Metal Testing Equipment

Self-Tightening Grips for Tensile Testing

Self-Tightening Grips for Tensile Testing

NextGen’s self-tightening grips are engineered for precise tensile testing of deformable and elastic materials such as elastomers, foams, thin plastics, textiles, and biomedical specimens. These grips automatically increase clamping pressure as tensile force is applied, adapting to changes in specimen thickness without manual adjustment. Ideal for soft or low-friction materials that are prone to slippage or damage, the grips come in popular designs like scissor grips, cam-action grips, and lever-actuated jaws—all optimized for compatibility with NextGen’s Universal Testing Machines. By maintaining reliable alignment and consistent gripping force throughout the loading cycle, they ensure accurate, repeatable results in both quality control and research environments.

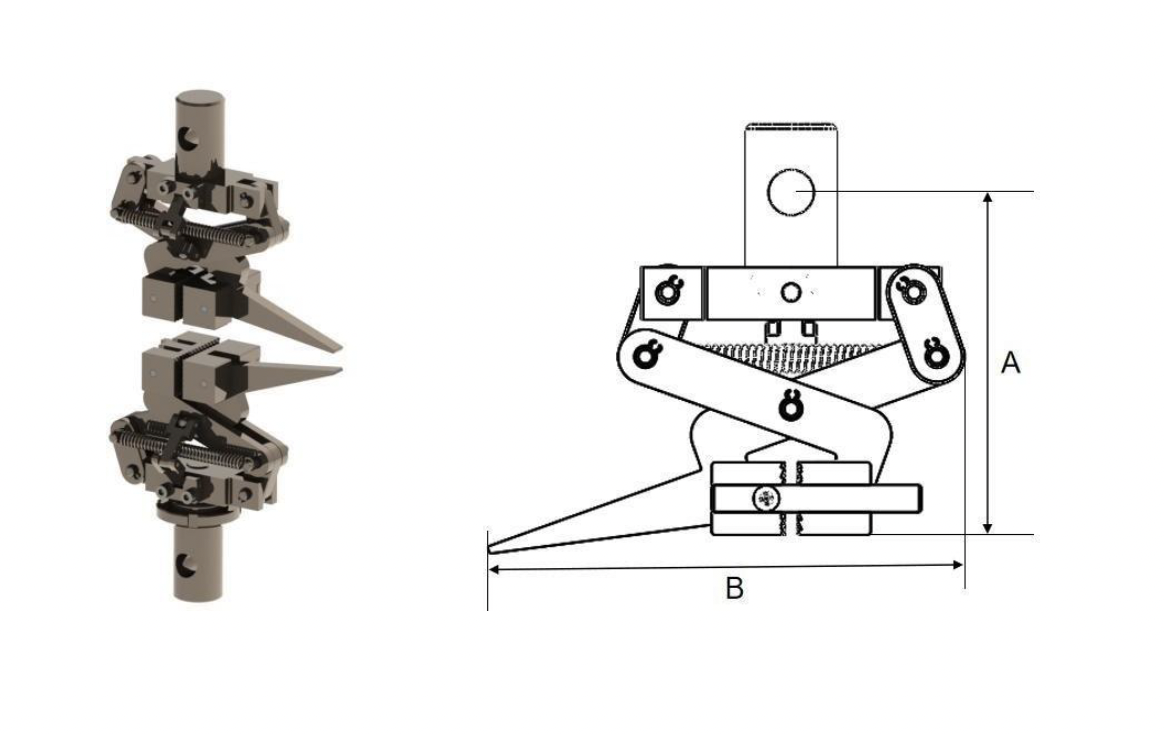

NGA203A – Self-Tightening Tensile Grip

The NGA203A Self-Tightening Grip is specifically designed for tensile testing of deformable and low-strength materials such as plastics and rubber. Its self-tightening mechanism ensures that clamping force increases automatically as tensile load is applied, making it ideal for specimens that thin or elongate during testing. This grip reduces slippage and avoids specimen damage without requiring manual adjustments. It is compatible with standard universal testing machines and provides stable performance in ambient laboratory conditions.

The NGA203A Self-Tightening Grip is specifically designed for tensile testing of deformable and low-strength materials such as plastics and rubber. Its self-tightening mechanism ensures that clamping force increases automatically as tensile load is applied, making it ideal for specimens that thin or elongate during testing. This grip reduces slippage and avoids specimen damage without requiring manual adjustments. It is compatible with standard universal testing machines and provides stable performance in ambient laboratory conditions.

- Application: Tension tests for soft plastic and rubber materials.

- Maximum Capacity: Up to 2 kN load.

- Connection: Ø10 mm pin mount (upper and lower), suitable for standard UTM interfaces.

- Dimensions: Height 75 mm; Grip body width 104 mm for secure and compact clamping.

- Specimen Range: Accommodates specimens up to 10 mm in thickness and 30 mm in width.

- Grip Weight: Approximately 0.49 kg each for upper and lower grip.

- Working Temperature: Ambient laboratory environment.

Technical Specifications – NGA203A Self-Tightening Grip for Plastic and Rubber

| Parameter | Specification |

|---|---|

| Application | Tension test for plastic and rubber |

| Maximum Force Capacity | ≤ 2 kN |

| Connection Type | Upper Grip: Ø10 mm pin Lower Grip: Ø10 mm pin |

| Overall Height (A) | 75 mm |

| Grip Body Width (B) | 104 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 0.49 kg Lower Grip: 0.49 kg |

| Compatible Specimen Thickness | ≤ 10 mm |

| Compatible Specimen Width | ≤ 30 mm |

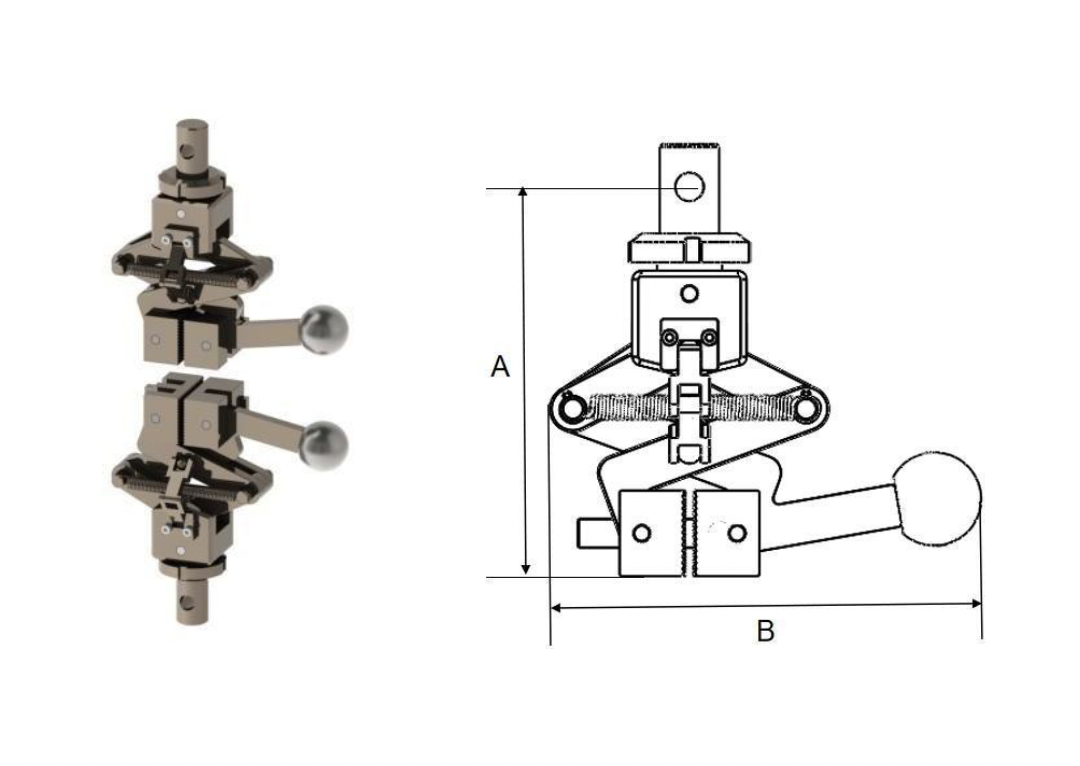

NG5203A – Self-Tightening Tensile Grip

The NG5203A Self-Tightening Grip is built for tensile testing of flexible, low-friction materials such as plastics and rubber. With a higher load capacity and wider specimen accommodation than lighter models, it is ideal for materials that stretch or deform under stress. Its self-tightening mechanism ensures progressive clamping force as the tensile load increases, minimizing slippage and preserving specimen integrity. Compatible with standard UTMs, the grip delivers consistent results in ambient laboratory environments.

The NG5203A Self-Tightening Grip is built for tensile testing of flexible, low-friction materials such as plastics and rubber. With a higher load capacity and wider specimen accommodation than lighter models, it is ideal for materials that stretch or deform under stress. Its self-tightening mechanism ensures progressive clamping force as the tensile load increases, minimizing slippage and preserving specimen integrity. Compatible with standard UTMs, the grip delivers consistent results in ambient laboratory environments.

- Application: Tension tests for plastic and rubber materials.

- Maximum Capacity: Up to 5 kN load.

- Connection: Ø10 mm pin mount (upper and lower), compatible with standard UTM systems.

- Dimensions: Height 137 mm; Grip body width 150 mm, offering a stable clamping surface.

- Specimen Range: Suitable for specimens up to 12 mm thick and 45 mm wide.

- Grip Weight: Approximately 1.5 kg each for upper and lower grip.

- Working Temperature: Ambient conditions.

Technical Specifications – NG5203A Self-Tightening Grip for Plastic and Rubber

| Parameter | Specification |

|---|---|

| Application | Tension test for plastic and rubber |

| Maximum Force Capacity | ≤ 5 kN |

| Connection Type | Upper Grip: Ø10 mm pin Lower Grip: Ø10 mm pin |

| Overall Height (A) | 137 mm |

| Grip Body Width (B) | 150 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 1.5 kg Lower Grip: 1.5 kg |

| Compatible Specimen Thickness | ≤ 12 mm |

| Compatible Specimen Width | ≤ 45 mm |

Self-tightening grips offer a practical and reliable solution for tensile testing of materials that deform, elongate, or have low surface friction, such as plastics, rubbers, foams, and textiles. By automatically adjusting clamping force during testing, these grips maintain secure specimen hold without manual tightening or the risk of early failure due to slippage. Available in various sizes and capacities, they are ideal for both quality control and research environments requiring repeatable and accurate results. Contact our technical sales team to request a quote or to integrate these advanced gripping solutions into your existing testing system today.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.