Metal Testing Equipment

Precision Shoulder Grips for Tensile Testing on NG-EML and SHM Series UTMs

NextGen’s shoulder fixtures are specialized tensile grips designed to accommodate specimens with shoulder geometries. These fixtures are critical for standardized testing in accordance with ISO and ASTM protocols where alignment, clamping precision, and repeatability are essential. Compatible with NG-EML and SHM UTMs, these fixtures ensure high-reliability results in both R&D and production environments.

NextGen’s shoulder fixtures are specialized tensile grips designed to accommodate specimens with shoulder geometries. These fixtures are critical for standardized testing in accordance with ISO and ASTM protocols where alignment, clamping precision, and repeatability are essential. Compatible with NG-EML and SHM UTMs, these fixtures ensure high-reliability results in both R&D and production environments.

Typical standards supported include:

- ASTM D638 (Tensile Properties of Plastics)

- ISO 527 (Tensile Testing of Plastics)

- GB/T 1040 (Plastic Tensile Test Methods)

Applications range across polymer composites, machined plastic components, and metals formed to shoulder profiles. All models support safe and rigid clamping under increasing loads.

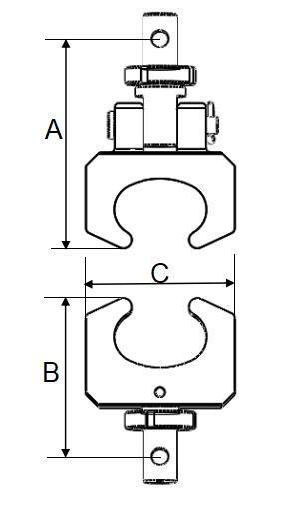

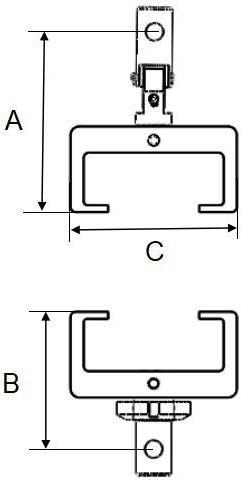

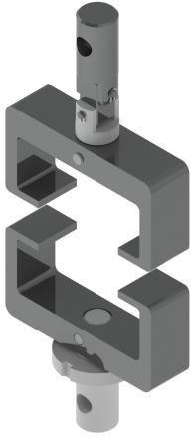

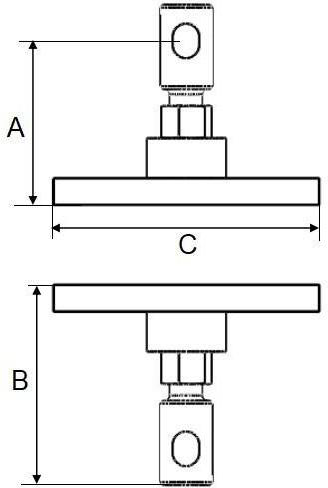

NGB203A – Tension Grip

The NGB203A Tension Grip is designed for low-force tensile testing of cement mortar specimens. With a load capacity of up to 2 kN, this fixture is ideal for evaluating the tensile strength of brittle, cement-based materials. It features a compact yet durable design, Ø10 mm pin connections, and is suitable for use with universal testing machines in ambient environments. The precision alignment and reliable clamping surface ensure accurate and repeatable results in material strength verification.

The NGB203A Tension Grip is designed for low-force tensile testing of cement mortar specimens. With a load capacity of up to 2 kN, this fixture is ideal for evaluating the tensile strength of brittle, cement-based materials. It features a compact yet durable design, Ø10 mm pin connections, and is suitable for use with universal testing machines in ambient environments. The precision alignment and reliable clamping surface ensure accurate and repeatable results in material strength verification.

- Application: Tension tests for cement mortar.

- Maximum Capacity: Up to 2 kN load.

- Connection: Ø10 mm pin (upper and lower), compatible with standard UTMs.

- Height: 120 mm (upper grip), 88 mm (lower grip).

- Width: 88 mm.

- Grip Weight: 1.18 kg (upper grip), 1.0 kg (lower grip).

- Working Temperature: Ambient.

Technical Specifications – NGB203A Tension Grip for Cement Mortar

| Parameter | Specification |

|---|---|

| Application | Tension test for cement mortar |

| Maximum Force Capacity | ≤ 2 kN |

| Upper Grip Weight | 1.18 kg |

| Lower Grip Weight | 1.0 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 120 mm |

| Lower Grip Height (B) | 88 mm |

| Width (C) | 88 mm |

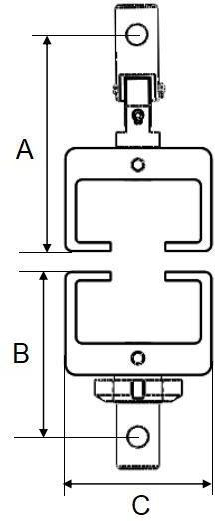

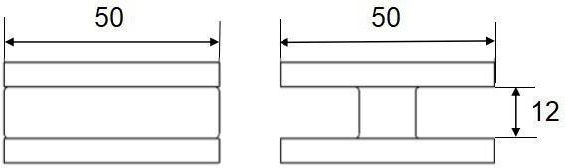

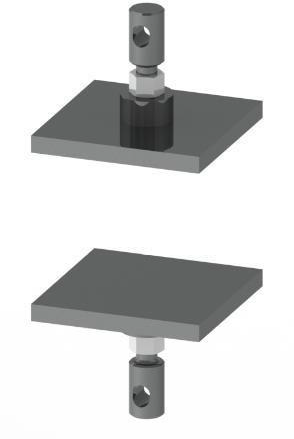

NGC103A – Tension Grip

The NGC103A Tension Grip is purpose-built for low-force adhesive tensile testing. With a force capacity of up to 1 kN, it is ideal for evaluating adhesive bond strength between substrates under controlled laboratory conditions. This compact fixture features a shoulder clamping mode and is designed for substrates measuring 50 × 50 mm and adhesives up to 12 mm thick. Standard Ø10 mm pin connections and stable construction make NGC103A a reliable choice for quality control and material development labs.

The NGC103A Tension Grip is purpose-built for low-force adhesive tensile testing. With a force capacity of up to 1 kN, it is ideal for evaluating adhesive bond strength between substrates under controlled laboratory conditions. This compact fixture features a shoulder clamping mode and is designed for substrates measuring 50 × 50 mm and adhesives up to 12 mm thick. Standard Ø10 mm pin connections and stable construction make NGC103A a reliable choice for quality control and material development labs.

- Application: Tension tests for adhesives and bonded materials.

- Maximum Capacity: Up to 1 kN load.

- Connection: Ø10 mm pin (upper and lower), compatible with most universal testing machines.

- Height: 100 mm (upper grip), 80 mm (lower grip).

- Width: 70 mm.

- Grip Weight: 0.75 kg (upper grip), 0.8 kg (lower grip).

- Clamping Mode: Shoulder.

- Specimen Size: Substrate: 50 × 50 mm; Adhesive: 50 × 12 mm.

- Working Temperature: Ambient.

Technical Specifications – NGC103A Tension Grip for Adhesive Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for adhesives |

| Maximum Force Capacity | ≤ 1 kN |

| Upper Grip Weight | 0.75 kg |

| Lower Grip Weight | 0.8 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 100 mm |

| Lower Grip Height (B) | 80 mm |

| Width (C) | 70 mm |

| Clamping Mode | Shoulder |

| Specimen Size | Substrate: 50 × 50 mm Adhesive: 50 × 12 mm |

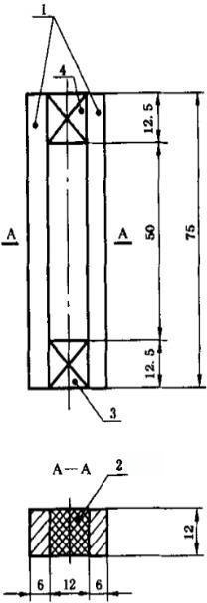

NGC103B – Tension Grip

The NGC103B Tension Grip is optimized for adhesive tensile testing where larger substrates or longer bonded joints are involved. With a 1 kN maximum load capacity and a shoulder clamping mechanism, it ensures stable and precise specimen alignment during testing. Designed for substrates up to 75 mm long and adhesives 12 mm thick, this fixture is well-suited for laboratories performing repeatable adhesive strength evaluations. Standard Ø10 mm pin compatibility makes it ideal for use with most tabletop universal testing systems.

- Application: Tension tests for adhesives and bonded assemblies.

- Maximum Capacity: Up to 1 kN load.

- Connection: Ø10 mm pin (upper and lower), standard UTM compatible.

- Height: 110 mm (upper grip), 80 mm (lower grip).

- Width: 95 mm.

-

Grip Weight: 0.5 kg (upper grip), 0.6 kg (lower grip).

- Clamping Mode: Shoulder.

- Specimen Size: Substrate: 75 × 12 mm; Adhesive: 50 × 12 mm.

- Working Temperature: Ambient.

Technical Specifications – NGC103B Tension Grip for Adhesive Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for adhesives |

| Maximum Force Capacity | ≤ 1 kN |

| Upper Grip Weight | 0.5 kg |

| Lower Grip Weight | 0.6 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 110 mm |

| Lower Grip Height (B) | 80 mm |

| Width (C) | 95 mm |

| Clamping Mode | Shoulder |

| Specimen Size | Substrate: 75 × 12 mm Adhesive: 50 × 12 mm |

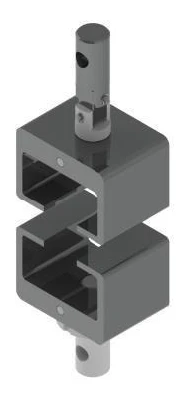

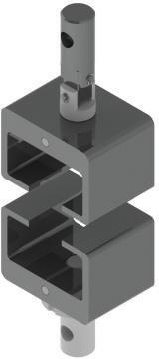

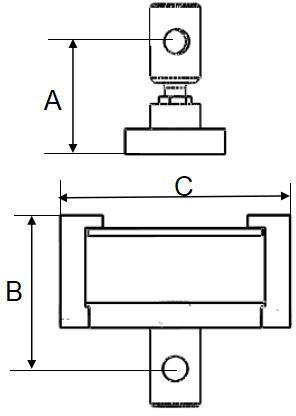

NGC203 – Tension Grip Series

The NGC203 Tension Grip Series is developed for adhesive strength testing across a wide range of specimen sizes. Available in three models—NGC203B, NGC203C, and NGC203E—this series supports test blocks from 50 × 50 mm to 200 × 200 mm, all within a 2 kN maximum force range. These grips feature a modular design that allows the number of bonding blocks to be tailored to specific testing requirements. Constructed for reliability and repeatability in ambient conditions, all models are equipped with Ø10 mm pin connections and standardized dimensions for integration with universal testing systems.

The NGC203 Tension Grip Series is developed for adhesive strength testing across a wide range of specimen sizes. Available in three models—NGC203B, NGC203C, and NGC203E—this series supports test blocks from 50 × 50 mm to 200 × 200 mm, all within a 2 kN maximum force range. These grips feature a modular design that allows the number of bonding blocks to be tailored to specific testing requirements. Constructed for reliability and repeatability in ambient conditions, all models are equipped with Ø10 mm pin connections and standardized dimensions for integration with universal testing systems.

- Application: Tension tests for adhesive strength.

- Models: NGC203B, NGC203C, NGC203E.

- Maximum Capacity: Up to 2 kN load.

- Specimen Sizes: 50 × 50 mm (B), 100 × 100 mm (C), 200 × 200 mm (E).

- Connection: Ø10 mm pin (upper and lower), compatible with standard UTMs.

- Height: 60 mm (both upper and lower grips).

- Widths: 50 mm (B), 100 mm (C), 200 mm (E).

- Grip Weight: See model-specific table below.

- Working Temperature: Ambient.

- Note: The number of bonding blocks can be customized based on client requirements.

Technical Specifications – NGC203 Tension Grip Series for Adhesive Strength Testing

| Model | NGC203B | NGC203C | NGC203E |

|---|---|---|---|

| Specimen Size | 50 mm × 50 mm | 100 mm × 100 mm | 200 mm × 200 mm |

| Maximum Force | ≤ 2 kN | ≤ 2 kN | ≤ 2 kN |

| Upper Grip Weight | 0.36 kg | 0.95 kg | 3.32 kg |

| Lower Grip Weight | 0.36 kg | 0.95 kg | 3.32 kg |

| Working Temp. | Ambient | ||

| Connection | Ø10 mm pin (upper and lower) | ||

| Upper Grip Height (A) | 60 mm | 60 mm | 60 mm |

| Lower Grip Height (B) | 60 mm | 60 mm | 60 mm |

| Width (C) | 50 mm | 100 mm | 200 mm |

| Bonding Block Count | Customizable per client request | ||

NGC503A – Tension Grip

The NGC503A Tension Grip is a compact fixture designed for precise adhesive strength testing under moderate tensile loads. Supporting forces up to 5 kN, this grip is ideal for small-scale bonded specimens, such as those with substrate dimensions of 70 × 70 mm and adhesive layers of 40 × 40 mm. The grip features a shoulder-type clamping mechanism for secure and repeatable alignment during testing. Its lightweight construction and Ø10 mm pin compatibility make it suitable for most tabletop universal testing machines operating in ambient environments.

The NGC503A Tension Grip is a compact fixture designed for precise adhesive strength testing under moderate tensile loads. Supporting forces up to 5 kN, this grip is ideal for small-scale bonded specimens, such as those with substrate dimensions of 70 × 70 mm and adhesive layers of 40 × 40 mm. The grip features a shoulder-type clamping mechanism for secure and repeatable alignment during testing. Its lightweight construction and Ø10 mm pin compatibility make it suitable for most tabletop universal testing machines operating in ambient environments.

- Application: Tension test for adhesives and bonding strength validation.

- Maximum Capacity: Up to 5 kN load.

- Connection: Ø10 mm pin (upper and lower), UTM-compatible.

- Height: 45 mm (upper grip), 60 mm (lower grip).

- Width: 90 mm.

- Grip Weight: 0.03 kg (upper grip), 0.16 kg (lower grip).

- Clamping Mode: Shoulder.

- Specimen Size: Substrate: 70 × 70 mm; Adhesive: 40 × 40 mm.

- Working Temperature: Ambient.

Technical Specifications – NGC503A Tension Grip for Adhesive Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for adhesives |

| Maximum Force Capacity | ≤ 5 kN |

| Upper Grip Weight | 0.03 kg |

| Lower Grip Weight | 0.16 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 45 mm |

| Lower Grip Height (B) | 60 mm |

| Width (C) | 90 mm |

| Clamping Mode | Shoulder |

| Specimen Size | Substrate: 70 × 70 mm Adhesive: 40 × 40 mm |

NextGen’s shoulder grip solutions are crafted for high-performance tensile testing where shoulder-type samples are standard. Their modular compatibility with NG-EML and SHM UTM machines ensures maximum utility across labs and testing departments. Contact us today to discuss your testing needs or to request a formal quotation for these fixtures.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.