Metal Testing Equipment

Precision Wedge Grips for High-Strength Tensile Testing

NextGen’s wedge tensile grips are engineered to deliver superior performance in tensile strength testing using Universal Testing Machines (UTMs). These grips use a mechanical wedge action that enhances gripping pressure proportionally with the applied tensile force, ensuring firm specimen clamping and minimizing slippage during testing. Built for rigorous tensile tests, these fixtures support compliance with global standards such as ASTM E8, ISO 6892, ISO 527, DIN 50125, and are suitable for metallic and composite materials.

NextGen’s wedge tensile grips are engineered to deliver superior performance in tensile strength testing using Universal Testing Machines (UTMs). These grips use a mechanical wedge action that enhances gripping pressure proportionally with the applied tensile force, ensuring firm specimen clamping and minimizing slippage during testing. Built for rigorous tensile tests, these fixtures support compliance with global standards such as ASTM E8, ISO 6892, ISO 527, DIN 50125, and are suitable for metallic and composite materials.

These grips are compatible with NG-EML and NG-SHM series universal testing machines, providing a reliable solution for laboratories and industrial applications in automotive, aerospace, civil engineering, and materials R&D.

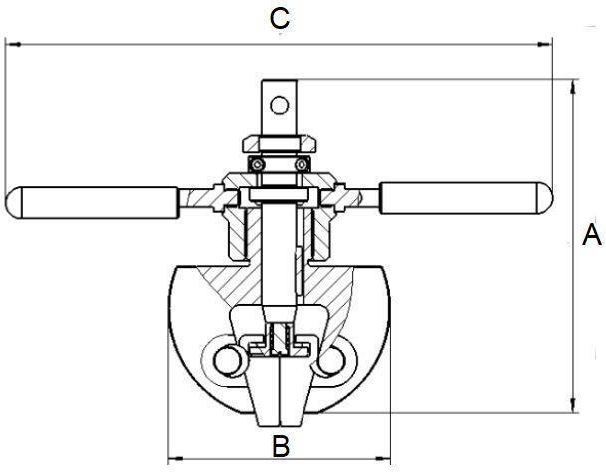

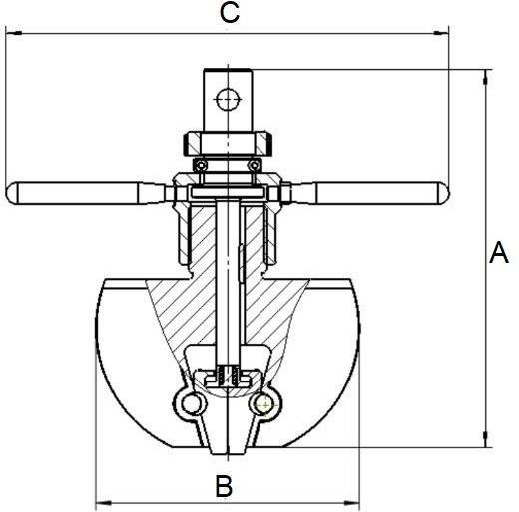

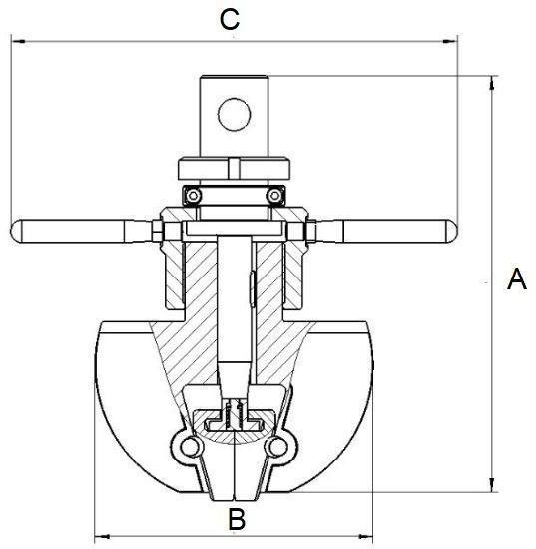

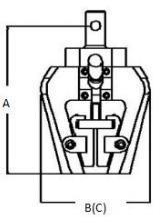

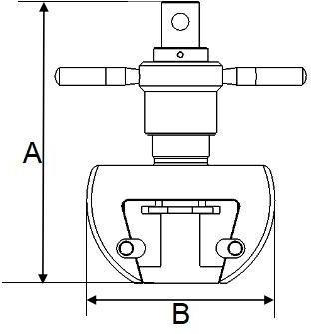

NGA204G – Wedge Action Tensile Grip

The NGA204G Wedge Action Tensile Grip is engineered for tension testing of flat and round specimens made from metal, plastic, and composite materials. With a rated capacity of 20 kN and a wide thermal working range from –73 °C to +315 °C, it offers stable clamping and self-tightening grip performance during test loading. Designed for specimens with hardness under 30 HRC and tensile strength below 600 MPa, the NGA204G is ideal for a range of moderate-force testing environments requiring precision and versatility.

The NGA204G Wedge Action Tensile Grip is engineered for tension testing of flat and round specimens made from metal, plastic, and composite materials. With a rated capacity of 20 kN and a wide thermal working range from –73 °C to +315 °C, it offers stable clamping and self-tightening grip performance during test loading. Designed for specimens with hardness under 30 HRC and tensile strength below 600 MPa, the NGA204G is ideal for a range of moderate-force testing environments requiring precision and versatility.

- Application: Tension test for flat and round specimens of metal, plastic, and composite materials.

- Maximum Capacity: 20 kN.

- Connection: Ø10 mm pin (upper and lower), compatible with universal testing machines.

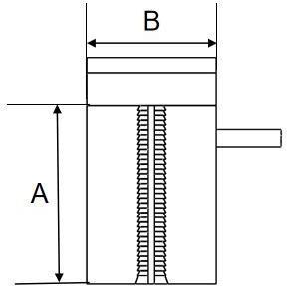

- Height (A): 192 mm.

- Grip Body Width (B): 128 mm.

- Overall Width (C): 316 mm.

- Grip Weight: 5.0 kg (upper and lower grips).

- Working Temperature: –73 °C to +315 °C.

- Note: Recommended for materials with hardness below 30 HRC and tensile strength under 600 MPa.

Technical Specifications – NGA204G Wedge Action Grip for Flat and Round Specimens

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite, plastic |

| Maximum Force Capacity | 20 kN |

| Upper Grip Weight | 5.0 kg |

| Lower Grip Weight | 5.0 kg |

| Working Temperature | –73 °C to +315 °C |

| Connection Type | Ø10 mm pin (upper and lower) |

| Height (A) | 192 mm |

| Grip Body Width (B) | 128 mm |

| Overall Width (C) | 316 mm |

| Note | Specimen hardness <30 HRC; Tensile strength <600 MPa |

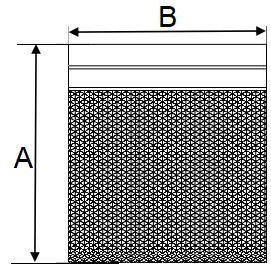

Optional Jaw Faces for NGA204G Wedge Action Grip

The NGA204G grip supports a modular set of jaw faces tailored for various specimen dimensions and forms. Both flat and Vee-type jaws are available for tension testing of rectangular and cylindrical specimens. Each jaw face is precision-machined with a 1.5 mm pitch serration to optimize grip force distribution and minimize slippage.

The NGA204G grip supports a modular set of jaw faces tailored for various specimen dimensions and forms. Both flat and Vee-type jaws are available for tension testing of rectangular and cylindrical specimens. Each jaw face is precision-machined with a 1.5 mm pitch serration to optimize grip force distribution and minimize slippage.

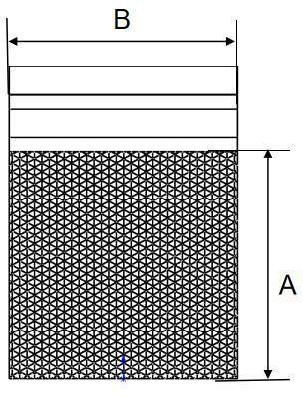

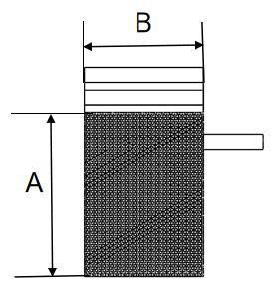

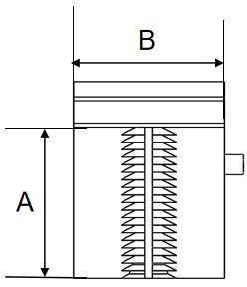

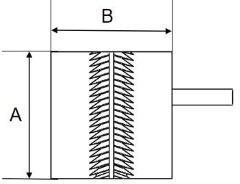

Flat Jaw Faces (Optional)

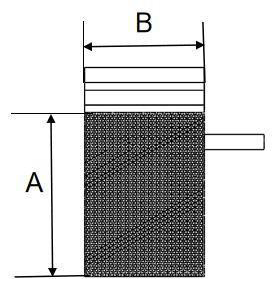

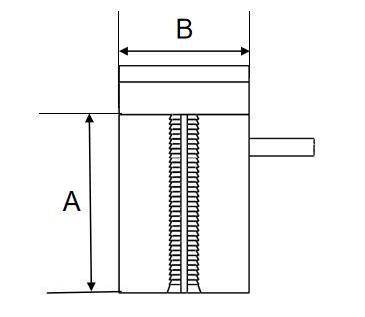

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA204G-13 | 0 – 6 | 40 | 40 |

| NGA204G-14 | 6 – 12 | 40 | 40 |

Note: All flat jaw faces have a pitch of 1.5 mm.

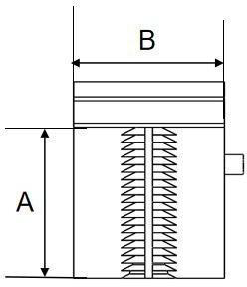

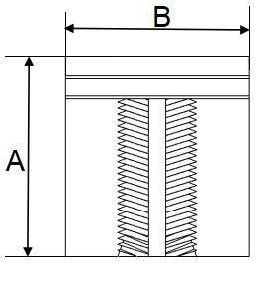

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| WXSA204G-15 | Φ4 – Φ9 | 40 | 40 |

| WXSA204G-16 | Φ9 – Φ14 | 40 | 40 |

Note: All vee jaw faces have a pitch of 1.5 mm.

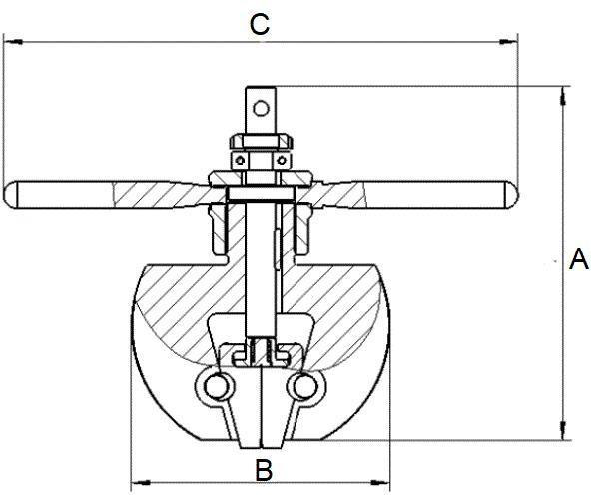

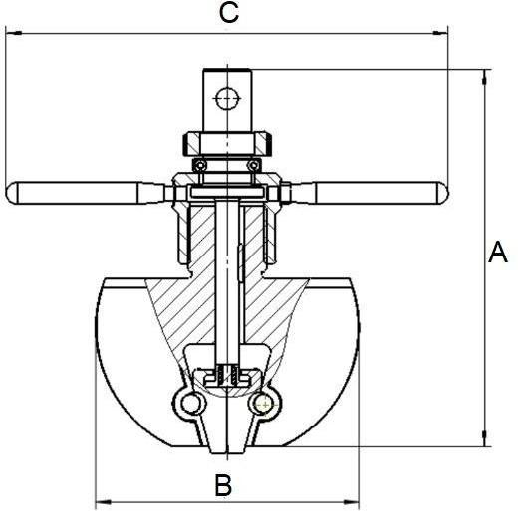

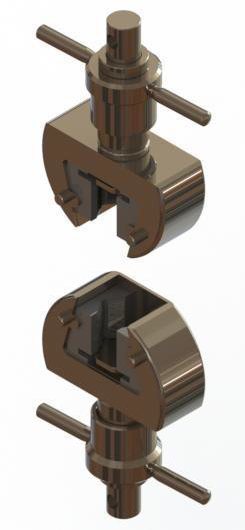

NGA304A – Wedge Action Tensile Grip

The NGA304A Wedge Action Grip is designed for reliable tensile testing of flat and round specimens made from metal, composite, and rigid plastic. With a force capacity of up to 30 kN, this system offers balanced grip performance for mid-range test applications. The wedge-action design provides automatic tightening as tensile force is applied, ensuring consistent holding force throughout the test. This model is suitable for materials with a hardness below 30 HRC and tensile strength below 600 MPa, making it ideal for quality control and research labs.

The NGA304A Wedge Action Grip is designed for reliable tensile testing of flat and round specimens made from metal, composite, and rigid plastic. With a force capacity of up to 30 kN, this system offers balanced grip performance for mid-range test applications. The wedge-action design provides automatic tightening as tensile force is applied, ensuring consistent holding force throughout the test. This model is suitable for materials with a hardness below 30 HRC and tensile strength below 600 MPa, making it ideal for quality control and research labs.

- Application: Tension test for flat and round specimens of metal, composite, and rigid plastic.

- Maximum Capacity: 30 kN.

- Connection: Ø10 mm pin (upper and lower), UTM-compatible.

- Height (A): 240 mm.

- Grip Body Width (B): 174 mm.

- Overall Width (C): 346 mm.

- Grip Weight: 7.6 kg (upper and lower grips).

- Working Temperature: Ambient.

- Note: For materials with hardness below 30 HRC and tensile strength below 600 MPa.

Technical Specifications – NGA304A Wedge Action Grip for Mid-Range Specimens

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite, rigid plastic |

| Maximum Force Capacity | 30 kN |

| Upper Grip Weight | 7.6 kg |

| Lower Grip Weight | 7.6 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Height (A) | 240 mm |

| Grip Body Width (B) | 174 mm |

| Overall Width (C) | 346 mm |

| Note | Specimen hardness <30 HRC; Tensile strength <600 MPa |

Optional Jaw Faces for NGA304A Wedge Action Grip

To accommodate a wide range of specimen sizes and profiles, the NGA304A grip supports both flat and vee jaw faces. Each jaw face is precision-machined with a 1.5 mm pitch serration to provide enhanced gripping and alignment during tensile testing.

To accommodate a wide range of specimen sizes and profiles, the NGA304A grip supports both flat and vee jaw faces. Each jaw face is precision-machined with a 1.5 mm pitch serration to provide enhanced gripping and alignment during tensile testing.

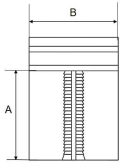

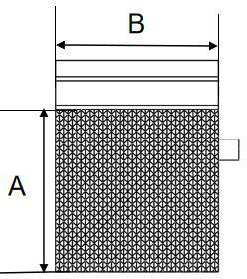

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA105A-13 | 0 – 7 | 55 | 40 |

| NGA105A-14 | 7 – 14 | 55 | 40 |

| NGA105A-15 | 14 – 21 | 55 | 40 |

Note: All flat jaw faces have a pitch of 1.5 mm.

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| WXSA105A-09 | Φ4 – Φ9 | 55 | 40 |

| WXSA105A-10 | Φ9 – Φ14 | 55 | 40 |

| WXSA105A-11 | Φ14 – Φ19 | 55 | 40 |

Note: All vee jaw faces have a pitch of 1.5 mm.

NGA504A – Wedge Action Tensile Grip

The NGA504A Wedge Tensile Grip is designed for high-capacity tensile testing of both flat and round specimens made from rigid plastic, composite, and metal materials. Supporting a force capacity of up to 50 kN and featuring a wedge-action mechanism, it ensures self-tightening engagement under load for stable and repeatable test conditions. This model is ideal for labs testing medium- to high-strength specimens with hardness under 30 HRC and tensile strength below 600 MPa.

The NGA504A Wedge Tensile Grip is designed for high-capacity tensile testing of both flat and round specimens made from rigid plastic, composite, and metal materials. Supporting a force capacity of up to 50 kN and featuring a wedge-action mechanism, it ensures self-tightening engagement under load for stable and repeatable test conditions. This model is ideal for labs testing medium- to high-strength specimens with hardness under 30 HRC and tensile strength below 600 MPa.

- Application: Tension test for flat and round specimens of metal, composite, and rigid plastic.

- Maximum Capacity: 50 kN.

- Connection: Ø18 mm pin (upper and lower), compatible with heavy-duty UTM models.

- Height (A): 236 mm.

- Grip Body Width (B): 178 mm.

- Overall Width (C): 337 mm.

- Grip Weight: 10.6 kg (upper and lower grips each).

- Working Temperature: Ambient.

- Note: For materials with hardness <30 HRC and tensile strength <600 MPa.

Technical Specifications – NGA504A Wedge Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite, rigid plastic |

| Maximum Force Capacity | 50 kN |

| Upper Grip Weight | 10.6 kg |

| Lower Grip Weight | 10.6 kg |

| Working Temperature | Ambient |

| Connection Type | Ø18 mm pin (upper and lower) |

| Height (A) | 236 mm |

| Grip Body Width (B) | 178 mm |

| Overall Width (C) | 337 mm |

| Note | Specimen hardness <30 HRC; Tensile strength <600 MPa |

Optional Jaw Faces for NGA504A Wedge Action Grip

The NGA504A grip system supports an interchangeable range of serrated jaw faces to accommodate a variety of specimen shapes and sizes. Optional flat and vee-type jaw faces are available for tension testing of rectangular and cylindrical samples. Each jaw is machined with a 1.5 mm serration pitch to ensure precise alignment and secure clamping throughout the test cycle.

The NGA504A grip system supports an interchangeable range of serrated jaw faces to accommodate a variety of specimen shapes and sizes. Optional flat and vee-type jaw faces are available for tension testing of rectangular and cylindrical samples. Each jaw is machined with a 1.5 mm serration pitch to ensure precise alignment and secure clamping throughout the test cycle.

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA105A-13 | 0 – 7 | 55 | 40 |

| NGA105A-14 | 7 – 14 | 55 | 40 |

| NGA105A-15 | 14 – 21 | 55 | 40 |

Note: All flat jaw faces have a pitch of 1.5 mm.

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA105A-16 | Φ4 – Φ9 | 55 | 40 |

| NGA105A-17 | Φ9 – Φ14 | 55 | 40 |

| NGA105A-18 | Φ14 – Φ19 | 55 | 40 |

Note: All vee jaw faces have a pitch of 1.5 mm.

NGA105A – Wedge Action Tensile Grip

The NGA105A Wedge Tensile Grip is a high-capacity solution engineered for tensile testing of both flat and round metal and composite specimens. With a maximum force rating of 100 kN, this grip utilizes a self-tightening wedge mechanism to maintain a firm and consistent hold throughout the loading cycle. Its robust construction and Ø18 mm pin connection make it a reliable component for demanding test applications. Suitable for specimens with hardness below 30 HRC and tensile strength under 600 MPa, this system ensures accuracy and repeatability across a broad range of materials.

The NGA105A Wedge Tensile Grip is a high-capacity solution engineered for tensile testing of both flat and round metal and composite specimens. With a maximum force rating of 100 kN, this grip utilizes a self-tightening wedge mechanism to maintain a firm and consistent hold throughout the loading cycle. Its robust construction and Ø18 mm pin connection make it a reliable component for demanding test applications. Suitable for specimens with hardness below 30 HRC and tensile strength under 600 MPa, this system ensures accuracy and repeatability across a broad range of materials.

- Application: Tension test for flat and round specimens of metal and composite materials.

- Maximum Capacity: 100 kN.

- Connection: Ø18 mm pin (upper and lower), compatible with high-capacity UTM systems.

- Height (A): 276 mm.

- Grip Body Width (B): 164 mm.

- Overall Width (C): 350 mm.

- Grip Weight: 14.7 kg for both upper and lower grips.

- Working Temperature: Ambient.

- Note: Recommended for specimens with hardness <30 HRC and tensile strength <600 MPa.

Technical Specifications – NGA105A Wedge Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite |

| Maximum Force Capacity | 100 kN |

| Upper Grip Weight | 14.7 kg |

| Lower Grip Weight | 14.7 kg |

| Working Temperature | Ambient |

| Connection Type | Ø18 mm pin (upper and lower) |

| Height (A) | 276 mm |

| Grip Body Width (B) | 164 mm |

| Overall Width (C) | 350 mm |

| Note | Specimen hardness <30 HRC; Tensile strength <600 MPa |

Optional Jaw Faces – NGA105A Grip

To accommodate a wide variety of specimen geometries, the NGA105A grip offers multiple interchangeable jaw face options. Each set is engineered with a 1.5 mm pitch for consistent and secure clamping. The available types include both flat and vee jaw faces, making this grip system ideal for flat and round specimens of varying sizes.

To accommodate a wide variety of specimen geometries, the NGA105A grip offers multiple interchangeable jaw face options. Each set is engineered with a 1.5 mm pitch for consistent and secure clamping. The available types include both flat and vee jaw faces, making this grip system ideal for flat and round specimens of varying sizes.

Flat Jaw Faces (Optional)

| No. | Specimen Thickness | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA105A-13 | 0–7 mm | 55 | 40 |

| NGA105A-14 | 7–14 mm | 55 | 40 |

| NGA105A-15 | 14–21 mm | 55 | 40 |

Note: All flat jaw faces have a pitch of 1.5 mm.

Vee Jaw Faces (Optional)

| No. | Specimen Diameter | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA105A-16 | Φ4–9 mm | 55 | 40 |

| NGA105A-17 | Φ9–14 mm | 55 | 40 |

| NGA105A-18 | Φ14–19 mm | 55 | 40 |

Note: All vee jaw faces have a pitch of 1.5 mm.

NGA305A – Wedge Tensile Grip

The NGA305A Wedge Tensile Grip is engineered for high-capacity tensile testing of flat and round specimens made from metal and composite materials. Its robust wedge-action clamping mechanism ensures secure and repeatable specimen alignment during demanding test conditions. Designed for universal testing machines, this grip accommodates heavy-duty applications requiring force levels up to 300 kN.

The NGA305A Wedge Tensile Grip is engineered for high-capacity tensile testing of flat and round specimens made from metal and composite materials. Its robust wedge-action clamping mechanism ensures secure and repeatable specimen alignment during demanding test conditions. Designed for universal testing machines, this grip accommodates heavy-duty applications requiring force levels up to 300 kN.

- Application: Tension testing for flat and round specimens of metal and composite materials

- Maximum Capacity: Up to 300 kN

- Connection Type: Φ28 mm pin mount (upper and lower), compatible with high-capacity UTM frames

- Dimensions: Height 367 mm; Grip body width 244 mm; Overall width 392 mm

- Grip Weight: 36.5 kg for both upper and lower grips

- Working Temperature: Ambient

- Note: Compatible with specimens having hardness below 30 HRC and tensile strength below 600 MPa

Technical Specifications – NGA305A Wedge Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension testing for flat and round specimens of metal, composite |

| Maximum Force Capacity | ≤ 300 kN |

| Connection Type | Upper Grip: Φ28 mm pin Lower Grip: Φ28 mm pin |

| Overall Height (A) | 367 mm |

| Grip Body Width (B) | 244 mm |

| Overall Width (C) | 392 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 36.5 kg Lower Grip: 36.5 kg |

| Note | Specimen hardness below 30 HRC and tensile strength below 600 MPa |

Optional Jaw Faces – NGA305A Grip

To support a broader range of specimen dimensions, the NGA305A grip is available with interchangeable flat and vee jaw face options. Each jaw face is precisely engineered with a 2.5 mm pitch to guarantee secure and uniform specimen clamping. These options make the grip system well-suited for both flat and round tensile specimens across various sizes.

To support a broader range of specimen dimensions, the NGA305A grip is available with interchangeable flat and vee jaw face options. Each jaw face is precisely engineered with a 2.5 mm pitch to guarantee secure and uniform specimen clamping. These options make the grip system well-suited for both flat and round tensile specimens across various sizes.

Flat Jaw Faces (Optional)

| No. | Specimen Thickness | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA305A-14 | 0–8 mm | 62 | 50 |

| NGA305A-15 | 8–16 mm | 62 | 50 |

| NGA305A-16 | 16–24 mm | 62 | 50 |

| NGA305A-17 | 24–32 mm | 62 | 50 |

Note: All flat jaw faces have a pitch of 2.5 mm.

Vee Jaw Faces (Optional)

| No. | Specimen Diameter | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA305A-18 | Φ4–9 mm | 62 | 50 |

| NGA305A-19 | Φ9–16 mm | 62 | 50 |

| NGA305A-20 | Φ16–23 mm | 62 | 50 |

| NGA305A-21 | Φ23–30 mm | 62 | 50 |

Note: All vee jaw faces have a pitch of 2.5 mm.

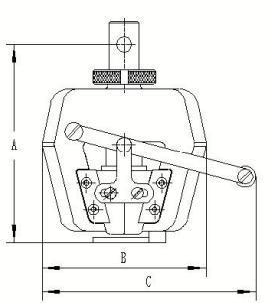

NGB204A – Wedge Tensile Grip

The NGB204A Wedge Tensile Grip is a high-strength clamping solution designed for flat and round specimens made from metals, composites, and plastics. This wedge-action grip securely tightens under load, delivering consistent tension without slippage. With a robust design and compatibility with standard UTM systems, the NGB204A is well-suited for demanding tensile applications in controlled environments.

The NGB204A Wedge Tensile Grip is a high-strength clamping solution designed for flat and round specimens made from metals, composites, and plastics. This wedge-action grip securely tightens under load, delivering consistent tension without slippage. With a robust design and compatibility with standard UTM systems, the NGB204A is well-suited for demanding tensile applications in controlled environments.

- Application: Tension tests for flat and round specimens of metal, composite, and plastic materials.

- Maximum Capacity: Up to 20 kN load.

- Grip Weight: 4.3 kg (Upper Grip), 7.8 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), compatible with standard UTM setups.

- Dimensions:

- Height (A): 162 mm

- Grip Body Width (B): 111 mm

- Overall Width (C): 111 mm

- Working Temperature: Ambient conditions.

- Material Compatibility: Specimen hardness below 30 HRC and tensile strength below 600 MPa.

Technical Specifications – NGB204A Wedge Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite, plastic |

| Maximum Force Capacity | ≤ 20 kN |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Overall Height (A) | 162 mm |

| Grip Body Width (B) | 111 mm |

| Overall Width (C) | 111 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 4.3 kg Lower Grip: 7.8 kg |

| Note | Specimen hardness below 30 HRC and tensile strength below 600 MPa |

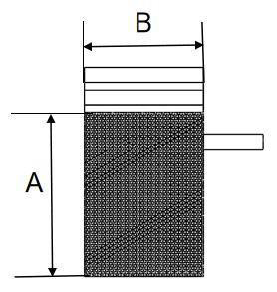

Optional Jaw Faces – NGB204A Grip

To accommodate various specimen geometries, the NGB204A grip is available with interchangeable flat and vee jaw faces. These optional inserts are engineered for reliable clamping of both flat and round specimens across different size ranges. Each jaw face is designed with consistent pitch for optimal grip performance.

To accommodate various specimen geometries, the NGB204A grip is available with interchangeable flat and vee jaw faces. These optional inserts are engineered for reliable clamping of both flat and round specimens across different size ranges. Each jaw face is designed with consistent pitch for optimal grip performance.

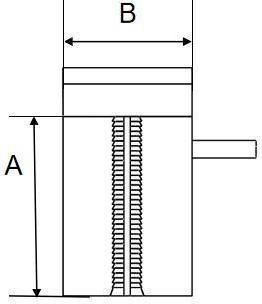

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGB204A-09 | 0–6 | 40 | 40 |

| NGB204A-10 | 6–12 | 40 | 40 |

Note: All flat jaw faces have a pitch of 1.5 mm.

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| WXSB204A-11 | Φ4–9 | 40 | 40 |

| WXSB204A-12 | Φ9–14 | 40 | 40 |

Note: All vee jaw faces have a pitch of 2.0 mm.

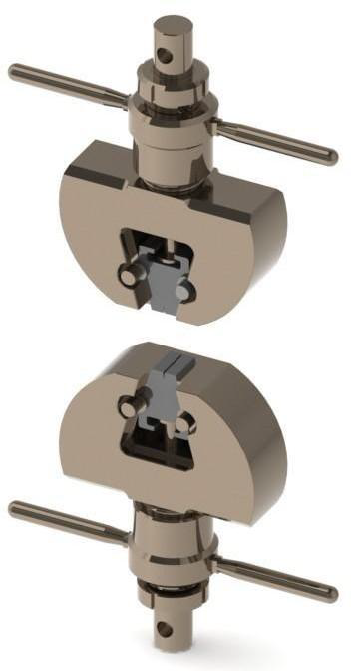

NGB204G – Wedge Tensile Grip

The NGB204G Wedge Tensile Grip is a precision wedge-action grip designed for flat and round specimens made of metal, composite, and plastic. Built to withstand extreme temperatures, it is ideal for testing under both cryogenic and high-heat conditions. The symmetrical design of the upper and lower grips allows for uniform clamping, ensuring consistent and reliable tensile results.

The NGB204G Wedge Tensile Grip is a precision wedge-action grip designed for flat and round specimens made of metal, composite, and plastic. Built to withstand extreme temperatures, it is ideal for testing under both cryogenic and high-heat conditions. The symmetrical design of the upper and lower grips allows for uniform clamping, ensuring consistent and reliable tensile results.

- Application: Tension tests for flat and round specimens of metal, composite, and plastic materials.

- Maximum Capacity: Up to 20 kN load.

- Grip Weight: 3.76 kg each (upper and lower grip).

- Connection: Φ10 mm pin (upper and lower), fully compatible with standard UTM systems.

- Dimensions:

- Height (A): 123.5 mm

- Grip Body Width (B): 108 mm

- Overall Width (C): 140 mm

- Working Temperature: –73 °C to +315 °C.

- Material Compatibility: For specimens with hardness below 30 HRC and tensile strength below 600 MPa.

Technical Specifications – NGB204G Wedge Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite, plastic |

| Maximum Force Capacity | ≤ 20 kN |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Overall Height (A) | 123.5 mm |

| Grip Body Width (B) | 108 mm |

| Overall Width (C) | 140 mm |

| Working Temperature | –73 °C to +315 °C |

| Grip Weight | Upper Grip: 3.76 kg Lower Grip: 3.76 kg |

| Note | Specimen hardness below 30 HRC and tensile strength below 600 MPa |

Optional Jaw Faces – NGB204G Grip

The NGB204G grip supports interchangeable flat and vee jaw faces to provide reliable clamping across different specimen shapes and sizes. Designed for compatibility and precise alignment, these optional jaw inserts enable optimal grip for various testing scenarios, especially under extreme temperature conditions.

The NGB204G grip supports interchangeable flat and vee jaw faces to provide reliable clamping across different specimen shapes and sizes. Designed for compatibility and precise alignment, these optional jaw inserts enable optimal grip for various testing scenarios, especially under extreme temperature conditions.

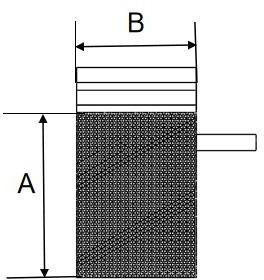

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGB204G-09 | 0–6 | 40 | 40 |

| NGB204G-10 | 6–12 | 40 | 40 |

Note: All flat jaw faces have a pitch of 1.5 mm.

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA204G-11 | Φ4–9 | 42 | 4 |

| NGA204G-12 | Φ9–14 | 42 | 4 |

Note: All vee jaw faces have a pitch of 2.0 mm.

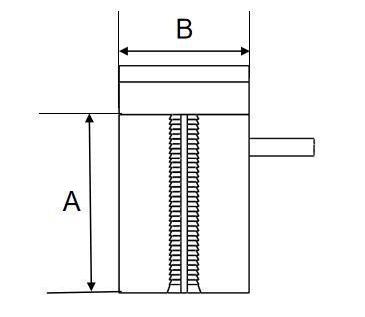

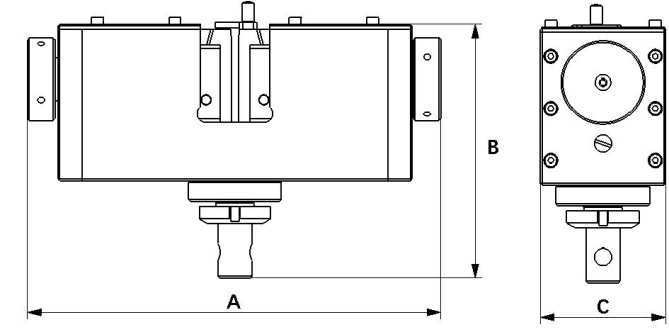

NGD104A – Wedge Tensile Grip

The NGD104A Wedge Tensile Grip features a self-tightening wedge mechanism designed for secure clamping of flat and round specimens made from metals, composites, and plastics. With equal upper and lower grip weights, this grip ensures stable and balanced tension application, making it suitable for routine tensile testing under ambient conditions.

The NGD104A Wedge Tensile Grip features a self-tightening wedge mechanism designed for secure clamping of flat and round specimens made from metals, composites, and plastics. With equal upper and lower grip weights, this grip ensures stable and balanced tension application, making it suitable for routine tensile testing under ambient conditions.

- Application: Tension tests for flat and round specimens of metal, composite, and plastic.

- Maximum Capacity: Up to 10 kN load.

- Grip Weight: 9.67 kg (Upper Grip), 9.67 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), compatible with standard UTM systems.

- Dimensions:

- Grip Body Width (A): 240 mm

Height (B): 148 mm

Height (B): 148 mm- Depth (C): 72 mm

- Working Temperature: Ambient conditions.

- Material Compatibility: For specimens with hardness below 30 HRC and tensile strength below 600 MPa.

Technical Specifications – NGD104A Wedge Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite, plastic |

| Maximum Force Capacity | ≤ 10 kN |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Grip Body Width (A) | 240 mm |

| Height (B) | 148 mm |

| Depth (C) | 72 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 9.67 kg Lower Grip: 9.67 kg |

| Note | Specimen hardness below 30 HRC and tensile strength below 600 MPa |

Optional Jaw Faces – NGD104A Grip

The NGD104A grip includes a selection of optional flat and vee jaw faces to accommodate different specimen types and sizes. These jaw faces ensure a secure and stable grip for both flat and round specimens in standard tensile testing applications.

The NGD104A grip includes a selection of optional flat and vee jaw faces to accommodate different specimen types and sizes. These jaw faces ensure a secure and stable grip for both flat and round specimens in standard tensile testing applications.

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGD104A.01-19 | 0–10 | 54 | 40 |

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGD104A.01-20 | Φ4–9 | 54 | 40 |

| NGD104A.01-21 | Φ9–16 | 54 | 40 |

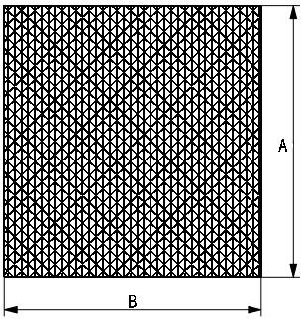

NGA105A – Wedge Tensile Grip

The NGA105A Wedge Tensile Grip features a high-capacity self-tightening wedge design suitable for demanding tensile testing applications. With equal upper and lower grip weights and robust geometry, this grip is ideal for specimens requiring force up to 100 kN. It supports flat and round specimens with moderate hardness and tensile strength, making it reliable for various material testing needs.

The NGA105A Wedge Tensile Grip features a high-capacity self-tightening wedge design suitable for demanding tensile testing applications. With equal upper and lower grip weights and robust geometry, this grip is ideal for specimens requiring force up to 100 kN. It supports flat and round specimens with moderate hardness and tensile strength, making it reliable for various material testing needs.

- Application: Medium-to-heavy duty tensile testing for flat and round specimens.

- Maximum Capacity: ≤ 100 kN load.

- Grip Weight: 13.7 kg (Upper Grip), 13.7 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), compatible with standard UTM systems.

- Dimensions:

- Width (A): 198 mm

- Grip Body Height (B): 300 mm

- Working Temperature: Ambient conditions.

- Material Compatibility: For specimens with hardness below 30 HRC and tensile strength below 600 MPa.

Technical Specifications – NGA105A Wedge Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Medium-to-heavy duty use |

| Maximum Force Capacity | ≤ 100 kN |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Width (A) | 198 mm |

| Grip Body Height (B) | 300 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 13.7 kg Lower Grip: 13.7 kg |

| Note | Specimen hardness below 30 HRC and tensile strength below 600 MPa |

Optional Jaw Faces – NGA105A Grip

The NGA105A grip offers a broad selection of flat and vee jaw faces designed to accommodate a wide range of specimen sizes. With consistent dimensions and reliable grip integrity, these jaw inserts are ideal for high-capacity tensile testing across varied material shapes and diameters.

The NGA105A grip offers a broad selection of flat and vee jaw faces designed to accommodate a wide range of specimen sizes. With consistent dimensions and reliable grip integrity, these jaw inserts are ideal for high-capacity tensile testing across varied material shapes and diameters.

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA105A-12 | 0–10 | 70 | 64 |

| NGA105A-13 | 10–20 | 70 | 64 |

| NGA105A-14 | 20–30 | 70 | 64 |

| NGA105A-15 | 30–40 | 70 | 64 |

| NGA105A-20 | 40–50 | 70 | 64 |

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGA105A-16 | Φ4–Φ10 | 70 | 64 |

| NGA105A-17 | Φ10–Φ20 | 70 | 64 |

| NGA105A-18 | Φ20–Φ30 | 70 | 64 |

| NGA105A-19 | Φ30–Φ40 | 70 | 64 |

| NGA105A-09 | Φ48 | 70 | 64 |

| NGA105A-10 | Φ60 | 70 | 64 |

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.