Protection: Force, displacement, and extensometer channels are governed by protective logic that halts test execution if inputs exceed calibrated operating ranges.

- Handheld Console Safety: The Handset V3.0 includes safeguards such as grip lockout, overload prevention, and a return-to-initial-position feature to avoid misalignment or misoperation during setup.

Optional Protection Shield

The optional protection shield features a fully enclosed structural design with an aluminum alloy reinforcement frame and high-impact polycarbonate panels. This safety enclosure is engineered in accordance with international mechanical safety standards to ensure maximum protection during critical testing operations. Equipped with an integrated door locking mechanism and software-linked interlock system, the shield restricts system movement when the door is open. This design minimizes the risk of injury and enhances occupational safety in high-throughput or high-force test scenarios.Streamlined Operation and Maintenance

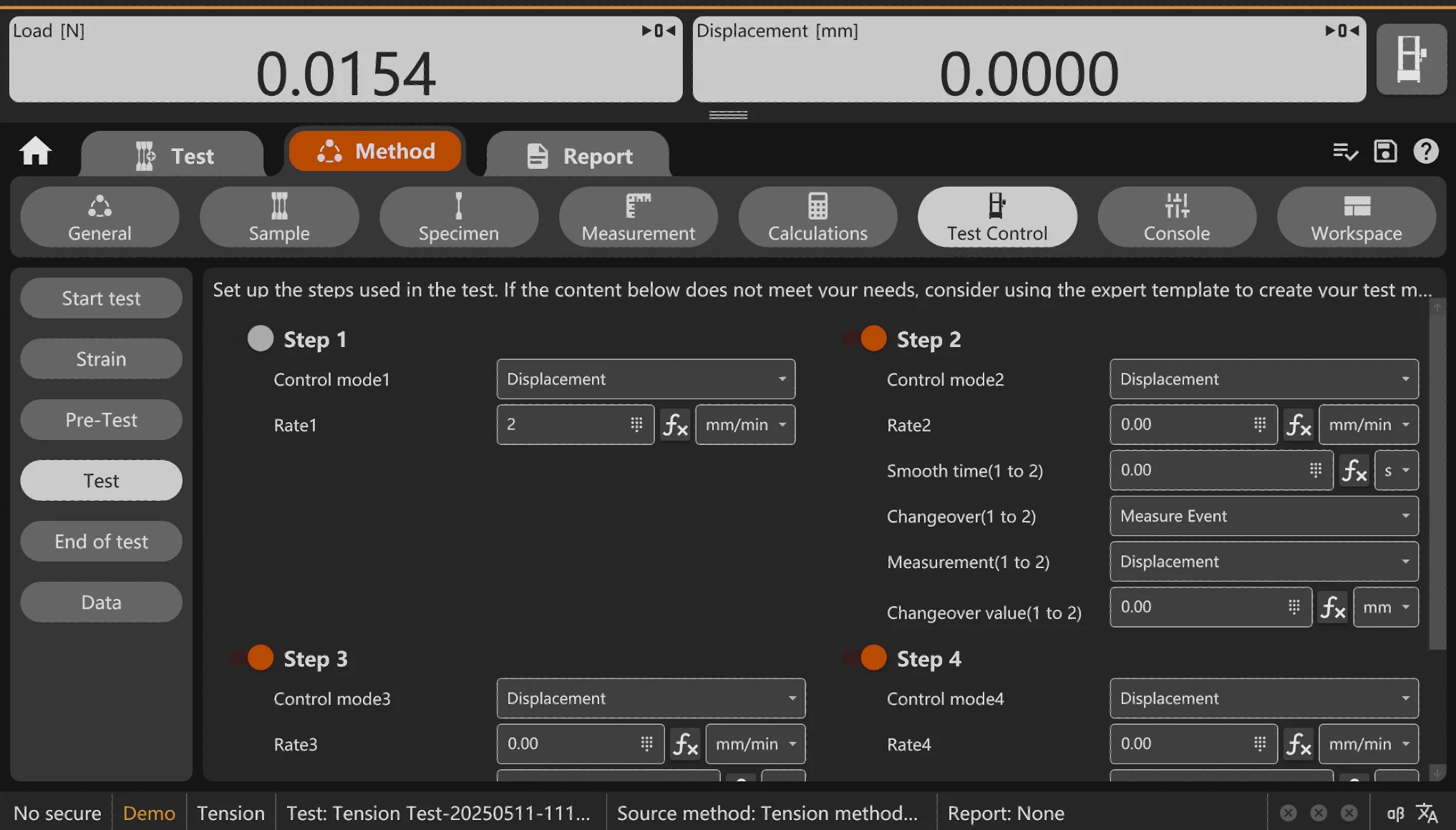

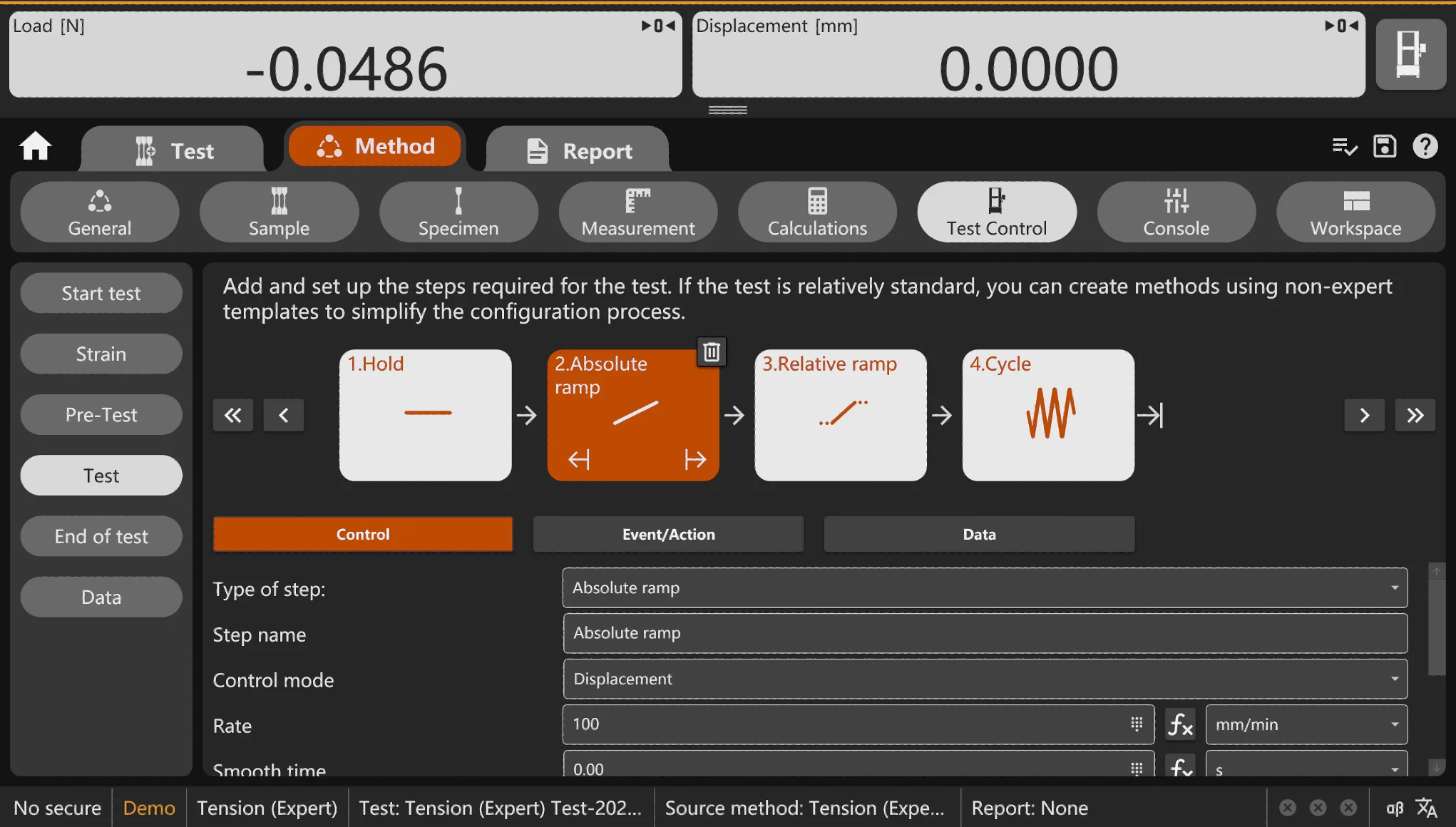

The NG-EML Series D Universal Testing Machine is engineered for ease of operation and maintenance, optimizing daily workflows while minimizing training requirements and service downtime.- User-Centered Software Workflow: The system runs on an intuitive, icon-driven interface. It includes preloaded test templates compliant with ASTM, ISO, GB/T, and EN standards. Users benefit from drag-and-drop test configuration and real-time graphical feedback.

- Guided Test Configuration: Operators can define test sequences through a step-by-step instructional interface, reducing the chance of setup errors and promoting repeatable testing across teams.

- Automated Reporting: Post-test processing includes automatic result calculation (e.g., modulus, yield strength, peak force) and one-click export of raw data and formatted reports. Batch operations are supported for high-throughput labs.

- Accessible Maintenance Architecture: The control unit features a pull-out controller, and redesigned outer covers provide easy tool-free access for inspecting belts, motors, or sensors. This simplifies service routines and minimizes machine downtime.

- Dual Operation Modes: The system can be operated via the 3.5” handheld touch-screen controller or an optional industrial-grade touchscreen PC, allowing flexibility for both standalone operation and synchronized PC-driven workflows.

Mechanical and Electronic Architecture

The Series D UTM is built with a highly rigid dual-column structure and advanced control electronics to guarantee stability, repeatability, and accuracy across various test conditions and material types.Precision Load Frame

The structural integrity of the NG-EML Series D is supported by a reinforced load frame engineered for high-precision, low-friction operation. Key features include:- High-Stiffness Linear Guide System: Reinforced guidance columns with integrated self-lubrication increase lateral stiffness and ensure precise, low-friction vertical movement of the crosshead. This minimizes misalignment and measurement error during displacement- and strain-sensitive testing.

- Synchronous Belt Drive: The direct-drive system uses a high-performance synchronous belt that delivers high-speed, low-vibration, and maintenance-free operation.

- Integrated Optical Encoder: A photoelectrical encoder built into the servo motor system captures crosshead position in real time, supporting micro-displacement measurements with a resolution of up to 0.0095 µm, depending on the model.

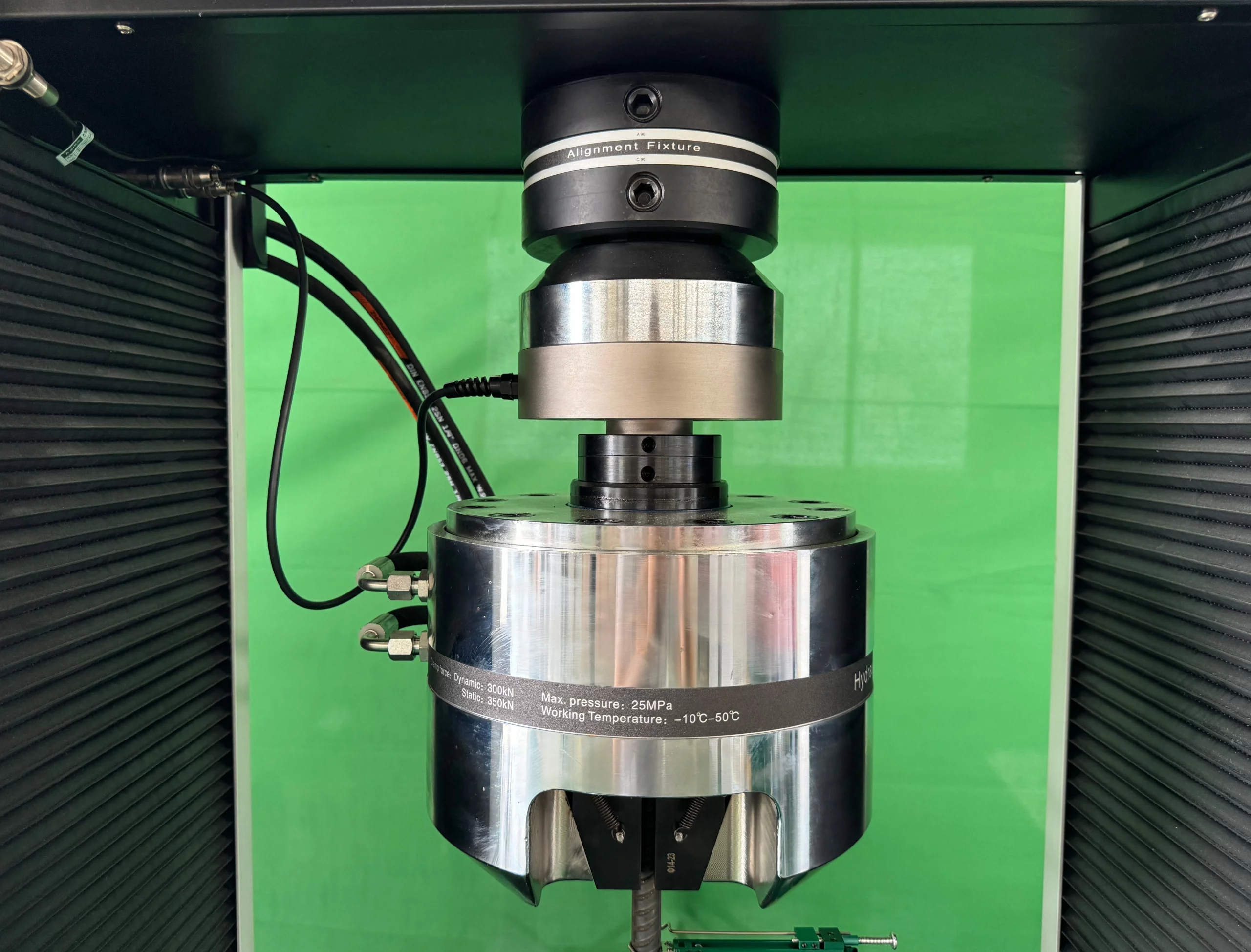

Load Cell Assembly

To ensure accurate and consistent force measurement, the system integrates a high-performance load cell assembly with advanced safety and calibration features:- High-Precision Load Cells: Provide high stiffness, stability, and linearity across the full rated capacity.

- Protection Functions: Built-in safeguards protect against overload and lateral force damage.

- Bidirectional Testing Capability: Supports both tensile and compression testing without reconfiguration.

- TEDS Auto-Recognition: IEEE 1451.4-compliant TEDS chips enable plug-and-play detection of load cells.

- Self-Calibration & Temperature Range: Regular self-verification is supported. Operating temperature range: -55°C to +90°C.

Closed-Loop Controller

The control system is built to deliver high responsiveness, precision, and flexibility for complex test conditions. It integrates advanced signal processing and waveform control features to support a wide range of test types with real-time feedback and accuracy. Key capabilities include:- Advanced PID Control Algorithm: Optimized to match the upgraded direct-drive transmission, allowing responsive system behavior across a wide variety of materials and strain profiles.

- Smooth Control Transitions: Designed for tests requiring high precision at low speeds (e.g., creep and relaxation) and smooth switching between different control types (e.g., force and displacement).

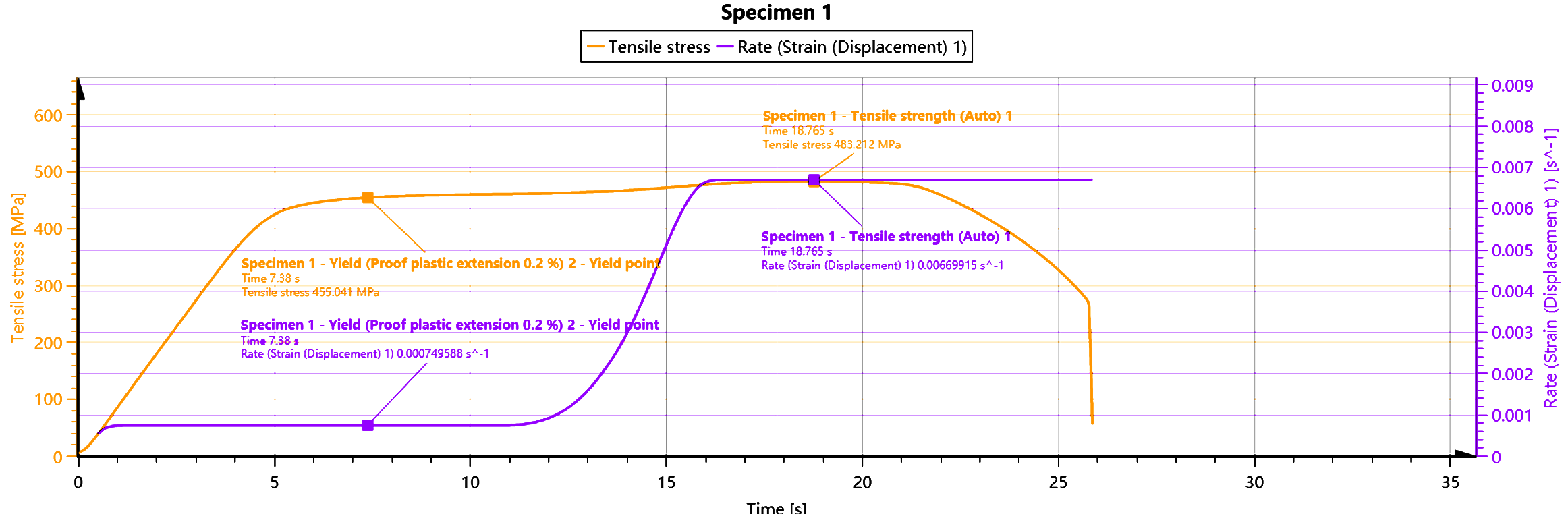

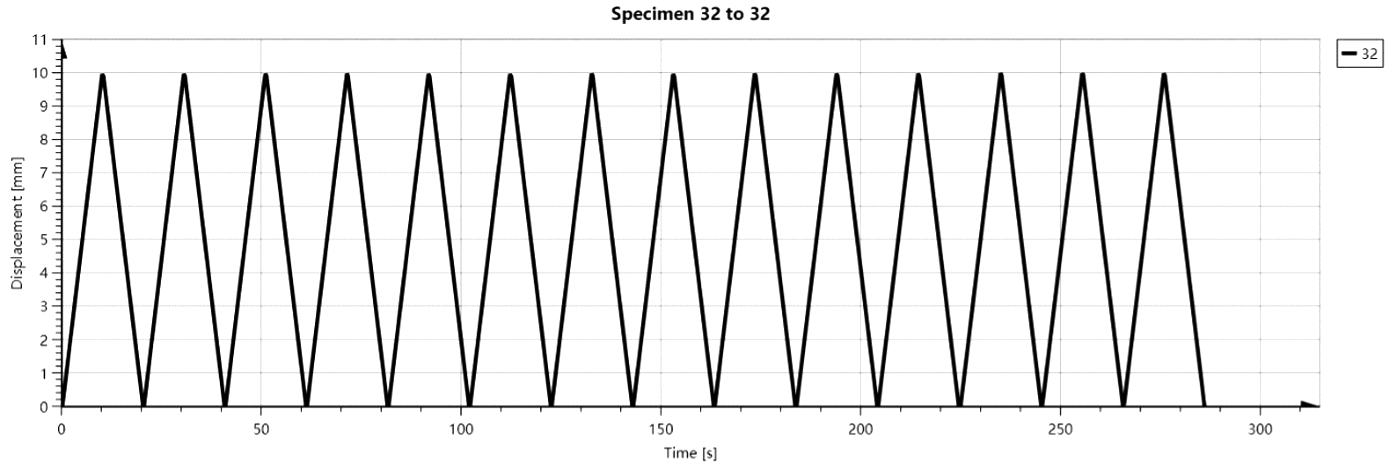

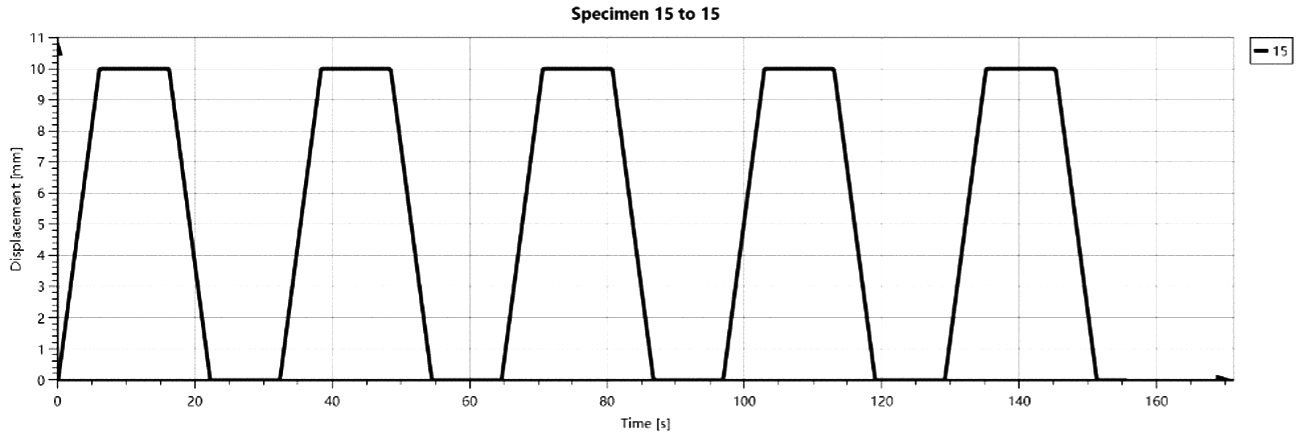

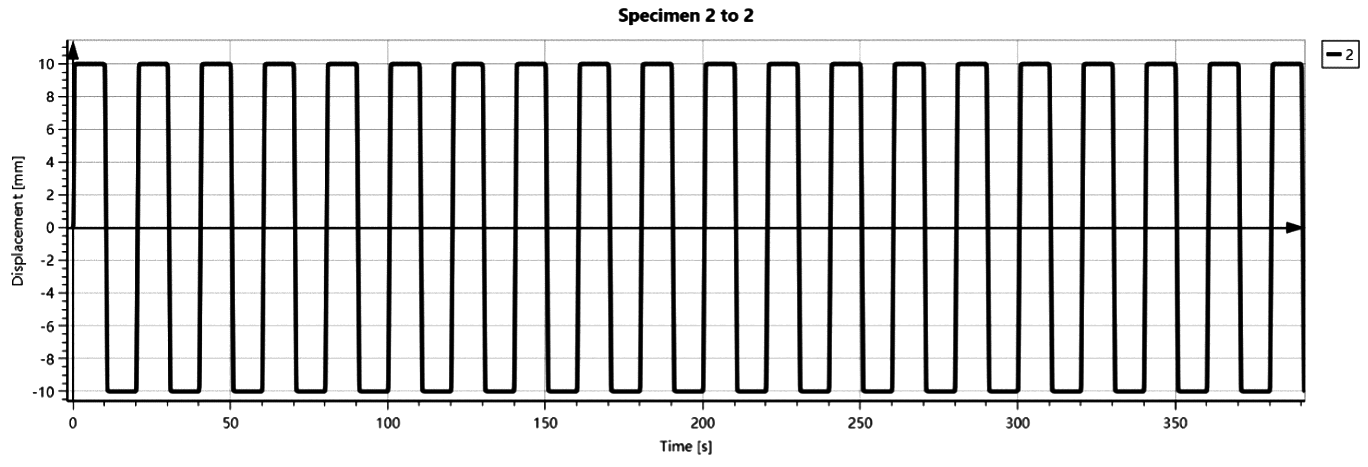

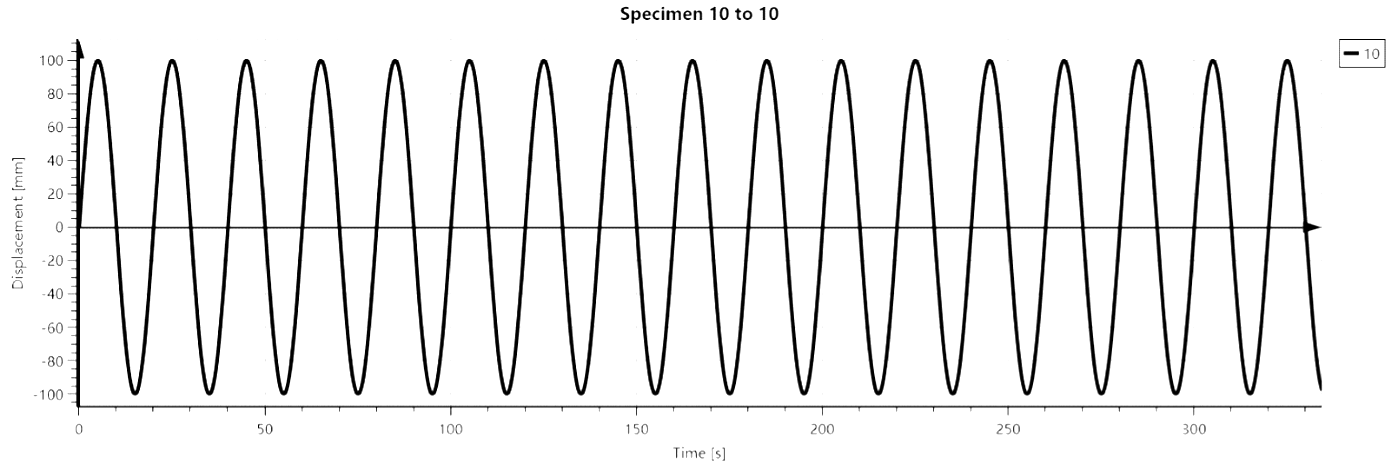

- Waveform Generation Capability: Supports sine and trapezoidal waveform control for

advanced cyclic testing.

advanced cyclic testing.- Multi-Channel Acquisition: Features 6 synchronized 24-bit analog channels and 3 high-speed digital channels for extensometers, strain gauges, and temperature sensors. Signal acquisition frequency reaches up to 4 MHz, with 1200 Hz closed-loop control frequency.

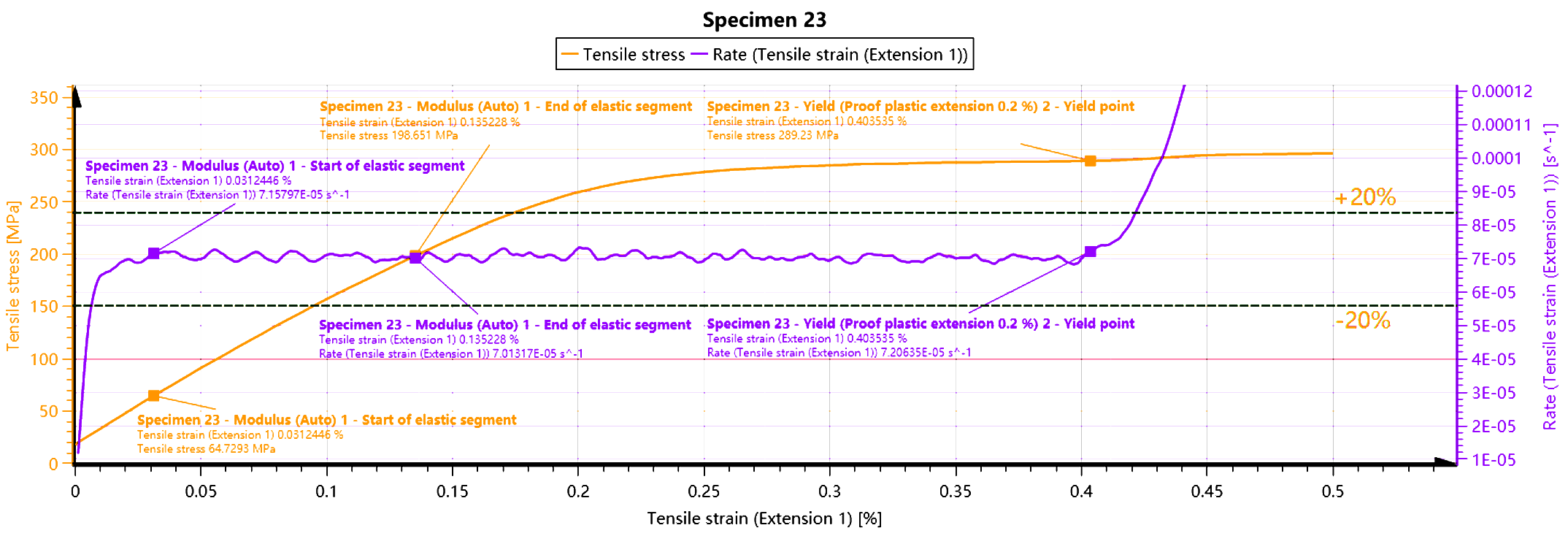

Live Data Visualization and Graphing

- Live Graphing: Real-time display of force-displacement, stress-strain, and time-based curves. Updated continuously at 1200 Hz sampling rate.

- Advanced Analysis: Includes zooming, panning, axis scaling, and overlay of multiple sample curves for comparative analysis.

- Export Formats: Raw data and graphs can be exported in CSV, Excel, PDF, PNG, and SVG formats for external analysis and documentation.

Integrated Control Interfaces

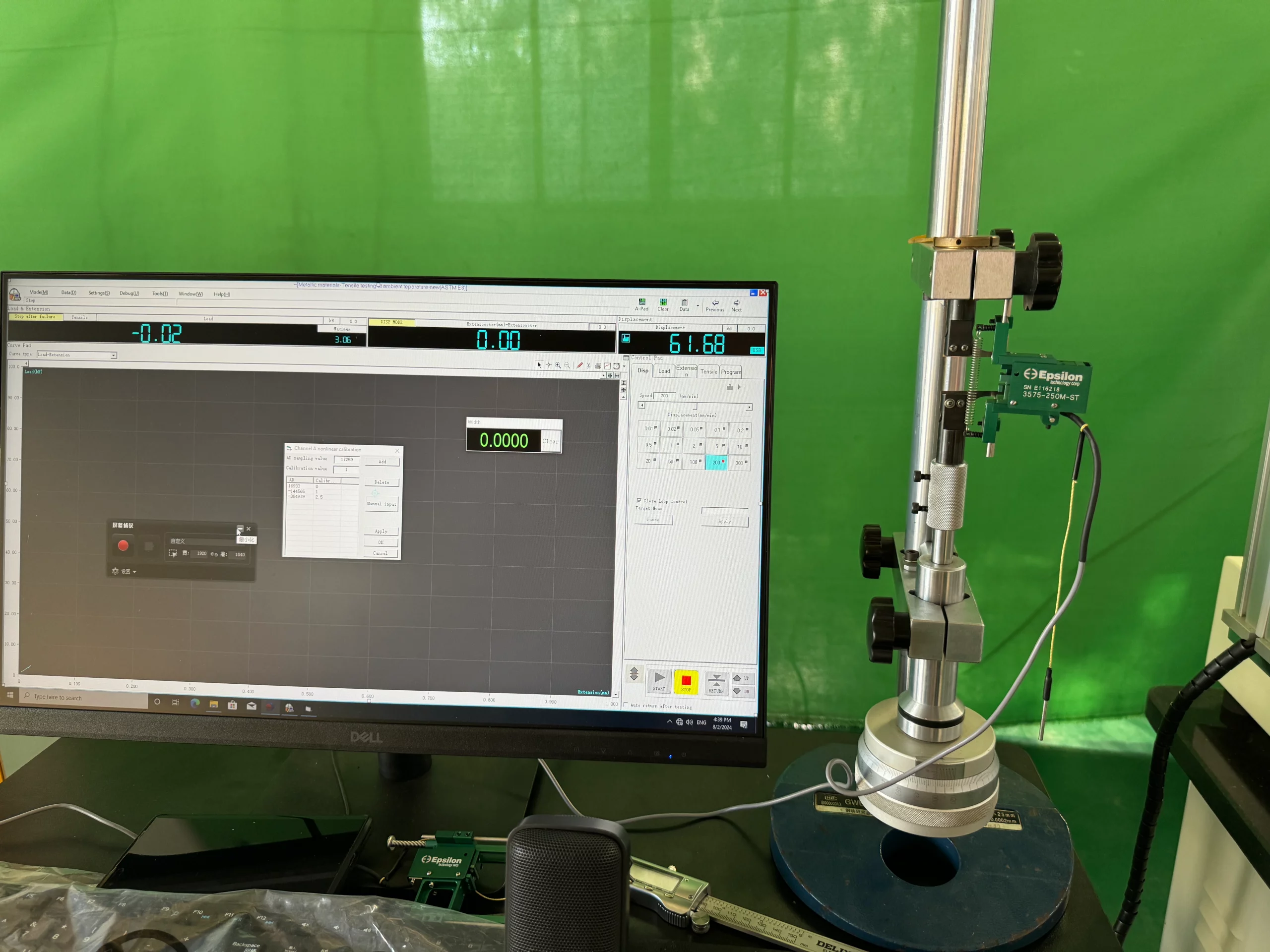

The Series D UTM is engineered to support multiple control and interaction modes, providing operators with ergonomic, efficient, and flexible access to all machine functions. Whether in production, R&D, or training environments, these interfaces streamline test execution, setup, and safety control.

Handheld Remote Controller – Included as Standard

This compact, magnetically mountable remote handset includes a fully integrated 3.5-inch full-color touchscreen display for direct user interaction with test status and parameter control.- Ergonomic Interface: Features silicone-coated buttons and a fine-resolution rotary wheel, which allows precise manual positioning of the crosshead. Operators can jog the crosshead, issue return-to-origin commands, or fine-tune alignment prior to clamping specimens.

- Real-Time Feedback: Live force, displacement, and system state are displayed on-screen. The user receives continuous updates, reducing the need to shift attention between the handset and PC.

- Core Control Functions:

- Start / Stop test

- Return to home position

- Manual jog of crosshead (up/down)

- Grip open/close control (if pneumatic system installed)

- Specimen protection logic – prevents excessive preload during setup

- Flexible Communication Modes: Can function either:

- In direct mode, communicating with the controller via embedded logic

- In PC-synchronized mode, acting as a secondary user input device for software-guided workflows

Optional Industrial Touchscreen PC

An optional all-in-one touchscreen computer can be mounted directly on the load frame, enabling standalone test execution without requiring an external desktop or laptop.- GenTest™ Software Ready: The integrated industrial PC is preloaded with the full version of GenTest™ software. It provides access to all standard test method libraries, custom sequence creation, live graphing, real-time analytics, and report generation tools.

- Intuitive Touch Interface: Multi-touch screen supports tap, drag, pinch-to-zoom, and gesture control. Graphs, test results, and settings are interactively accessible on-screen, minimizing the learning curve for new users.

- Industrial-Grade Build: The PC unit features:

- Shock-absorbing housing

- Sealed surface for dust and moisture resistance

- Vibration isolation mounts (optional)

- Port Expansion: Offers multiple USB ports for data export, printer connection, barcode scanning, or peripheral automation.

GenTest™ Software

- Interface Design: Employs a simplified, flat UI conforming to modern design standards. Optimized font display enhances readability and aesthetic coherence, improving the operator experience significantly.

- Layout and Touch Optimization: Supports both horizontal and vertical display layouts; a numeric keypad is integrated for streamlined touch-based input under operational constraints.

- Demonstration Mode: Enables simulation of tests, allowing familiarization with the software interface without physical specimen interaction.

- Recalculation: Post-test recalculation allows users to modify parameters and reprocess results efficiently.

- Test Standards: Preloaded with built-in test methods compliant with GB/T, ASTM, ISO, and EN standards, organized modularly for streamlined selection.

- Method List: Intuitive display and keyword filtering of test procedures facilitate rapid method identification and selection.

- Quick Test Method: Optimized for tensile and compression tests with minimal configuration steps.

- Data Export: One-click raw data export streamlines post-test processing.

- Test Progress Visualization: Real-time tracking of test steps, cycles, control modes, and duration provides operational transparency.

- Test Graph: Multi-mode interaction with graphs (e.g., touch, keyboard, zoom, and axis panning). Advanced plotting options support complex data visualization needs.

- Function Key Customization: Allows tailored UI controls for specific test methods, maximizing testing efficiency.

- Test Log Recording: Records comprehensive metadata including parameter inputs, system states, and abnormal events for traceability.

- Pre-test Parameter Verification: Enforces parameter validation prior to execution to eliminate procedural errors and reduce waste.

- Sample Protection Mechanism: Prevents premature damage by controlling the clamping sequence and forces.

- Real-Time Data Display: Supports up to 12 configurable channels with customizable layout, units, time formats, and refresh intervals.

- Multifunction Operation Panel: Consolidates manual control functions for connected accessories and core equipment.

- Basic Templates: Pre-configured test method templates support rapid onboarding and expert-level customization.

- Unit System: Includes metric and imperial units; conversion is automatic per selected method or test item.

- Expression Generator: Allows construction of advanced test expressions using logic or variable inputs.

- Measurement Function: Supports multi-channel data collection and live result synthesis.

- Calculation Function: Provides a suite of pre-programmed algorithms for dynamic and static calculations.

- Rounding Function: Permits configurable rounding logic in processed data to ensure result uniformity.

- Test Control: Supports step-based sequencing (ramp, hold, waveform) with customizable trigger events and acquisition strategies.

- Voice Broadcasting Function: Configurable voice prompts guide users through critical testing stages and events.

- Accessory Connection: Broad compatibility with extensometers, chambers, and other peripheral testing hardware.

- Accessory Action Control: Granular control of peripheral device behavior across the test sequence timeline.

- Data Acquisition Strategy: Customizable interval settings prevent data loss during rapid measurement changes.

- Automatic Fixture Pressure Setting: Pressure automatically adjusts based on force thresholds to prevent sample damage.

- Test Report: Full customization of report content and export format, including watermarking and formatting templates.

- Multi-language Switching: Real-time language changes without system reboot enhance international usability.

- Data Analysis: Enables inter-test and inter-batch statistical comparisons for deeper analytical insight.

- Maintenance Reminder: Intelligent system tracking prompts timely servicing to optimize hardware lifespan.

- Permission Configuration Management: Tiered access rights improve operational control and accountability.

- Safety Performance: Covers multi-dimensional safety metrics including electrical, overload, and thermal protections with real-time monitoring.

Technical Specifications

| Model | NG-EML 50–100 | NG-EML 200–300 | NG-EML 500–600 | NG-EML 1000 |

|---|---|---|---|---|

| Force Capacity | 11,240 / 22,480 lbf (50 / 100 kN) | 44,960 / 67,440 lbf (200 / 300 kN) | 112,400 / 134,880 lbf (500 / 600 kN) | 224,810 lbf (1000 kN) |

| Frame Type | Floor-standing | |||

| Test Space | Single-space / Dual-space | |||

| Max Speed | 850 mm/min | 600 mm/min | 330 mm/min | 300 mm/min |

| Min Speed | 0.00005 mm/min | |||

| Return Speed | 1200 mm/min | 500 mm/min | 400 mm/min | |

| Position Resolution | 0.0095 µm | 0.0067 µm | 0.011 µm | 0.011 µm |

| Frame Stiffness | 270 kN/mm | 380 kN/mm | 900 kN/mm | 1300 kN/mm |

| Weight | 2205 / 2690 lbs (1000 / 1220 kg) | 2701 / 3307 lbs (1225 / 1500 kg) | 6528 / 7654 lbs (2960 / 3470 kg) | 12,082 / 13,621 lbs (5480 / 6180 kg) |

| Power Supply | 2 kW | 7 kW | 11 kW | |

| Voltage | 3-phase AC 220 V ±10 %, 50 Hz / 60 Hz | |||

| Common Parameters | |

|---|---|

| Accuracy | Class 0.5 |

| Force Range | 500 N – 1000 kN (0.2% – 100% FS) 10 N – 250 N (0.4% – 100% FS) |

| Calibration Standard | GB/T 16825.1, ISO 7500 (Class 0.5), ASTM E4 |

| Speed Accuracy | ±0.2% of set speed |

| Position Accuracy | ±0.2% of set position |

| Force Resolution | 1 / 600000 FS |

| Extension Resolution | 1 / 600000 FS |

| Strain Accuracy | Better than GB/T 228, ISO 6892-1, ASTM E8, ASTM E21 |

| Safety Protection | Overload protection (103% of rated force), position limit, over-voltage protection |

| Single-Channel Data Sampling Rate | 1200 Hz |

| Control Frequency | 1200 Hz |

| Environmental and Operational Conditions | |

|---|---|

| Working Temperature | +5 °C to +40 °C |

| Storage Temperature | −25 °C to +55 °C |

| Relative Humidity | At 20 °C, +10% to 90%, non-condensing |

| Maximum Operating Altitude | 2000 meters |

| Motor Type | AC servo motor |

| Ball Screw | Pre-loaded |

| Position Measurement | Optical encoder |

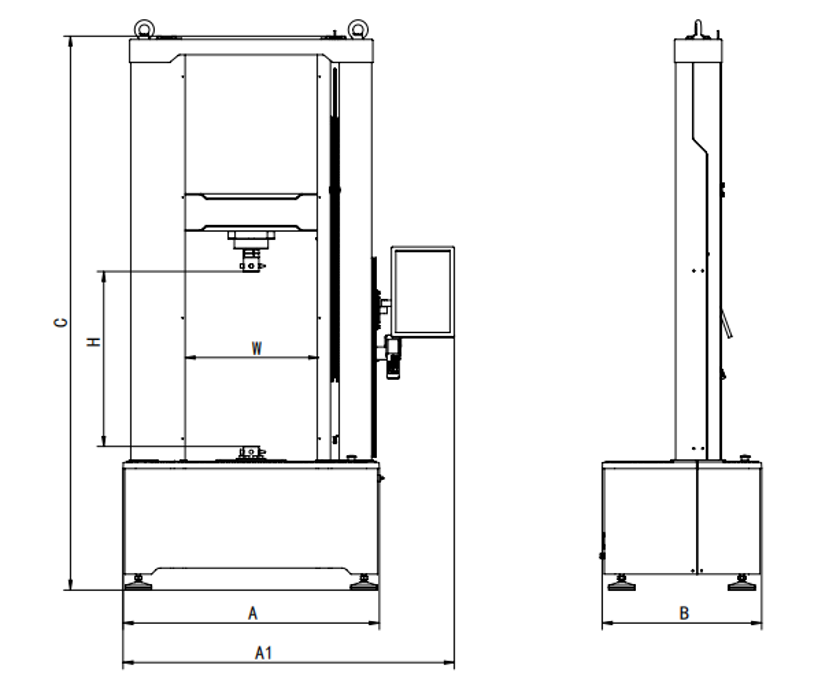

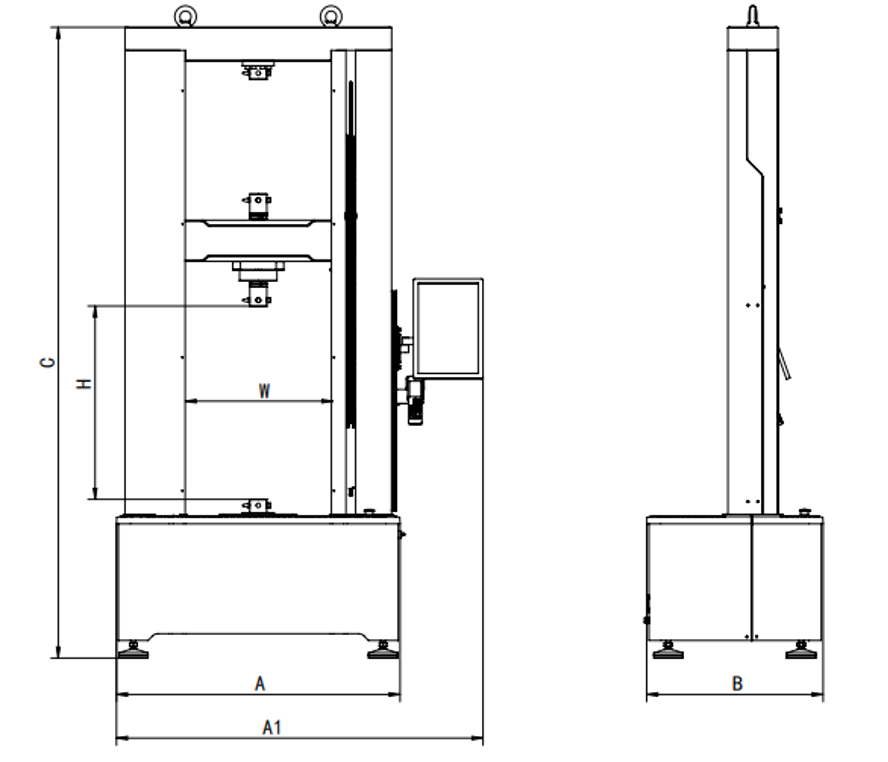

Dimensional Specifications and Drawing References

Machine dimensions depend on the selected kN capacity. Please refer to the tables below for the corresponding values.NG-EML 50–100 & NG-EML 200–300 Models

| Frame Type | Dimensions (A × B × C) | Crosshead Travel (H) | Test Width (W) | Full Width with Display (A1) |

|---|---|---|---|---|

| Standard (single-space) | 46.3 × 28.0 × 100.4 in (1175 × 710 × 2550 mm) | 53.1 in (1350 mm) | 23.6 in (600 mm) | 65.2 in (1655 mm) |

| Standard (dual-space) | 46.3 × 28.0 × 103.1 in (1175 × 710 × 2620 mm) | 49.2 in (1250 mm) | ||

| Extended 300 mm (single-space) | 46.3 × 28.0 × 112.2 in (1175 × 710 × 2850 mm) | 65.0 in (1650 mm) | ||

| Extended 300 mm (dual-space) | 46.3 × 28.0 × 115.0 in (1175 × 710 × 2920 mm) | 61.0 in (1550 mm) | ||

| Extended 600 mm (single-space) | 46.3 × 28.0 × 124.0 in (1175 × 710 × 3150 mm) | 76.8 in (1950 mm) | ||

| Extended 600 mm (dual-space) | 46.3 × 28.0 × 126.8 in (1175 × 710 × 3220 mm) | 72.8 in (1850 mm) |

Single-Space Frame Configuration

Dual-Space Frame Configuration

NG-EML 500–600 Models

| Frame Type | Dimensions (A × B × C) | Crosshead Travel (H) | Test Width (W) | Full Width with Display (A1) |

|---|---|---|---|---|

| Standard (single-space) | 56.3 × 33.5 × 108.7 in (1430 × 850 × 2760 mm) | 29.5 in (750 mm) | 29.5 in (750 mm) | 90.6 in (2300 mm) |

| Standard (dual-space) | 56.3 × 33.5 × 111.8 in (1430 × 850 × 2840 mm) | 25.6 in (650 mm) | 29.5 in (750 mm) | 90.6 in (2300 mm) |

| Extended 300 mm (single-space) | 56.3 × 33.5 × 120.5 in (1430 × 850 × 3060 mm) | 41.3 in (1050 mm) | 29.5 in (750 mm) | 90.6 in (2300 mm) |

| Extended 300 mm (dual-space) | 56.3 × 33.5 × 123.6 in (1430 × 850 × 3140 mm) | 37.4 in (950 mm) | 29.5 in (750 mm) | 90.6 in (2300 mm) |

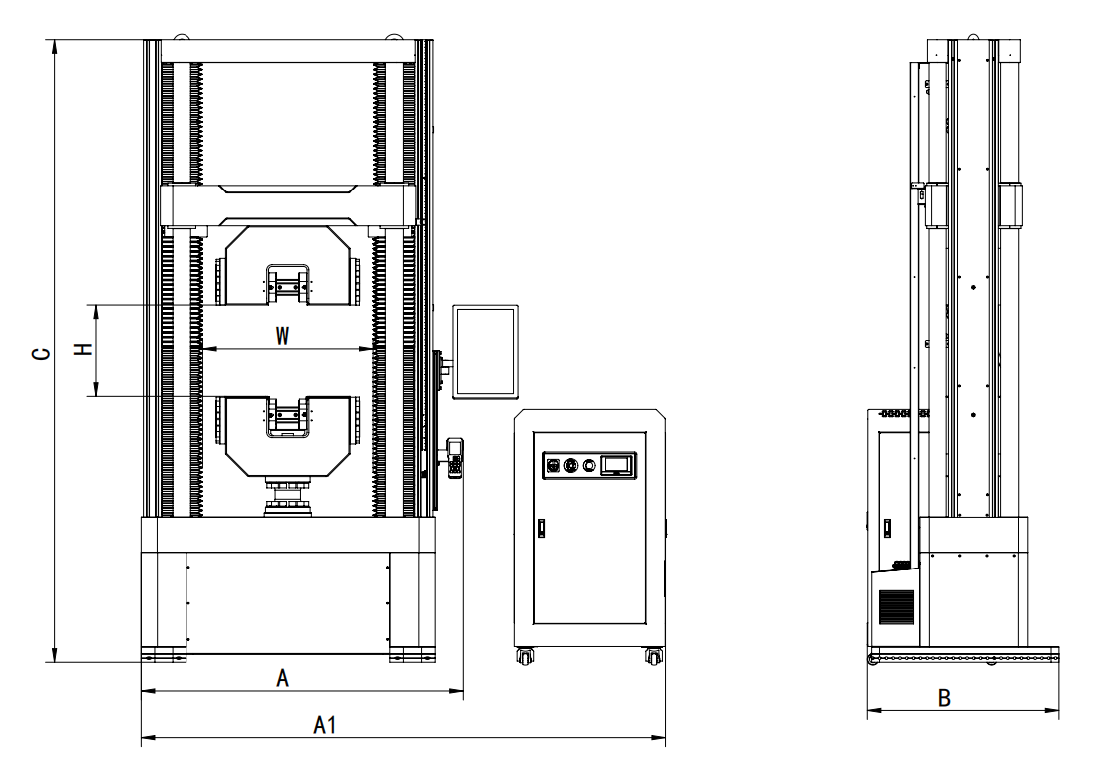

NG-EML 1000 Model

| Frame Type | Dimensions (A × B × C) | Crosshead Travel (H) | Test Width (W) | Full Width with Display (A1) |

|---|---|---|---|---|

| Standard (single-space) | 61.8 × 39.4 × 122.0 in (1570 × 1000 × 3100 mm) | 19.7 in (500 mm) | 35.0 in (890 mm) | 96.5 in (2450 mm) |

| Standard (dual-space) | 61.8 × 39.4 × 128.0 in (1570 × 1000 × 3250 mm) | 35.4 in (900 mm) | 35.0 in (890 mm) | 96.5 in (2450 mm) |

| Extended 300 mm (single-space) | 61.8 × 39.4 × 133.9 in (1570 × 1000 × 3400 mm) | 31.5 in (800 mm) | 35.0 in (890 mm) | 96.5 in (2450 mm) |

| Extended 300 mm (dual-space) | 61.8 × 39.4 × 139.8 in (1570 × 1000 × 3550 mm) | 23.6 in (600 mm) | 35.0 in (890 mm) | 96.5 in (2450 mm) |

Single-Space Frame Configuration

FAQs

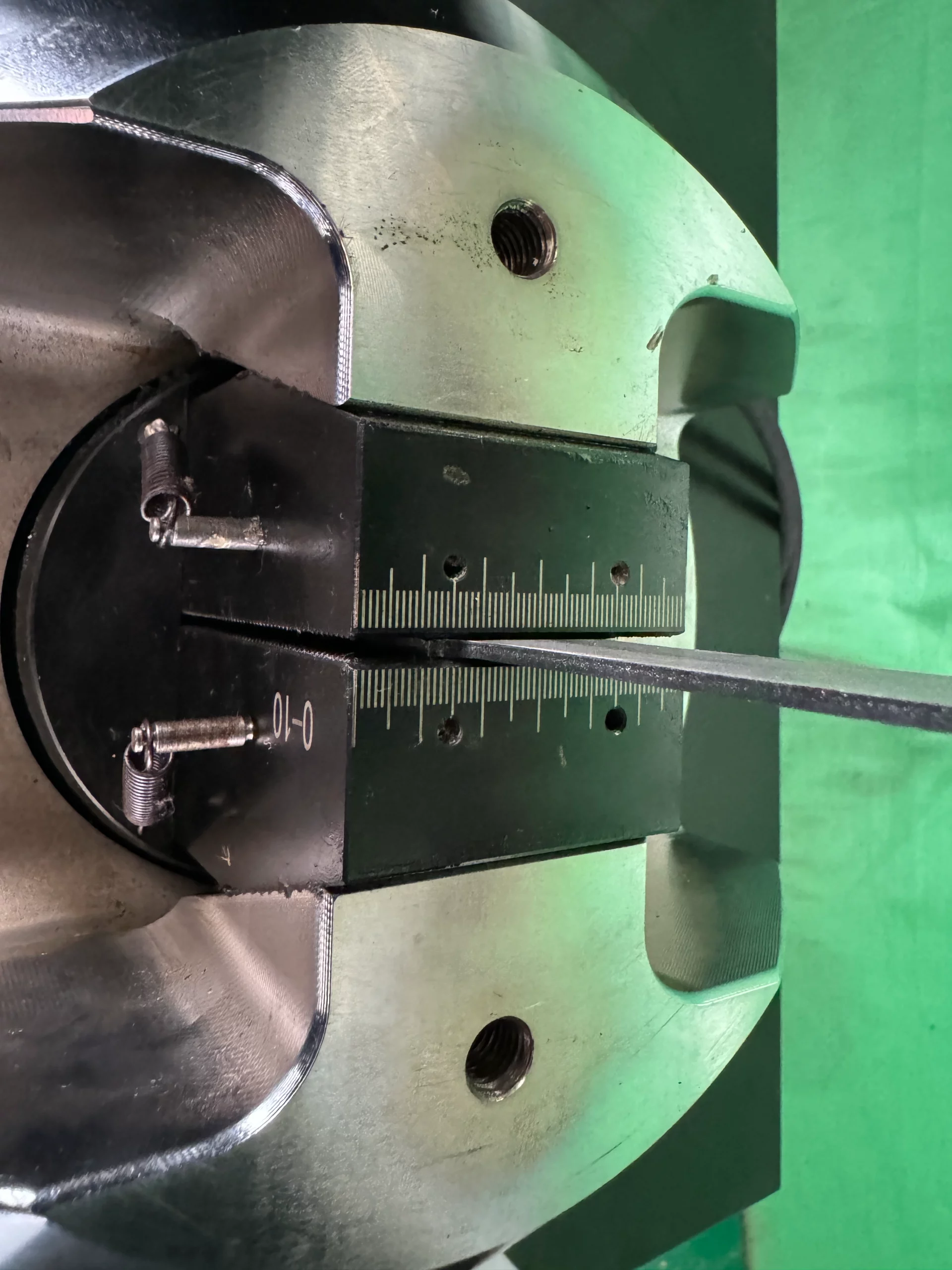

NextGen Material Testing offers a comprehensive range of high-precision grips and fixtures specifically designed for use with NG-EML Series Universal Testing Machines. These accessories enable accurate and repeatable tensile, compression, flexural, shear, peel, and puncture testing across a wide range of materials, including metals, plastics, composites, rubber, and wood.

The available solutions include:

- Wedge grips for high-load metal and composite testing (ASTM E8, ISO 6892)

- Pneumatic grips for fast, repeatable clamping of soft and flexible specimens

- Side-action grips with interchangeable jaw faces for general-purpose applications

- Self-tightening and eccentric roller grips for deformable or low-friction materials

- Flexural fixtures for 3-point and 4-point bending (ASTM D790, C393, D6272)

- Compression platens and cages for ASTM D695 and other compression tests

- Snubbing grips for cable and wire testing using the capstan method

- Threaded grips for bolt and nut tensile verification (ASTM F606)

- Specialized fixtures for tear, peel, puncture, delamination, and wood testing (ASTM D143, D2344, D3167, etc.)

Each fixture is engineered for optimal load alignment, high-strength durability, and full compliance with ASTM, ISO, and other global testing standards. From basic clamping to advanced high-capacity or component-specific testing, these fixtures are designed to support consistent performance across all NG-EML Series UTM configurations.

Yes, NextGen Material Testing Inc. offers professional calibration services for all NG-EML Series Universal Testing Machines, including Series A, B, C, and D. These services are designed to maintain compliance with international standards such as ASTM E4, ISO 7500-1, ASTM E8, and ISO/IEC 17025:2017.

As a general industry requirement, universal testing machines must be calibrated annually to ensure ongoing accuracy and traceability. Our calibration services are performed by certified technicians and qualified engineers, either during initial installation or as part of routine equipment servicing.

Calibration includes:

- Verification of force measurement systems

- Accuracy checks of extensometers and displacement systems

- Issuance of traceable calibration certificates aligned with ASTM and ISO standards

Alongside calibration, we also provide on-site installation and training, including system setup, mechanical and electrical checks, operational testing, and software introduction for up to three users.

Yes, all NG-EML Series UTMs from NextGen Material Testing Inc. are designed to comply with key international standards, including ASTM E4, ISO 7500-1, ASTM E8, and ISO 6892. These standards ensure that the systems meet the highest levels of accuracy, repeatability, and reliability for force measurement and material testing.

Additionally, NextGen offers full certification and calibration services for both in-house and third-party testing equipment. We work closely with ISO/IEC 17025:2017-accredited partners to support certification under a wide range of international standards such as:

-

ASTM E4 – Force verification for universal testing machines

-

ISO 7500-1 – Verification of force-measuring systems in tension/compression testing

-

ASTM E83 and ISO 9513 – Calibration of extensometers and strain measurement devices

-

ASTM E1012 – Alignment verification for load frames

-

ANSI/NCSL Z540-1-1994 – Calibration system accuracy and traceability

-

NADCAP – For aerospace/defense sector certification (with alignment fixtures available to meet NASM 1312B and ASTM E1012 coaxiality requirements)

All NG-EML Series machines are powered by GenTest™ – an advanced data acquisition and control software platform engineered for precision mechanical testing across a wide range of materials and applications.

Key features include:

-

Preloaded test methods compliant with ASTM, ISO, GB/T, EN, and DIN standards, organized by application type for quick selection

-

A modern, intuitive interface with real-time graphing, live data acquisition, and streamlined navigation for both new and experienced users

-

Advanced analysis tools, such as recalculation, zoomable charts, curve overlays, and multi-batch comparisons

-

Full support for modular accessories, including extensometers, thermal chambers, strain sensors, and pneumatic grips

-

Customizable test reports, automated result calculations, and export options in Excel, PDF, CSV, and image formats

-

Real-time sample protection logic, voice-guided testing prompts, multilingual support, and remote demonstration mode

-

Integrated expression builders, step-based sequencing, waveform generation (e.g., ramp, hold, sine), and automated fixture control

GenTest makes sure that all NG-EML models are fully compliant, easy to use, and give accurate data output, whether they are used in quality control labs or research and development settings.

If you would like to learn more about this software, please visit the official GenTest™ software page.

Yes — NG‑EML Series machines are supported by a robust stocked consumables and spare parts program designed for maximum uptime:

- We maintain an extensive inventory of critical consumables — including grips (manual, pneumatic, hydraulic), extensometer accessories, load cells, bearings, belts, seals, and electronic modules — tailored to bench-top and floor-standing UTM platforms.

- Spare parts are NIST‑traceable, factory‑calibrated, and ready for quick shipment, eliminating extended lead times.

- For higher‑wear items like seal kits or grips, we offer bulk reorder options, making them easy to stock in your lab.

- All parts are plug-and-play compatible with GenTest™ equipped systems, ensuring a hassle-free installation—no technician visit required.

- Replacement orders are filled from regional warehouses, guaranteeing fast delivery worldwide and keeping your machines operational.

- If a rare or specialized component is needed, NextGen will expedite sourcing and shipping, so you're never left waiting.

This guarantees that you can quickly and easily get the parts you need for your UTM investment, exactly when you need them.

Each NG-EML Series machine comes backed by NextGen's Lifetime Product Support Advantage, ensuring long-term technical assistance for the lifetime of the system. From pre-sale consultation to post-installation support, our goal is to provide comprehensive service that aligns with your needs.

NextGen offers both remote and in-person technical support:

-

Over 95% of technical issues are resolved remotely through guided troubleshooting, reducing downtime and eliminating the need for service visits in most cases.

-

If on-site assistance is required, NextGen coordinates with certified local partners in your region. These partners work under our direct guidance to resolve the issue quickly and effectively.

-

Our equipment is supported globally, and its standardized design allows qualified labs familiar with material testing systems to service the equipment with ease.

If you’d like to learn more, feel free to contact us directly or request a quote for a technical support inquiry.

The NG-EML Series Universal Testing Machines are designed with ultimate user-friendliness in mind, making them suitable for both experienced professionals and first-time operators. Every model—whether bench-top or floor-standing—comes equipped with an intuitive, icon-driven interface via the GenTest™ software. This platform supports:

-

Preloaded test method templates (ASTM, ISO, GB/T, EN) to reduce setup time

-

Step-by-step test configuration with guided prompts

-

Real-time graphing and visual feedback for easy monitoring

-

Multilingual interface and voice-guided operation, minimizing the learning curve

-

Handheld touchscreen remote controller (3.5”) with jog wheel and core control functions like start/stop, return-to-origin, and grip actuation

-

Optional industrial touchscreen PC for fully independent control without a computer

In addition, the system allows for rapid accessory changes through a plug-and-test interface, eliminating the need for manual calibration or setup when switching grips or extensometers.

Whether installed in a production lab or research environment, NG-EML machines deliver a seamless and straightforward testing experience for any user level.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.