Metal Testing Equipment

Standards

ASTM E23, ASTM E8, ISO 6892-1, DIN 50125, JIS Z2201

Description

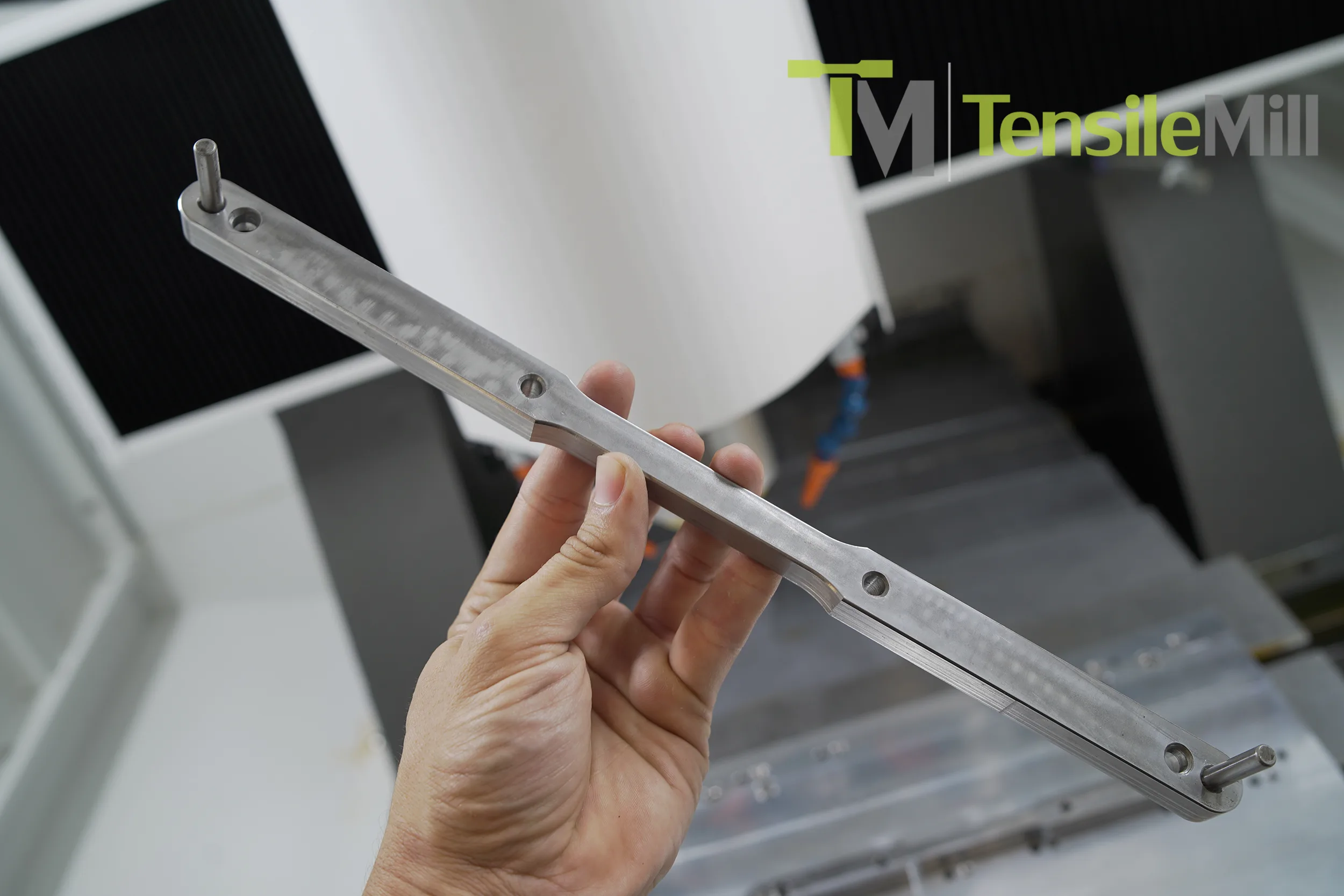

The TensileMill CNC – Classic Upgrade is a hybrid CNC specimen preparation system offered by our partner, TensileMill CNC. It is designed for the precise machining of both flat tensile and Charpy/Izod impact test specimens in-house. The system integrates the dedicated TensileSoft™ specimen preparation interface with a FANUC industrial controller, making operation suitable for both trained CNC machinists and laboratory personnel with minimal machining background.

The system supports specimen preparation for a range of standardized testing methods, including:

- ASTM E8 for metallic tensile specimens

- ASTM E23 for Charpy and Izod impact specimens (U- and V-notch)

- ISO 6892-1 for tensile testing of metallic materials

- DIN 50125 for standardized tensile specimen geometries

- JIS Z2201 for mechanical test specimen dimensions

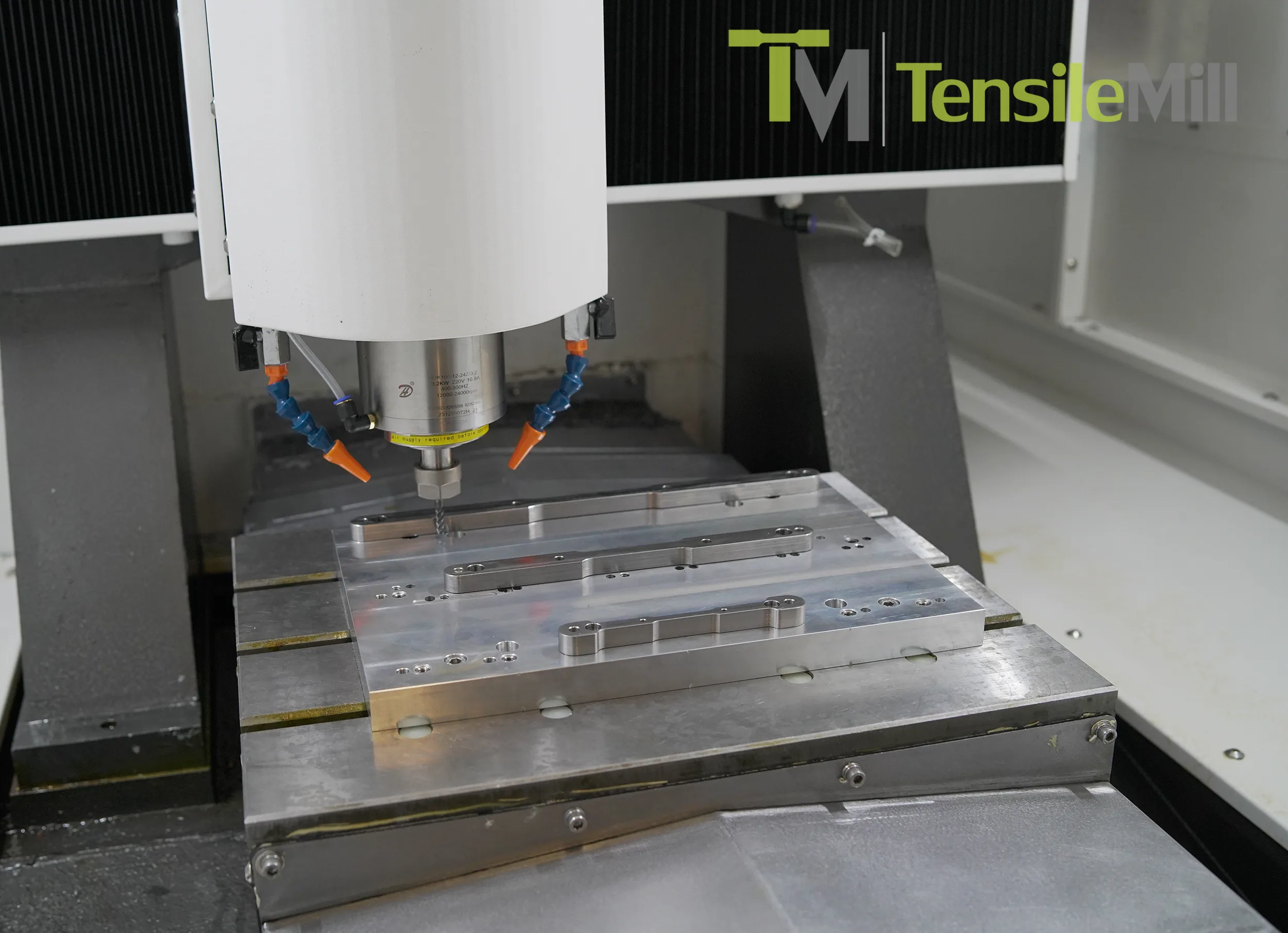

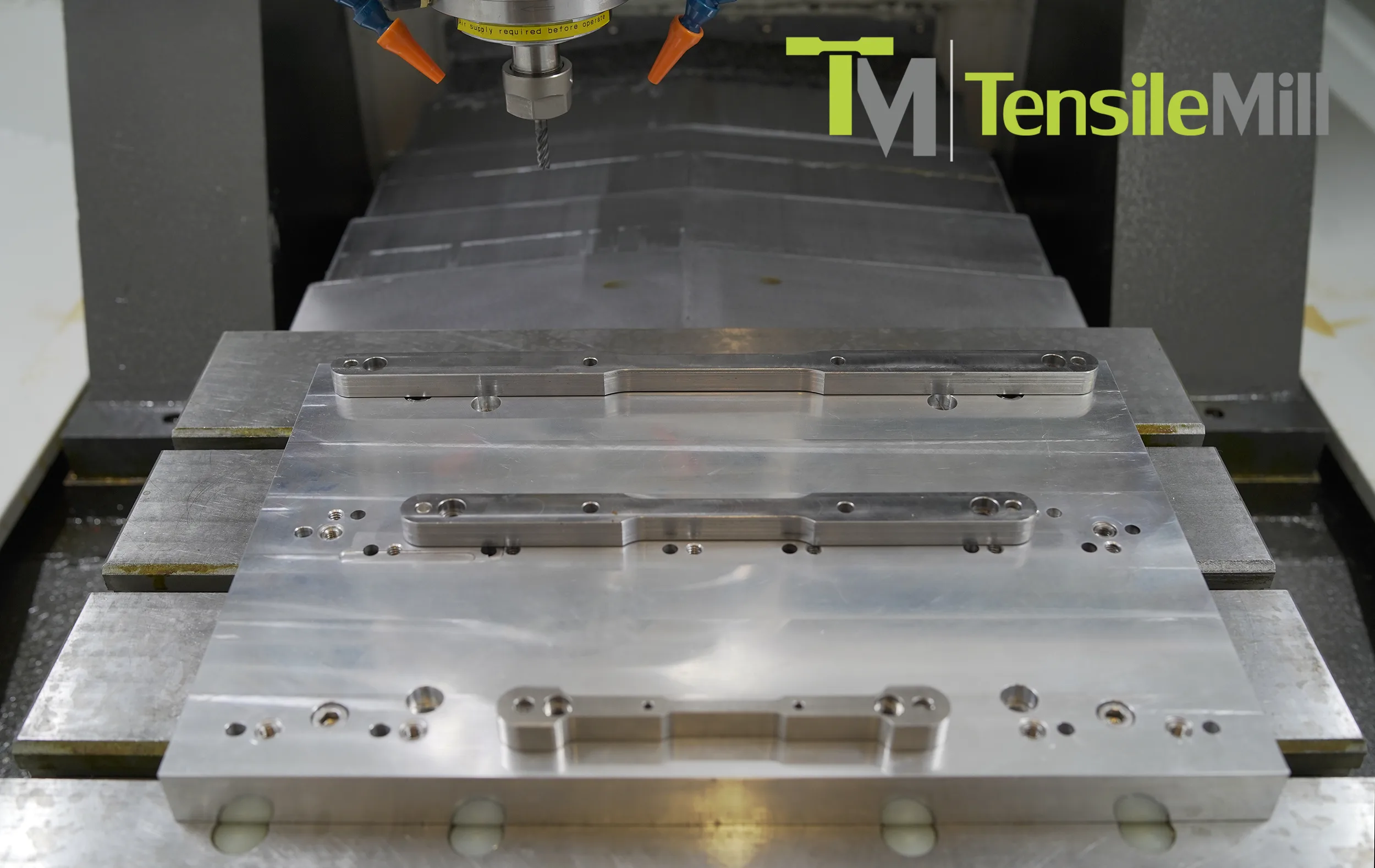

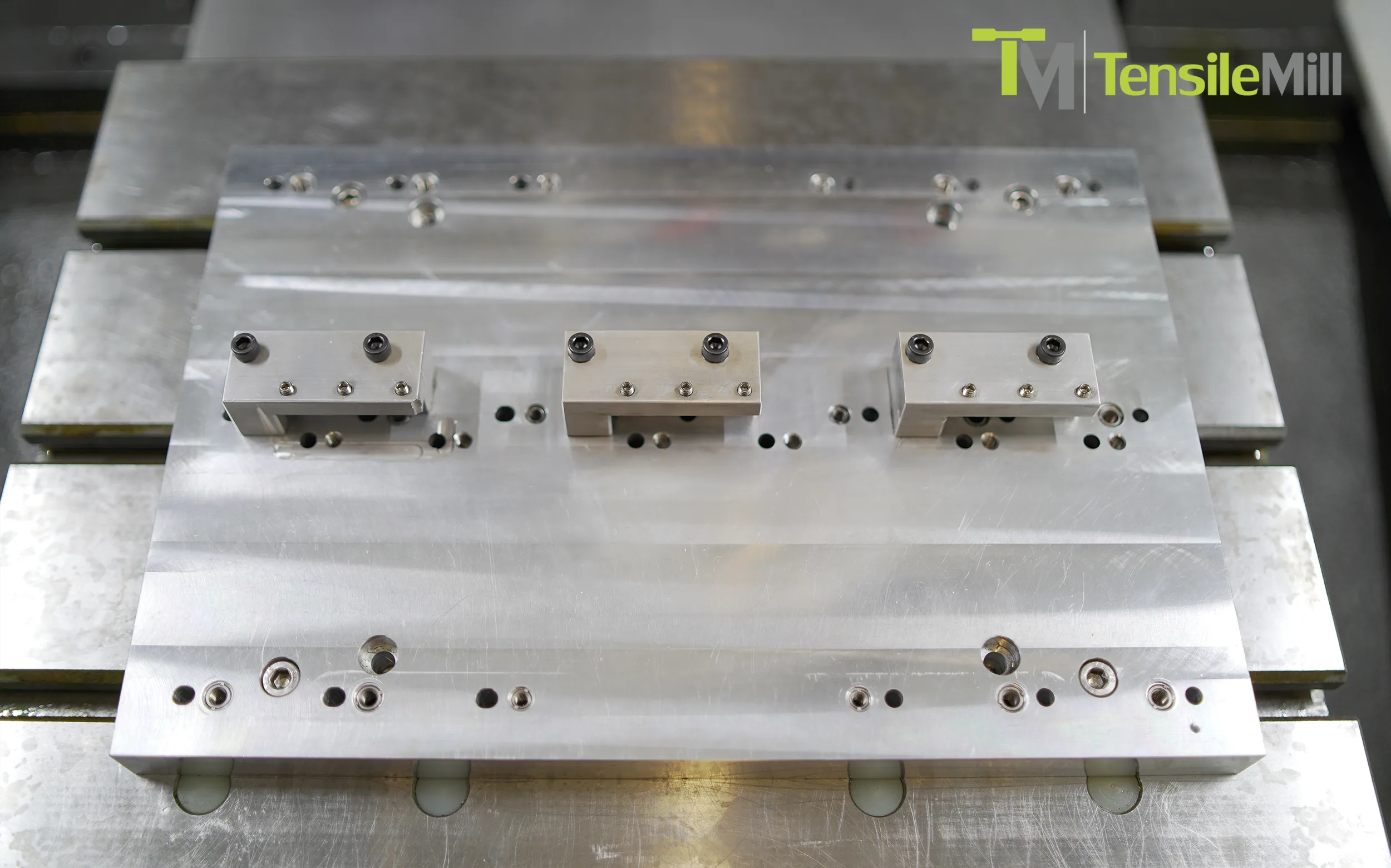

The machining envelope accommodates specimens up to 14" (350 mm) in length, 2" (50 mm) in width, and 0.5" (12.5 mm) in thickness. A 3.2 kW (3 HP) servo-driven spindle provides repeatable dimensional stability with positioning accuracy of 0.0003" (0.008 mm). The system is capable of machining materials up to 60 HRC. When equipped with the triple clamping fixture, up to three stacked sets of 1.0" (25 mm) thick specimens can be prepared in a single setup, supporting both small research batches and high-throughput QC workflows.

The World’s First Hybrid CNC Solution for Tensile and Impact Specimen Preparation

The TensileMill CNC – Classic Upgrade is a hybrid CNC specimen preparation system designed to machine both flat tensile and Charpy/Izod impact test specimens within the same platform. This configuration supports standardized preparation workflows in laboratories that require consistent dimensional accuracy for both tensile and impact testing programs.

For impact samples, the system can be used in conjunction with an external Impact Notching Machine, allowing the preparation of U- and V-notched specimens in accordance with ASTM E23. This pairing provides a controlled sequence for rough milling, finishing passes, and final notching, ensuring the dimensional uniformity required for repeatable impact energy results.

The Classic Upgrade supports impact sample preparation with surface finish tolerances below 75 Ra, and when configured for multi-sample operation, up to 8 specimens can be prepared in the same machining sequence. This workflow reduces overall specimen preparation time and supports higher sample throughput in production and research environments.

System Features

This system incorporates mechanical and software elements that support stable and consistent specimen preparation. It is designed so that operators can work with different specimen sizes and materials without complex setup steps. Below are the primary functional characteristics of the unit:

- Cast iron machine base with linear guideways provides rigidity and supports stable cutting performance during continuous operation.

- Automatic lubrication system distributes oil to rails and bearings to maintain smooth motion across all axes.

- TensileSoft™ control interface receives remote software updates, with major revisions deployed without requiring on-site service visits.

- Preloaded specimen geometry library includes templates aligned with ASTM E8, ASTM E23, ISO 6892-1, DIN 50125, and JIS Z2201 dimensional standards.

- Custom geometry entry allows operators to define gauge length, reduced section width, fillet radius, shoulder length, and total specimen length directly in the software.

- FANUC controller platform supports guided specimen preparation and also allows manual CNC programming for machining additional components when needed.

Impact Specimen Preparation Capabilities

The TensileMill CNC – Classic Upgrade supports standardized machining workflows for Charpy and Izod impact test specimens. The system accommodates the two most commonly used pendulum impact specimen formats:

- 10 × 10 × 55 mm

- 7.5 × 10 × 55 mm

These dimensions are prepared in accordance with ASTM E23, with surface finish and dimensional uniformity suitable for repeatable impact energy measurements.

For final U- and V-notch formation, the system can be paired with a motorized Impact Notching or Broaching unit, allowing operators to notch one or two samples at a time in compliance with ASTM procedures. This configuration supports efficient, controlled preparation of batches for routine testing or development work.

Technical Specifications

| Parameter | Specification |

|---|---|

| Working / Traveling Area | 15.75 × 15.75 × 8 in (400 × 400 × 200 mm) |

| Gantry Clearance | 7.87 in (200 mm) |

| Spindle Nose Clearance | 1.97 in (50 mm) |

| Spindle Motor | 3.2 kW water-cooled spindle |

| Spindle Taper | ER20 collet (ISO20 optional) |

| Axis Drives | PMI precision rolling ball screw drives |

| Axis Servo Motors | FANUC |

| Axis Bearings | NSK precision-grade bearings (Japan) |

| Max Traverse Speed (X/Y/Z) | 10,000 mm/min |

| Feed Rate | 1–3,000 mm/min |

| Positioning Accuracy | ±0.13 mm |

| Repeatability | ±0.02 mm |

| Coolant Pump Flow | ≥ 20 L/min |

| Spindle Speed | 24,000 rpm |

| Max Torque at Low RPM | 2.8 N·m |

| Machine Frame | Fully cast iron body on casters |

| Controller Interface | FANUC 10.4" touch screen (0i-MF Plus) |

| Work Table | T-slot cast iron table with tensile specimen clamping fixture |

| Operating Voltage | 220V / 50–60 Hz / 3-phase |

| Machine Dimensions (W × D × H) | 59 × 53 × 79 in (1500 × 1350 × 2000 mm) |

| Recommended Floor Area | 72 × 72 in (1829 × 1829 mm) |

| Weight | 2,640 lbs (1,200 kg) |

FAQs

Support for troubleshooting and software updates is available by phone, by email/online service request, through remote diagnostics and remote software updates, and by on-site service and training when needed; NextGen’s technical engineers typically respond to technical inquiries within 24 hours and the TensileMill CNC software can be updated remotely so you can get fixes or new features without shipping the machine.

Phone and direct support: contact NextGen’s technical team by the North American toll-free line for fastest escalation; phone calls are the usual first step for time-sensitive machining or specimen-prep issues because an engineer can walk a technician through checks, request photos or log files, and open a support case.

Remote diagnostics and software updates: TensileMill CNC supports remote access to the machine controller so engineers can install software updates, push new specimen libraries or apply configuration changes. Labs commonly use remote sessions to add an ASTM E8 profile or activate the Carbon/CNC unlock without interrupting production.

On-site service, training and calibration: when the problem requires hands-on work NextGen arranges field service, commissioning visits, operator training, and calibration services through accredited labs or local service partners; warranty and preventative maintenance options are also available for scheduled checks and spare parts support.

If you need immediate help or want a software update scheduled, see the product details and open a support case directly through our site by following the product page and then contact us.

Yes. NextGen offers on-site installation, system setup, and basic operator training for this TensileMill CNC Classic Upgrade, so your technicians will receive a hands-on introduction to the machine, its fixtures, and the TensileSoft/FANUC interface needed to run standard specimen programs.

The standard on-site installation typically covers these activities:

- Installation: setting up and mounting the machine and supplied fixtures.

- Connections: making required electrical and utility hookups.

- Verification: powering the machine, checking mechanical assemblies and electrical components, and testing supplied transducers and peripherals.

Basic system and software training is provided for up to three operators and includes safety awareness, an overview of the major machine components, mounting and testing of fixtures, a guided tour of the TensileSoft interface and FANUC controls, and delivery of operation manuals and reference videos.

On-site calibration is not included with the standard installation package, but extended services such as formal calibration, additional operator sessions, or advanced CNC programming can be arranged through NextGen’s service team on request.

To read full product details or to schedule installation and training, learn more or request a quote.

This system supports flat tensile specimen preparation to ASTM E8/E8M and related North American and international standards, based on the supplied custom fixture solution (clamping and locating fixtures are selected to match the specimen geometry your team prepares).

Common tensile standards include ASTM E8/E8M, ASTM A370, ASTM B557, ISO 6892-1, and JIS Z 2241, with fixtures configured for the target geometry (full- and sub-size specimens as required).

For impact work, the system can blank Charpy/Izod bars to ASTM E23 dimensions; U- and V-notch ready bars can be produced when paired with the companion notcher.

If your specimen geometry is not one of the common formats, share your drawing (or a sample) and we can adjust or supply alternative clamping/locating fixtures to ensure consistent, repeatable preparation.

To review machine specifications and available options learn more or request a quote.

Accuracy and repeatability come from three practical areas: a mechanically stable machining platform, predictable tooling and motion control, and repeatable setup/workflow through software and fixtures. The machine’s heavy frame and precision motion components hold cuts steady, the spindle and toolpath strategy deliver consistent finished geometry, and the control software plus multi-part fixtures let operators reproduce the same offsets and sequences every run.

Mechanical stability: the mill uses a rigid cast-iron base and precision linear guidance with preloaded screw drives and quality bearings so the axes move the same way from part to part. That stability keeps the gauge section centered and prevents dimensional drift when you run several cycles in a row.

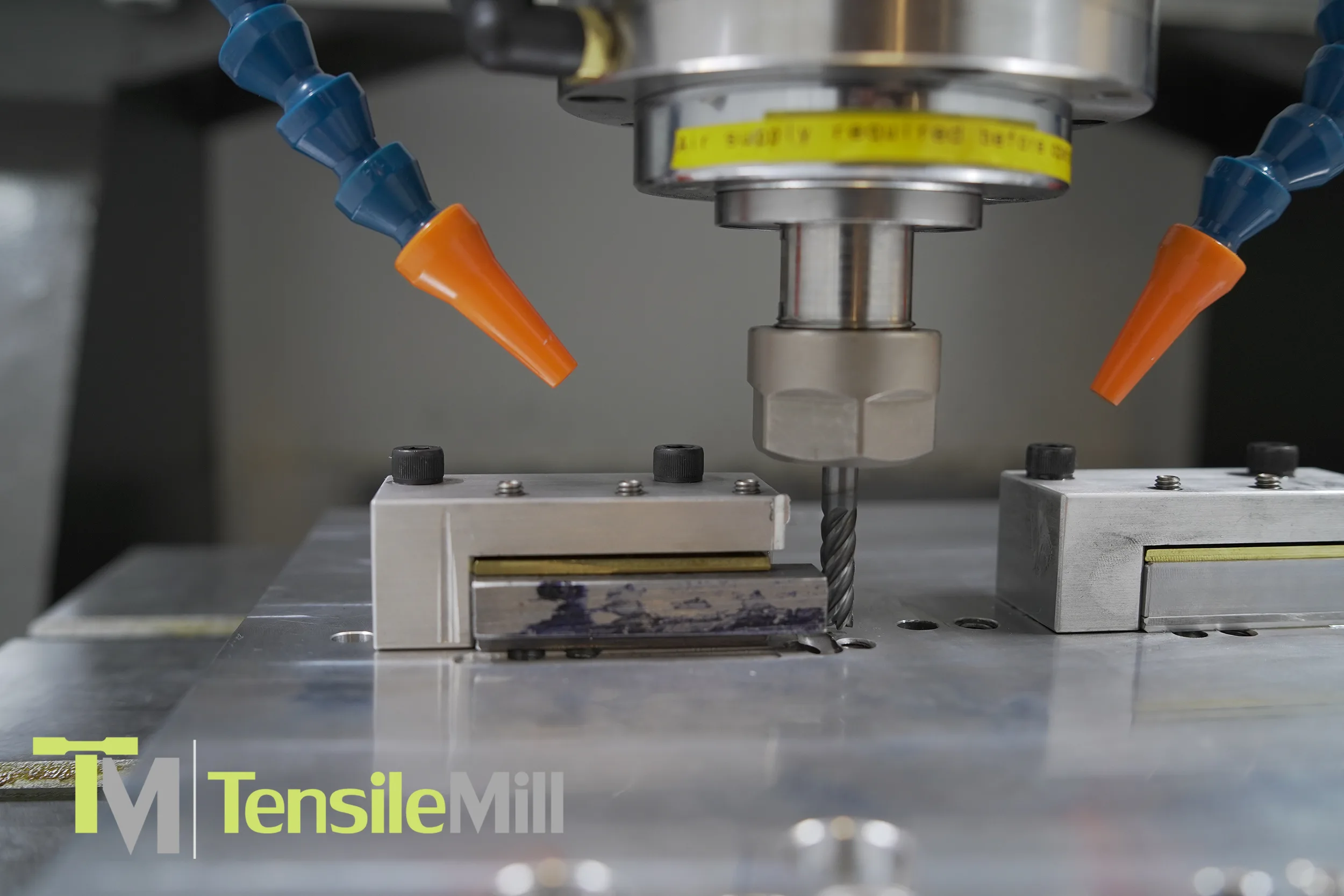

Motion and tooling control: a water-cooled spindle with an ER collet and purpose-built feeds and finish passes reduces runout and tool deflection. Operators use a light finish pass and controlled coolant flow to hold surface finish and final width, which lowers variability in fracture behavior and tensile results.

Repeatable fixturing and probing: the system accepts multi-specimen fixtures that clamp blanks outside the gauge area, plus soft-jaw or nest-style locating that eliminates part-to-part mislocation. Built-in probing and saved work offsets let the controller check alignment and automatically compensate for tool length or minor stock variations before the program runs.

Software and process control: a template library for standard specimen geometries lets the lab store exact toolpaths, feeds, and finish-pass parameters for ASTM and ISO tensile profiles, so technicians load the same program each batch. The controller logs program IDs, offsets, and cycle records for traceability and makes it straightforward to repeat an approved setup on future lots.

Planned maintenance and environmental measures also matter: automatic rail lubrication, a spindle chiller and consistent coolant practice reduce wear and thermal change, and a routine PM schedule preserves the initial alignment and repeatability of the machine over time. In practice labs fixture batches of 6–8 blanks, run the saved template, then verify a sample or two with a caliper or bench micrometer to confirm the batch before testing.

For details on available specimen templates, multi-part fixtures, and service options you can learn more or request a quote.

Yes, the Classic Upgrade will machine both flat tensile specimens and Charpy/Izod impact blanks on the same platform. It produces standard flat tensile profiles and common Charpy/Izod impact blanks; for final U- and V-notch preparation, pair it with the companion notching/broaching system: Specimen Notching/Broaching Machine.

The unit handles standard impact blank sizes, including 10 × 10 × 55 mm and 7.5 × 10 × 55 mm, and accepts flat tensile geometries from common metallic standards. Its working envelope accommodates specimens up to about 14 inches (350 mm) long, 2 inches (50 mm) wide, and 0.5 inches (12.5 mm) thick, and the product literature cites surface finish tolerances below 75 Ra and the ability to machine materials up to about 60 HRC.

The usual workflow in labs is to run rough and finish milling for all blanks on the TensileMill CNC, then move impact blanks to the motorized notcher for controlled U- or V-notch formation; the notcher can notch one or two samples at a time depending on configuration. For higher throughput the Classic Upgrade supports multi-sample operation and fixtures such as a triple clamping fixture, which lets technicians prepare stacked specimens or batches before final notching and testing, a practical approach for QC or R&D runs.

If you want the full technical details or help matching a configuration to your lab, learn more or request a quote.

This system accepts single-piece blanks up to 14 in (350 mm) long and 2 in (50 mm) wide, and it can machine specimens up to 1.5 in (38 mm) thick—including harder materials that can exceed the HRC 60 range.

The available machining envelope and clearances govern these limits: the working/traveling area is 15.75 × 15.75 × 8 in (400 × 400 × 200 mm), gantry clearance is 7.87 in (200 mm), and spindle nose clearance is 1.97 in (50 mm). These values determine how you orient and fixture longer or odd-shaped blanks during setup.

For full specifications or to discuss a specific specimen workflow, learn more or request a quote.

This system machines metallic tensile and Charpy/Izod impact specimens across the full range commonly encountered in QA and R&D laboratories, from soft and ductile alloys through hardened steels. With appropriate tooling and parameters, it can machine materials with hardness values exceeding 60 HRC.

Typical materials include aluminum and copper alloys, stainless and low-alloy steels, and tool or tool-hardened steels. The system supports standardized tensile specimen geometries such as ASTM E8/E8M and equivalent international formats, based on the selected fixturing.

In terms of part size, the Classic Upgrade accommodates specimens up to approximately 14 in (350 mm) long and 2 in (50 mm) wide, and it can machine single-piece stock up to 1.5 in (38 mm) thick. Fixturing options and the available machining envelope determine how parts are oriented and whether multiple specimens are run in one setup.

For impact testing, the system prepares standard Charpy/Izod impact blanks (for example 10 × 10 × 55 mm and 7.5 × 10 × 55 mm) with surface finishes suitable for reliable impact results. Final U- or V-notch preparation is typically performed using a dedicated impact notching or broaching machine in accordance with ASTM E23 and related standards.

If you need confirmation for a specific alloy, a high-hardness heat-treated material, thicker stock, or a higher-throughput workflow, learn more or request a quote and our applications team will review your material and specimen requirements.

Related Products

TensileMill CNC XL – Flat Tensile Specimen Preparation Machine

The TensileMill CNC XL – Flat Tensile Specimen Preparation Machine is an advanced CNC system built for accurate and repeatable flat specimen machining. Designed for high-volume testing environments, it supports ASTM E8, ASTM A370, ISO 6892-1, and DIN 50125 standards. Its powerful 5 hp spindle, Mach4-based Carbon™ control, and automatic tool changer deliver fast material processing across metals, polymers, and composites. The heavy cast iron frame ensures vibration-free precision, while the intuitive TensileSoft™ interface allows both trained and new operators to achieve consistent results.

TensileMill CNC MINI – Compact Flat Tensile Specimen Preparation System

The TensileMill CNC MINI is a compact CNC system designed for preparing standardized flat tensile test specimens. It supports specimen geometries based on ASTM E8, ASTM A370 / E370, ISO 6892-1, DIN 50125, and JIS Z2201. The system uses a cast iron frame, linear guideways, and a guided TensileSoft™ interface to support consistent specimen dimensions. Operators can select preloaded standard profiles or enter custom dimensions directly into the control interface. The MINI is suitable for routine testing workflows, training environments, and production quality control applications.