Metal Testing Equipment

NextGen Material Testing, Inc. offers a complete portfolio of advanced grips and fixtures specifically engineered for composite material testing with universal testing machines. These solutions meet a wide array of international testing standards including ASTM D3039, ISO 527, ASTM D2344, ISO 14125, and DIN EN 2562. Designed for high-precision tensile, compression, shear, bending, and peel testing, our composite fixtures enable reliable evaluation of fiber-reinforced plastics, carbon composites, laminates, and hybrid materials. Whether you’re conducting R&D, quality assurance, or regulatory compliance testing, NextGen’s grip systems are essential tools for ensuring repeatable and accurate material behavior analysis.

NextGen Material Testing, Inc. offers a complete portfolio of advanced grips and fixtures specifically engineered for composite material testing with universal testing machines. These solutions meet a wide array of international testing standards including ASTM D3039, ISO 527, ASTM D2344, ISO 14125, and DIN EN 2562. Designed for high-precision tensile, compression, shear, bending, and peel testing, our composite fixtures enable reliable evaluation of fiber-reinforced plastics, carbon composites, laminates, and hybrid materials. Whether you’re conducting R&D, quality assurance, or regulatory compliance testing, NextGen’s grip systems are essential tools for ensuring repeatable and accurate material behavior analysis.

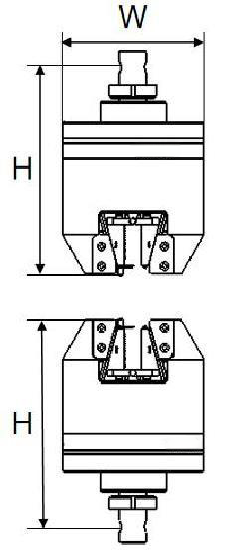

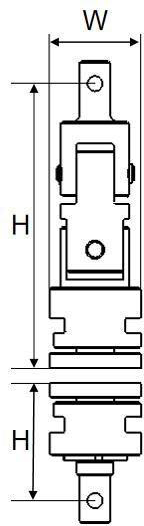

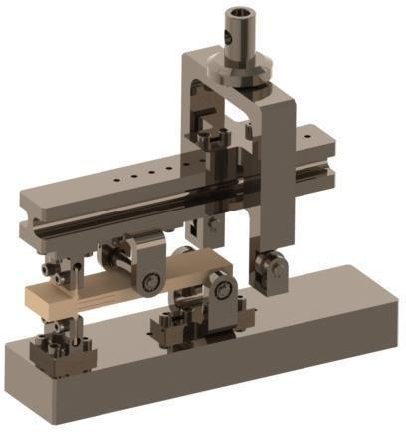

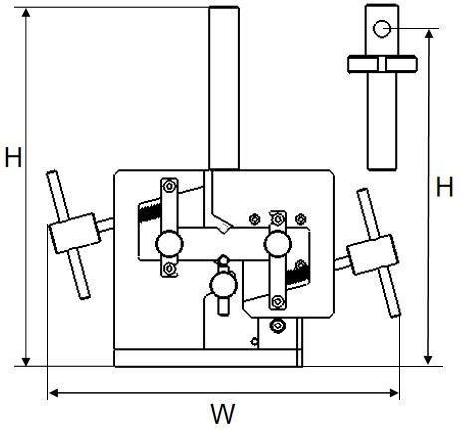

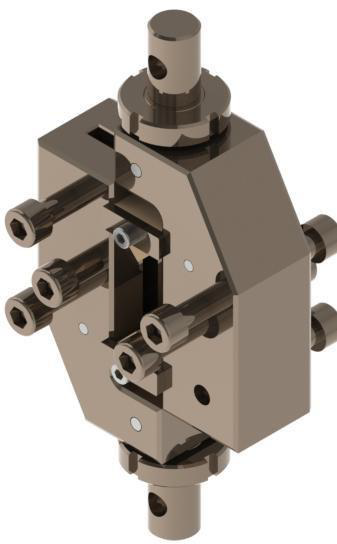

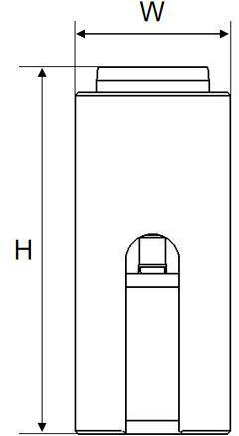

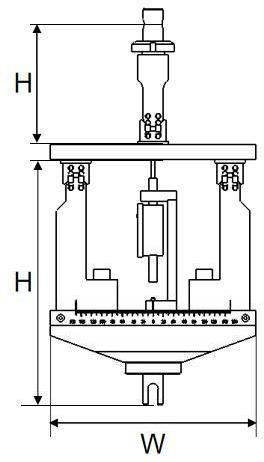

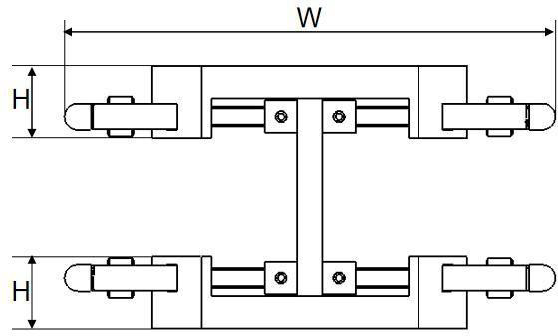

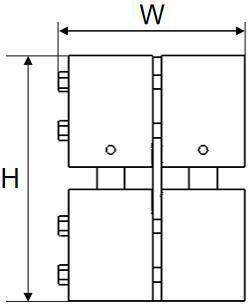

NGC105B – Tensile Grip

NGC105B – Tensile Grip

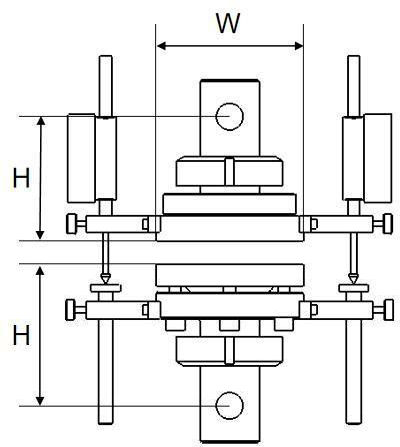

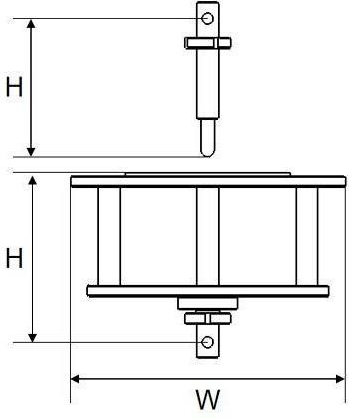

The NGC105B Hydraulic Wedge Grip is engineered for high-capacity tensile testing of metals and composite materials. Designed for reliability under force loads up to 100 kN, this grip system provides stable clamping with uniform hydraulic wedge action. Featuring heavy-duty construction and Φ18 mm pin connection, it is suitable for industrial environments operating between 0°C and 40°C.

- Application: Tension test for metal and composite materials.

- Maximum Capacity: ≤ 100 kN.

- Weight: 57 kg (Upper Grip), 57 kg (Lower Grip).

- Height: 310 mm (Upper and Lower Grips).

- Grip Width (W): 215 mm.

- Working Temperature: 0°C to 40°C.

- Connection: Φ18 mm pin (upper and lower), compatible with standard testing machines.

Technical Specifications – NGC105B Hydraulic Wedge Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for metal, composite |

| Maximum Force Capacity | ≤ 100 kN |

| Upper Grip Weight | 57 kg |

| Lower Grip Weight | 57 kg |

| Upper Grip Height (H) | 310 mm |

| Lower Grip Height (H) | 310 mm |

| Grip Width (W) | 215 mm |

| Working Temperature | 0°C – 40°C |

| Connection – Upper Grip | Φ18 mm pin |

| Connection – Lower Grip | Φ18 mm pin |

Optional Accessories – NGC105B Hydraulic Wedge Grip

Optional Accessories – NGC105B Hydraulic Wedge Grip

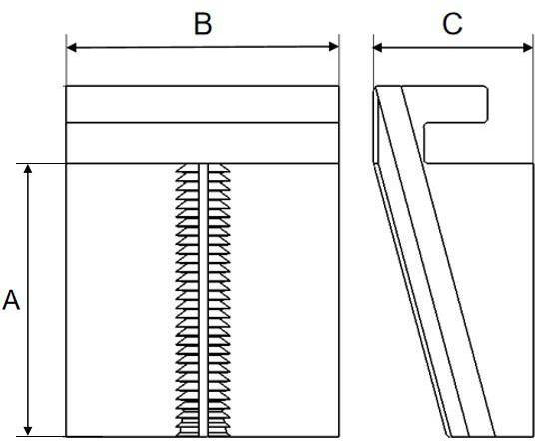

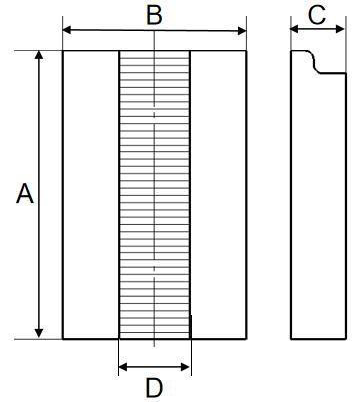

Jaw Faces (Optional)

| No. | Type | Specimen Size (mm) | Height A (mm) | Width B (mm) | Thickness C (mm) |

|---|---|---|---|---|---|

| NGC105B-11 | VEE | Φ4 – Φ12 | 65 | 50 | 35 |

| NGC105B-12 | VEE | Φ12 – Φ20 | 65 | 50 | 32 |

| NGC105B-13 | Flat | 0 – 12 | 65 | 50 | 34 |

| NGC105B-14 | Flat | 12 – 24 | 65 | 50 | 28 |

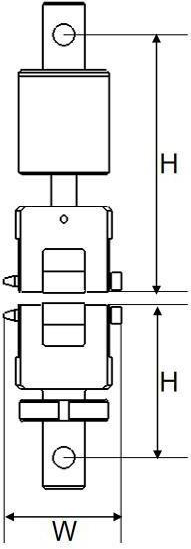

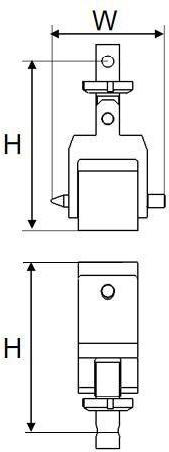

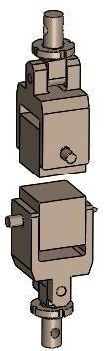

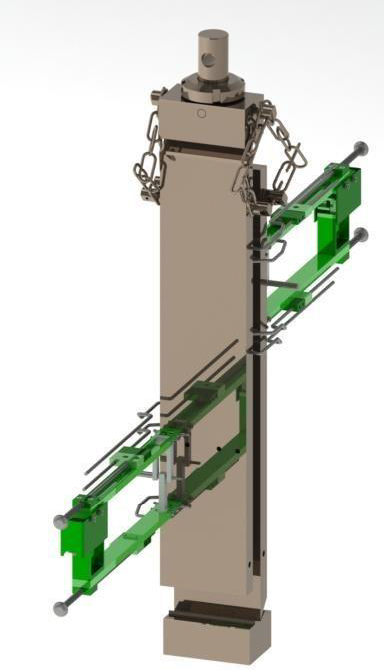

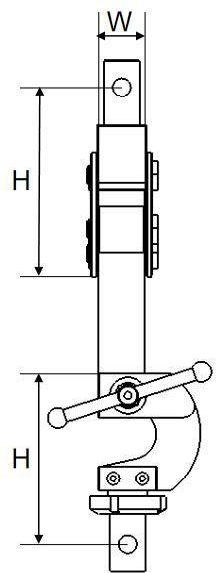

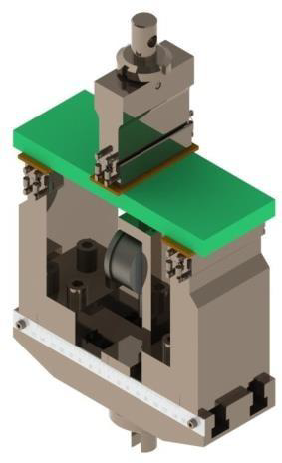

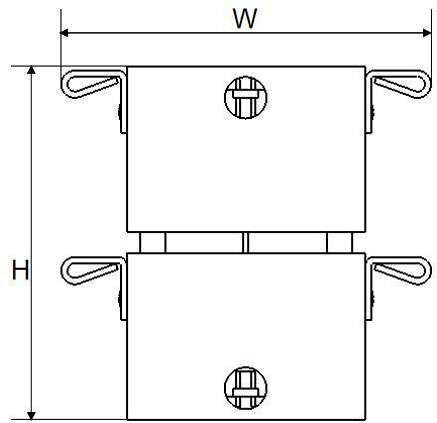

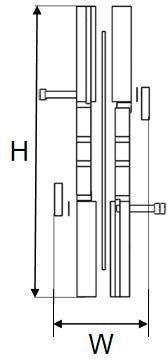

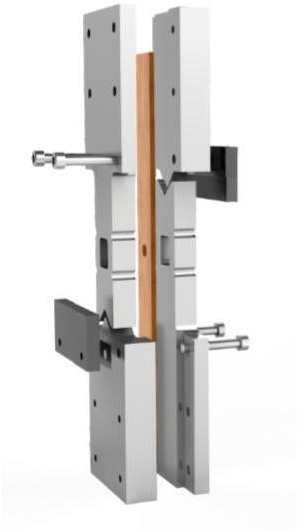

NGC105G – Tensile Grip

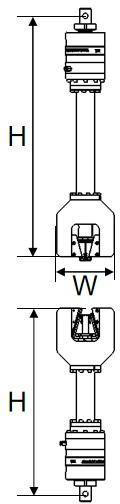

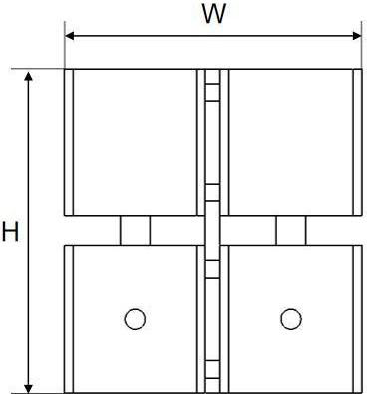

The NGC105G Hydraulic Wedge Grip is designed for high-capacity tensile testing of metal and composite materials, especially under extreme temperature conditions. With a wide working range from −70°C to +350°C and strong clamping force up to 100 kN, this grip is ideal for harsh testing environments. Heavy-duty construction and Φ18 mm pin compatibility ensure stable and precise test setups.

The NGC105G Hydraulic Wedge Grip is designed for high-capacity tensile testing of metal and composite materials, especially under extreme temperature conditions. With a wide working range from −70°C to +350°C and strong clamping force up to 100 kN, this grip is ideal for harsh testing environments. Heavy-duty construction and Φ18 mm pin compatibility ensure stable and precise test setups.

- Application: Tension test for metal and composite materials.

- Maximum Capacity: ≤ 100 kN.

- Weight:

- Upper Grip: 101 kg

- Lower Grip: 85 kg

- Height:

- Upper Grip: 840 mm

- Lower Grip: 554 mm

- Grip Width (W): 238 mm

- Working Temperature: −70°C to +350°C

- Connection: Φ18 mm pin (upper and lower)

- Specimen Hardness Compatibility: ≤ HRC24

Technical Specifications – NGC105G Hydraulic Wedge Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for metal, composite |

| Maximum Force Capacity | ≤ 100 kN |

| Upper Grip Weight | 101 kg |

| Lower Grip Weight | 85 kg |

| Upper Grip Height (H) | 840 mm |

| Lower Grip Height (H) | 554 mm |

| Grip Width (W) | 238 mm |

| Working Temperature | −70°C to +350°C |

| Connection – Upper Grip | Φ18 mm pin |

| Connection – Lower Grip | Φ18 mm pin |

| Specimen Hardness | ≤ HRC24 |

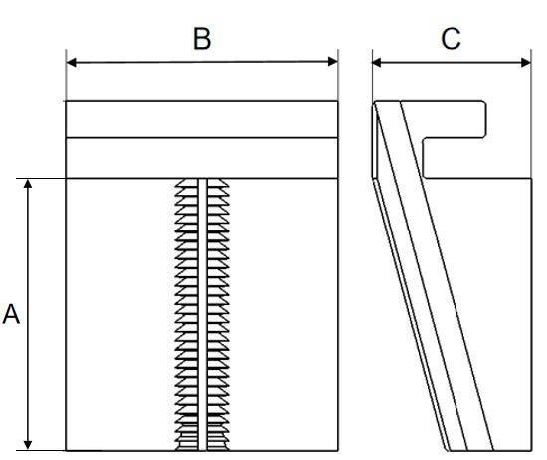

Optional Accessories – NGC105G Hydraulic Wedge Grip

Optional Accessories – NGC105G Hydraulic Wedge Grip

Jaw Faces (Optional)

| No. | Type | Specimen Size (mm) | Height A (mm) | Width B (mm) | Thickness C (mm) |

|---|---|---|---|---|---|

| NGC105G-16 | VEE | Φ4 – Φ12 | 65 | 50 | 35 |

| NGC105G-17 | VEE | Φ12 – Φ20 | 65 | 50 | 32 |

| NGC105G-18 | Flat | 0 – 12 | 65 | 50 | 34 |

| NGC105G-19 | Flat | 12 – 24 | 65 | 50 | 28 |

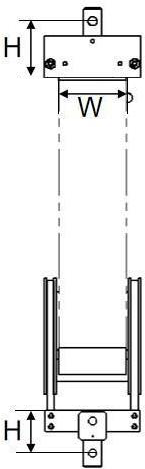

NGA502A – Tensile Grip

The NGA502A Node Tensile Grip is specifically designed for tensile testing of honeycomb core materials according to ASTM C363. Featuring lightweight upper and lower grips, the system supports a maximum force of 500 N and operates within 0°C to 40°C. It accommodates precise clamping of thin materials with a clamping range of up to 20 mm and is compatible with Φ10 mm UTM pin connections.

The NGA502A Node Tensile Grip is specifically designed for tensile testing of honeycomb core materials according to ASTM C363. Featuring lightweight upper and lower grips, the system supports a maximum force of 500 N and operates within 0°C to 40°C. It accommodates precise clamping of thin materials with a clamping range of up to 20 mm and is compatible with Φ10 mm UTM pin connections.

- Application: Tension test for honeycomb core materials.

- Maximum Capacity: 500 N.

- Grip Weight: 1 kg (Upper), 1 kg (Lower).

- Height: 110 mm (Upper and Lower Grip).

- Grip Width (W): 145 mm.

- Working Temperature: 0°C to 40°C.

- Standard Compliance: ASTM C363.

- Connection: Φ10 mm pin (upper and lower).

- Specimen Size: 260 mm (L) × 130 mm (W) × 12(16) mm (T).

- Pin Diameter: Φ4.5 mm.

- Clamping Range: 0–20 mm.

Technical Specifications – NGA502A Node Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for honeycomb core materials |

| Maximum Force Capacity | 500 N |

| Upper Grip Weight | 1 kg |

| Lower Grip Weight | 1 kg |

| Upper Grip Height (H) | 110 mm |

| Lower Grip Height (H) | 110 mm |

| Grip Width (W) | 145 mm |

| Working Temperature | 0°C – 40°C |

| Standard | ASTM C363 |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Specimen Size | 260 (L) × 130 (W) × 12(16) (T) mm |

| Pin Diameter | Φ4.5 mm |

| Clamping Range | 0 – 20 mm |

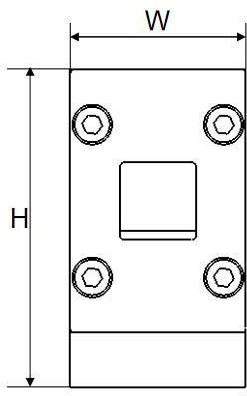

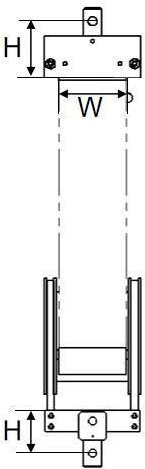

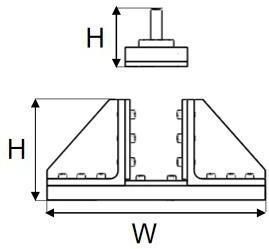

NGB103A – Tensile Grip

The NGB103A Plane Tensile Grip is engineered for plane tensile testing of bonded honeycomb sandwich structures. Designed for extreme environments, it functions within a wide temperature range from −70°C to +350°C. With compact dimensions and lightweight construction, it meets the requirements of QJ 1123 standard and fits universal testing machines using Φ10 mm pin connections.

The NGB103A Plane Tensile Grip is engineered for plane tensile testing of bonded honeycomb sandwich structures. Designed for extreme environments, it functions within a wide temperature range from −70°C to +350°C. With compact dimensions and lightweight construction, it meets the requirements of QJ 1123 standard and fits universal testing machines using Φ10 mm pin connections.

- Application: Plane tension test for bonded honeycomb sandwich structure.

- Maximum Capacity: 1 kN.

- Grip Weight:

- Upper Grip: 2.2 kg

- Lower Grip: 0.7 kg

- Height:

- Upper Grip: 188 mm

- Lower Grip: 78 mm

- Grip Width (W): 60 mm.

- Working Temperature: −70°C to +350°C.

- Standard Compliance: QJ 1123.

- Connection: Φ10 mm pin (upper and lower), UTM-compatible.

Technical Specifications – NGB103A Plane Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Plane tension test for bonded honeycomb sandwich structure |

| Maximum Force Capacity | 1 kN |

| Upper Grip Weight | 2.2 kg |

| Lower Grip Weight | 0.7 kg |

| Upper Grip Height (H) | 188 mm |

| Lower Grip Height (H) | 78 mm |

| Grip Width (W) | 60 mm |

| Working Temperature | −70°C to +350°C |

| Standard | QJ 1123 |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

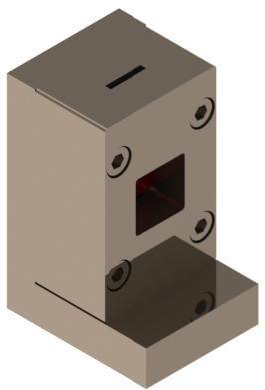

NGA104C – Tensile Grip

The NGA104C Platwise Tensile Grip is purpose-built for flatwise tensile testing of sandwich constructions in accordance with ASTM C297. This grip system features symmetric upper and lower grips, a compact footprint, and a working range of 0°C to 40°C, making it ideal for structural testing of bonded core materials.

The NGA104C Platwise Tensile Grip is purpose-built for flatwise tensile testing of sandwich constructions in accordance with ASTM C297. This grip system features symmetric upper and lower grips, a compact footprint, and a working range of 0°C to 40°C, making it ideal for structural testing of bonded core materials.

- Application: Flatwise tension test for sandwich constructions.

- Maximum Capacity: 10 kN.

- Grip Weight: 2.2 kg (Upper and Lower).

- Height: 143 mm (Upper and Lower).

- Grip Width (W): 95 mm.

- Working Temperature: 0°C to 40°C.

- Standard Compliance: ASTM C297.

- Connection: Φ10 mm pin (upper and lower).

- Specimen Size: 50 (H) × 50 (W) mm.

Technical Specifications – NGA104C Platwise Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Flatwise tension test for sandwich constructions |

| Maximum Force Capacity | 10 kN |

| Upper Grip Weight | 2.2 kg |

| Lower Grip Weight | 2.2 kg |

| Upper Grip Height (H) | 143 mm |

| Lower Grip Height (H) | 143 mm |

| Grip Width (W) | 95 mm |

| Working Temperature | 0°C – 40°C |

| Standard | ASTM C297 |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Specimen Size | 50 (H) × 50 (W) mm |

NGA202A – Tensile Grip

The NGA202A Loading Block Grip is designed for precise testing of interlaminar fracture toughness (Mode I) in unidirectional fiber-reinforced polymer matrix composites. It complies with ASTM D5528 and ISO 15024 standards and is optimized for use with small-scale specimens. Lightweight and compact, it operates reliably at ambient and sub-zero temperatures.

- Application: Determination of Mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites.

- Maximum Capacity: 200 N.

- Grip Weight:

- Upper Grip: 0.8 kg

- Lower Grip: 0.4 kg

- Height:

- Upper Grip: 121 mm

- Lower Grip: 72 mm

- Grip Width (W): 55 mm.

- Working Temperature: 0°C to 40°C.

- Standard Compliance: ASTM D5528, ISO 15024.

- Connection: Φ10 mm pin (upper and lower).

- Specimen Size: 125 (L) × 25 (W) mm.

Technical Specifications – NGA202A Loading Block Grip

| Parameter | Specification |

|---|---|

| Application | Mode I fracture toughness test for unidirectional fiber-reinforced composites |

| Maximum Force Capacity | 200 N |

| Upper Grip Weight | 0.8 kg |

| Lower Grip Weight | 0.4 kg |

| Upper Grip Height (H) | 121 mm |

| Lower Grip Height (H) | 72 mm |

| Grip Width (W) | 55 mm |

| Working Temperature | 0°C – 40°C |

| Standard | ASTM D5528, ISO 15024 |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Specimen Size | 125 (L) × 25 (W) mm |

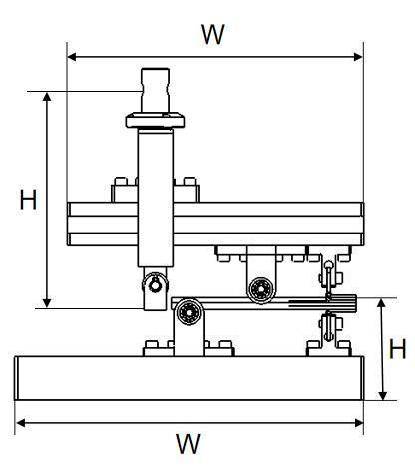

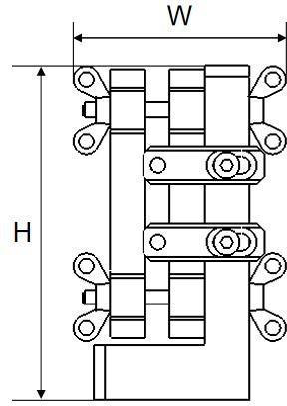

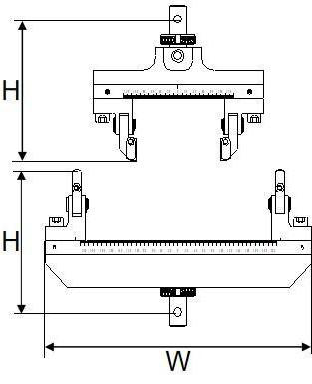

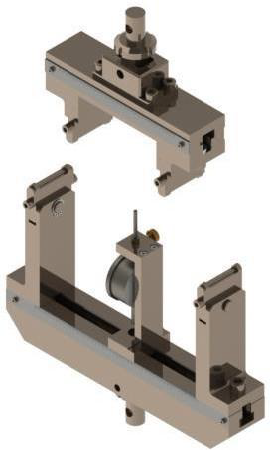

NGA502B – Mixed Mode I & II Test Fixture

The NGA502B Mixed Mode I & II Test Fixture is engineered for evaluating the interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites under combined loading. Designed in accordance with ASTM D6671, it enables accurate measurement of Mode I and Mode II fracture behavior. This fixture features separate upper and lower grip assemblies and is ideal for testing under ambient laboratory conditions.

The NGA502B Mixed Mode I & II Test Fixture is engineered for evaluating the interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites under combined loading. Designed in accordance with ASTM D6671, it enables accurate measurement of Mode I and Mode II fracture behavior. This fixture features separate upper and lower grip assemblies and is ideal for testing under ambient laboratory conditions.

- Application: Mixed mode (Mode I and Mode II) fracture toughness testing of unidirectional fiber-reinforced composites.

- Maximum Capacity: 500 N.

- Grip Weight:

- Upper Grip: 1.7 kg

- Lower Grip: 4.2 kg

- Height (H):

- Upper Grip: 160 mm

- Lower Grip: 74 mm

- Width (W):

- Upper Grip: 216 mm

- Lower Grip: 254 mm

- Working Temperature: 0°C to 40°C.

- Standard Compliance: ASTM D6671.

- Connection: Φ10 mm pin (upper and lower).

- Specimen Size: 125 (L) × 25 (W) mm.

Technical Specifications – NGA502B Mixed Mode I & II Test Fixture

| Parameter | Specification |

|---|---|

| Application | Mixed mode (I & II) fracture testing of fiber-reinforced polymer matrix composites |

| Maximum Force Capacity | 500 N |

| Upper Grip Weight | 1.7 kg |

| Lower Grip Weight | 4.2 kg |

| Upper Grip Height (H) | 160 mm |

| Lower Grip Height (H) | 74 mm |

| Upper Grip Width (W) | 216 mm |

| Lower Grip Width (W) | 254 mm |

| Working Temperature | 0°C – 40°C |

| Standard | ASTM D6671 |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Specimen Size | 125 (L) × 25 (W) mm |

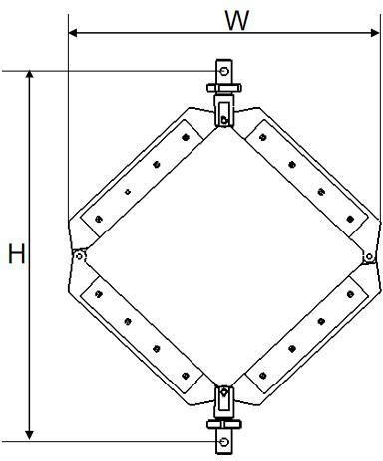

NGA502A – Picture Frame Shear Fixture

The NGA502A Picture Frame Shear Fixture is specifically designed for evaluating the in-plane shear strength and stiffness of flat sandwich panels with composite face sheets. Compliant with ASTM D8067, this fixture supports a wide testing temperature range, making it ideal for both ambient and extreme thermal environments. It features compact construction with precision pin-mount connections and a secure clamping mechanism.

The NGA502A Picture Frame Shear Fixture is specifically designed for evaluating the in-plane shear strength and stiffness of flat sandwich panels with composite face sheets. Compliant with ASTM D8067, this fixture supports a wide testing temperature range, making it ideal for both ambient and extreme thermal environments. It features compact construction with precision pin-mount connections and a secure clamping mechanism.

- Application: In-plane shear testing of flat sandwich constructions with composite face sheets.

- Maximum Capacity: ≤ 500 N.

- Fixture Weight: 1.3 kg.

- Working Temperature: –70°C to +200°C.

- Standard Compliance: ASTM D8067.

- Connection: Φ10 mm pin mount (upper and lower).

- Fixture Height (H): 469 mm.

- Fixture Width (W): 392 mm.

- Clamping Range: 0–5 mm.

- Specimen Size: 180 (H) × 180 (W) mm.

Technical Specifications – NGA502A Picture Frame Shear Fixture

| Parameter | Specification |

|---|---|

| Application | In-plane shear strength and stiffness testing of flat sandwich composite panels |

| Maximum Force Capacity | ≤ 500 N |

| Weight | 1.3 kg |

| Working Temperature | –70°C to +200°C |

| Standard | ASTM D8067 |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Fixture Height (H) | 469 mm |

| Fixture Width (W) | 392 mm |

| Clamping Range | 0–5 mm |

| Specimen Size | 180 (H) × 180 (W) mm |

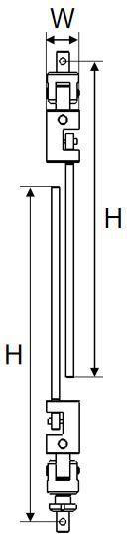

NGA104D – Tensile Shear Fixture

The NGA104D Tensile Shear Fixture is designed for evaluating the shear properties of sandwich core materials under tension, following international testing standards such as ASTM C273 and GB/T 1455. Built with precision-ground grip surfaces and shoulder clamping, this fixture supports testing at ambient and controlled temperatures with stable axial alignment.

The NGA104D Tensile Shear Fixture is designed for evaluating the shear properties of sandwich core materials under tension, following international testing standards such as ASTM C273 and GB/T 1455. Built with precision-ground grip surfaces and shoulder clamping, this fixture supports testing at ambient and controlled temperatures with stable axial alignment.

- Application: Shear testing of sandwich core materials under tensile load.

- Maximum Capacity: 10 kN.

- Working Temperature: 0°C to +40°C.

- Standards Compliance: ASTM C273, GB/T 1455.

- Clamping Mode: Shoulder.

- Clamping Range: 5–20 mm.

- Connection: Φ10 mm pin (upper and lower).

- Specimen Size: 150 (H) × 50 (W) mm.

Technical Specifications – NGA104D Tensile Shear Fixture

| Parameter | Specification |

|---|---|

| Application | Shear property testing for sandwich core materials |

| Maximum Force Capacity | 10 kN |

| Weight – Upper Grip | 3 kg |

| Weight – Lower Grip | 3 kg |

| Height – Upper Grip | 400 mm |

| Height – Lower Grip | 400 mm |

| Grip Width (W) | 50 mm |

| Working Temperature | 0°C to +40°C |

| Standards | ASTM C273, GB/T 1455 |

| Connection – Upper | Φ10 mm pin |

| Connection – Lower | Φ10 mm pin |

| Clamping Range | 5–20 mm |

| Clamping Mode | Shoulder |

| Specimen Size | 150 (H) × 50 (W) mm |

NGB104C – Compression Shear Fixture

The NGB104C Compression Shear Fixture is engineered to evaluate the shear properties of sandwich core materials under compressive loading. Built for accurate axial alignment and compliance with international testing standards, it delivers precise and repeatable results within controlled laboratory environments.

The NGB104C Compression Shear Fixture is engineered to evaluate the shear properties of sandwich core materials under compressive loading. Built for accurate axial alignment and compliance with international testing standards, it delivers precise and repeatable results within controlled laboratory environments.

- Application: Compression shear testing of sandwich core materials.

- Maximum Capacity: 10 kN.

- Working Temperature: 0°C to +40°C.

- Standards Compliance: ASTM C273, GB/T 1455.

- Connection: Φ10 mm pin (upper and lower).

Technical Specifications – NGB104C Compression Shear Fixture

| Parameter | Specification |

|---|---|

| Application | Shear testing for sandwich core materials |

| Maximum Force Capacity | 10 kN |

| Fixture Weight | 5 kg |

| Height (H) | 413 mm |

| Grip Width (W) | 77 mm |

| Working Temperature | 0°C to +40°C |

| Standards | ASTM C273, GB/T 1455 |

| Connection – Upper | Φ10 mm pin |

| Connection – Lower | Φ10 mm pin |

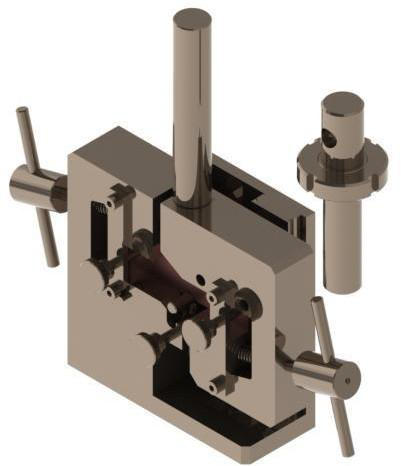

NGB204E – V-Notched Beam Shear Fixture

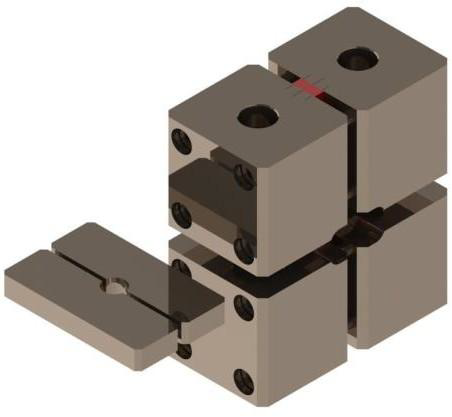

The NGB204E V-Notched Beam Shear Fixture is designed to evaluate the shear properties of unidirectional laminates and fabric fiber composites. Compliant with ASTM D5379, this fixture ensures accurate alignment and secure clamping of thin specimens under high and low temperature conditions. It supports testing in extreme environments and is ideal for precision composite material characterization.

The NGB204E V-Notched Beam Shear Fixture is designed to evaluate the shear properties of unidirectional laminates and fabric fiber composites. Compliant with ASTM D5379, this fixture ensures accurate alignment and secure clamping of thin specimens under high and low temperature conditions. It supports testing in extreme environments and is ideal for precision composite material characterization.

- Application: Shear testing of laminates and fiber-reinforced composites.

- Maximum Capacity: 20 kN.

- Working Temperature: -70°C to +350°C.

- Standard: ASTM D5379.

- Connection: Φ10 mm pin.

- Clamping Range: 0–6 mm.

Technical Specifications – NGB204E V-Notched Beam Shear Fixture

| Parameter | Specification |

|---|---|

| Application | Testing shear properties of unidirectional laminates or fabric fiber composites |

| Maximum Force | 20 kN |

| Fixture Weight | 3.6 kg |

| Height (Left) | 220 mm |

| Height (Right) | 206 mm |

| Grip Width (W) | 215 mm |

| Working Temperature | -70°C to +350°C |

| Standard | ASTM D5379 |

| Connection | Φ10 mm pin (upper and lower) |

| Clamping Range | 0–6 mm |

| Specimen Size | 76(L) × 19(W) × (3–4)(T) mm |

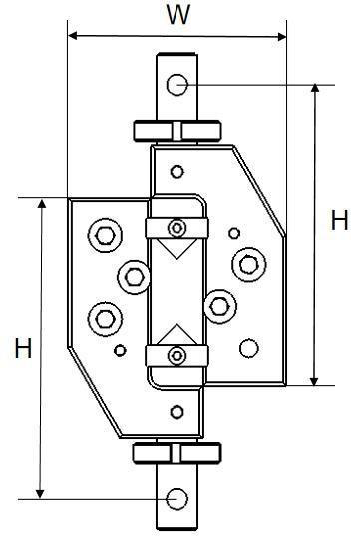

NGB204F – V-Notched Rail Shear Fixture

The NGB204F V-Notched Rail Shear Fixture is designed for precise shear property determination of fiber-reinforced composite materials. Compliant with ASTM D7078 and GB/T 28889, this fixture supports accurate clamping, consistent load distribution, and high-temperature resistance. Its robust construction is ideal for challenging composite testing environments, both in research and industrial quality control.

The NGB204F V-Notched Rail Shear Fixture is designed for precise shear property determination of fiber-reinforced composite materials. Compliant with ASTM D7078 and GB/T 28889, this fixture supports accurate clamping, consistent load distribution, and high-temperature resistance. Its robust construction is ideal for challenging composite testing environments, both in research and industrial quality control.

- Application: V-notched shear testing of composite laminates.

- Maximum Capacity: 20 kN.

- Standards: ASTM D7078, GB/T 28889.

- Working Temperature: -70°C to +350°C.

- Connection: Φ10 mm pin.

- Clamping Range: 1–6 mm.

Technical Specifications – NGB204F V-Notched Rail Shear Fixture

| Parameter | Specification |

|---|---|

| Application | Testing shear properties of unidirectional laminates or fabric fiber composites |

| Maximum Force | 20 kN |

| Fixture Weight | 3.6 kg |

| Height (Left) | 220 mm |

| Height (Right) | 206 mm |

| Grip Width (W) | 215 mm |

| Working Temperature | -70°C to +350°C |

| Standard | ASTM D5379 |

| Connection | Φ10 mm pin (upper and lower) |

| Clamping Range | 0–6 mm |

| Specimen Size | 76(L) × 19(W) × (3–4)(T) mm |

NGB204F – In-Plane Shear Fixture

The NGB204F In-Plane Shear Fixture is engineered for evaluating the in-plane shear strength and stiffness of fiber-reinforced composite materials. Compliant with GB/T 5258 Type C, it is suitable for high-precision material testing within a wide thermal range. Its compact yet robust design supports repeatable testing in research laboratories and composite manufacturing facilities.

The NGB204F In-Plane Shear Fixture is engineered for evaluating the in-plane shear strength and stiffness of fiber-reinforced composite materials. Compliant with GB/T 5258 Type C, it is suitable for high-precision material testing within a wide thermal range. Its compact yet robust design supports repeatable testing in research laboratories and composite manufacturing facilities.

- Application: In-plane shear testing of fiber-reinforced composites.

- Maximum Load: 20 kN.

- Operating Temperature: -70°C to +350°C.

- Standard Compliance: GB/T 5258 Type C.

- Specimen Size: 25 (L) × 25 (W) × 4–10 (T) mm.

Technical Specifications – NGB204F In-Plane Shear Fixture

| Parameter | Specification |

|---|---|

| Application | In-plane shear test for fiber-reinforced composite materials |

| Maximum Force | 20 kN |

| Weight | 5.9 kg |

| Height (H) | 145 mm |

| Grip Width (W) | 80 mm |

| Working Temperature | -70°C to +350°C |

| Standard | GB/T 5258 Type C |

| Specimen Size | 25(L) × 25(W) × 4–10(T) mm |

| Connection | Φ10 mm pin (upper and lower) |

| Clamping Range | 0–6 mm |

| Specimen Size | 76(L) × 19(W) × (3–4)(T) mm |

NGB204J – In-Plane Shear Fixture

The NGB204J In-Plane Shear Fixture is designed for precision testing of fiber-reinforced composite materials under in-plane shear conditions. Compliant with ASTM D695, it supports high-temperature applications and is suited for both research and production environments. Its lightweight construction allows for easy integration and handling across various testing systems.

The NGB204J In-Plane Shear Fixture is designed for precision testing of fiber-reinforced composite materials under in-plane shear conditions. Compliant with ASTM D695, it supports high-temperature applications and is suited for both research and production environments. Its lightweight construction allows for easy integration and handling across various testing systems.

- Application: In-plane shear testing of fiber-reinforced composites.

- Maximum Load Capacity: 20 kN.

- Operating Temperature Range: -70°C to +350°C.

- Standard Compliance: ASTM D695.

- Specimen Size: 75–80 (L) × 12.5 (W) × 2–6 (T) mm.

Technical Specifications – NGB204J In-Plane Shear Fixture

| Parameter | Specification |

|---|---|

| Application | In-plane shear test for fiber-reinforced composite materials |

| Maximum Force | 20 kN |

| Weight | 0.8 kg |

| Height (H) | 90 mm |

| Grip Width (W) | 60 mm |

| Working Temperature | -70°C to +350°C |

| Standard | ASTM D695 |

| Specimen Size | 75–80 (L) × 12.5 (W) × 2–6 (T) mm |

| Connection | Φ10 mm pin (upper and lower) |

| Clamping Range | 0–6 mm |

| Specimen Size | 76(L) × 19(W) × (3–4)(T) mm |

NGB304K – Wedge Compression Fixture

The NGB304K Wedge Compression Fixture is designed for in-plane compression testing of polymer matrix composites. Conforming to EN 2850 (Type A1) and ISO 14126 (Type A, Method 1), this fixture supports standardized evaluation of composite compressive behavior. Its compact and lightweight build allows for accurate testing under controlled ambient conditions.

The NGB304K Wedge Compression Fixture is designed for in-plane compression testing of polymer matrix composites. Conforming to EN 2850 (Type A1) and ISO 14126 (Type A, Method 1), this fixture supports standardized evaluation of composite compressive behavior. Its compact and lightweight build allows for accurate testing under controlled ambient conditions.

- Application: In-plane compression testing of polymer matrix composites.

- Maximum Load Capacity: 30 kN.

- Operating Temperature Range: 0°C to +40°C.

- Standard Compliance: EN 2850 (Type A1), ISO 14126 (Type A, Method 1).

- Specimen Size: 110 (L) × 10 (W) × 2 (T) mm.

Technical Specifications – NGB304K Wedge Compression Fixture

| Parameter | Specification |

|---|---|

| Application | In-plane compression test of polymer matrix composites |

| Maximum Force | 30 kN |

| Weight | 1.3 kg |

| Height (H) | 138 mm |

| Grip Width (W) | 60 mm |

| Working Temperature | 0°C to +40°C |

| Standard | EN 2850 (Type A1), ISO 14126 (Type A, Method 1) |

| Specimen Size | 110 (L) × 10 (W) × 2 (T) mm |

NGB202A – Floating Roller Peel Test Fixture

The NGB202A Floating Roller Peel Test Fixture is specifically engineered for peel testing of flexible adhesives and bonded structures in accordance with ASTM D3167. Rated for forces up to 200 N, it features precision alignment and a stable clamping system, making it ideal for evaluating the peel strength of sandwich panel facings, films, or composite layers. The fixture accommodates specimens up to 25.4 mm wide and supports ambient testing within 0°C–40°C.

The NGB202A Floating Roller Peel Test Fixture is specifically engineered for peel testing of flexible adhesives and bonded structures in accordance with ASTM D3167. Rated for forces up to 200 N, it features precision alignment and a stable clamping system, making it ideal for evaluating the peel strength of sandwich panel facings, films, or composite layers. The fixture accommodates specimens up to 25.4 mm wide and supports ambient testing within 0°C–40°C.

- Application: Peel strength testing of adhesive bonds and layered materials.

- Maximum Force Capacity: 200 N.

- Temperature Range: 0°C to 40°C.

- Standards: ASTM D3167.

- Clamping Range: ≤25.4 mm.

Technical Specifications – NGB202A Floating Roller Peel Test Fixture

| Parameter | Specification |

|---|---|

| Application | High suitability for peel testing applications |

| Maximum Force | 200 N |

| Weight (Upper Grip) | 0.6 kg |

| Weight (Lower Grip) | 0.5 kg |

| Height (Upper Grip) | 105 mm |

| Height (Lower Grip) | 95 mm |

| Grip Width (W) | 25.4 mm |

| Working Temperature | 0°C to 40°C |

| Standard | ASTM D3167 |

| Connection (Upper) | Φ10 mm pin |

| Connection (Lower) | Φ10 mm pin |

| Clamping Range | ≤25.4 mm |

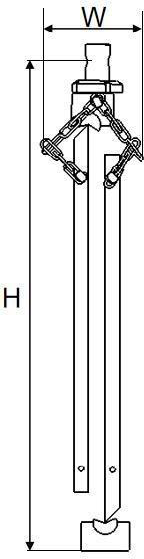

NGB303A – Climbing Drum Peel Test Fixture

The NGB303A Climbing Drum Peel Test Fixture is designed for evaluating the peel resistance of sandwich structures in compliance with ASTM D1781. With a force capacity of up to 3 kN, it features a Φ102 mm drum for controlled peeling, offering accurate data on adhesion performance in composite or layered materials. It operates within an ambient temperature range of 0°C to 40°C and connects via standard Φ10 mm pins.

The NGB303A Climbing Drum Peel Test Fixture is designed for evaluating the peel resistance of sandwich structures in compliance with ASTM D1781. With a force capacity of up to 3 kN, it features a Φ102 mm drum for controlled peeling, offering accurate data on adhesion performance in composite or layered materials. It operates within an ambient temperature range of 0°C to 40°C and connects via standard Φ10 mm pins.

- Application: Peel resistance testing of sandwich structures.

- Maximum Force Capacity: 3 kN.

- Drum Diameter: Φ102 mm.

- Standard: ASTM D1781.

- Operating Temperature: 0°C to 40°C.

Technical Specifications – NGB303A Climbing Drum Peel Test Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of the peel resistance of sandwich structure |

| Maximum Force | 3 kN |

| Weight (Upper Grip) | 0.7 kg |

| Weight (Lower Grip) | 0.4 kg |

| Height (Upper Grip) | 64 mm |

| Height (Lower Grip) | 48 mm |

| Grip Width (W) | 108 mm |

| Working Temperature | 0°C to 40°C |

| Standard | ASTM D1781 |

| Connection (Upper) | Φ10 mm pin |

| Connection (Lower) | Φ10 mm pin |

| Drum Diameter | Φ102 mm |

NGB303F – Climbing Drum Peel Test Fixture

The NGB303F Climbing Drum Peel Test Fixture is designed for accurate evaluation of peel resistance in sandwich structures, in accordance with GB/T 1457. With a maximum capacity of 3 kN, the fixture includes a Φ100 mm drum and standard Φ10 mm pin connections. This lightweight fixture supports testing under ambient conditions ranging from 0°C to 40°C, making it ideal for standard lab testing of bonded materials.

The NGB303F Climbing Drum Peel Test Fixture is designed for accurate evaluation of peel resistance in sandwich structures, in accordance with GB/T 1457. With a maximum capacity of 3 kN, the fixture includes a Φ100 mm drum and standard Φ10 mm pin connections. This lightweight fixture supports testing under ambient conditions ranging from 0°C to 40°C, making it ideal for standard lab testing of bonded materials.

- Application: Peel resistance testing for sandwich structures.

- Maximum Force: 3 kN.

- Standard: GB/T 1457.

- Drum Diameter: Φ100 mm.

- Working Temperature: 0°C to 40°C.

Technical Specifications – NGB303F Climbing Drum Peel Test Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of the peel resistance of sandwich structure |

| Maximum Force | 3 kN |

| Weight (Upper Grip) | 0.7 kg |

| Weight (Lower Grip) | 0.4 kg |

| Height (Upper Grip) | 64 mm |

| Height (Lower Grip) | 48 mm |

| Grip Width (W) | 108 mm |

| Working Temperature | 0°C to 40°C |

| Standard | GB/T 1457 |

| Connection (Upper) | Φ10 mm pin |

| Connection (Lower) | Φ10 mm pin |

| Drum Diameter | Φ100 mm |

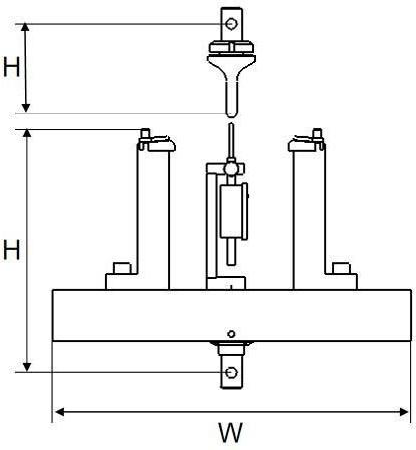

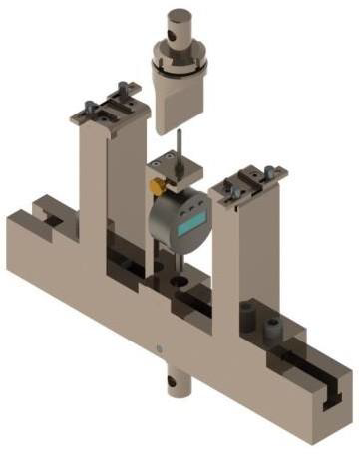

NGA104A – 3-Point Bending Fixture

The NGA104A 3-Point Bending Fixture is designed for precise flexural testing of polymer matrix composite materials and reinforced plastic specimens. Engineered to support ASTM and ISO standards, this fixture provides a stable and adjustable platform for three-point bending tests with high accuracy. It includes an upper loading nose and two support rollers, allowing users to vary the span from 10 to 200 mm. The fixture's durable structure and modular grip system make it ideal for standardized and repeatable bending tests in ambient conditions.

The NGA104A 3-Point Bending Fixture is designed for precise flexural testing of polymer matrix composite materials and reinforced plastic specimens. Engineered to support ASTM and ISO standards, this fixture provides a stable and adjustable platform for three-point bending tests with high accuracy. It includes an upper loading nose and two support rollers, allowing users to vary the span from 10 to 200 mm. The fixture's durable structure and modular grip system make it ideal for standardized and repeatable bending tests in ambient conditions.

- Application: Three-point bending tests of polymer matrix composite materials and reinforced plastic samples.

- Maximum Capacity: Up to 10 kN load.

- Weight: 0.5 kg (upper grip), 9.2 kg (lower grip).

- Dimensions: Height – 90 mm (upper grip), 232 mm (lower grip); Grip width – 340 mm.

- Working Temperature: 0°C to 40°C.

- Standards: ASTM D7264, ISO 14125, GB/T 9341.

- Connection Type: Φ10 mm pin mount (upper and lower), compatible with UTM fittings.

- Span (Adjustable): 10–200 mm, allowing flexibility for different specimen lengths.

- Loading Nose: R5 mm.

- Support Rollers: R2 and R5 mm sizes included.

Note: The bending deformation of the samples can be directly measured with an optional digital indicator and other devices.

Technical Specifications – NGA104A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Three-point bending test of polymer matrix composite materials and reinforced plastic samples |

| Maximum Force Capacity | 10 kN |

| Weight | Upper Grip: 0.5 kg Lower Grip: 9.2 kg |

| Height (H) | Upper Grip: 90 mm Lower Grip: 232 mm |

| Grip Width (W) | 340 mm |

| Working Temperature | 0°C–40°C |

| Standard | ASTM D7264, ISO 14125, GB/T 9341 |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Span (Adjustable) | 10–200 mm |

| Loading Nose | R5 mm |

| Support Roller | R2 mm, R5 mm |

NGA204D – Short-Beam Shear Test Fixture

The NGA204D Short-Beam Shear Test Fixture is purpose-built for evaluating the interlaminar shear strength of high-modulus fiber-reinforced composite materials. It features a compact structure with a rigid support system, capable of testing within a wide temperature range of -70°C to +350°C. This fixture is compatible with multiple international standards, offering adjustable span lengths and precise loading through a rounded nose. Its robust design makes it ideal for high-load applications in composite materials research and quality control.

The NGA204D Short-Beam Shear Test Fixture is purpose-built for evaluating the interlaminar shear strength of high-modulus fiber-reinforced composite materials. It features a compact structure with a rigid support system, capable of testing within a wide temperature range of -70°C to +350°C. This fixture is compatible with multiple international standards, offering adjustable span lengths and precise loading through a rounded nose. Its robust design makes it ideal for high-load applications in composite materials research and quality control.

- Application: Determination of interlaminar shear strength of high-modulus fiber-reinforced composite materials.

- Maximum Capacity: Up to 20 kN load.

- Weight: 8.9 kg.

- Dimensions: Height – 200 mm; Grip width – 260 mm.

- Working Temperature: -70°C to +350°C.

- Standards: ASTM D2344, ISO 14130, EN 2563, EN 2377, JC/T 773.

- Connection Type: Φ10 mm pin, compatible with standard universal testing machines.

- Specimen Width Compatibility: ≤ 40 mm.

- Span (Adjustable): 6 mm – 50 mm.

- Loading Nose Radius: R3 mm.

- Support Radius: R1.5 mm.

Technical Specifications – NGA204D Short-Beam Shear Test Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of interlaminar shear strength of high-modulus fiber-reinforced composite materials |

| Maximum Force Capacity | 20 kN |

| Weight | 8.9 kg |

| Height (H) | 200 mm |

| Grip Width (W) | 260 mm |

| Working Temperature | -70°C to +350°C |

| Standard | ASTM D2344, ISO 14130, EN 2563, EN 2377, JC/T 773 |

| Connection Type | Φ10 mm pin |

| Specimen Width | ≤ 40 mm |

| Span (Adjustable) | 6 mm – 50 mm |

| Loading Nose | R3 mm |

| Support | R1.5 mm |

Optional Spare Parts – NGA204D

| No. | Description | Radius |

|---|---|---|

| NGA204D-14 | Support roller 2 | R3 mm |

| NGA204D-15 | Loading nose | R5 mm |

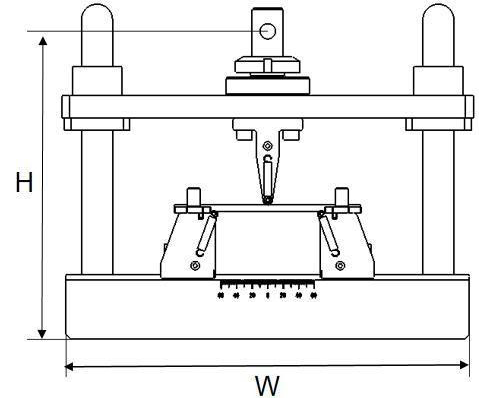

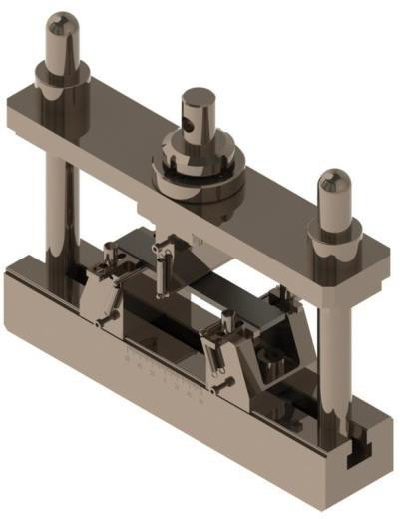

NGA204E – 3-Point Bending Fixture

The NGA204E 3-Point Bending Fixture is designed for shear testing of sandwich constructions made from composite materials. Built to comply with ASTM C393, this fixture supports high-load conditions and accommodates large specimen sizes. With adjustable span and optional digital indicators, the system enables accurate and repeatable flexural performance evaluation under standard ambient conditions.

The NGA204E 3-Point Bending Fixture is designed for shear testing of sandwich constructions made from composite materials. Built to comply with ASTM C393, this fixture supports high-load conditions and accommodates large specimen sizes. With adjustable span and optional digital indicators, the system enables accurate and repeatable flexural performance evaluation under standard ambient conditions.

- Application: Determination of shear properties of sandwich constructions of composite materials.

- Maximum Capacity: Up to 20 kN load.

- Weight: 1.4 kg (upper grip), 10.3 kg (lower grip).

- Dimensions: Height – 117 mm (upper grip), 240 mm (lower grip); Grip width – 200 mm.

- Working Temperature: 0°C to 40°C.

- Standard: ASTM C393.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Span (Adjustable): 150 mm.

- Recommended Specimen Size: 200 mm (L) × 75 mm (W).

Note: The bending deformation of the samples can be directly measured with an optional digital indicator and other devices.

Technical Specifications – NGA204E 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of shear properties of sandwich constructions of composite materials |

| Maximum Force Capacity | 20 kN |

| Weight | Upper Grip: 1.4 kg Lower Grip: 10.3 kg |

| Height (H) | Upper Grip: 117 mm Lower Grip: 240 mm |

| Grip Width (W) | 200 mm |

| Working Temperature | 0°C–40°C |

| Standard | ASTM C393 |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Span (Adjustable) | 150 mm |

| Specimen Size | 200 mm (L) × 75 mm (W) |

NGC204A – 3/4-Point Bending Fixture

The NGC204A 3/4-Point Bending Fixture is engineered for high-accuracy flexural testing of fiber-reinforced plastic composites. This system supports both three-point and four-point bending configurations, providing flexibility in standard-compliant testing. Designed for a wide range of spans and loads up to 20 kN, it includes precision-machined loading noses and support rollers to ensure stable, repeatable deformation measurements. Optional digital indicators can be integrated for enhanced precision.

The NGC204A 3/4-Point Bending Fixture is engineered for high-accuracy flexural testing of fiber-reinforced plastic composites. This system supports both three-point and four-point bending configurations, providing flexibility in standard-compliant testing. Designed for a wide range of spans and loads up to 20 kN, it includes precision-machined loading noses and support rollers to ensure stable, repeatable deformation measurements. Optional digital indicators can be integrated for enhanced precision.

- Application: Determination of flexural properties of fiber-reinforced plastic composites.

- Maximum Capacity: Up to 20 kN load.

- Weight: 7 kg.

- Dimensions: Height – 154 mm (upper grip), 220 mm (lower grip); Grip width – 310 mm.

- Working Temperature: 0°C to 40°C.

- Standards: ASTM D7264, ASTM D6272, ISO 14125.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Support Width: 40 mm.

- Upper Span Range: 30–200 mm.

- Lower Span Range: 30–280 mm.

- Loading Nose & Support Roller (3-point bending): R3 mm, R5 mm.

- Loading Nose & Support Roller (4-point bending): R3 mm.

Note: The bending deformation of the samples can be directly measured with an optional digital indicator and other devices.

Technical Specifications – NGC204A 3/4-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of flexural properties of fiber-reinforced plastic composites |

| Maximum Force Capacity | 20 kN |

| Weight | 7 kg |

| Height (H) | Upper Grip: 154 mm Lower Grip: 220 mm |

| Grip Width (W) | 310 mm |

| Working Temperature | 0°C–40°C |

| Standard | ASTM D7264, ASTM D6272, ISO 14125 |

| Support Width | 40 mm |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Upper Span | 30–200 mm |

| Lower Span | 30–280 mm |

| Loading Nose & Support (3-Point Bending) | R3 mm, R5 mm |

| Loading Nose & Support (4-Point Bending) | R3 mm |

Optional Spare Parts – NGC204A

| No. | Description | Radius |

|---|---|---|

| NGC204A-02 | Support | R2 mm |

| NGC204A-14 | Support roller | R2 mm |

NGB303A – Edgewise Compression Fixture

The NGB303A Edgewise Compression Fixture is engineered for testing the edgewise compressive strength of sandwich composite constructions. Designed in accordance with ASTM C364, this fixture offers reliable results under controlled ambient conditions. With symmetrical upper and lower grip designs, it supports uniform clamping and stable load application, making it ideal for lightweight composite structure evaluation.

The NGB303A Edgewise Compression Fixture is engineered for testing the edgewise compressive strength of sandwich composite constructions. Designed in accordance with ASTM C364, this fixture offers reliable results under controlled ambient conditions. With symmetrical upper and lower grip designs, it supports uniform clamping and stable load application, making it ideal for lightweight composite structure evaluation.

- Application: Determination of edgewise compressive strength of sandwich constructions of composite materials.

- Maximum Capacity: Up to 3 kN load.

- Weight: 0.9 kg (upper grip), 0.9 kg (lower grip).

- Dimensions: Height – 22 mm (upper and lower grip); Grip width – 150 mm.

- Working Temperature: 0°C to 40°C.

- Standard: ASTM C364.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Clamping Range: 0–40 mm.

- Specimen Size Compatibility: ≥ 40 mm (L) × ≤ 75 mm (W) × ≤ 40 mm (T).

Technical Specifications – NGB303A Edgewise Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of edgewise compressive strength of sandwich composite constructions |

| Maximum Force Capacity | 3 kN |

| Weight | Upper Grip: 0.9 kg Lower Grip: 0.9 kg |

| Height (H) | Upper Grip: 22 mm Lower Grip: 22 mm |

| Grip Width (W) | 150 mm |

| Working Temperature | 0°C–40°C |

| Standard | ASTM C364 |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Clamping Range | 0–40 mm |

| Specimen Size | ≥ 40 mm (L) × ≤ 75 mm (W) × ≤ 40 mm (T) |

NGB204A – Wedge Compression Fixture

The NGB204A Wedge Compression Fixture is purpose-built for evaluating the compressive properties of polymer matrix composite materials. Compliant with ASTM D3410 and GB/T 5258 Type A2 standards, the fixture features a secure wedge-type design that enables precise alignment and strong clamping of specimens. It accommodates demanding temperature ranges and offers compatibility with a range of specimen dimensions for standardized material testing.

The NGB204A Wedge Compression Fixture is purpose-built for evaluating the compressive properties of polymer matrix composite materials. Compliant with ASTM D3410 and GB/T 5258 Type A2 standards, the fixture features a secure wedge-type design that enables precise alignment and strong clamping of specimens. It accommodates demanding temperature ranges and offers compatibility with a range of specimen dimensions for standardized material testing.

- Application: Determination of compressive properties of polymer matrix composite materials.

- Maximum Capacity: Up to 20 kN load.

- Weight: 9.2 kg.

- Dimensions: Height – 200 mm; Grip width – 115 mm.

- Working Temperature: -70°C to +350°C.

- Standards: ASTM D3410, GB/T 5258 Type A2.

- Clamping Range: 0–8 mm.

- Recommended Specimen Sizes:

- 140 mm (L) × 12 mm (W) × 1–2 mm (T)

- 110 mm (L) × 10 mm (W) × 2 mm (T)

Technical Specifications – NGB204A Wedge Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of compressive properties of polymer matrix composite materials |

| Maximum Force Capacity | 20 kN |

| Weight | 9.2 kg |

| Height (H) | 200 mm |

| Grip Width (W) | 115 mm |

| Working Temperature | -70°C to +350°C |

| Standard | ASTM D3410, GB/T 5258 Type A2 |

| Clamping Range | 0–8 mm |

| Specimen Size | 140 mm (L) × 12 mm (W) × 1–2 mm (T) 110 mm (L) × 10 mm (W) × 2 mm (T) |

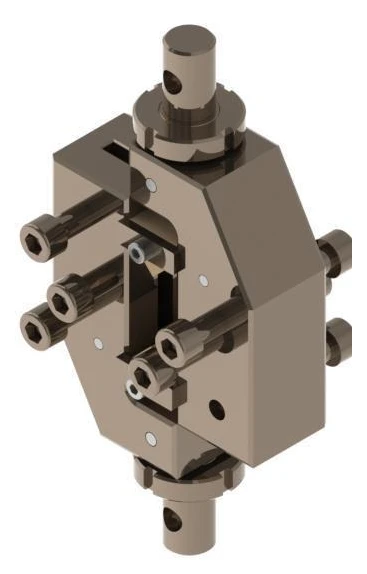

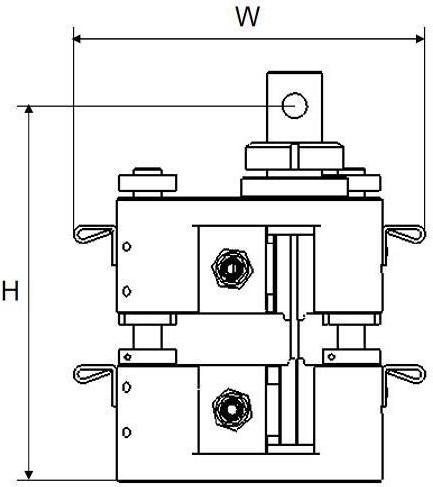

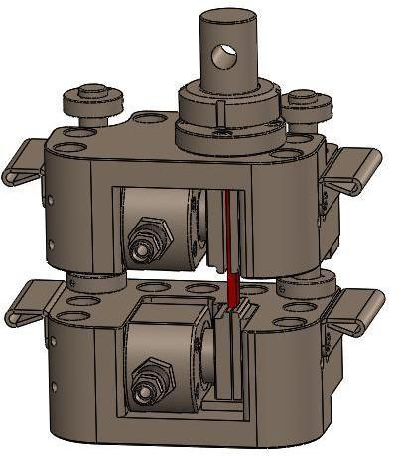

NGB105A – Hydraulic Compression Fixture

The NGB105A Hydraulic Compression Fixture is a high-force testing tool specifically designed for the compressive strength evaluation of polymer matrix composite materials. Compliant with major international standards, this heavy-duty fixture accommodates up to 100 kN force and features robust Φ18 mm pin connections. Its solid construction and integrated flat jaws offer secure clamping for medium-sized composite specimens, making it ideal for routine and advanced mechanical testing in ambient conditions.

The NGB105A Hydraulic Compression Fixture is a high-force testing tool specifically designed for the compressive strength evaluation of polymer matrix composite materials. Compliant with major international standards, this heavy-duty fixture accommodates up to 100 kN force and features robust Φ18 mm pin connections. Its solid construction and integrated flat jaws offer secure clamping for medium-sized composite specimens, making it ideal for routine and advanced mechanical testing in ambient conditions.

- Application: Determination of compressive properties of polymer matrix composite materials.

- Maximum Capacity: Up to 100 kN load.

- Weight: 29 kg.

- Dimensions: Height – 275 mm; Grip width – 260 mm.

- Working Temperature: 0°C to 40°C.

- Standards: ASTM D6641, ASTM D3410, ISO 14126 (Methods 1 & 2), GB/T 5258 (Specimen 1).

- Connection Type: Φ18 mm pin.

- Flat Jaw Range: 4–8 mm.

- Specimen Hardness: Less than HRC24.

Technical Specifications – NGB105A Hydraulic Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of compressive properties of polymer matrix composite materials |

| Maximum Force Capacity | 100 kN |

| Weight | 29 kg |

| Height (H) | 275 mm |

| Grip Width (W) | 260 mm |

| Working Temperature | 0°C–40°C |

| Standard | ASTM D6641, ASTM D3410, ISO 14126 (Method 1, 2), GB/T 5258 (Specimen 1) |

| Connection Type | Φ18 mm pin |

| Flat Jaw Range | 4–8 mm |

| Specimen Hardness | Less than HRC24 |

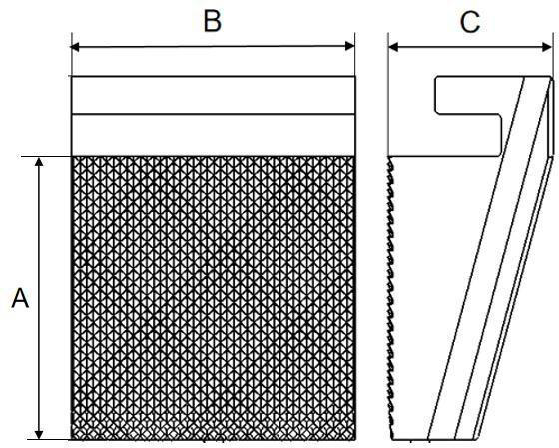

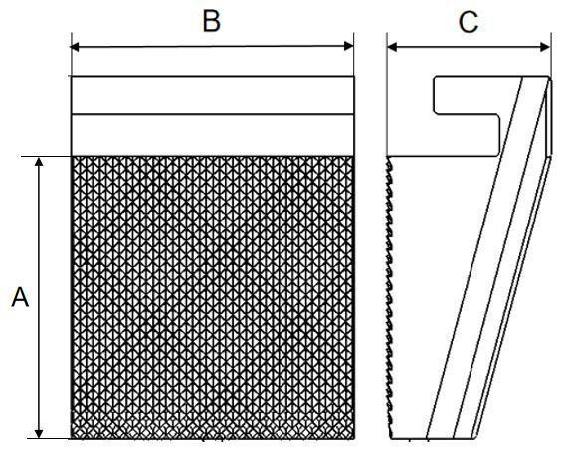

Optional Jaw Faces – NGB105A

| No. | Description | Height A (mm) | Width B (mm) | Thickness C (mm) | Specimen Width D (mm) |

|---|---|---|---|---|---|

| NGB105A-08 | Fixed jaw face 2 | 63.5 | 40 | 12 | 10 |

| NGB105A-09 | Fixed jaw face 3 | 63.5 | 40 | 12 | 12 |

NGA105G – Compression Fixture

The NGA105G Compression Fixture is designed for high-precision compression testing of composite materials under controlled laboratory conditions. With a force capacity of up to 100 kN and a spherical seat design for self-alignment, this fixture ensures accurate load distribution across the specimen. It features dual Φ18 mm pin connections and a compact structure, making it ideal for integration with standard universal testing machines.

The NGA105G Compression Fixture is designed for high-precision compression testing of composite materials under controlled laboratory conditions. With a force capacity of up to 100 kN and a spherical seat design for self-alignment, this fixture ensures accurate load distribution across the specimen. It features dual Φ18 mm pin connections and a compact structure, making it ideal for integration with standard universal testing machines.

- Application: Compression testing of composite materials.

- Maximum Capacity: Up to 100 kN load.

- Weight: 3.3 kg (upper grip), 3.3 kg (lower grip).

- Dimensions: Height – 85 mm (upper grip), 96 mm (lower grip); Grip width – Φ100 mm.

- Spherical Seat: Included (Yes).

- Working Temperature: 0°C to 40°C.

- Connection Type: Φ18 mm pin (upper and lower grips).

Note: The compression deformation of the samples can be directly measured with optional digital indicators and other devices.

Technical Specifications – NGA105G Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Compression test for composite materials |

| Maximum Force Capacity | 100 kN |

| Weight | Upper Grip: 3.3 kg Lower Grip: 3.3 kg |

| Height (H) | Upper Grip: 85 mm Lower Grip: 96 mm |

| Grip Width (W) | Φ100 mm |

| With Spherical Seat | Yes |

| Working Temperature | 0°C–40°C |

| Connection Type | Upper Grip: Φ18 mm pin Lower Grip: Φ18 mm pin |

NGB204H – In-Plane Compression Fixture

The NGB204H In-Plane Compression Fixture is designed to evaluate the in-plane compressive strength of fiber-reinforced plastics. With its compact design and compatibility with GB/T 5258 standards, this fixture is ideal for assessing material resistance under compressive stress in elevated temperatures. The fixture accommodates standard rectangular specimens and offers dependable performance in controlled environments.

The NGB204H In-Plane Compression Fixture is designed to evaluate the in-plane compressive strength of fiber-reinforced plastics. With its compact design and compatibility with GB/T 5258 standards, this fixture is ideal for assessing material resistance under compressive stress in elevated temperatures. The fixture accommodates standard rectangular specimens and offers dependable performance in controlled environments.

- Application: Determination of in-plane compression properties of fiber-reinforced plastic materials.

- Maximum Capacity: Up to 20 kN load.

- Weight: 3.9 kg.

- Dimensions: Height – 110 mm; Grip width – 101 mm.

- Working Temperature: Ambient to 80°C.

- Standard: GB/T 5258.

- Recommended Specimen Size: 110 mm (L) × 10 mm (W) × 2–10 mm (T).

Technical Specifications – NGB204H In-Plane Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of in-plane compression properties of fiber-reinforced plastic |

| Maximum Force Capacity | 20 kN |

| Weight | 3.9 kg |

| Height (H) | 110 mm |

| Grip Width (W) | 101 mm |

| Working Temperature | Ambient–80°C |

| Standard | GB/T 5258 |

| Specimen Size | 110 mm (L) × 10 mm (W) × 2–10 mm (T) |

NGB204I – Compression Fixture

The NGB204I Compression Fixture is developed for testing the compressive strength of polymer matrix composite materials under a wide temperature range. With compliance to ASTM D6641, this fixture provides secure clamping, a stable base, and excellent thermal endurance for demanding testing environments. It supports specimens of standard dimensions and is well-suited for quality assurance and R&D applications.

The NGB204I Compression Fixture is developed for testing the compressive strength of polymer matrix composite materials under a wide temperature range. With compliance to ASTM D6641, this fixture provides secure clamping, a stable base, and excellent thermal endurance for demanding testing environments. It supports specimens of standard dimensions and is well-suited for quality assurance and R&D applications.

- Application: Determination of compressive properties of polymer matrix composite materials.

- Maximum Capacity: Up to 20 kN load.

- Weight: 5.2 kg.

- Dimensions: Height – 140 mm; Grip width – 100 mm.

- Working Temperature: -70°C to +350°C.

- Standard: ASTM D6641.

- Recommended Specimen Size: 140 mm (L) × 12 mm (W) × 1–4 mm (T).

- Clamping Range: 0–12.7 mm.

Technical Specifications – NGB204I Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of compressive properties of polymer matrix composite materials |

| Maximum Force Capacity | 20 kN |

| Weight | 5.2 kg |

| Height (H) | 140 mm |

| Grip Width (W) | 100 mm |

| Working Temperature | -70°C to +350°C |

| Standard | ASTM D6641 |

| Specimen Size | 140 mm (L) × 12 mm (W) × 1–4 mm (T) |

| Clamping Range | 0–12.7 mm |

NGA104A – Open-Hole Compression Fixture

The NGA104A Open-Hole Compression Fixture is developed for testing the open-hole compressive strength of polymer matrix composite specimens. Designed in accordance with ASTM D5961 and ASTM D6484 standards, the fixture supports testing under extreme temperature conditions and accommodates standardized rectangular specimens. Its durable structure and reliable performance make it ideal for high-precision aerospace and structural testing applications.

The NGA104A Open-Hole Compression Fixture is developed for testing the open-hole compressive strength of polymer matrix composite specimens. Designed in accordance with ASTM D5961 and ASTM D6484 standards, the fixture supports testing under extreme temperature conditions and accommodates standardized rectangular specimens. Its durable structure and reliable performance make it ideal for high-precision aerospace and structural testing applications.

- Application: Determination of open-hole compressive strength of polymer matrix composite materials.

- Maximum Capacity: ≤ 10 kN load.

- Weight: 4.8 kg.

- Dimensions: Height – 300 mm; Grip width – 100 mm.

- Working Temperature: -70°C to +350°C.

- Standards: ASTM D5961, ASTM D6484.

- Recommended Specimen Size: 300 mm (L) × 36 mm (W) × 4 mm (T).

Technical Specifications – NGA104A Open-Hole Compression Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of open-hole compressive strength of polymer matrix composite |

| Maximum Force Capacity | ≤ 10 kN |

| Weight | 4.8 kg |

| Height (H) | 300 mm |

| Grip Width (W) | 100 mm |

| Working Temperature | -70°C to +350°C |

| Standard | ASTM D5961, ASTM D6484 |

| Specimen Size | 300 mm (L) × 36 mm (W) × 4 mm (T) |

| Clamping Range | 0–12.7 mm |

NGB104A – Compression Fixture After Impact

The NGB104A Compression Fixture After Impact is specifically designed to measure the residual compressive strength of polymer matrix composite plates following impact. It conforms to ASTM D7137 and is optimized for evaluating damage tolerance and post-impact performance under extreme temperature conditions. The fixture accommodates large specimens and offers a secure clamping range suitable for high-reliability strength assessment.

The NGB104A Compression Fixture After Impact is specifically designed to measure the residual compressive strength of polymer matrix composite plates following impact. It conforms to ASTM D7137 and is optimized for evaluating damage tolerance and post-impact performance under extreme temperature conditions. The fixture accommodates large specimens and offers a secure clamping range suitable for high-reliability strength assessment.

- Application: Determination of compressive residual strength properties of damaged polymer matrix composite plates.

- Maximum Capacity: ≤ 10 kN load.

- Weight: 1.8 kg (upper grip), 9.5 kg (lower grip).

- Dimensions: Height – 95 mm (upper grip), 160 mm (lower grip); Grip width – 350 mm.

- Working Temperature: -70°C to +350°C.

- Standard: ASTM D7137.

- Recommended Specimen Size: 150 mm (H) × 100 mm (W) × 4–6 mm (T).

- Clamping Range: 0–18 mm.

Technical Specifications – NGB104A Compression Fixture After Impact

| Parameter | Specification |

|---|---|

| Application | Determination of compressive residual strength of damaged polymer composite plates |

| Maximum Force Capacity | ≤ 10 kN |

| Weight | Upper Grip: 1.8 kg Lower Grip: 9.5 kg |

| Height (H) | Upper Grip: 95 mm Lower Grip: 160 mm |

| Grip Width (W) | 350 mm |

| Working Temperature | -70°C to +350°C |

| Standard | ASTM D7137 |

| Specimen Size | 150 mm (H) × 100 mm (W) × 4–6 mm (T) |

| Clamping Range | 0–18 mm |

NGP502E – Puncture Fixture

The NGP502E Puncture Fixture is engineered for evaluating the puncture resistance of carbon fiber-reinforced plastic materials under controlled force and temperature conditions. Designed for use with Φ12 mm probes and large-diameter specimens, this fixture supports high-precision puncture testing up to 500 N in accordance with demanding environmental ranges. Its robust design accommodates a wide specimen range with consistent results across varying thicknesses.

The NGP502E Puncture Fixture is engineered for evaluating the puncture resistance of carbon fiber-reinforced plastic materials under controlled force and temperature conditions. Designed for use with Φ12 mm probes and large-diameter specimens, this fixture supports high-precision puncture testing up to 500 N in accordance with demanding environmental ranges. Its robust design accommodates a wide specimen range with consistent results across varying thicknesses.

- Application: Determination of puncture resistance for carbon fiber-reinforced plastic materials.

- Maximum Capacity: ≤ 500 N load.

- Weight: 8.5 kg.

- Dimensions: Height – 126 mm (upper grip), 155 mm (lower grip); Grip width – 250 mm.

- Working Temperature: -70°C to +350°C.

- Connection Type: Φ10 mm pin (upper and lower grips).

- Specimen Diameter: ≤ 250 mm.

- Specimen Thickness: 0–18 mm.

- Probe Diameter: Φ12 mm.

Technical Specifications – NGP502E Puncture Fixture

| Parameter | Specification |

|---|---|

| Application | Determination of puncture resistance for carbon fiber-reinforced plastic |

| Maximum Force Capacity | ≤ 500 N |

| Weight | 8.5 kg |

| Height (H) | Upper Grip: 126 mm Lower Grip: 155 mm |

| Grip Width (W) | 250 mm |

| Working Temperature | -70°C to +350°C |

| Connection Type | Upper Grip: Φ10 mm pin Lower Grip: Φ10 mm pin |

| Specimen Diameter | ≤ 250 mm |

| Specimen Thickness | 0–18 mm |

| Probe Diameter | Φ12 mm |

NextGen’s extensive suite of composite grips and fixtures ensures precision, consistency, and compliance in universal testing machine applications. Whether performing routine quality assurance or advanced failure analysis, our catalog supports every major composite testing protocol. Contact our technical sales team to configure the ideal testing solution for your lab or production floor.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.