Metal Testing Equipment

Accurate Tensile Testing of Fasteners with NextGen UTM Grips

NextGen offers a specialized range of bolt and nut tensile grips designed for accurate tensile testing of threaded fasteners using universal testing machines (UTMs). These fixtures provide secure clamping and axial loading for bolts, studs, and nuts, ensuring reliable testing under standardized procedures. The design accommodates high tensile forces while preventing slippage or thread stripping. All grips are engineered to meet international standards including ASTM F606, ISO 898, and DIN 50125, and are compatible with most industry test configurations.

This equipment is ideal for quality control and research applications in sectors such as construction, automotive, aerospace, and manufacturing, where threaded fastener performance must be validated. Whether you are testing according to ISO, ASTM, or DIN protocols, these grips support compliance with precision and repeatability.

NGA105A – Bolt and Nut Tensile Grip

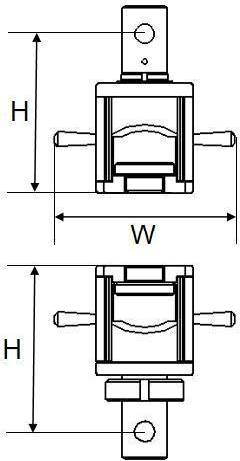

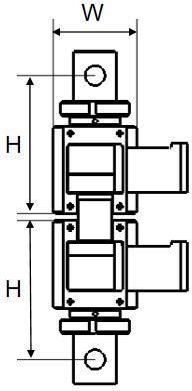

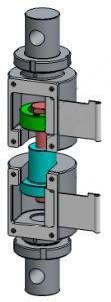

The NGA105A Bolt and Nut Tensile Grip is specifically engineered for tensile testing of bolts and nuts, ensuring compliance with GB/T 3098.1-2010 standards. With a 100 kN load capacity and compact structure, it’s ideal for precision testing of fasteners across various thread sizes. This grip supports M5 to M18 threaded samples and requires a minimum bolt length of ≥2.5d. The unit is lightweight and compatible with Ø18 mm pin-mounted universal testing machines under ambient conditions.

The NGA105A Bolt and Nut Tensile Grip is specifically engineered for tensile testing of bolts and nuts, ensuring compliance with GB/T 3098.1-2010 standards. With a 100 kN load capacity and compact structure, it’s ideal for precision testing of fasteners across various thread sizes. This grip supports M5 to M18 threaded samples and requires a minimum bolt length of ≥2.5d. The unit is lightweight and compatible with Ø18 mm pin-mounted universal testing machines under ambient conditions.

- Application: Tensile tests for bolts and nuts.

- Maximum Capacity: Up to 100 kN load.

- Connection: Ø18 mm pin mount (upper and lower), compatible with standard UTM setups.

- Dimensions: Height – 5.6 in / 143 mm (upper); 5.9 in / 149 mm (lower); Grip Width – 6.5 in / 165 mm.

- Grip Weight: 19.8 lbs / 9 kg each for upper and lower grip.

- Working Temperature: Ambient.

- Standard Compliance: GB/T 3098.1-2010.

- Thread Sizes Supported: M5, M6, M8, M8×1, M10, M10×1.25, M10×1.25, M12×1, M12×1.25, M14, M14×1.5, M18, M18×1.5.

- Minimum Bolt Length Requirement: L ≥ 2.5d.

Technical Specifications – NGA105A Bolt and Nut Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for bolts and nuts |

| Maximum Force Capacity | 100 kN |

| Grip Weight | Upper Grip: 9 kg Lower Grip: 9 kg |

| Working Temperature | Ambient |

| Standard | GB/T 3098.1-2010 |

| Overall Height (H) | Upper Grip: 143 mm Lower Grip: 149 mm |

| Grip Width (W) | 165 mm |

| Connection Type | Upper Grip: Ø18 mm pin Lower Grip: Ø18 mm pin |

| Thread Specification | M5, M6, M8, M8×1, M10, M10×1.25, M10×1.25,M12×1, M12×1.25, M14, M14×1.5, M18, M18×1.5 |

| Minimum Bolt Length | L ≥ 2.5d |

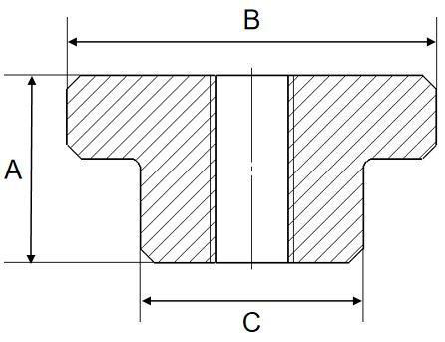

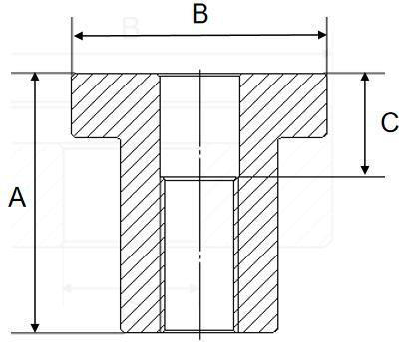

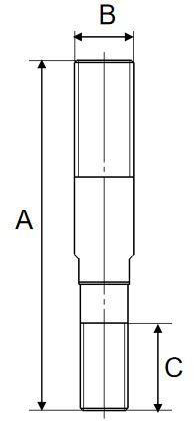

Optional Thread Bushings – NGA105A Grip

Thread bushings are designed to match internal thread sizes and are inserted into the grip body to ensure proper specimen alignment and load distribution during testing.

Thread bushings are designed to match internal thread sizes and are inserted into the grip body to ensure proper specimen alignment and load distribution during testing.

| No. | Specification | A (mm) | B (mm) | C (mm) |

|---|---|---|---|---|

| NGA105A-27 | M5 | 27 | 53 | 32 |

| NGA105A-14 | M6 | 27 | 53 | 32 |

| NGA105A-09 | M8 | 27 | 53 | 32 |

| NGA105A-26 | M8×1.0 | 27 | 53 | 32 |

| NGA105A-08 | M10 | 27 | 53 | 32 |

| NGA105A-15 | M12 | 27 | 53 | 32 |

| NGA105A-17 | M12×1.0 | 27 | 53 | 32 |

| NGA105A-18 | M12×1.25 | 27 | 53 | 32 |

| NGA105A-16 | M14 | 27 | 53 | 32 |

| NGA105A-24 | M14×1.5 | 27 | 53 | 32 |

| NGA105A-10 | M18×1.5 | 27 | 53 | 32 |

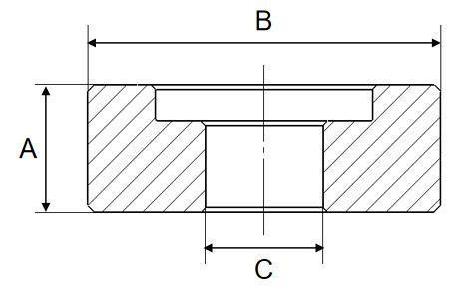

Optional Thread Bushings – NGA105A Grip

Bolt thimbles serve as sleeves to accommodate bolts of varying outer thread diameters, enabling correct axial alignment and consistent loading during tests.

| No. | Specification | A (mm) | B (mm) | C (mm) |

|---|---|---|---|---|

| NGA105A-28 | M5 | 27 | 53 | 32 |

| NGA105A-19 | M6 | 27 | 53 | 32 |

| NGA105A-20 | M8 | 27 | 53 | 32 |

| NGA105A-21 | M10 | 27 | 53 | 32 |

| NGA105A-22 | M12 | 27 | 53 | 32 |

| NGA105A-23 | M14 | 27 | 53 | 32 |

| NGA105A-25 | M18 | 27 | 53 | 32 |

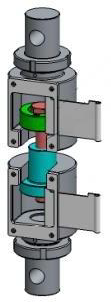

NGA305C – Bolt and Nut Tensile Grip

The NGA305C Bolt and Nut Tensile Grip is designed for high-force tensile testing of bolts and nuts in compliance with GB/T 3098.1-2010 and GB/T 3098.2-2015 standards. With a rated load capacity of 300 kN and compatibility with a wide range of metric thread sizes from M3 to M22, this system is ideal for advanced testing environments. The grip operates under ambient conditions and features Ø28 mm pin connections for easy integration with universal testing machines. It accommodates bolts with a minimum length of 2.5 times their nominal diameter.

The NGA305C Bolt and Nut Tensile Grip is designed for high-force tensile testing of bolts and nuts in compliance with GB/T 3098.1-2010 and GB/T 3098.2-2015 standards. With a rated load capacity of 300 kN and compatibility with a wide range of metric thread sizes from M3 to M22, this system is ideal for advanced testing environments. The grip operates under ambient conditions and features Ø28 mm pin connections for easy integration with universal testing machines. It accommodates bolts with a minimum length of 2.5 times their nominal diameter.

- Application: Tension tests for bolts and nuts.

- Maximum Capacity: Up to 300 kN load.

- Connection: Ø28 mm pin mount (upper and lower).

- Dimensions: Height – 7.8 in / 197 mm (upper and lower); Grip Width – 4.6 in / 118 mm.

- Grip Weight: 25.6 lbs / 11.6 kg each for upper and lower grip.

- Working Temperature: Ambient.

- Standard Compliance: GB/T 3098.1-2010, GB/T 3098.2-2015.

- Thread Sizes Supported: M3, M4, M5, M6, M8, M8×1, M10, M10×1, M10×1.25, M12, M12×1.25, M12×1.5, M14, M14×1.5, M16, M16×1.5, M18, M18×1.5, M20, M20×1.5, M22.

- Minimum Bolt Length Requirement: L ≥ 2.5d.

Technical Specifications – NGA305C Bolt and Nut Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for bolts and nuts |

| Maximum Force Capacity | 300 kN |

| Grip Weight | Upper Grip: 11.6 kg Lower Grip: 11.6 kg |

| Working Temperature | Ambient |

| Standard | GB/T 3098.1-2010GB/T 3098.2-2015 |

| Overall Height (H) | Upper Grip: 197 mm Lower Grip: 197 mm |

| Grip Width (W) | 118 mm |

| Connection Type | Upper Grip: Ø28 mm pin Lower Grip: Ø28 mm pin |

| Thread Specification | M3, M4, M5, M6, M8, M8×1, M10, M10×1,M10×1.25, M12, M12×1.25, M12×1.5, M14, M14×1.5,M16, M16×1.5, M18, M18×1.5, M20, M20×1.5, M22 |

| Minimum Bolt Length | L ≥ 2.5d |

Optional Thread Bushings – NGA305C Grip

These optional thread bushings allow precise fitment for a wide range of bolt sizes and threads. Manufactured to high tolerances, each bushing ensures proper centering and alignment under test load.

| No. | Specification | A (mm) | B (mm) | C (mm) |

|---|---|---|---|---|

| NGA305C-07-01 | M3 | 80 | 78 | 74 |

| NGA305C-07-02 | M4 | 80 | 78 | 72 |

| NGA305C-07-03 | M5 | 80 | 78 | 70 |

| NGA305C-07-04 | M6 | 80 | 78 | 68 |

| NGA305C-07-05 | M8×1 | 80 | 78 | 64 |

| NGA305C-07-06 | M8 | 80 | 78 | 64 |

| NGA305C-07-07 | M10×1 | 80 | 78 | 60 |

| NGA305C-07-08 | M10×1.25 | 80 | 78 | 60 |

| NGA305C-07-09 | M10 | 80 | 78 | 60 |

| NGA305C-07-10 | M12×1.25 | 80 | 78 | 58 |

| NGA305C-07-11 | M12×1.5 | 80 | 78 | 56 |

| NGA305C-07-12 | M12 | 80 | 78 | 56 |

| NGA305C-07-13 | M14×1.5 | 80 | 78 | 52 |

| NGA305C-07-14 | M14 | 80 | 78 | 52 |

| NGA305C-07-15 | M16×1.5 | 80 | 78 | 48 |

| NGA305C-07-16 | M16 | 80 | 78 | 48 |

| NGA305C-07-17 | M18×1.5 | 80 | 78 | 44 |

| NGA305C-07-18 | M18 | 80 | 78 | 44 |

| NGA305C-07-19 | M20×1.5 | 80 | 78 | 40 |

| NGA305C-07-20 | M20 | 80 | 78 | 40 |

| NGA305C-07-21 | M22×1.5 | 80 | 78 | 36 |

| NGA305C-07-22 | M22 | 80 | 78 | 36 |

| NGA305C-07-23 | M24×2 | 80 | 78 | 32 |

| NGA305C-07-24 | M24 | 80 | 78 | 32 |

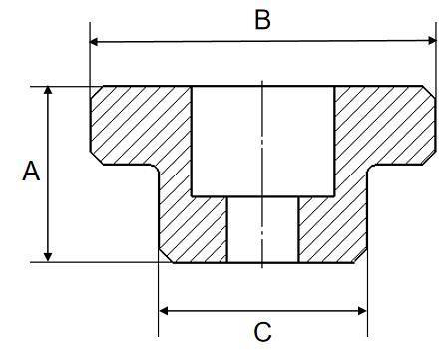

Optional Thread Bushings – NGA305C Grip (Compact/Short Type)

These compact bushings offer reduced height and are ideal for applications requiring space savings.

| No. | Specification | A (mm) | B (mm) | C (mm) |

|---|---|---|---|---|

| WLA305C-06-01 | M3 | 22 | 78 | 3.5 |

| WLA305C-06-02 | M4 | 22 | 78 | 4.5 |

| WLA305C-06-03 | M5 | 22 | 78 | 5.5 |

| WLA305C-06-04 | M6 | 22 | 78 | 6.6 |

| WLA305C-06-05 | M8 | 22 | 78 | 9 |

| NGA305C-06-06 | M10 | 22 | 78 | 11 |

| NGA305C-06-07 | M12 | 22 | 78 | 13.5 |

| NGA305C-06-08 | M14 | 22 | 78 | 15.5 |

| NGA305C-06-09 | M16 | 22 | 78 | 17.5 |

| NGA305C-06-10 | M18 | 22 | 78 | 20 |

| NGA305C-06-11 | M20 | 22 | 78 | 22 |

| NGA305C-06-12 | M22 | 22 | 78 | 24 |

| NGA305C-06-13 | M24 | 22 | 78 | 26 |

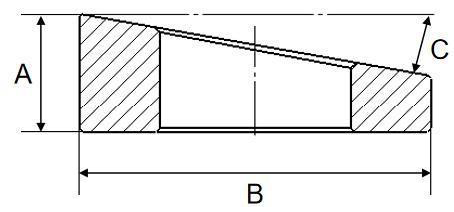

Optional Wedges – NGA305C Grip

The optional wedges are designed to provide optimal centering and load distribution for specific thread sizes. Each wedge is available in multiple entry angles (4°, 6°, 10°) to suit different test configurations. Manufactured from high-strength materials, these wedges enhance grip performance and prevent slippage during high-force tensile tests.

The optional wedges are designed to provide optimal centering and load distribution for specific thread sizes. Each wedge is available in multiple entry angles (4°, 6°, 10°) to suit different test configurations. Manufactured from high-strength materials, these wedges enhance grip performance and prevent slippage during high-force tensile tests.

| No. | Specification | A (mm) | B (mm) | C (°) |

|---|---|---|---|---|

| NGA305C-08-01 | M3–4° | 4 | 7 | 4 |

| NGA305C-08-02 | M3–6° | 4 | 7 | 6 |

| NGA305C-08-03 | M3–10° | 4 | 7 | 10 |

| NGA305C-08-04 | M4–4° | 5 | 9 | 4 |

| NGA305C-08-05 | M4–6° | 5 | 9 | 6 |

| NGA305C-08-06 | M4–10° | 5 | 9 | 10 |

| NGA305C-08-07 | M5–4° | 6 | 10 | 4 |

| NGA305C-08-08 | M5–6° | 6 | 10 | 6 |

| NGA305C-08-09 | M5–10° | 6 | 10 | 10 |

| NGA305C-08-10 | M6–4° | 7 | 12 | 4 |

| NGA305C-08-11 | M6–6° | 7 | 12 | 6 |

| NGA305C-08-12 | M6–10° | 7 | 12 | 10 |

| NGA305C-08-13 | M8–4° | 8 | 16 | 4 |

| NGA305C-08-14 | M8–6° | 8 | 16 | 6 |

| NGA305C-08-15 | M8–10° | 8 | 16 | 10 |

| NGA305C-08-16 | M10–4° | 10 | 20 | 4 |

| NGA305C-08-17 | M10–6° | 10 | 20 | 6 |

| NGA305C-08-18 | M10–10° | 10 | 20 | 10 |

| NGA305C-08-19 | M12–4° | 11 | 24 | 4 |

| NGA305C-08-20 | M12–6° | 11 | 24 | 6 |

| NGA305C-08-21 | M12–10° | 11 | 24 | 10 |

| NGA305C-08-22 | M14–4° | 12 | 28 | 4 |

| NGA305C-08-23 | M14–6° | 12 | 28 | 6 |

| NGA305C-08-24 | M14–10° | 12 | 28 | 10 |

| NGA305C-08-25 | M16–4° | 13 | 30 | 4 |

| NGA305C-08-26 | M16–6° | 13 | 30 | 6 |

| NGA305C-08-27 | M16–10° | 13 | 30 | 10 |

| NGA305C-08-28 | M18–4° | 15 | 34 | 4 |

| NGA305C-08-29 | M18–6° | 15 | 34 | 6 |

| NGA305C-08-30 | M18–10° | 15 | 34 | 10 |

| NGA305C-08-31 | M20–4° | 16 | 37 | 4 |

| NGA305C-08-32 | M20–6° | 16 | 37 | 6 |

| NGA305C-08-33 | M20–10° | 16 | 37 | 10 |

| NGA305C-08-34 | M22–4° | 17 | 42 | 4 |

| NGA305C-08-35 | M22–6° | 17 | 42 | 6 |

| NGA305C-08-36 | M22–10° | 17 | 42 | 10 |

| NGA305C-08-37 | M24–4° | 18 | 44 | 4 |

| NGA305C-08-38 | M24–6° | 18 | 44 | 6 |

| NGA305C-08-39 | M24–10° | 18 | 44 | 10 |

Optional Mandrels – NGA305C Grip

Mandrels are essential for clamping bolt samples during tensile testing. These optional accessories match a wide variety of thread sizes and ensure firm, axial alignment inside the fixture. The NGA305C mandrels are available for metric and fine threads ranging from M3 to M24×2.

Mandrels are essential for clamping bolt samples during tensile testing. These optional accessories match a wide variety of thread sizes and ensure firm, axial alignment inside the fixture. The NGA305C mandrels are available for metric and fine threads ranging from M3 to M24×2.

| No. | Specification | A (mm) | B (mm) | C (mm) |

|---|---|---|---|---|

| NGA305C-09-01 | M3 | 77 | M16 | 10 |

| NGA305C-09-02 | M4 | 77 | M16 | 10 |

| NGA305C-09-03 | M5 | 77 | M16 | 16 |

| NGA305C-09-04 | M6 | 77 | M16 | 16 |

| NGA305C-09-05 | M8×1 | 77 | M16 | 20 |

| NGA305C-09-06 | M8 | 77 | M16 | 20 |

| NGA305C-09-07 | M10×1 | 77 | M16 | 25 |

| NGA305C-09-08 | M10×1.25 | 77 | M16 | 25 |

| NGA305C-09-09 | M10 | 77 | M16 | 25 |

| NGA305C-09-10 | M12×1.25 | 77 | M16 | 30 |

| NGA305C-09-11 | M12×1.5 | 77 | M16 | 30 |

| NGA305C-09-12 | M12 | 77 | M16 | 30 |

| NGA305C-10-01 | M14×1.5 | 115 | M24 | 35 |

| NGA305C-10-02 | M14 | 115 | M24 | 35 |

| NGA305C-10-03 | M16×1.5 | 115 | M24 | 35 |

| NGA305C-10-04 | M16 | 115 | M24 | 35 |

| NGA305C-10-05 | M18×1.5 | 115 | M24 | 40 |

| NGA305C-10-06 | M18 | 115 | M24 | 40 |

| NGA305C-11-01 | M20×1.5 | 180 | M30 | 45 |

| NGA305C-11-02 | M20 | 180 | M30 | 45 |

| NGA305C-11-03 | M22×1.5 | 180 | M30 | 45 |

| NGA305C-11-04 | M22 | 180 | M30 | 45 |

| NGA305C-11-05 | M24×2 | 180 | M30 | 45 |

| NGA305C-11-06 | M24 | 180 | M30 | 45 |

NextGen’s bolt and nut tensile grips deliver consistent, accurate, and standard-compliant testing results. Whether you are validating mechanical properties of fasteners for R&D or certifying production batches, these grips integrate seamlessly with NextGen’s universal testing machines. Contact us today to discuss configuration compatibility and order the right tensile grip set for your application.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.