Metal Testing Equipment

Versatile, High-Performance Fixtures for Advanced Mechanical Testing

NextGen's TestStar® grips and fixtures are purpose-built to deliver superior mechanical testing performance in demanding industrial applications. These high-precision components are engineered to integrate seamlessly with our universal testing machines (UTMs), offering broad compatibility with international standards such as ASTM D638, ISO 6892, DIN 50125, and others.

NextGen's TestStar® grips and fixtures are purpose-built to deliver superior mechanical testing performance in demanding industrial applications. These high-precision components are engineered to integrate seamlessly with our universal testing machines (UTMs), offering broad compatibility with international standards such as ASTM D638, ISO 6892, DIN 50125, and others.

Covering a comprehensive range of testing modes—including tensile, compression, bending, shear, and puncture—these fixtures provide flexibility and repeatability for research labs, quality control departments, and material certification facilities.

Each TestStar® accessory is designed with rigid construction, ergonomic use, and quick interchangeability, supporting both manual and pneumatic operation modes. Optimized for testing various materials including metals, polymers, composites, geotextiles, and more.

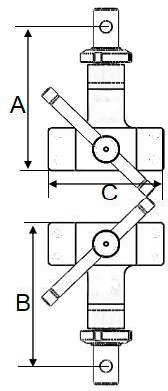

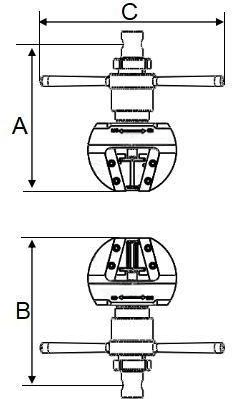

NGQA502A – Pneumatic Tensile Grip (Snubbing Type)

The NGQA502A Pneumatic Tensile Grip is designed for low-force tension testing of filament materials using a snubbing configuration. This pneumatic grip delivers consistent clamping pressure and precision alignment under ambient conditions. Compatible with standard Φ10 mm pin connections, it is ideal for delicate materials such as fibers or threads with specimen diameters up to 1.5 mm.

The NGQA502A Pneumatic Tensile Grip is designed for low-force tension testing of filament materials using a snubbing configuration. This pneumatic grip delivers consistent clamping pressure and precision alignment under ambient conditions. Compatible with standard Φ10 mm pin connections, it is ideal for delicate materials such as fibers or threads with specimen diameters up to 1.5 mm.

- Application: Tension test for filament materials.

- Maximum Capacity: ≤ 500 N load.

- Grip Weight: 0.56 kg (upper grip), 0.56 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Height: 140 mm (upper grip), 140 mm (lower grip).

- Width: 115 mm.

- Specimen Size Compatibility: ≤ Φ1.5 mm.

Technical Specifications – NGQA502A Pneumatic Tensile Grip (Snubbing Type)

| Parameter | Specification |

|---|---|

| Application | Tension test for filament |

| Maximum Force Capacity | ≤ 500 N |

| Grip Weight | Upper Grip: 0.56 kg Lower Grip: 0.56 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Height (A/B) | Upper Grip: 140 mm Lower Grip: 140 mm |

| Width (C) | 115 mm |

| Specimen Size | ≤ Φ1.5 mm |

| Jaw Face Width (Shoe Upper) | 40 mm |

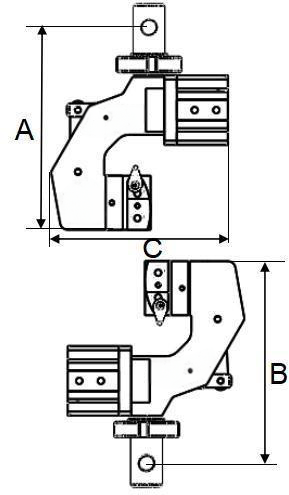

NGH203A – Tensile Grip (Manual Snubbing)

The NGH203A Manual Snubbing Tensile Grip is designed for tension testing of flexible materials such as glass fiber, cotton thread, and nylon cord. It uses a manual snubbing configuration to maintain secure grip without slippage. With a maximum capacity of 2 kN, it is suitable for low-force testing in ambient environments. Compatible with standard Φ10 mm pin mounts, this grip accommodates samples below 500 tex.

The NGH203A Manual Snubbing Tensile Grip is designed for tension testing of flexible materials such as glass fiber, cotton thread, and nylon cord. It uses a manual snubbing configuration to maintain secure grip without slippage. With a maximum capacity of 2 kN, it is suitable for low-force testing in ambient environments. Compatible with standard Φ10 mm pin mounts, this grip accommodates samples below 500 tex.

- Application: Tension test for glass fiber, cotton thread, and nylon cord.

- Maximum Capacity: ≤ 2 kN load.

- Grip Weight: 1.7 kg (upper grip), 1.7 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Height: 165 mm (upper grip), 165 mm (lower grip).

- Grip Width: 125 mm.

- Specimen Size Compatibility: < 500 tex.

Technical Specifications – NGH203A Tensile Grip (Manual Snubbing)

| Parameter | Specification |

|---|---|

| Application | Tension test for glass fiber, cotton thread, nylon cord |

| Maximum Force Capacity | ≤ 2 kN |

| Grip Weight | Upper Grip: 1.7 kg Lower Grip: 1.7 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Height (A/B) | Upper Grip: 165 mm Lower Grip: 165 mm |

| Grip Width (C) | 125 mm |

| Specimen Size | < 500 tex |

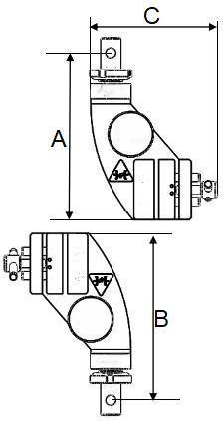

NGB502B – Tensile Grip (Snubbing)

The NGB502B Tensile Grip is a snubbing-type fixture specifically designed for tension testing of steel wire. Ideal for delicate, thin-diameter samples up to Φ1.5 mm, this grip offers precision and control for low-force testing up to 500 N. It features compact construction, uniform upper/lower grip heights, and a wave-profile jaw face for stable sample engagement.

The NGB502B Tensile Grip is a snubbing-type fixture specifically designed for tension testing of steel wire. Ideal for delicate, thin-diameter samples up to Φ1.5 mm, this grip offers precision and control for low-force testing up to 500 N. It features compact construction, uniform upper/lower grip heights, and a wave-profile jaw face for stable sample engagement.

- Application: Tension test for steel wire.

- Maximum Capacity: ≤ 500 N load.

- Grip Weight: 0.7 kg (upper grip), 0.7 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Height: 115 mm (upper grip), 115 mm (lower grip).

- Grip Width: 90 mm.

- Jaw Face Dimensions: 36 mm (H) × 10 mm (W).

- Specimen Diameter Compatibility: ≤ Φ1.5 mm.

Technical Specifications – NGB502B Tensile Grip (Snubbing)

| Parameter | Specification |

|---|---|

| Application | Tension test for steel wire |

| Maximum Force Capacity | ≤ 500 N |

| Grip Weight | Upper Grip: 0.7 kg Lower Grip: 0.7 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Height (A/B) | Upper Grip: 115 mm Lower Grip: 115 mm |

| Grip Width (C) | 90 mm |

| Jaw Face Dimensions | 36 mm (H) × 10 mm (W) |

| Specimen Diameter | ≤ Φ1.5 mm |

NGSD503A – Tensile Grip (Side Action)

The NGSD503A Tensile Grip is designed for tension testing of textiles and similar soft materials. With a side-action mechanism and wave-profile jaw faces, it provides consistent clamping without damaging delicate samples. Suitable for forces up to 5 kN, the grip supports ambient testing conditions and handles specimen thicknesses up to 14 mm. It is compatible with Φ10 mm pin connections for integration with standard testing machines.

The NGSD503A Tensile Grip is designed for tension testing of textiles and similar soft materials. With a side-action mechanism and wave-profile jaw faces, it provides consistent clamping without damaging delicate samples. Suitable for forces up to 5 kN, the grip supports ambient testing conditions and handles specimen thicknesses up to 14 mm. It is compatible with Φ10 mm pin connections for integration with standard testing machines.

- Application: Tension test for textile materials.

- Maximum Capacity: ≤ 5 kN load.

- Grip Weight: 1.73 kg (upper grip), 1.73 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Height: 120 mm (upper grip), 120 mm (lower grip).

- Grip Width: 95 mm.

- Jaw Face Dimensions: 95 mm × 35 mm (wave-profile).

- Specimen Thickness Compatibility: ≤ 14 mm.

Technical Specifications – NGSD503A Tensile Grip (Side Action)

| Parameter | Specification |

|---|---|

| Application | Tension test for textile |

| Maximum Force Capacity | ≤ 5 kN |

| Grip Weight | Upper Grip: 1.73 kg Lower Grip: 1.73 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Height (A/B) | Upper Grip: 120 mm Lower Grip: 120 mm |

| Grip Width (C) | 95 mm |

| Jaw Face Dimensions | 95 mm × 35 mm (Wave-profile) |

| Specimen Thickness | ≤ 14 mm |

NGSA105A – Wedge Tensile Grip (Wedge Action)

The NGSA105A Wedge Tensile Grip is built for high-force tension testing of both flat and round specimens made of metal or composite materials. With a robust construction rated for loads up to 100 kN, this fixture is ideal for samples with hardness below 30 HRC and tensile strength under 600 MPa. It integrates easily with universal testing machines using Φ18 mm pin connections and delivers uniform clamping through wedge action.

The NGSA105A Wedge Tensile Grip is built for high-force tension testing of both flat and round specimens made of metal or composite materials. With a robust construction rated for loads up to 100 kN, this fixture is ideal for samples with hardness below 30 HRC and tensile strength under 600 MPa. It integrates easily with universal testing machines using Φ18 mm pin connections and delivers uniform clamping through wedge action.

- Application: Tension test for flat and round specimens of metal and composite materials.

- Maximum Capacity: ≤ 100 kN load.

- Grip Weight: 15.3 kg (upper grip), 15.3 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ18 mm pin (upper and lower grips).

- Height: 290 mm (upper grip), 290 mm (lower grip).

- Grip Width: 370 mm.

- Note: Suitable for specimens with hardness < 30 HRC and tensile strength < 600 MPa.

Technical Specifications – NGSA105A Wedge Tensile Grip (Wedge Action)

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimens of metal, composite |

| Maximum Force Capacity | ≤ 100 kN |

| Grip Weight | Upper Grip: 15.3 kg Lower Grip: 15.3 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ18 mm pin Lower Grip: Φ18 mm pin |

| Height (A/B) | Upper Grip: 290 mm Lower Grip: 290 mm |

| Grip Width (C) | 370 mm |

| Specimen Requirement | Hardness < 30 HRC, Tensile Strength < 600 MPa |

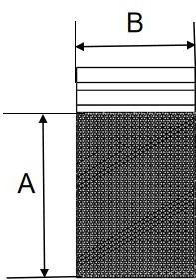

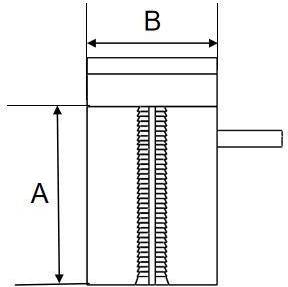

Optional Jaw Faces – NGSA105A Grip

To accommodate a wider variety of specimen shapes and sizes, the NGSA105A Wedge Tensile Grip is available with optional flat and vee jaw faces. All jaw faces are designed with a 1.5 mm pitch to ensure stable and uniform clamping. Both flat and vee types offer consistent dimensions and compatibility with specimens of varying thicknesses and diameters.

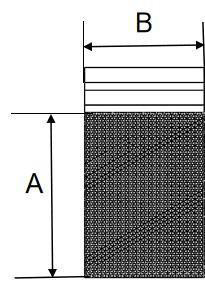

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGSA105A-13 | 0–7 | 50 | 40 |

| NGSA105A-14 | 7–14 | 50 | 40 |

| NGSA105A-15 | 14–21 | 50 | 40 |

Note: All flat jaw faces have a pitch of 1.5 mm.

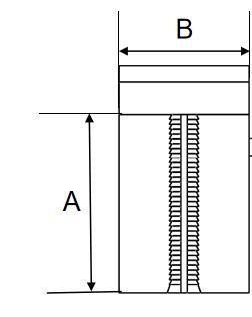

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGSA105A-16 | Φ4–9 | 50 | 40 |

| NGSA105A-17 | Φ9–14 | 50 | 40 |

| NGSA105A-18 | Φ14–19 | 50 | 40 |

Note: All vee jaw faces have a pitch of 1.5 mm.

NGSA304A – Wedge Tensile Grip (Wedge Action)

The NGSA304A Wedge Tensile Grip is designed for performing tension tests on flat and round specimens made from metals and composite materials. With a maximum force capacity of 30 kN, this grip is ideal for medium-load testing environments. It supports specimens with hardness below 30 HRC and tensile strength below 600 MPa. The wedge-action mechanism ensures stable gripping, while Φ10 mm pin connections allow for easy integration into standard testing machines.

The NGSA304A Wedge Tensile Grip is designed for performing tension tests on flat and round specimens made from metals and composite materials. With a maximum force capacity of 30 kN, this grip is ideal for medium-load testing environments. It supports specimens with hardness below 30 HRC and tensile strength below 600 MPa. The wedge-action mechanism ensures stable gripping, while Φ10 mm pin connections allow for easy integration into standard testing machines.

- Application: Tension test for flat and round specimens of metal and composite materials.

- Maximum Capacity: ≤ 30 kN load.

- Grip Weight: 13.5 kg (upper grip), 13.5 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Height: 255 mm (upper grip), 175 mm (lower grip).

- Grip Width: 350 mm.

- Note: Suitable for specimens with hardness < 30 HRC and tensile strength < 600 MPa.

Technical Specifications – NGSA304A Wedge Tensile Grip (Wedge Action)

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimens of metal, composite |

| Maximum Force Capacity | ≤ 30 kN |

| Grip Weight | Upper Grip: 13.5 kg Lower Grip: 13.5 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Height (A/B) | Upper Grip: 255 mm Lower Grip: 175 mm |

| Grip Width (C) | 350 mm |

| Specimen Requirement | Hardness < 30 HRC, Tensile Strength < 600 MPa |

Optional Jaw Faces – NGSA304A Wedge Tensile Grip

The NGSA304A Wedge Tensile Grip supports a range of optional jaw faces designed to accommodate both flat and round specimens. All jaws are engineered with a 1.5 mm pitch, ensuring firm, non-slip engagement during medium-load testing of metal and composite materials.

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGSA105A-13 | 0–7 | 50 | 40 |

| NGSA105A-14 | 7–14 | 50 | 40 |

| NGSA105A-15 | 14–21 | 50 | 40 |

Note: All flat jaw faces have a pitch of 1.5 mm.

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGSA105A-16 | Φ4–9 | 50 | 40 |

| NGSA105A-17 | Φ9–14 | 50 | 40 |

| NGSA105A-18 | Φ14–19 | 50 | 40 |

Note: All vee jaw faces have a pitch of 1.5 mm.

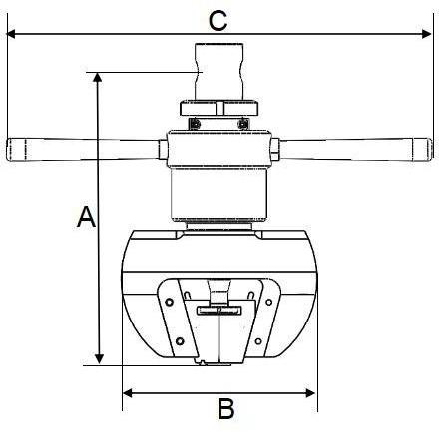

NGSA305A – Wedge Tensile Grip (Wedge Action)

The NGSA305A Wedge Tensile Grip is designed for high-capacity tensile testing of flat and round specimens made from metal and composite materials. With a maximum load capacity of 300 kN and a heavy-duty wedge-action mechanism, it offers reliable and stable clamping for demanding applications. The grip is compatible with Φ28 mm pin connections and supports specimens with hardness below 30 HRC and tensile strength below 600 MPa.

The NGSA305A Wedge Tensile Grip is designed for high-capacity tensile testing of flat and round specimens made from metal and composite materials. With a maximum load capacity of 300 kN and a heavy-duty wedge-action mechanism, it offers reliable and stable clamping for demanding applications. The grip is compatible with Φ28 mm pin connections and supports specimens with hardness below 30 HRC and tensile strength below 600 MPa.

- Application: Tension test for flat and round specimens of metal and composite materials.

- Maximum Capacity: ≤ 300 kN load.

- Grip Weight: 38.5 kg (upper grip), 38.5 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ28 mm pin (upper and lower grips).

- Height: 348 mm.

- Grip Body Width: 248 mm.

- Overall Width: 538 mm.

- Note: Suitable for specimens with hardness < 30 HRC and tensile strength < 600 MPa.

Technical Specifications – NGSA305A Wedge Tensile Grip (Wedge Action)

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimens of metal, composite |

| Maximum Force Capacity | ≤ 300 kN |

| Grip Weight | Upper Grip: 38.5 kg Lower Grip: 38.5 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ28 mm pin Lower Grip: Φ28 mm pin |

| Height (A) | 348 mm |

| Grip Body Width (B) | 248 mm |

| Overall Width (C) | 538 mm |

| Specimen Requirement | Hardness < 30 HRC, Tensile Strength < 600 MPa |

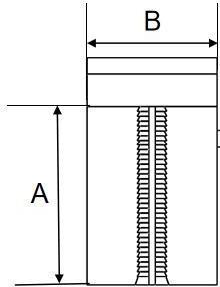

Optional Jaw Faces – NGSA305A Wedge Tensile Grip

The NGSA305A supports a full range of optional flat and vee jaw faces, allowing adaptation to a variety of flat and round specimens. All jaws are precisely machined with a 2.0 mm pitch to maintain uniform gripping pressure and prevent slippage during high-capacity tensile testing.

Flat Jaw Faces (Optional)

| No. | Specimen Thickness (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGSA305A-13 | 0–8 | 62 | 50 |

| NGSA305A-14 | 8–16 | 62 | 50 |

| NGSA305A-15 | 16–24 | 62 | 50 |

| NGSA305A-16 | 24–32 | 62 | 50 |

Note: All flat jaw faces have a pitch of 2.0 mm.

Vee Jaw Faces (Optional)

| No. | Specimen Diameter (mm) | Height A (mm) | Width B (mm) |

|---|---|---|---|

| NGSA305A-17 | Φ4–9 | 62 | 50 |

| NGSA305A-18 | Φ9–16 | 62 | 50 |

| NGSA305A-19 | Φ16–23 | 62 | 50 |

| NGSA305A-20 | Φ23–30 | 62 | 50 |

Note: All flat jaw faces have a pitch of 2.0 mm.

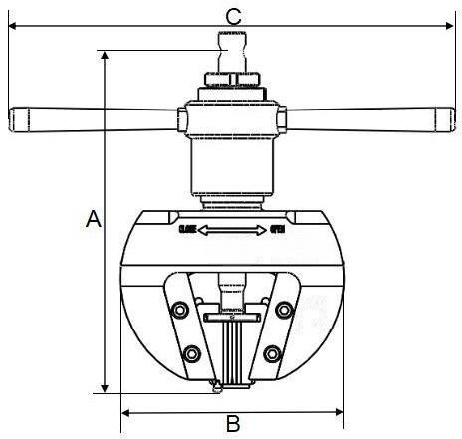

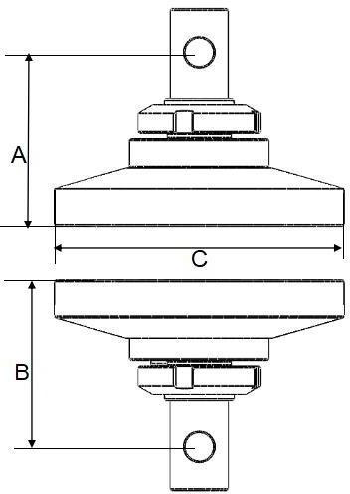

NGA204A – Wedge Action Grip

The NGA204A Wedge Action Grip is engineered for compression testing of concrete, metal, and plastic specimens. Designed for medium-capacity loads up to 20 kN, this fixture combines compact form with reliable performance under ambient conditions. Compatible with Φ10 mm pin connections, the grip provides a stable setup for compressive force applications in various material testing environments.

The NGA204A Wedge Action Grip is engineered for compression testing of concrete, metal, and plastic specimens. Designed for medium-capacity loads up to 20 kN, this fixture combines compact form with reliable performance under ambient conditions. Compatible with Φ10 mm pin connections, the grip provides a stable setup for compressive force applications in various material testing environments.

- Application: Compression test for concrete, metal, and plastic materials.

- Maximum Capacity: ≤ 20 kN load.

- Grip Weight: 1.4 kg (upper grip), 1.4 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Height: 70 mm (upper grip), 60 mm (lower grip).

- Diameter: 100 mm.

Technical Specifications – NGA204A Wedge Action Grip

| Parameter | Specification |

|---|---|

| Application | Compression test for concrete, metal, plastic |

| Maximum Force Capacity | ≤ 20 kN |

| Grip Weight | Upper Grip: 1.4 kg Lower Grip: 1.4 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Height (A/B) | Upper Grip: 70 mm Lower Grip: 60 mm |

| Diameter (C) | 100 mm |

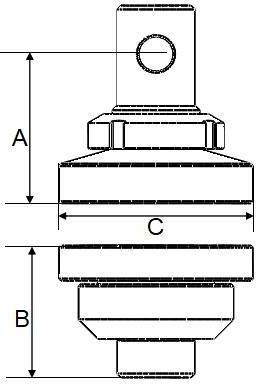

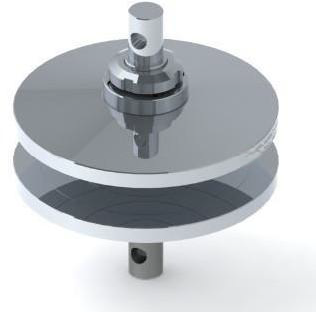

NGA105A – Compression Fixture

The NGA105A Compression Fixture is designed for high-force compression testing of concrete, metals, plastics, and composite materials. Built to withstand forces up to 100 kN, the fixture features Φ18 mm pin connections and a sphere-seated configuration for improved load alignment and accuracy. It is ideal for general-purpose compression testing in ambient environments.

The NGA105A Compression Fixture is designed for high-force compression testing of concrete, metals, plastics, and composite materials. Built to withstand forces up to 100 kN, the fixture features Φ18 mm pin connections and a sphere-seated configuration for improved load alignment and accuracy. It is ideal for general-purpose compression testing in ambient environments.

- Application: Compression test for concrete, metal, plastic, composite, and similar materials.

- Maximum Capacity: ≤ 100 kN load.

- Grip Weight: 2.5 kg (upper grip), 2.4 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ18 mm pin (upper and lower grips).

- Height: 75 mm (upper grip), 68 mm (lower grip).

- Diameter: 100 mm.

- Sphere Seated: Yes.

Technical Specifications – NGA105A Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Compression test for concrete, metal, plastic, composite etc |

| Maximum Force Capacity | ≤ 100 kN |

| Grip Weight | Upper Grip: 2.5 kg Lower Grip: 2.4 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ18 mm pin Lower Grip: Φ18 mm pin |

| Height (A/B) | Upper Grip: 75 mm Lower Grip: 68 mm |

| Diameter (C) | 100 mm |

| Sphere Seated | Yes |

NGC502A – Compression Fixture

The NGC502A Compression Fixture is purpose-built for low-force compression testing of non-metallic materials. With a maximum capacity of 500 N, this fixture is lightweight and features Φ10 mm pin connections for seamless integration with standard testing machines. Its 150 mm diameter offers a broad, stable base suitable for softer and flexible specimen types.

The NGC502A Compression Fixture is purpose-built for low-force compression testing of non-metallic materials. With a maximum capacity of 500 N, this fixture is lightweight and features Φ10 mm pin connections for seamless integration with standard testing machines. Its 150 mm diameter offers a broad, stable base suitable for softer and flexible specimen types.

- Application: Compression test for non-metallic materials.

- Maximum Capacity: ≤ 500 N load.

- Grip Weight: 1.5 kg (upper grip), 1.5 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Height: 55 mm (upper grip), 60 mm (lower grip).

- Diameter: 150 mm.

Technical Specifications – NGC502A Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Compression test for non-metallic material |

| Maximum Force Capacity | ≤ 500 N |

| Grip Weight | Upper Grip: 1.5 kg Lower Grip: 1.5 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Height (A/B) | Upper Grip: 55 mm Lower Grip: 60 mm |

| Diameter (C) | 150 mm |

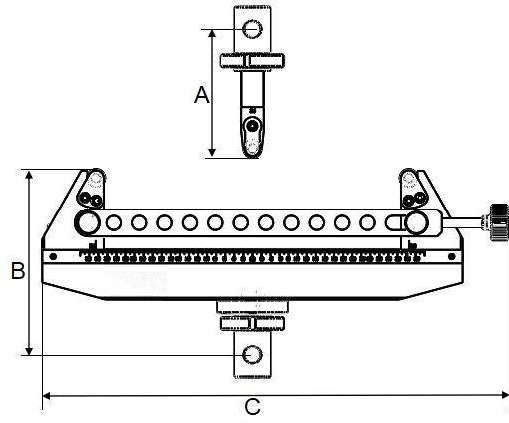

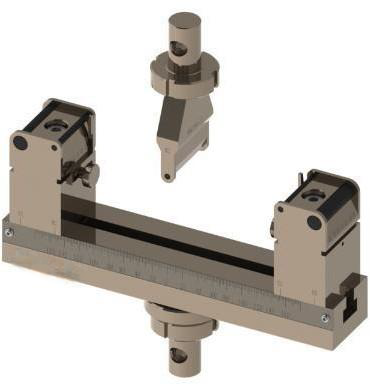

NGA105A – Bending Fixture (3-Point Bending)

The NGA105A 3-Point Bending Fixture is designed for high-load testing of flat and round metallic specimens. It supports forces up to 100 kN and provides an adjustable span up to 360 mm, ensuring flexibility in test setup. The fixture includes Φ20 mm loading and support rollers and is suitable for ambient laboratory conditions. Compatible with Φ18 mm pin-mounted machines.

The NGA105A 3-Point Bending Fixture is designed for high-load testing of flat and round metallic specimens. It supports forces up to 100 kN and provides an adjustable span up to 360 mm, ensuring flexibility in test setup. The fixture includes Φ20 mm loading and support rollers and is suitable for ambient laboratory conditions. Compatible with Φ18 mm pin-mounted machines.

- Application: Bending test for flat and round metallic specimens.

- Maximum Capacity: ≤ 100 kN load.

- Grip Weight: 0.3 kg (upper grip), 3.1 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ18 mm pin (upper and lower grips).

- Span (Adjustable): ≤ 360 mm.

- Height: 140 mm (upper grip), 205 mm (lower grip).

- Maximum Specimen Width: 80 mm.

- Base Width: 505 mm.

- Loading Roller Diameter: Φ20 mm.

- Support Roller Diameter: Φ20 mm.

Technical Specifications – NGA105A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for flat and round metallic specimens |

| Maximum Force Capacity | ≤ 100 kN |

| Grip Weight | Upper Grip: 0.3 kg Lower Grip: 3.1 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ18 mm pin Lower Grip: Φ18 mm pin |

| Span (Adjustable) | ≤ 360 mm |

| Height (A/B) | Upper Grip: 140 mm Lower Grip: 205 mm |

| Maximum Specimen Width | 80 mm |

| Base Width (C) | 505 mm |

| Loading Roller | Φ20 mm |

| Support Roller | Φ20 mm |

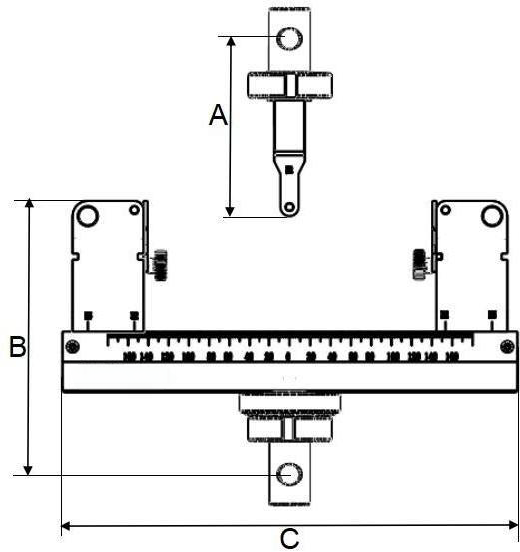

NGA104A – Bending Fixture (3-Point Bending)

The NGA104A 3-Point Bending Fixture is a compact and lightweight solution for performing bending tests on flat and round metallic specimens. With a capacity of up to 10 kN and an adjustable span of up to 160 mm, it is ideal for low-force applications. The fixture is equipped with both R5 mm and R2 mm rollers for flexible specimen support.

The NGA104A 3-Point Bending Fixture is a compact and lightweight solution for performing bending tests on flat and round metallic specimens. With a capacity of up to 10 kN and an adjustable span of up to 160 mm, it is ideal for low-force applications. The fixture is equipped with both R5 mm and R2 mm rollers for flexible specimen support.

- Application: Bending test for flat and round metallic specimens.

- Maximum Capacity: ≤ 10 kN load.

- Grip Weight: 0.1 kg (upper grip), 0.6 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Span (Adjustable): ≤ 160 mm.

- Height: 90 mm (upper grip), 140 mm (lower grip).

- Maximum Specimen Width: 40 mm.

- Base Width: 505 mm.

- Loading Roller: R5 mm, R2 mm.

- Support Roller: R5 mm, R2 mm.

Technical Specifications – NGA104A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for flat and round metallic specimens |

| Maximum Force Capacity | ≤ 10 kN |

| Grip Weight | Upper Grip: 0.1 kg Lower Grip: 0.6 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Span (Adjustable) | ≤ 160 mm |

| Height (A/B) | Upper Grip: 90 mm Lower Grip: 140 mm |

| Maximum Specimen Width | 40 mm |

| Base Width (C) | 505 mm |

| Loading Roller | R5 mm, R2 mm |

| Support Roller | R5 mm, R2 mm |

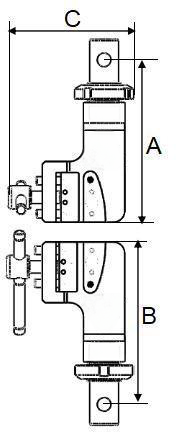

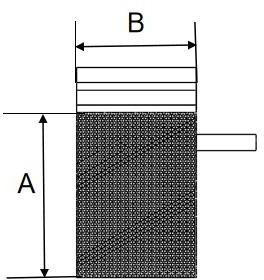

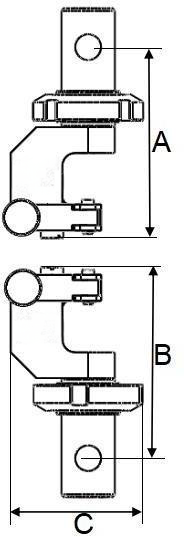

NGSA102A – Tensile Grip (Side Action)

The NGSA102A Tensile Grip is designed for tension testing of delicate, non-metallic single wires such as spandex wire. With a low force capacity of up to 100 N, this lightweight fixture is ideal for precision applications requiring minimal clamping force. Its compact design supports Φ10 mm pin mounting and features small jaw faces for secure gripping of wires ≤Φ1.5 mm in diameter.

The NGSA102A Tensile Grip is designed for tension testing of delicate, non-metallic single wires such as spandex wire. With a low force capacity of up to 100 N, this lightweight fixture is ideal for precision applications requiring minimal clamping force. Its compact design supports Φ10 mm pin mounting and features small jaw faces for secure gripping of wires ≤Φ1.5 mm in diameter.

- Application: Tension test for spandex wire and other non-metal single wire.

- Maximum Capacity: ≤ 100 N load.

- Grip Weight: 0.4 kg (upper grip), 0.4 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Height: 75 mm (upper and lower grips).

- Overall Width: 50 mm.

- Specimen Size: ≤ Φ1.5 mm.

- Jaw Face Size: 10 mm (H) × 10 mm (W).

Technical Specifications – NGSA102A Tensile Grip (Side Action)

| Parameter | Specification |

|---|---|

| Application | Tension test for spandex wire and non-metal single wire |

| Maximum Force Capacity | ≤ 100 N |

| Grip Weight | Upper Grip: 0.4 kg Lower Grip: 0.4 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Height (A/B) | 75 mm (both grips) |

| Overall Width (C) | 50 mm |

| Specimen Size | ≤ Φ1.5 mm |

| Jaw Face Size | 10 mm (H) × 10 mm (W) |

NextGen’s TestStar® grips and fixtures collection provides a best-in-class solution for laboratories and facilities seeking accurate, repeatable mechanical test results. From snubbing grips to wedge-action tensile and multi-point bending setups, the TestStar® series is a proven choice across industries.

All fixtures are fully compatible with NextGen’s universal testing machines and can be ordered as part of new system builds or integrated into existing setups. Contact our technical sales team to configure the optimal solution for your testing needs.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.