Metal Testing Equipment

Precision Flexure Fixtures for High-Load Testing of Ceramics, Composites, and Concrete

NextGen offers a specialized range of flexure fixtures designed for accurate high-force flexural testing of metals, ceramics, composites, and construction materials. Compatible with hydraulic universal testing machines, these fixtures meet rigorous standards such as GB/T 2542, GB/T 4111, GB/T 50081, and JC/T 239, providing reliable performance for industrial, academic, and quality control applications. With maximum capacities up to 2000 kN, these fixtures are built to handle demanding flexural evaluations, from single-point to four-point test configurations.

Engineered with adjustable span ranges and precision alignment, NextGen’s flexure fixtures accommodate a wide variety of specimen sizes and shapes. Models in this category support standard specimen formats (e.g., 150×150×600 mm, 100×100×400 mm) and allow integration of optional digital indicators to measure elastic modulus. Whether you're testing concrete beams, laminated composites, or advanced ceramics, these fixtures deliver accurate, repeatable results in ambient conditions.

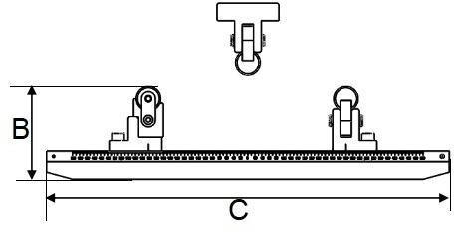

NGA206B – Flexure Fixture

The NGA206B Flexure Fixture is designed for high-capacity flexure testing of metallic, ceramic, and composite specimens. With a rated capacity of ≤2000 kN, this fixture provides reliable three-point or four-point bending evaluations using roller supports. The system is compliant with standards such as GB/T2542, GB/T4111, and JC/T 239, and features a lightweight lower grip and precision mandrel and roller components for adaptable testing.

The NGA206B Flexure Fixture is designed for high-capacity flexure testing of metallic, ceramic, and composite specimens. With a rated capacity of ≤2000 kN, this fixture provides reliable three-point or four-point bending evaluations using roller supports. The system is compliant with standards such as GB/T2542, GB/T4111, and JC/T 239, and features a lightweight lower grip and precision mandrel and roller components for adaptable testing.

- Application: Flexure testing for metal, composite, and ceramic materials.

- Maximum Capacity: ≤2000 kN load.

Weight:

Weight:

- Lower Grip: 23 kg

- Connection:

- Upper Grip: Fixing block and screw

- Lower Grip: Positioning pin

- Working Temperature: Ambient.

- Standard Compliance: GB/T2542, GB/T4111, JC/T 239.

- Grip Dimensions:

- Lower Grip Height (B): 130 mm

- Lower Grip Width (C): 574 mm

- Minimum Test Space: 280 mm

- Loading & Support Rollers:

- Roller 1: Φ35 × 210 mm

- Roller 2: Φ30 × 160 mm

- Included Mandrel Diameters: Φ32, Φ60, Φ88, Φ160

Technical Specifications – NGA206B Flexure Fixture

| Parameter | Specification |

|---|---|

| Application | Flexure test for metal, composite, ceramic, etc. |

| Maximum Force | ≤ 2000 kN |

| Lower Grip Weight | 23 kg |

| Connection | Upper: Fixing block and screw Lower: Positioning pin |

| Working Temperature | Ambient |

| Standard | GB/T2542, GB/T4111, JC/T 239 |

| Lower Grip Height (B) | 130 mm |

| Lower Grip Width (C) | 574 mm |

| Minimum Test Space | 280 mm |

| Roller 1 (Φ × Length) | Φ35 × 210 mm |

| Roller 2 (Φ × Length) | Φ30 × 160 mm |

| Mandrel Diameter (included) | Φ32, Φ60, Φ88, Φ160 |

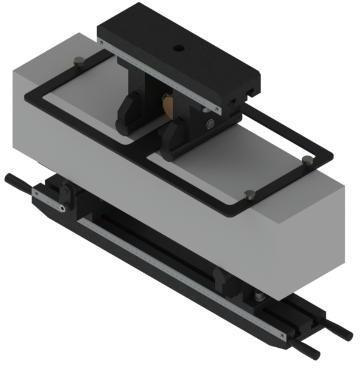

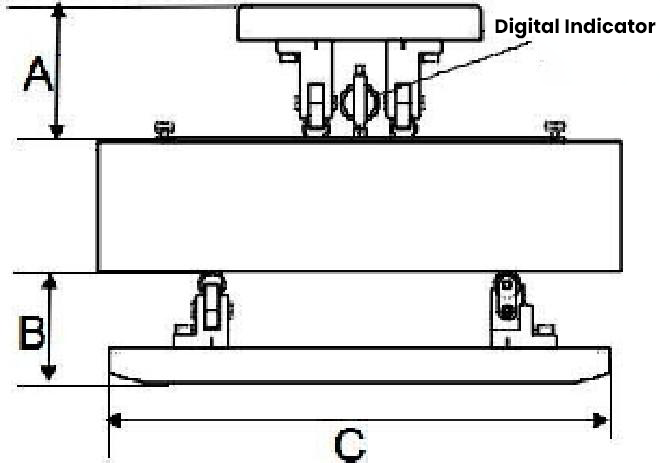

NGB206A – 4-Point Flexure Fixture

The NGB206A 4-Point Flexure Fixture is engineered for precise flexural testing of composite materials, concrete, and construction components. Designed to handle forces up to 2000 kN, this fixture complies with GB/T 50081 and offers fully adjustable lower and upper spans for flexible specimen sizing. It supports large concrete specimens and is optionally equipped with a digital indicator and elasticity modulus measurement device, making it suitable for both R&D and quality control applications.

The NGB206A 4-Point Flexure Fixture is engineered for precise flexural testing of composite materials, concrete, and construction components. Designed to handle forces up to 2000 kN, this fixture complies with GB/T 50081 and offers fully adjustable lower and upper spans for flexible specimen sizing. It supports large concrete specimens and is optionally equipped with a digital indicator and elasticity modulus measurement device, making it suitable for both R&D and quality control applications.

- Application: Flexure testing of composite, concrete, and construction materials.

- Maximum Capacity: ≤2000 kN load.

- Weight:

- Upper Grip: 12 kg

- Lower Grip: 20 kg

Connection:Upper Grip: Fixing block and screw

Connection:Upper Grip: Fixing block and screw

- Lower Grip: Positioning pin

- Working Temperature: Ambient.

- Standard Compliance: GB/T 50081.

- Grip Dimensions:

- Upper Grip Height (A): 157 mm

- Lower Grip Height (B): 127 mm

- Lower Grip Width (C): 574 mm

- Adjustable Span Ranges:

- Lower Span: 60–480 mm

- Upper Span: 60–180 mm

- Minimum Test Space: 450 mm

- Compatible Concrete Specimens:

- 150 × 150 × 600 mm

- 150 × 150 × 550 mm

- 100 × 100 × 400 mm

- Optional Features: Digital indicator and elasticity modulus measurement system

Technical Specifications – NGB206A 4-Point Flexure Fixture

| Parameter | Specification |

|---|---|

| Application | Flexure test for composite, concrete, construction material |

| Maximum Force | ≤ 2000 kN |

| Upper Grip Weight | 12 kg |

| Lower Grip Weight | 20 kg |

| Connection | Upper: Fixing block and screw Lower: Positioning pin |

| Working Temperature | Ambient |

| Standard | GB/T 50081 |

| Upper Grip Height (A) | 157 mm |

| Lower Grip Height (B) | 127 mm |

| Lower Grip Width (C) | 574 mm |

| Lower Span (adjustable) | 60–480 mm |

| Upper Span (adjustable) | 60–180 mm |

| Minimum Test Space | 450 mm |

| Concrete Specimen Sizes | 150×150×600 mm 150×150×550 mm 100×100×400 mm |

| Optional Add-ons | Digital indicator & elasticity modulus device |

NextGen’s flexure fixtures for hydraulic UTMs offer outstanding adaptability, mechanical strength, and test control. With secure fixing systems, variable support spans, and standardized compatibility, these solutions are a critical tool for evaluating structural integrity and deformation behavior. For organizations requiring precise flexural strength analysis, NextGen provides dependable equipment tailored for long-term use and strict compliance. Contact NextGen Material Testing Inc. to find the right flexure fixture solution for your setup.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.