Metal Testing Equipment

Dual Side Action and Wedge Hydraulic Grips for High-Capacity Tensile Testing

NextGen’s Dual Side Action and Wedge Hydraulic Grips are engineered for high-load, high-precision tensile testing using universal testing machines (UTMs). These grips are ideal for laboratories and manufacturers conducting rigorous tests in compliance with ASTM, ISO, DIN, JIS, and GB/T standards. Their robust hydraulic design ensures uniform gripping pressure, preventing specimen slippage and deformation, especially under elevated forces. Applicable for metals, plastics, and composite materials, these grips support automated test cycles, enhancing safety and repeatability in industrial or research environments.

NextGen’s Dual Side Action and Wedge Hydraulic Grips are engineered for high-load, high-precision tensile testing using universal testing machines (UTMs). These grips are ideal for laboratories and manufacturers conducting rigorous tests in compliance with ASTM, ISO, DIN, JIS, and GB/T standards. Their robust hydraulic design ensures uniform gripping pressure, preventing specimen slippage and deformation, especially under elevated forces. Applicable for metals, plastics, and composite materials, these grips support automated test cycles, enhancing safety and repeatability in industrial or research environments.

Compatible with all NextGen's UTM platforms, these grips are built for performance across tensile, compression, shear, and cyclic testing operations.

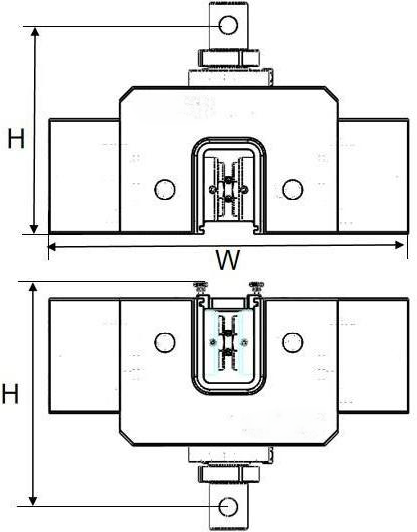

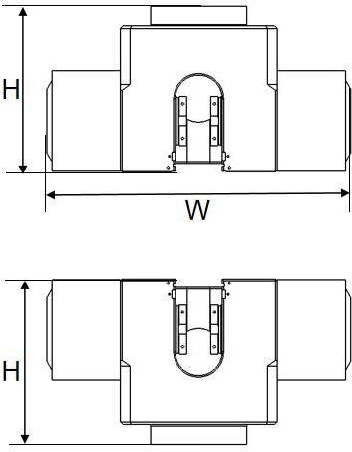

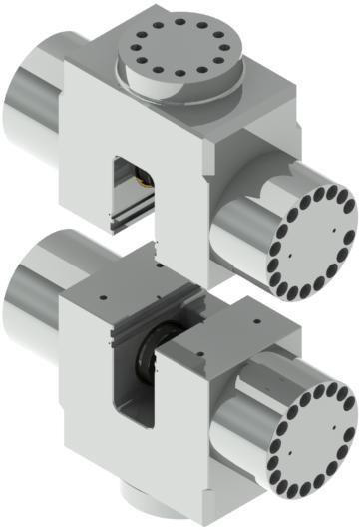

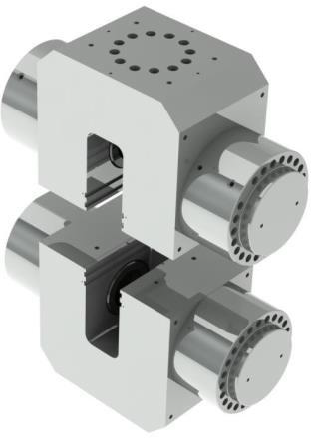

NGA105B – Hydraulic Tensile Grip (Dual Side Action)

The NGA105B Hydraulic Tensile Grip is a robust, dual side action grip engineered for flat and round metal or composite specimens. With a high load capacity of 100 kN and hydraulic actuation via the HPU200A system, it delivers reliable performance for demanding tensile applications. This grip supports Φ18 mm pin connections and offers uniform clamping force across a wide body.

The NGA105B Hydraulic Tensile Grip is a robust, dual side action grip engineered for flat and round metal or composite specimens. With a high load capacity of 100 kN and hydraulic actuation via the HPU200A system, it delivers reliable performance for demanding tensile applications. This grip supports Φ18 mm pin connections and offers uniform clamping force across a wide body.

- Application: Tension test for flat and round specimen of metal, composite, etc.

- Maximum Capacity: 100 kN load.

- Grip Weight: 80 kg (upper grip), 80 kg (lower grip).

- Working Temperature: Ambient.

- Connection Type: Φ18 mm pin (upper and lower grips).

- Height: 275 mm (upper and lower grips).

- Grip Body Width: 526 mm.

- Specimen Hardness: < HRC24.

- Hydraulic Power Unit (HPU): HPU200A.

Technical Specifications – NGA105B Hydraulic Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite |

| Maximum Force Capacity | 100 kN |

| Grip Weight | Upper Grip: 80 kg Lower Grip: 80 kg |

| Working Temperature | Ambient |

| Connection Type | Upper Grip: Φ18 mm pin Lower Grip: Φ18 mm pin |

| Height (H) | 275 mm (both grips) |

| Grip Body Width (W) | 526 mm |

| Specimen Hardness | < HRC24 |

| Hydraulic Power Unit | HPU200A |

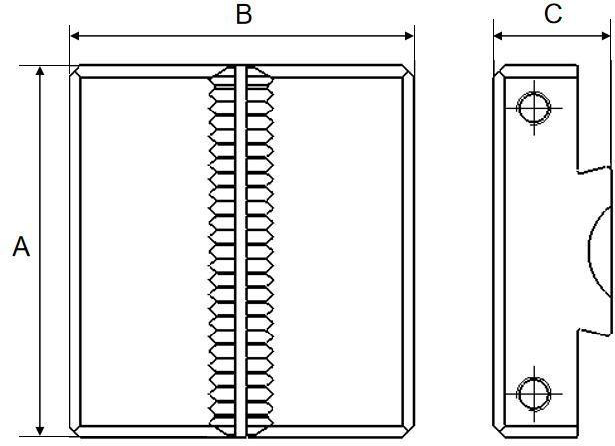

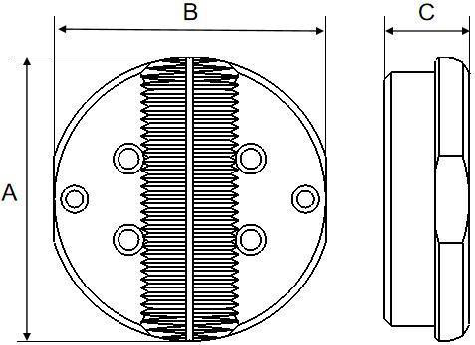

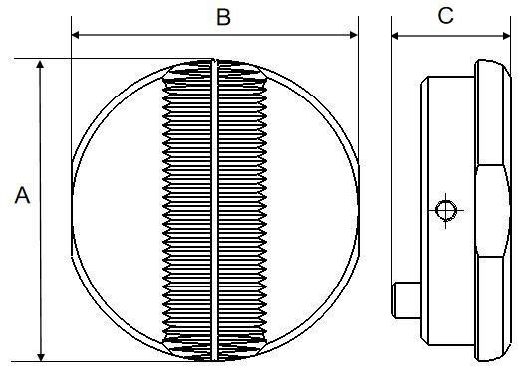

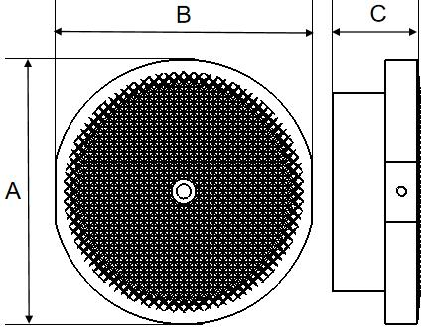

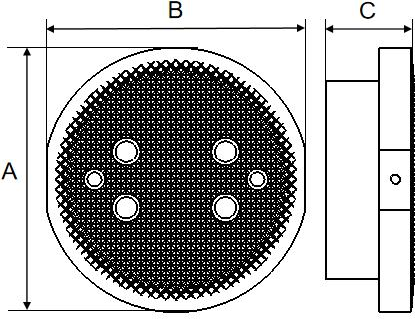

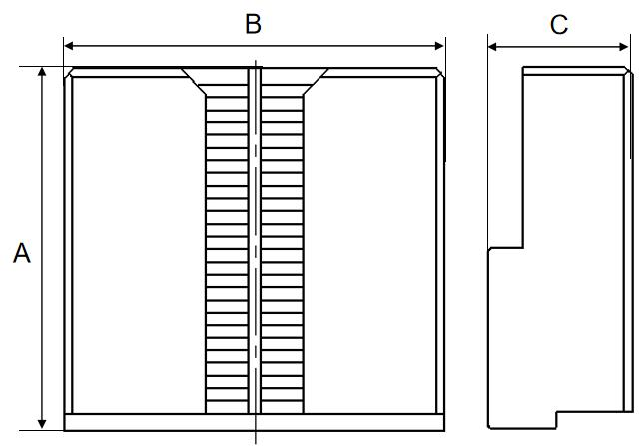

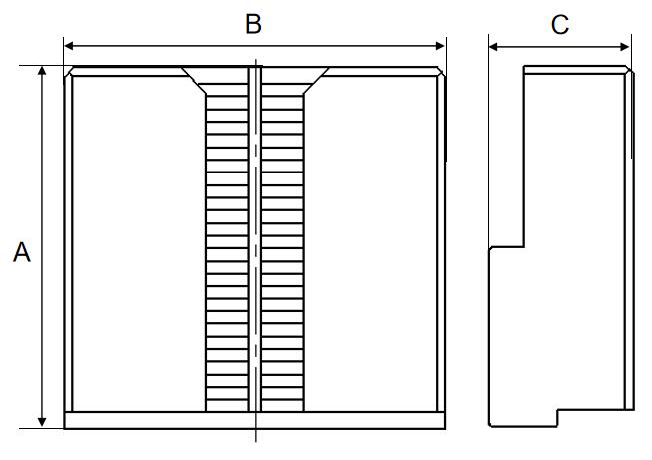

Optional Jaw Faces – NGA105B Hydraulic Grip

To accommodate various specimen types and geometries, the NGA105B hydraulic grip is compatible with multiple interchangeable jaw face options. These include ordinary flat, fine pitch, vee, and coarse pitch jaw faces—each designed for secure, damage-free clamping of metallic and composite specimens.

Flat and Vee Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Size (mm) | Height (A) mm | Width (B) mm | Thickness (C) mm |

|---|---|---|---|---|---|

| NGA105B-21 | Ordinary flat | 0–20 | 65 | 60 | 19 |

| NGA105B-22 | Fine pitch flat | 0–20 | 65 | 60 | 19 |

| NGA105B-33 | Vee | Φ6–16 | 65 | 60 | 20.5 |

| NGA105B-34 | Vee | Φ16–26 | 65 | 60 | 20.5 |

| NGA105B-35 | Coarse pitch flat | 0–20 | 65 | 60 | 19 |

Note: All jaw faces are precision-engineered for reliable clamping. Vee jaws are designed for round specimens, while flat jaws suit flat tensile samples.

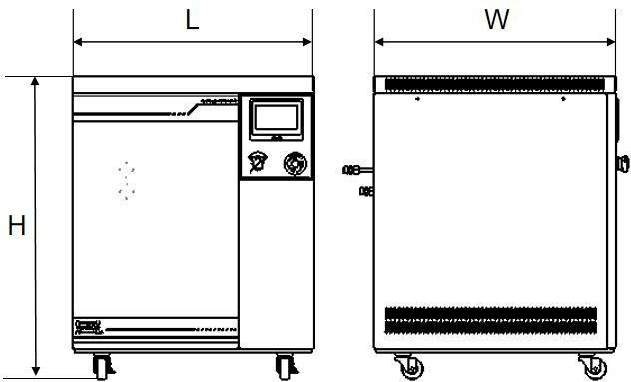

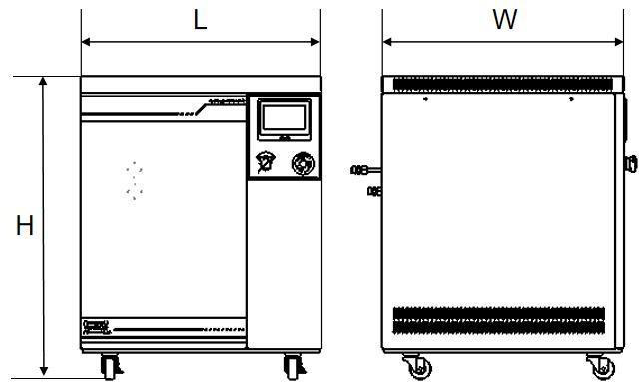

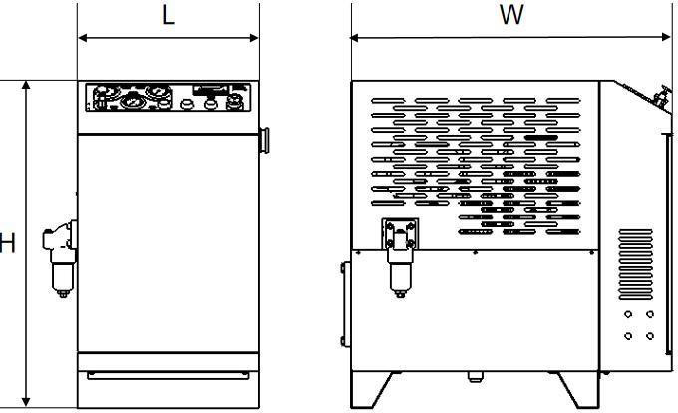

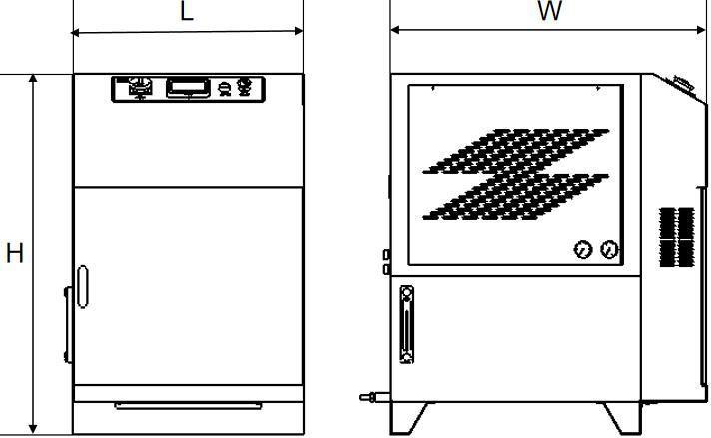

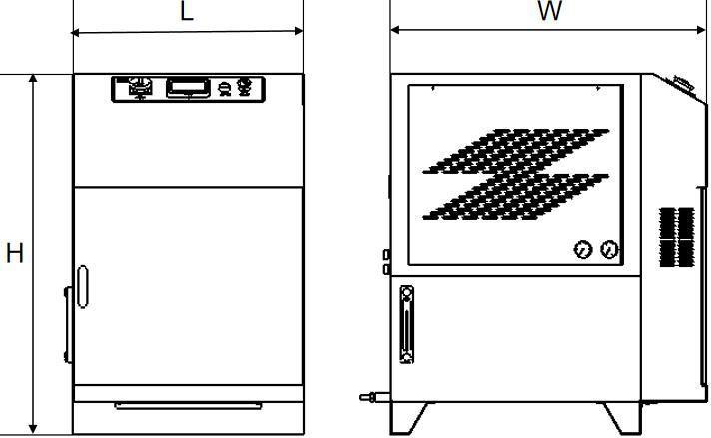

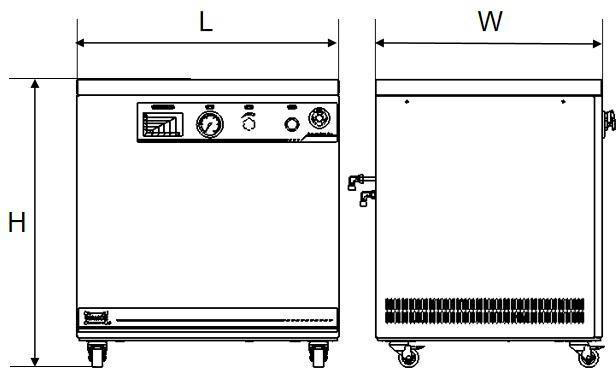

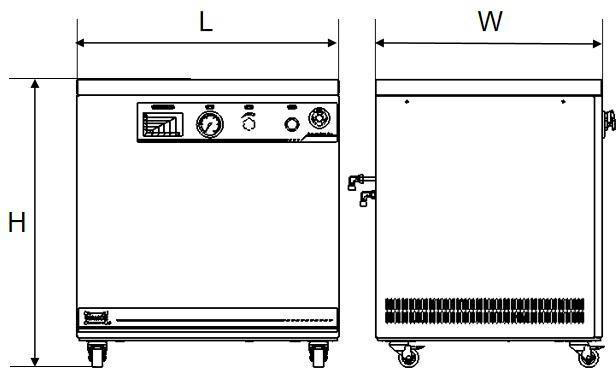

Hydraulic Power Unit – HPU200A

Hydraulic Power Unit – HPU200A

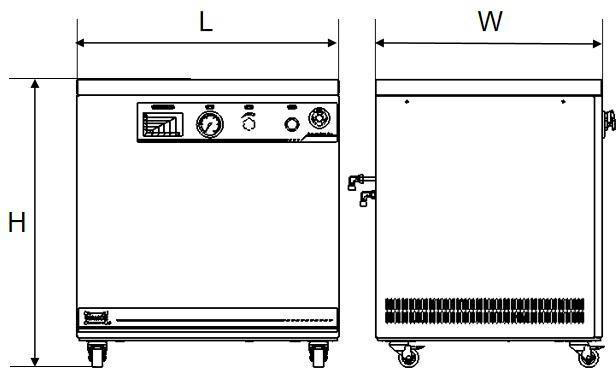

The HPU200A hydraulic power unit provides the necessary actuation for the NGA105B grip system. It features robust industrial-grade components, an ample 30L reservoir, and delivers smooth, controlled hydraulic force with a rated flow rate of 2 L/min and pressure up to 23 MPa.

Hydraulic Power Unit Specifications

| Parameter | Specification |

|---|---|

| Model | HPU200A |

| Weight | 196.2 lb / 89 kg |

| Tank volume | 30 L |

| Dimension | 22.8×22.8×27.6 in / 580×580×700 mm (L×W×H) |

| Power supply | 3-phase, 380 V / 50 Hz / 1 kW |

| Rated flow rate | 2 L/min |

| Max. pressure | 23 MPa |

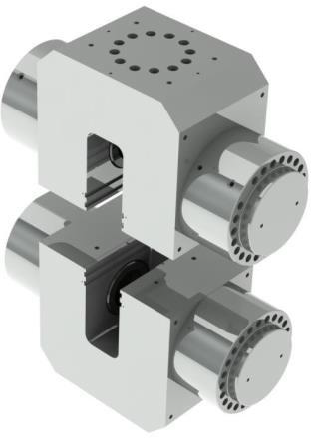

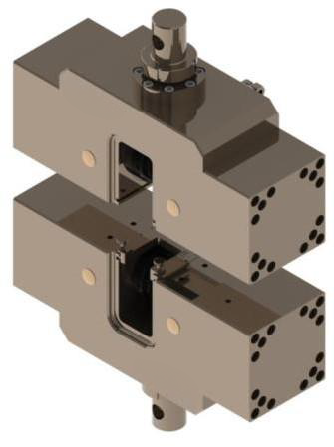

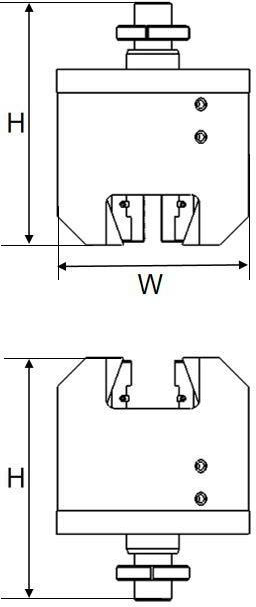

NGA305C – Hydraulic Tensile Grip (Dual Side Action)

The NGA305C Hydraulic Tensile Grip is a robust, high-force grip designed for tensile testing of both flat and round specimens made of metals, composites, and other advanced materials. With a dual side-action hydraulic mechanism, this grip offers exceptional clamping stability under extreme loading conditions. The system supports testing under ambient conditions and features heavy-duty construction, making it ideal for high-capacity material testing laboratories.

The NGA305C Hydraulic Tensile Grip is a robust, high-force grip designed for tensile testing of both flat and round specimens made of metals, composites, and other advanced materials. With a dual side-action hydraulic mechanism, this grip offers exceptional clamping stability under extreme loading conditions. The system supports testing under ambient conditions and features heavy-duty construction, making it ideal for high-capacity material testing laboratories.

- Application: Tension tests for flat and round metal and composite specimens.

- Maximum Capacity: Up to 300 kN load.

- Connection: Ø28 mm pin mount (upper and lower), compatible with standard UTM configurations.

- Dimensions: Height – 12.9 in / 327 mm (Upper), 13.8 in / 350 mm (Lower); Body Width – 22 in / 560 mm.

- Grip Weight: 330.7 lbs / 150 kg each for upper and lower grip.

- Working Temperature: Ambient.

- Specimen Hardness Support: < HRC24.

- Jaw Actuation: Requires Hydraulic Power Unit – Model HPU700A.

Technical Specifications – NGA305C Hydraulic Dual Side Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite, etc. |

| Maximum Force Capacity | 300 kN |

| Connection Type | Upper Grip: Ø28 mm pin Lower Grip: Ø28 mm pin |

| Overall Height (H) | Upper Grip: 327 mm Lower Grip: 350 mm |

| Grip Body Width (W) | 560 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 150 kg Lower Grip: 150 kg |

| Specimen Hardness Support | < HRC24 |

| HPU | HPU700A |

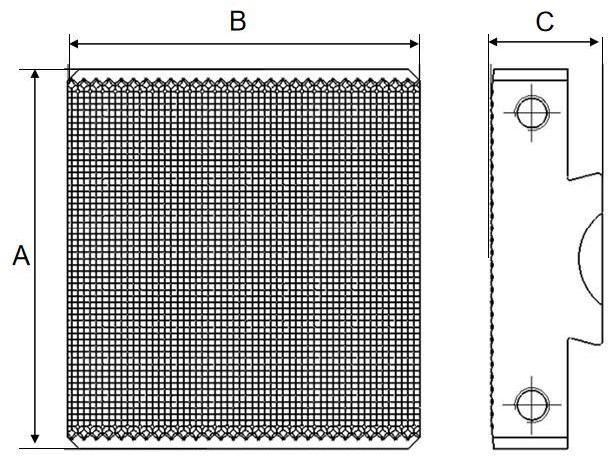

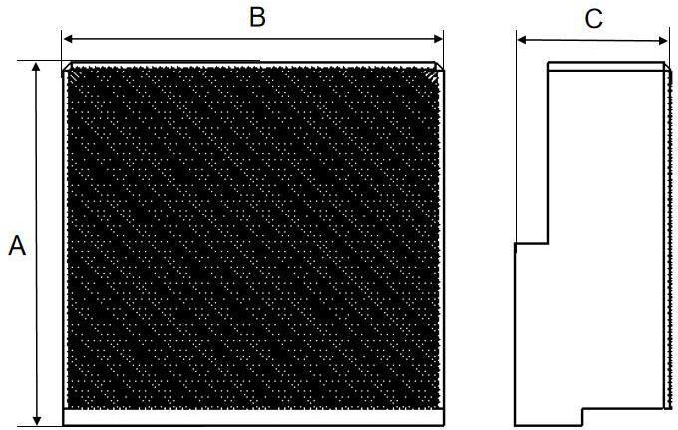

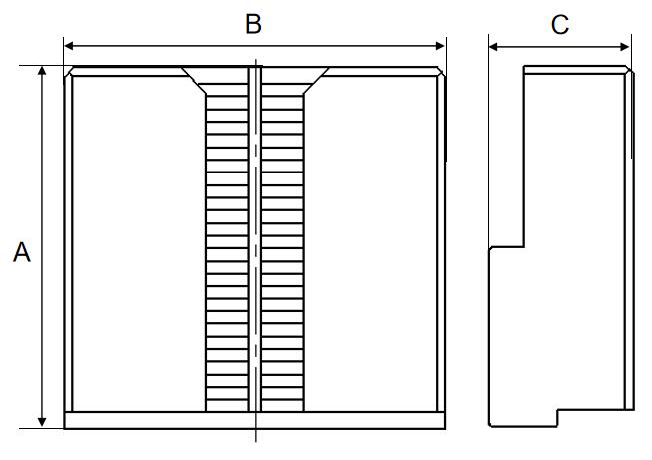

Optional Jaw Faces – NGA305C Grip

Optional Jaw Faces – NGA305C Grip

To accommodate a range of specimen geometries, the NGA305C Grip can be equipped with optional flat and vee jaw faces. Each jaw face is machined for precision and durability, enabling secure and uniform specimen clamping.

Flat Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Size (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGA305C-14 | Flat | 0–30 | 75 | 73 | 20 |

Vee Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Diameter (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGA305C-18 | Vee | Φ6–20 | 84 | 80 | 25 |

| NGA305C-19 | Vee | Φ20–36 | 84 | 80 | 25 |

Hydraulic Power Unit – Model HPU700A

The HPU700A is a high-performance hydraulic power unit tailored to operate the NGA305C grip system. It features robust construction, efficient fluid flow, and optimal pressure management for consistent testing performance.

The HPU700A is a high-performance hydraulic power unit tailored to operate the NGA305C grip system. It features robust construction, efficient fluid flow, and optimal pressure management for consistent testing performance.

Hydraulic Power Unit Specifications

| Model | HPU700A |

|---|---|

| Weight | 89 kg |

| Tank Volume | 30 L |

| Dimensions | 580 mm (L) × 580 mm (W) × 700 mm (H) |

| Power Supply | 3-phase, 380V / 50Hz / 4 kW |

| Rated Flow Rate | 7 L/min |

| Maximum Pressure | 30 MPa |

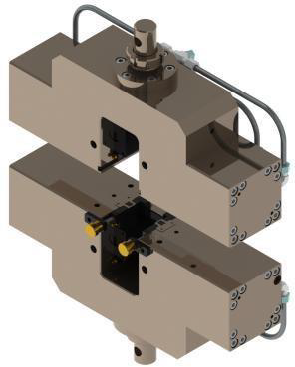

NG605DPS.01 – Hydraulic Tensile Grip (Dual Side Action)

The NG605DPS.01 Hydraulic Tensile Grip is a heavy-duty, dual side action grip designed for flat and round specimen tensile testing. Built for demanding test environments, this grip supports extremely high-capacity loading of up to 600 kN. Precision machining, enhanced durability, and compatibility with hydraulic systems like the HPU141B make this grip ideal for laboratories testing high-strength metals and alloys.

The NG605DPS.01 Hydraulic Tensile Grip is a heavy-duty, dual side action grip designed for flat and round specimen tensile testing. Built for demanding test environments, this grip supports extremely high-capacity loading of up to 600 kN. Precision machining, enhanced durability, and compatibility with hydraulic systems like the HPU141B make this grip ideal for laboratories testing high-strength metals and alloys.

- Application: Tension tests for flat and round metal specimens.

- Maximum Capacity: Up to 600 kN load.

- Dimensions: Height – 13.4 in / 340 mm (upper and lower); Body Width – 24.4 in / 620 mm.

- Grip Weight: 535.7 lbs / 243 kg each for upper and lower grips.

- Working Temperature: Ambient conditions.

- Specimen Hardness Support: < HRC24 (surface hardened to 60–65 HRC).

- Hydraulic Power Unit: Required – Model HPU141B.

Technical Specifications – NG605DPS.01 Hydraulic Dual Side Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal |

| Maximum Force Capacity | 600 kN |

| Overall Height (H) | Upper Grip: 340 mm Lower Grip: 340 mm |

| Grip Body Width (W) | 620 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 243 kg Lower Grip: 243 kg |

| Specimen Hardness Support | < HRC24Surface Hardness: 60–65 HRC |

| HPU | HPU141B |

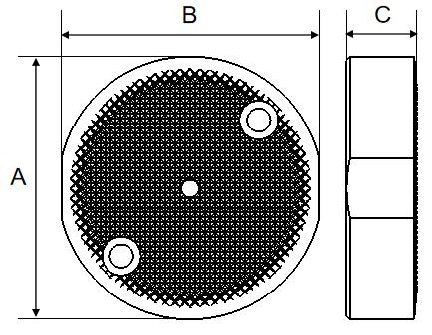

Optional Jaw Faces – NG605DPS.01 Grip

Optional Jaw Faces – NG605DPS.01 Grip

The NG605DPS.01 Grip can be paired with a variety of optional jaw face types to accommodate different specimen geometries. All jaws are surface-hardened and precision-machined for secure, slip-free clamping under high loads.

Flat Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Size (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NG605DPS.01-07 | Flat | 2–60 | 100 | 98 | 42 |

Vee Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Diameter (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NG605DPS.01-08 | Vee | Φ10–20 | 100 | 98 | 42 |

| NG605DPS.01-09 | Vee | Φ20–45 | 100 | 98 | 42 |

| NG605DPS.01-12 | Vee | Φ6–16 | 100 | 98 | 42 |

Hydraulic Power Unit – Model HPU141B

The HPU141B Hydraulic Power Unit is a high-capacity, heavy-duty system built to operate with NG605DPS.01 grips. With an extended tank volume, high-pressure output, and precision hydraulic control, it ensures safe and consistent grip actuation under extreme testing loads.

The HPU141B Hydraulic Power Unit is a high-capacity, heavy-duty system built to operate with NG605DPS.01 grips. With an extended tank volume, high-pressure output, and precision hydraulic control, it ensures safe and consistent grip actuation under extreme testing loads.

Hydraulic Power Unit Specifications

| Model | HPU141B |

|---|---|

| Weight | 130 kg |

| Tank Volume | 98 L |

| Dimensions | 550 mm (L) × 880 mm (W) × 900 mm (H) |

| Power Supply | 3-phase, 380V / 50Hz / 1.5 kW |

| Rated Flow Rate | 14.6 L/min |

| Maximum Pressure | 40 MPa |

NG106DPS.01 – Hydraulic Tensile Grip (Dual Side Action)

The NG106DPS.01 Hydraulic Tensile Grip is an ultra-heavy-duty grip engineered for tensile testing of high-strength flat and round metal specimens. Designed to handle extreme loads of up to 1000 kN, this grip system features rugged construction and precision alignment. With a hardened surface (60–65 HRC) and robust support from the HPU401B hydraulic power unit, this grip is ideal for advanced material testing in critical applications.

The NG106DPS.01 Hydraulic Tensile Grip is an ultra-heavy-duty grip engineered for tensile testing of high-strength flat and round metal specimens. Designed to handle extreme loads of up to 1000 kN, this grip system features rugged construction and precision alignment. With a hardened surface (60–65 HRC) and robust support from the HPU401B hydraulic power unit, this grip is ideal for advanced material testing in critical applications.

- Application: Tension tests for flat and round metal specimens.

- Maximum Capacity: Up to 1000 kN load.

- Dimensions: Height – 18.7 in / 475 mm (upper and lower); Body Width – 33 in / 838 mm.

- Grip Weight: 1292.6 lbs / 586 kg each for upper and lower grip.

- Working Temperature: Ambient conditions.

- Specimen Hardness Support: < HRC24 (Surface hardened to 60–65 HRC).

- Hydraulic Power Unit: Required – Model HPU401B.

Technical Specifications – NG106DPS.01 Hydraulic Dual Side Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal |

| Maximum Force Capacity | 1000 kN |

| Overall Height (H) | Upper Grip: 475 mm Lower Grip: 475 mm |

| Grip Body Width (W) | 838 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 586 kg Lower Grip: 586 kg |

| Specimen Hardness Support | < HRC24Surface Hardness: 60–65 HRC |

| HPU | HPU401B |

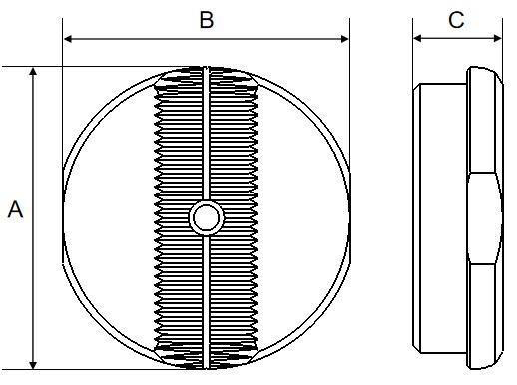

Optional Jaw Faces – NG106DPS.01 Grip

The NG106DPS.01 Grip can be equipped with optional flat and vee jaw faces, providing strong and secure clamping for a wide range of specimen sizes. All jaws are manufactured to high tolerances and surface-hardened to handle high-capacity loading without deformation.

The NG106DPS.01 Grip can be equipped with optional flat and vee jaw faces, providing strong and secure clamping for a wide range of specimen sizes. All jaws are manufactured to high tolerances and surface-hardened to handle high-capacity loading without deformation.

Flat Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Size (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NG106DPS-06 | Flat | 2–60 | 137.7 | 137.7 | 54.5 |

Vee Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Diameter (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NG106DPS-07 | Vee | Φ30–60 | 140 | 137.7 | 55 |

| NG106DPS-08 | Vee | Φ15–30 | 140 | 137.7 | 55 |

Hydraulic Power Unit – Model HPU401B

The HPU401B is a high-capacity, precision-engineered hydraulic power unit specifically designed to support the NG106DPS.01 grips. With a large tank capacity and powerful flow rate, it ensures consistent hydraulic pressure even during the most demanding material testing routines.

The HPU401B is a high-capacity, precision-engineered hydraulic power unit specifically designed to support the NG106DPS.01 grips. With a large tank capacity and powerful flow rate, it ensures consistent hydraulic pressure even during the most demanding material testing routines.

Hydraulic Power Unit Specifications

| Model | HPU401B |

|---|---|

| Weight | 214.5 kg |

| Tank Volume | 140 L |

| Dimensions | 700 mm (L) × 960 mm (W) × 1100 mm (H) |

| Power Supply | 3-phase, 380V / 50Hz / 4 kW |

| Rated Flow Rate | 40 L/min |

| Maximum Pressure | 40 MPa |

NG206DPS.01 – Hydraulic Tensile Grip (Dual Side Action)

The NG206DPS.01 Hydraulic Tensile Grip is a top-tier, dual side action grip system developed for ultra-high-capacity tensile testing applications. Designed to handle loads of up to 2000 kN, it is suitable for both flat and round metal specimens under ambient testing conditions. The grips are built with a hardened surface (60–65 HRC) and engineered to operate using the heavy-duty HPU401B hydraulic power unit. With massive grip size, body width, and jaw holding force, this model is ideal for the most demanding material strength validation processes.

The NG206DPS.01 Hydraulic Tensile Grip is a top-tier, dual side action grip system developed for ultra-high-capacity tensile testing applications. Designed to handle loads of up to 2000 kN, it is suitable for both flat and round metal specimens under ambient testing conditions. The grips are built with a hardened surface (60–65 HRC) and engineered to operate using the heavy-duty HPU401B hydraulic power unit. With massive grip size, body width, and jaw holding force, this model is ideal for the most demanding material strength validation processes.

- Application: Tension tests for flat and round metal specimens.

- Maximum Capacity: Up to 2000 kN load.

- Dimensions: Height – 22.6 in / 575 mm (upper and lower); Body Width – 44.6 in / 1134 mm.

- Grip Weight: 3184.8 lbs / 1445 kg each for upper and lower grip.

- Working Temperature: Ambient conditions.

- Specimen Hardness Support: < HRC24 (Surface hardened: 60–65 HRC).

- Hydraulic Power Unit: Required – Model HPU401B.

Technical Specifications – NG206DPS.01 Hydraulic Dual Side Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal |

| Maximum Force Capacity | 2000 kN |

| Overall Height (H) | Upper Grip: 575 mm Lower Grip: 575 mm |

| Grip Body Width (W) | 1134 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 1445 kg Lower Grip: 1445 kg |

| Specimen Hardness Support | < HRC24Surface Hardness: 60–65 HRC |

| HPU | HPU401B |

Optional Jaw Faces – NG206DPS.01 Grip

Optional Jaw Faces – NG206DPS.01 Grip

To accommodate large-diameter and thick specimens, the NG206DPS.01 Grip supports a set of robust, high-strength jaw faces. These optional jaw faces are surface-hardened, precision-ground, and available in both flat and vee configurations.

Flat Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Size (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NG206DPS-14 | Flat | 2–80 | 220 | 214.2 | 85 |

Vee Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Diameter (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NG206DPS-17 | Vee | Φ5–15 | 220 | 216 | 85 |

| NG206DPS-18 | Vee | Φ15–40 | 220 | 216 | 85 |

| NG206DPS-19 | Vee | Φ40–100 | 220 | 216 | 85 |

Hydraulic Power Unit – Model HPU401B

Hydraulic Power Unit – Model HPU401B

The HPU401B is a high-performance hydraulic power unit tailored for the NG206DPS.01 grip system. Its large reservoir, high flow rate, and heavy-duty construction make it the optimal choice for operating ultra-high-capacity grips.

Hydraulic Power Unit Specifications

| Model | HPU401B |

|---|---|

| Weight | 214.5 kg |

| Tank Volume | 140 L |

| Dimensions | 700 mm (L) × 960 mm (W) × 1100 mm (H) |

| Power Supply | 3-phase, 380V / 50Hz / 4 kW |

| Rated Flow Rate | 40 L/min |

| Maximum Pressure | 40 MPa |

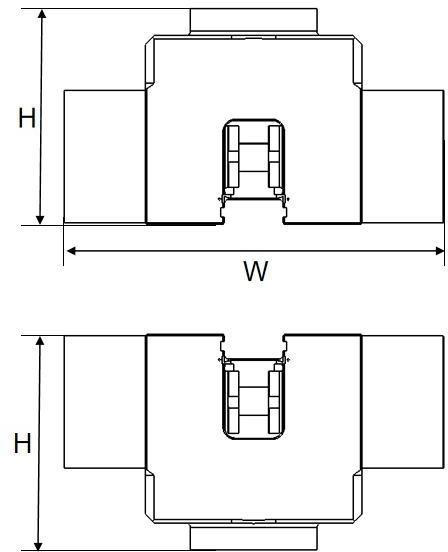

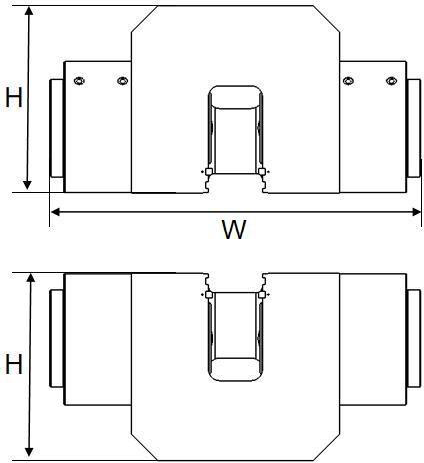

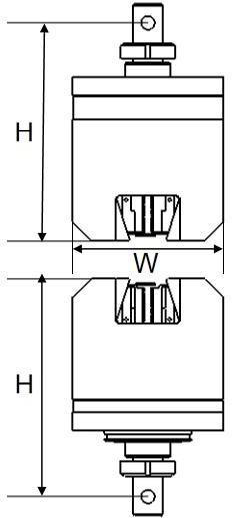

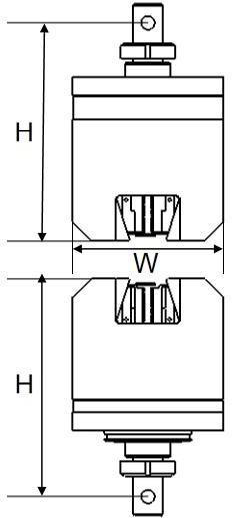

NGC105A – Hydraulic Tensile Grip (Wedge Action)

The NGC105A Hydraulic Tensile Grip features a wedge action design optimized for secure and stable clamping during tensile testing of flat and round metal specimens. This compact and lightweight grip is engineered for medium-capacity applications, offering a load capacity of up to 100 kN. The system is suitable for ambient temperature testing and is compatible with hydraulic power systems such as the HPU440 unit. With precision alignment, surface-hardened jaws, and 18 mm pin connections, it is a versatile solution for various laboratory environments.

The NGC105A Hydraulic Tensile Grip features a wedge action design optimized for secure and stable clamping during tensile testing of flat and round metal specimens. This compact and lightweight grip is engineered for medium-capacity applications, offering a load capacity of up to 100 kN. The system is suitable for ambient temperature testing and is compatible with hydraulic power systems such as the HPU440 unit. With precision alignment, surface-hardened jaws, and 18 mm pin connections, it is a versatile solution for various laboratory environments.

- Application: Tension tests for flat and round metal specimens.

- Maximum Capacity: Up to 100 kN load.

- Connection: Ø18 mm pin mount (upper and lower), compatible with standard UTM configurations.

- Dimensions: Height – 11.4 in / 289 mm (upper and lower); Body Width – 7.9 in / 200 mm.

- Grip Weight: 99.2 lbs / 45 kg each for upper and lower grip.

- Working Temperature: Ambient conditions.

- Specimen Hardness Support: < HRC24.

- Hydraulic Power Unit: Required – Model HPU440.

Technical Specifications – NGC105A Hydraulic Wedge Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal |

| Maximum Force Capacity | 100 kN |

| Connection Type | Upper Grip: Ø18 mm pin Lower Grip: Ø18 mm pin |

| Overall Height (H) | Upper Grip: 289 mm Lower Grip: 289 mm |

| Grip Body Width (W) | 200 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 45 kg Lower Grip: 45 kg |

| Specimen Hardness Support | < HRC24 |

| HPU | HPU440 |

Optional Jaw Faces – NGC105A Grip

The NGC105A Grip supports a wide range of specimen sizes thanks to its optional flat and vee jaw faces. Each face is surface hardened, dimensionally stable, and designed for consistent clamping performance during testing.

The NGC105A Grip supports a wide range of specimen sizes thanks to its optional flat and vee jaw faces. Each face is surface hardened, dimensionally stable, and designed for consistent clamping performance during testing.

Flat Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Size (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGC105A-16 | Flat | 0–8 | 60 | 60 | 18 |

| NGC105A-17 | Flat | 8–15 | 60 | 60 | 15 |

Vee Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Diameter (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGC105A-14 | Vee | Φ4–12 | 60 | 60 | 17.6 |

| NGC105A-15 | Vee | Φ12–20 | 60 | 60 | 15.9 |

Hydraulic Power Unit – Model HPU440

The HPU440 is a compact and efficient hydraulic power unit purpose-built for operating the NGC105A grip system. With a modest footprint and stable pressure output, it provides reliable grip actuation for moderate-capacity testing needs.

The HPU440 is a compact and efficient hydraulic power unit purpose-built for operating the NGC105A grip system. With a modest footprint and stable pressure output, it provides reliable grip actuation for moderate-capacity testing needs.

Hydraulic Power Unit Specifications

| Model | HPU440 |

|---|---|

| Weight | 108 kg |

| Tank Volume | 30 L |

| Dimensions | 670 mm (L) × 580 mm (W) × 736 mm (H) |

| Power Supply | 3-phase, 380V / 50Hz / 1 kW |

| Rated Flow Rate | 7 L/min |

| Maximum Pressure | 18 MPa |

NGC305A – Hydraulic Tensile Grip (Wedge Action)

The NGC305A Hydraulic Tensile Grip is a mid-to-high capacity wedge-action grip system designed for tensile testing of flat and round specimens, including deformed steel bars. Supporting up to 300 kN of force, this grip features automatic clamping under load, surface-hardened jaws, and 28 mm pin compatibility. Operating under ambient conditions, the NGC305A is ideal for testing metals and composites and is powered by the HPU440 hydraulic unit. A wide range of optional jaw faces enables accurate and secure testing across various specimen geometries.

The NGC305A Hydraulic Tensile Grip is a mid-to-high capacity wedge-action grip system designed for tensile testing of flat and round specimens, including deformed steel bars. Supporting up to 300 kN of force, this grip features automatic clamping under load, surface-hardened jaws, and 28 mm pin compatibility. Operating under ambient conditions, the NGC305A is ideal for testing metals and composites and is powered by the HPU440 hydraulic unit. A wide range of optional jaw faces enables accurate and secure testing across various specimen geometries.

- Application: Tension tests for flat, round, and deformed steel specimens made of metal or composite materials.

- Maximum Capacity: Up to 300 kN load.

- Connection: Ø28 mm pin mount (upper and lower), UTM-compatible.

- Dimensions: Height – 13.8 in / 350 mm (upper and lower); Body Width – 10.6 in / 270 mm.

- Grip Weight: 205.9 lbs / 93.4 kg each for upper and lower grip.

- Working Temperature: Ambient.

- Specimen Hardness Support: < HRC24.

- Hydraulic Power Unit: Required – Model HPU440.

Technical Specifications – NGC305A Hydraulic Wedge Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite etc. |

| Maximum Force Capacity | 300 kN |

| Connection Type | Upper Grip: Ø28 mm pin Lower Grip: Ø28 mm pin |

| Overall Height (H) | Upper Grip: 350 mm Lower Grip: 350 mm |

| Grip Body Width (W) | 270 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 93.4 kg Lower Grip: 93.4 kg |

| Specimen Hardness Support | < HRC24 |

| HPU | HPU440 |

Optional Jaw Faces – NGC305A Grip

The NGC305A Grip supports a wide range of optional jaw faces for flat, round, and deformed steel bar specimens. All jaws are surface-hardened and precisely machined to provide secure clamping under high-load conditions.

The NGC305A Grip supports a wide range of optional jaw faces for flat, round, and deformed steel bar specimens. All jaws are surface-hardened and precisely machined to provide secure clamping under high-load conditions.

Flat Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Size (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGC305A-16 | Flat | 0–6 | 71 | 70 | 29 |

| NGC305A-17 | Flat | 6–18 | 71 | 70 | 26 |

| NGC305A-18 | Flat | 18–30 | 71 | 70 | 20 |

Vee Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Diameter (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGC305A-13 | Vee | Φ6–16 | 71 | 70 | 29 |

| NGC305A-14 | Vee | Φ16–26 | 71 | 70 | 26 |

| NGC305A-15 | Vee | Φ26–36 | 71 | 70 | 22.5 |

| NGC305A-19 | Vee (Deformed Bar) | Φ6–16 | 71 | 70 | 29 |

| NGC305A-20 | Vee (Deformed Bar) | Φ16–26 | 71 | 70 | 26 |

| NGC305A-21 | Vee (Deformed Bar) | Φ26–36 | 71 | 70 | 22.5 |

Hydraulic Power Unit – Model HPU440

The HPU440 is a compact and efficient hydraulic power unit compatible with NGC305A grips. It provides consistent hydraulic pressure for wedge action systems in moderate to high-capacity tensile testing environments.

The HPU440 is a compact and efficient hydraulic power unit compatible with NGC305A grips. It provides consistent hydraulic pressure for wedge action systems in moderate to high-capacity tensile testing environments.

Hydraulic Power Unit Specifications

| Model | HPU440 |

|---|---|

| Weight | 108 kg |

| Tank Volume | 30 L |

| Dimensions | 670 mm (L) × 580 mm (W) × 736 mm (H) |

| Power Supply | 3-phase, 380V / 50Hz / 1 kW |

| Rated Flow Rate | 7 L/min |

| Maximum Pressure | 18 MPa |

NGB605C – Hydraulic Tensile Grip (Wedge Action)

The NGB605C Hydraulic Tensile Grip is a heavy-duty wedge-action system designed for tensile testing of flat and round specimens made of metal and composite materials. Capable of withstanding forces up to 600 kN, this grip offers high clamping strength and reliable performance under ambient test conditions. With hardened clamping surfaces and a robust body, the NGB605C operates in combination with the HPU440 hydraulic power unit to ensure stable and precise gripping throughout the test cycle.

The NGB605C Hydraulic Tensile Grip is a heavy-duty wedge-action system designed for tensile testing of flat and round specimens made of metal and composite materials. Capable of withstanding forces up to 600 kN, this grip offers high clamping strength and reliable performance under ambient test conditions. With hardened clamping surfaces and a robust body, the NGB605C operates in combination with the HPU440 hydraulic power unit to ensure stable and precise gripping throughout the test cycle.

- Application: Tension tests for flat and round metal or composite specimens.

- Maximum Capacity: Up to 600 kN load.

- Connection: Ø28 mm pin mount (upper and lower), suitable for standard UTM systems.

- Dimensions: Height – 16.4 in / 416 mm (upper and lower); Body Width – 13 in / 330 mm.

- Grip Weight: 357.1 lbs / 162 kg each for upper and lower grip.

- Working Temperature: Ambient.

- Specimen Hardness Support: < HRC24.

- Hydraulic Power Unit: Required – Model HPU440.

Technical Specifications – NGB605C Hydraulic Wedge Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite etc. |

| Maximum Force Capacity | 600 kN |

| Overall Height (H) | Upper Grip: 416 mm Lower Grip: 416 mm |

| Grip Body Width (W) | 330 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 162 kg Lower Grip: 162 kg |

| Specimen Hardness Support | < HRC24 |

| HPU | HPU440 |

Optional Jaw Faces – NGB605C Grip

The NGB605C Grip offers a full selection of optional jaw faces, enabling the system to securely grip standard and deformed specimens across a wide range of diameters and thicknesses. The jaws are surface-hardened and precision-machined to deliver optimal force distribution and clamping security.

The NGB605C Grip offers a full selection of optional jaw faces, enabling the system to securely grip standard and deformed specimens across a wide range of diameters and thicknesses. The jaws are surface-hardened and precision-machined to deliver optimal force distribution and clamping security.

Flat Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Size (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGB605C-09 | Flat | 0–6 | 86 | 90 | 37 |

| NGB605C-10 | Flat | 6–23 | 86 | 90 | 31.5 |

| NGB605C-11 | Flat | 23–40 | 86 | 90 | 23 |

Vee Jaw Faces (Optional)

| No. | Jaw Face Type | Specimen Diameter (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGB605C-06 | Vee | Φ6–12 | 86 | 90 | 37 |

| NGB605C-07 | Vee | Φ12–27 | 86 | 90 | 34 |

| NGB605C-08 | Vee | Φ27–42 | 86 | 90 | 30 |

Vee Jaw Faces for Deformed Steel Bars (Optional)

| No. | Jaw Face Type | Specimen Diameter (mm) | Height (A) (mm) | Width (B) (mm) | Thickness (C) (mm) |

|---|---|---|---|---|---|

| NGB605C-17 | Vee for Deformed Bar | Φ6–12 | 86 | 90 | 37 |

| NGB605C-18 | Vee for Deformed Bar | Φ12–27 | 86 | 90 | 34 |

| NGB605C-19 | Vee for Deformed Bar | Φ27–42 | 86 | 90 | 30 |

Hydraulic Power Unit – Model HPU440

The HPU440 is a compact and efficient hydraulic power unit designed to operate a range of hydraulic tensile grips. With consistent pressure control and a small footprint, it’s ideal for mid-to-high capacity material testing systems.

The HPU440 is a compact and efficient hydraulic power unit designed to operate a range of hydraulic tensile grips. With consistent pressure control and a small footprint, it’s ideal for mid-to-high capacity material testing systems.

Hydraulic Power Unit Specifications

| Model | HPU440 |

|---|---|

| Weight | 108 kg |

| Tank Volume | 30 L |

| Dimensions | 670 mm (L) × 580 mm (W) × 736 mm (H) |

| Power Supply | 3-phase, 380V / 50Hz / 1 kW |

| Rated Flow Rate | 7 L/min |

| Maximum Pressure | 18 MPa |

NextGen’s full range of Dual Side Action and Wedge Hydraulic Grips represents the pinnacle of tensile testing technology. Whether your lab requires high-capacity solutions or precision gripping for various material types, our grips integrate seamlessly with universal testing machines. Backed by international standards and decades of engineering refinement, these grips are trusted by industrial QA teams and research institutions worldwide. Contact us to request specifications, pricing, or compatibility support for your existing UTM system.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.