Metal Testing Equipment

Specialized Grips and Fixtures for Wood Tensile, Shear, Bending, and Fastener Withdrawal Testing

NextGen offers a robust line of specialized grips and fixtures for wood material testing, supporting universal testing machines (UTM) across industrial and academic laboratories. These components are engineered to meet the stringent standards of wood testing such as ASTM D198, ISO 3349, ISO 3340, and GB/T 1936.1, allowing accurate mechanical characterization under tension, shear, bending, and fastener withdrawal modes.

NextGen offers a robust line of specialized grips and fixtures for wood material testing, supporting universal testing machines (UTM) across industrial and academic laboratories. These components are engineered to meet the stringent standards of wood testing such as ASTM D198, ISO 3349, ISO 3340, and GB/T 1936.1, allowing accurate mechanical characterization under tension, shear, bending, and fastener withdrawal modes.

These fixtures are designed for compatibility with NG-EML and NG-SHM series UTMs and cover a wide range of sample dimensions and geometries found in engineered wood, structural panels, and fastener assemblies.

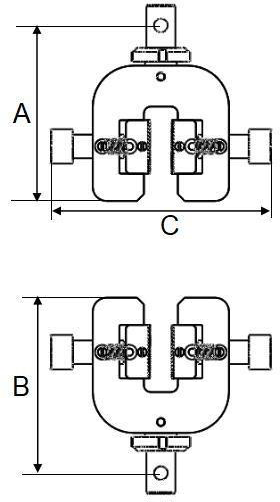

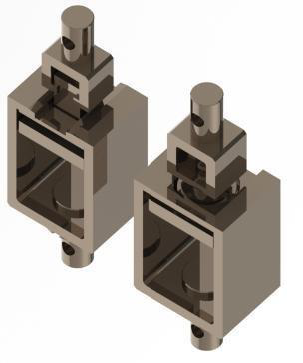

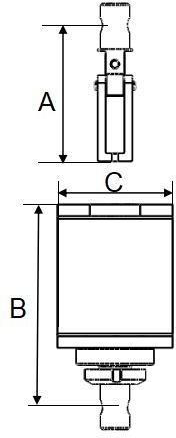

NGB104B – Tensile Grip

NGB104B – Tensile Grip

The NGB104B Tensile Grip is designed for tension testing of wood-based panels and wooden boards. With a symmetrical grip structure, side-action clamping, and Φ10 mm pin compatibility, it offers a secure and reliable setup for low-force testing applications. Its robust construction supports up to 10 kN of force under ambient conditions.

- Application: Tension tests for wood-based panels and wooden board.

- Maximum Capacity: ≤ 10 kN.

- Grip Weight: 3.82 kg (Upper Grip), 3.82 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), compatible with standard UTM systems.

- Dimensions:

- Upper Grip Height (A): 130 mm

- Lower Grip Height (B): 130 mm

- Grip Width (C): 160 mm

- Clamping Mode: Side action

- Jaw Face Dimensions: 60 mm × 40 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGB104B Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for wood-based panels and wooden board |

| Maximum Force Capacity | ≤ 10 kN |

| Upper Grip Weight | 3.82 kg |

| Lower Grip Weight | 3.82 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Upper Grip Height (A) | 130 mm |

| Lower Grip Height (B) | 130 mm |

| Grip Width (C) | 160 mm |

| Clamping Mode | Side action |

| Jaw Face | 60 mm × 40 mm |

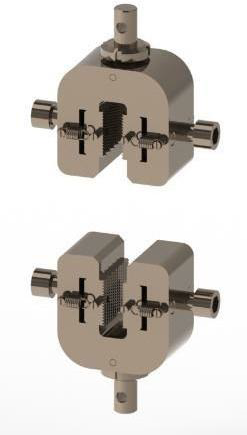

NGB203A – Shearing Fixture

The NGB203A Shearing Fixture is developed for shearing tests on layered wood with adhesives and for interlaminar shear evaluation of fiber-reinforced plastics. This compact fixture provides stable performance at low force ranges, ideal for adhesive bond strength studies and material delamination behavior in wood and composites.

The NGB203A Shearing Fixture is developed for shearing tests on layered wood with adhesives and for interlaminar shear evaluation of fiber-reinforced plastics. This compact fixture provides stable performance at low force ranges, ideal for adhesive bond strength studies and material delamination behavior in wood and composites.

- Application: Shearing tests for layered wood with adhesives and interlaminar shearing for fiber-reinforced plastic.

- Maximum Capacity: ≤ 2 kN.

- Grip Weight: 0.56 kg.

- Working Temperature: Ambient conditions.

- Dimensions:

- Grip Height (A): 48 mm

- Grip Height (B): 54 mm

Technical Specifications – NGB203A Shearing Fixture

| Parameter | Specification |

|---|---|

| Application | Shearing test for layered wood with adhesives and interlaminar shearing for fiber reinforce plastic |

| Maximum Force Capacity | ≤ 2 kN |

| Grip Weight | 0.56 kg |

| Working Temperature | Ambient |

| Grip Height (A) | 48 mm |

| Grip Height (B) | 54 mm |

| Jaw Face | 60 mm × 40 mm |

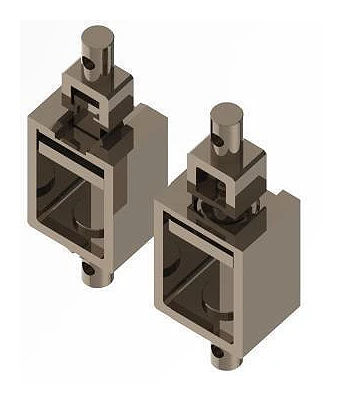

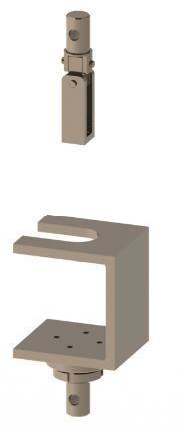

NGH104A – Tensile Fixture

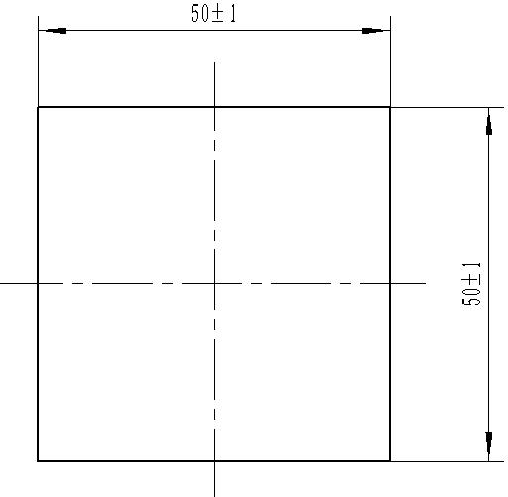

The NGH104A Tensile Fixture is developed for evaluating the internal bond strength of wood specimens. With left and right grip assemblies, it accommodates small wood samples with high accuracy. This fixture is suitable for low-force applications and features compact symmetrical grips for 50 mm × 50 mm samples, tested under ambient conditions.

The NGH104A Tensile Fixture is developed for evaluating the internal bond strength of wood specimens. With left and right grip assemblies, it accommodates small wood samples with high accuracy. This fixture is suitable for low-force applications and features compact symmetrical grips for 50 mm × 50 mm samples, tested under ambient conditions.

- Application: Tension test for determination of internal bond strength of wood specimen.

- Maximum Capacity: ≤ 10 kN.

- Grip Weight: 1.8 kg (Left), 1.7 kg (Right).

- Connection: Φ10 mm pin (upper and lower), UTM-compatible.

- Grip Heights:

- Left & Right Upper Grip Height (A): 86 mm / 96 mm

- Left & Right Lower Grip Height (B): 66 mm / 80 mm

- Left & Right Upper Grip Height (A): 86 mm / 96 mm

- Grip Width × Height: 66 mm × 80 mm (Left & Right)

- Specimen Size: 50 mm × 50 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGH104A Tensile Fixture

| Parameter | Specification |

|---|---|

| Application | Tension test for determination of internal bond strength of wood specimen |

| Maximum Force Capacity | ≤ 10 kN |

| Left Grips Weight | 1.8 kg |

| Right Grips Weight | 1.7 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Left and Right Upper Grips Height (A) | 86 mm, 96 mm |

| Left and Right Lower Grips Height (B) | 66 mm, 80 mm |

| Left and Right Grips Width × Height (B) | 66 mm × 80 mm |

| Specimen Size | 50 mm × 50 mm |

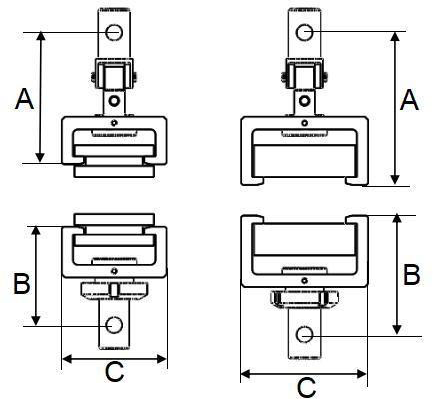

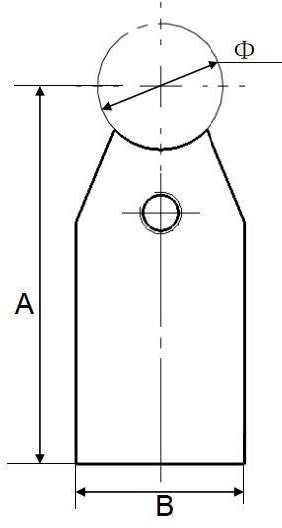

NGH104B – Tensile Fixture

The NGH104B Tensile Fixture is designed for determining surface bond strength and surface soundness of wood specimens. With symmetrical left and right grips and precise clamping, this fixture supports small-format sample testing with a maximum capacity of 10 kN. It is optimized for ambient conditions and features standard Φ10 mm pin connections.

The NGH104B Tensile Fixture is designed for determining surface bond strength and surface soundness of wood specimens. With symmetrical left and right grips and precise clamping, this fixture supports small-format sample testing with a maximum capacity of 10 kN. It is optimized for ambient conditions and features standard Φ10 mm pin connections.

- Application: Tension test for determination of surface bond strength and surface soundness of wood specimen.

- Maximum Capacity: ≤ 10 kN.

- Grip Weight: 1.56 kg (Left), 1.56 kg (Right).

- Connection: Φ10 mm pin (upper and lower), UTM-compatible.

- Dimensions:

- Left Grip Height (A): 180 mm

- Right Grip Height (B): 185 mm

- Left Grip Width (C): 66 mm

- Right Grip Width (D): 69 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGH104B Tensile Fixture

| Parameter | Specification |

|---|---|

| Application | Tension test for determination of surface bond strength and surface soundness of wood specimen |

| Maximum Force Capacity | ≤ 10 kN |

| Left Grip Weight | 1.56 kg |

| Right Grip Weight | 1.56 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Left Grip Height (A) | 180 mm |

| Right Grip Height (B) | 185 mm |

| Left Grip Width (C) | 66 mm |

| Right Grip Width (D) | 69 mm |

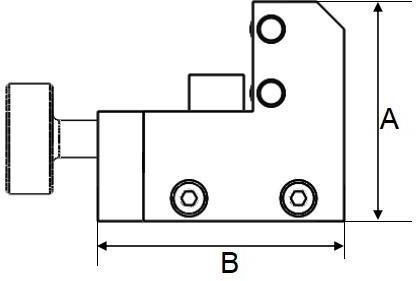

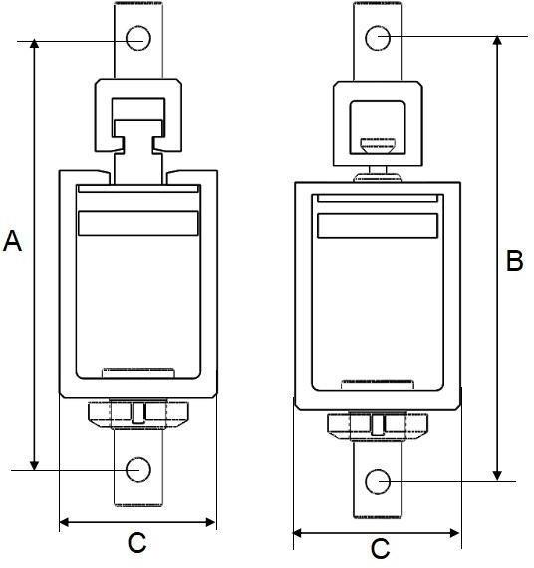

NGB502A – Tensile Fixture

The NGB502A Tensile Fixture is purpose-built for withdrawing nails and screws from wood specimens. With a low force capacity and precise clamping system, this fixture is ideal for testing fastener resistance in wood-based assemblies. Compact and lightweight, it supports accurate testing with a Φ10 mm pin connection in ambient environments.

The NGB502A Tensile Fixture is purpose-built for withdrawing nails and screws from wood specimens. With a low force capacity and precise clamping system, this fixture is ideal for testing fastener resistance in wood-based assemblies. Compact and lightweight, it supports accurate testing with a Φ10 mm pin connection in ambient environments.

- Application: Used for withdrawing nail or screw from wood.

- Maximum Capacity: ≤ 500 N.

- Grip Weight: 0.24 kg (Upper Grip), 1.6 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), UTM-compatible.

- Dimensions:

- Upper Grip Height: 95 mm

- Lower Grip Height: 141 mm

- Grip Width (C): 90 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGB502A Tensile Fixture

| Parameter | Specification |

|---|---|

| Application | Used for withdrawing nail/screw from wood |

| Maximum Force Capacity | ≤ 500 N |

| Upper Grip Weight | 0.24 kg |

| Lower Grip Weight | 1.6 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Upper Grip Height | 95 mm |

| Lower Grip Height | 141 mm |

| Grip Width (C) | 90 mm |

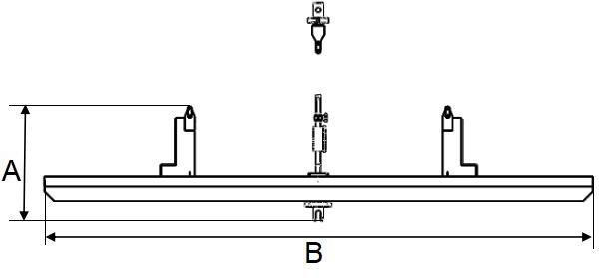

NGC104C – Bending Fixture

The NGC104C Bending Fixture is engineered for 3-point and 4-point bending tests on wood-based panels and wooden boards. With a robust construction and high grip width (1120 mm), it supports long-span testing with adjustable loading positions and spans. Ideal for large-format material testing in ambient conditions.

The NGC104C Bending Fixture is engineered for 3-point and 4-point bending tests on wood-based panels and wooden boards. With a robust construction and high grip width (1120 mm), it supports long-span testing with adjustable loading positions and spans. Ideal for large-format material testing in ambient conditions.

- Application: Bending test for wood-based panels and wooden board.

- Maximum Capacity: ≤ 10 kN.

- Weight: 43.5 kg (total assembly).

- Connection: Φ10 mm pin (upper and lower), compatible with standard UTMs.

Dimensions:

Dimensions:

- Lower Grip Height (A): 230 mm

- Grip Width (B): 1120 mm

- Adjustable Spans:

- Upper Span: ≤ 340 mm

- Lower Span: ≤ 1000 mm

- Specimen Width Capacity: ≤ 90 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGC104C Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for wood-based panels and wooden board |

| Maximum Force Capacity | ≤ 10 kN |

| Weight | 43.5 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Lower Grip Height (A) | 230 mm |

| Grip Width (B) | 1120 mm |

| Upper Span (Adjustable) | ≤ 340 mm |

| Lower Span (Adjustable) | ≤ 1000 mm |

| Specimen Width | ≤ 90 mm |

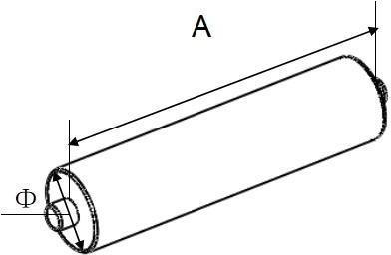

Optional Accessories – NGC104C Bending Fixture

Optional Accessories – NGC104C Bending Fixture

Roller (Optional)

| No. | Diameter (mm) | Width A (mm) |

|---|---|---|

| WZWC104C-07 | 10 | 92 |

| WZWC104C-11 | 15 | 92 |

| WZWC104C-13 | 30 | 92 |

Roller Support (Optional)

| No. | Diameter (mm) | Width A (mm) | Height B (mm) |

|---|---|---|---|

| NGC104C-06 | 10 | 45 | 20 |

| NGC104C-10 | 15 | 45 | 20 |

| NGC104C-16 | 30 | 49 | 20 |

Whether you’re testing wood for structural integrity, assessing fastener performance, or evaluating engineered timber properties, NextGen’s range of fixtures ensures maximum testing precision and compliance. All products are compatible with NG universal testing machines and supported by industry standards. Contact our technical team to configure the right setup for your wood testing application or to request a demonstration.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.