Metal Testing Equipment

3-Point and Marker Bending Fixtures for Flexural Testing

NextGen's bending fixtures are engineered for precision flexural testing of various materials, including thermoplastics, composites, metals, and laminated structures. Designed to operate with NG-EML and SHM Universal Testing Machines, these fixtures offer compliant and repeatable setups for standardized 3-point and marker bending tests.

Supported testing standards include:

- ASTM D790 (Flexural Properties of Plastics)

- ISO 178 (Plastics – Flexural Properties)

- ISO 14125 (Fiber-Reinforced Plastic Composites)

- ASTM E290 (Bend Testing for Ductility)

- GB/T 9341 (Flexural Properties of Plastics)

Fixtures are available in multiple capacities, support spans, and loading configurations, allowing labs to perform accurate testing in compliance with global standards.

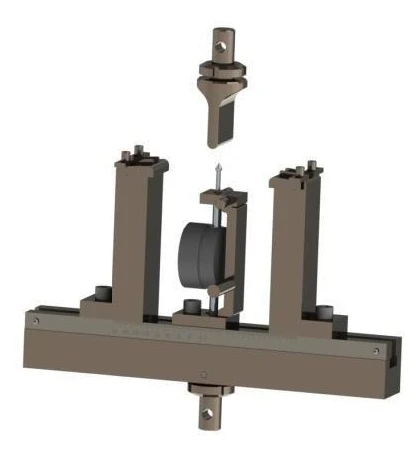

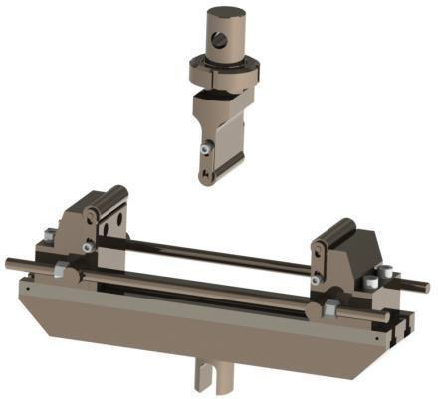

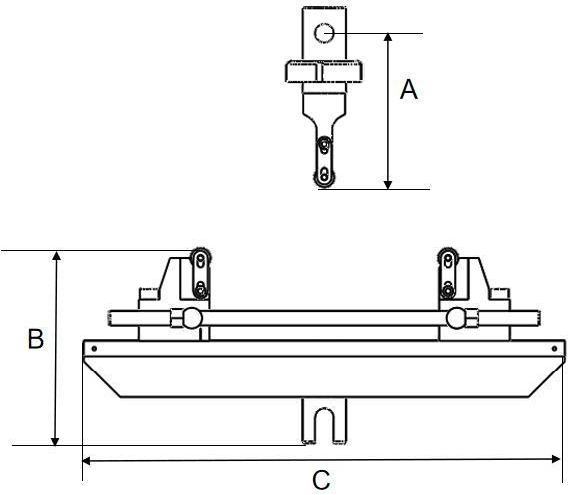

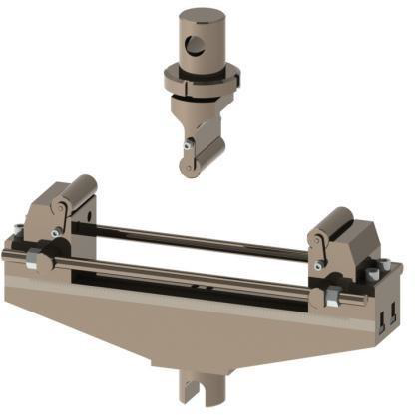

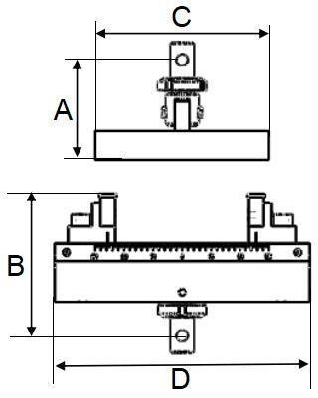

NGA204A – 3-Point Bending Fixture

The NGA204A 3-Point Bending Fixture is designed for accurate flexural testing of a wide range of materials including plastics, alloys, composites, and ceramics. Built to support forces up to 20 kN, this fixture features an adjustable span up to 200 mm, making it suitable for various specimen sizes. The system includes interchangeable loading noses and support rollers, allowing customization for specific test standards and applications. With high stability and robust construction, NGA204A delivers consistent, repeatable results across quality control and research environments.

The NGA204A 3-Point Bending Fixture is designed for accurate flexural testing of a wide range of materials including plastics, alloys, composites, and ceramics. Built to support forces up to 20 kN, this fixture features an adjustable span up to 200 mm, making it suitable for various specimen sizes. The system includes interchangeable loading noses and support rollers, allowing customization for specific test standards and applications. With high stability and robust construction, NGA204A delivers consistent, repeatable results across quality control and research environments.

- Application: Bending tests for plastic, alloy, composite, ceramic, and other rigid materials.

- Maximum Capacity: Up to 20 kN load.

- Connection: Ø10 mm pin mount (upper and lower), compatible with standard UTMs.

- Dimensions: Height 85 mm; Grip body width 157 mm; Overall width 231 mm.

- Span: Adjustable up to 200 mm.

- Specimen Range: Supports specimens up to 30 mm wide.

- Loading Nose: R5 (customizable).

- Support Roller: R2, R5 (customizable).

- Grip Weight: 0.5 kg (upper grip), 5.3 kg (lower grip).

- Working Temperature: Ambient.

- Note: NextGen can provide various loading noses and support rollers according to client requirements.

Technical Specifications – NGA204A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for plastic, alloy, composite, ceramic, etc. |

| Maximum Force Capacity | ≤ 20 kN |

| Connection Type | Upper Grip: Ø10 mm pin Lower Grip: Ø10 mm pin |

| Span (Adjustable) | ≤ 200 mm |

| Overall Height (A) | 85 mm |

| Grip Body Width (B) | 157 mm |

| Overall Width (C) | 231 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 0.5 kg Lower Grip: 5.3 kg |

| Compatible Specimen Width | ≤ 30 mm |

| Loading Nose | R5 (custom options available) |

| Support Roller | R2, R5 (custom options available) |

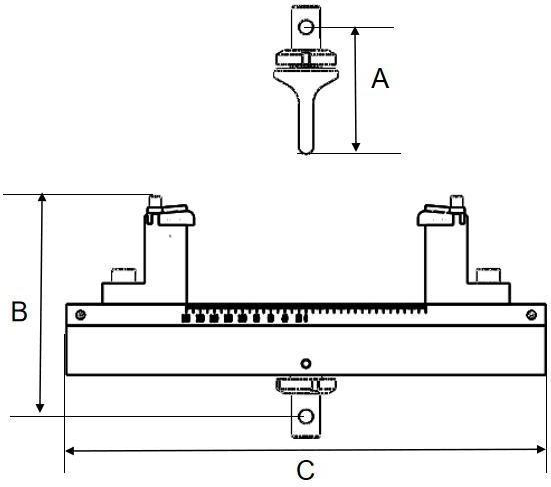

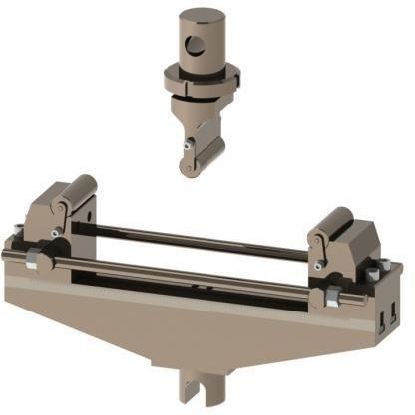

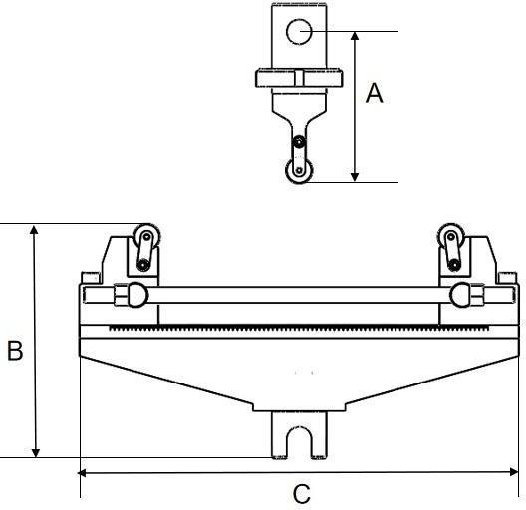

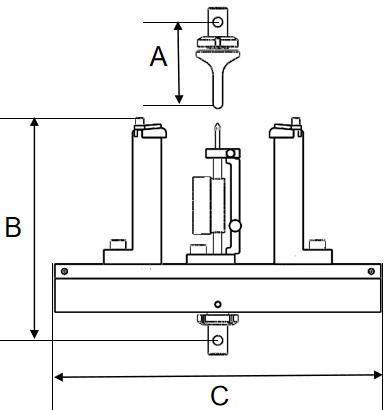

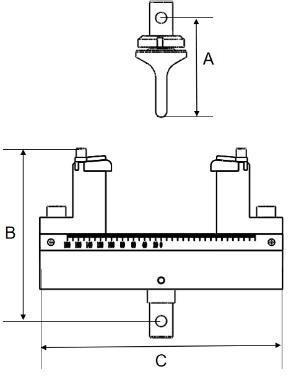

NGA504A – 3-Point Bending Fixture

The NGA504A 3-Point Bending Fixture is a heavy-duty solution for flexural testing of high-strength materials, including metals, advanced composites, ceramics, and construction-grade materials. Built to handle forces up to 50 kN, it features an adjustable span up to 280 mm, with a robust steel body designed for long-term reliability. The fixture includes Ø20 mm loading and support rollers, with the flexibility to accommodate various roller sizes upon request. The NGA504A is ideal for structural material evaluation in demanding industrial and research environments.

The NGA504A 3-Point Bending Fixture is a heavy-duty solution for flexural testing of high-strength materials, including metals, advanced composites, ceramics, and construction-grade materials. Built to handle forces up to 50 kN, it features an adjustable span up to 280 mm, with a robust steel body designed for long-term reliability. The fixture includes Ø20 mm loading and support rollers, with the flexibility to accommodate various roller sizes upon request. The NGA504A is ideal for structural material evaluation in demanding industrial and research environments.

- Application: Bending tests for metal, alloy, composite, ceramic, and structural materials.

- Maximum Capacity: Up to 50 kN load.

- Connection: Ø18 mm pin mount (upper and lower), suitable for heavy-load UTMs.

- Dimensions: Height 123 mm; Grip body width 190 mm; Overall width 400 mm.

- Span: Adjustable up to 280 mm.

- Specimen Range: Accommodates specimens up to 80 mm wide.

- Rollers: Ø20 mm loading and support rollers (custom sizes available).

- Grip Weight: 2.5 kg (upper grip), 18.5 kg (lower grip).

- Working Temperature: Ambient.

- Note: NextGen can provide various loading and support rollers according to client requirements.

Technical Specifications – NGA504A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for metal, alloy, composite, ceramic, construction material etc. |

| Maximum Force Capacity | ≤ 50 kN |

| Connection Type | Upper Grip: Ø18 mm pin Lower Grip: Ø18 mm pin |

| Span (Adjustable) | ≤ 280 mm |

| Overall Height (A) | 123 mm |

| Grip Body Width (B) | 190 mm |

| Overall Width (C) | 400 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 2.5 kg Lower Grip: 18.5 kg |

| Compatible Specimen Width | ≤ 80 mm |

| Loading Roller | Ø20 mm |

| Support Roller | Ø20 mm |

NGA105A – 3-Point Bending Fixture

The NGA105A 3-Point Bending Fixture is a high-capacity fixture engineered for flexural testing of strong and rigid materials, including metal, ceramic, composite, and construction materials. With a load capacity of up to 100 kN and an adjustable span up to 340 mm, it is ideal for evaluating large specimens and high-strength materials under demanding testing conditions. The system features Ø20 mm loading and support rollers, with custom roller options available upon request. Designed for compatibility with high-force universal testing machines, NGA105A delivers robust and repeatable performance in both industrial and laboratory settings.

The NGA105A 3-Point Bending Fixture is a high-capacity fixture engineered for flexural testing of strong and rigid materials, including metal, ceramic, composite, and construction materials. With a load capacity of up to 100 kN and an adjustable span up to 340 mm, it is ideal for evaluating large specimens and high-strength materials under demanding testing conditions. The system features Ø20 mm loading and support rollers, with custom roller options available upon request. Designed for compatibility with high-force universal testing machines, NGA105A delivers robust and repeatable performance in both industrial and laboratory settings.

- Application: Bending tests for metal, alloy, composite, ceramic, and structural materials.

- Maximum Capacity: Up to 100 kN load.

- Connection: Ø18 mm pin mount (upper and lower), built for high-load test frames.

- Dimensions: Height 145 mm; Grip body width 190 mm; Overall width 464 mm.

- Span: Adjustable up to 340 mm.

- Specimen Range: Supports specimens up to 80 mm wide.

- Rollers: Ø20 mm loading and support rollers (customizable).

- Grip Weight: 2.5 kg (upper grip), 20.6 kg (lower grip).

- Working Temperature: Ambient.

- Note: NextGen can provide various loading and support rollers according to client requirements.

Technical Specifications – NGA105A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for metal, alloy, composite, ceramic, construction material etc. |

| Maximum Force Capacity | ≤ 100 kN |

| Connection Type | Upper Grip: Ø18 mm pin Lower Grip: Ø18 mm pin |

| Span (Adjustable) | ≤ 340 mm |

| Overall Height (A) | 145 mm |

| Grip Body Width (B) | 190 mm |

| Overall Width (C) | 464 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 2.5 kg Lower Grip: 20.6 kg |

| Compatible Specimen Width | ≤ 80 mm |

| Loading Roller | Ø20 mm |

| Support Roller | Ø20 mm |

NGA305A – 3-Point Bending Fixture

The NGA305A 3-Point Bending Fixture is built for high-capacity flexural testing of tough and dense materials, such as metals, ceramics, composites, and structural-grade construction materials. With a maximum force capacity of 300 kN and a span adjustable up to 400 mm, it is designed to handle demanding test conditions and large specimen sizes. The system features Ø30 mm loading and support rollers and offers customization options to suit specific standards. With an extremely durable construction and precise alignment, the NGA305A is a reliable solution for advanced material testing.

- Application: Bending tests for metal, alloy, composite, ceramic, and construction materials.

- Maximum Capacity: Up to 300 kN load.

- Connection: Ø18 mm pin mount (upper and lower), compatible with heavy-duty universal testing machines.

- Dimensions: Height 156 mm; Grip body width 267 mm; Overall width 500 mm.

- Span: Adjustable up to 400 mm.

- Specimen Range: Supports specimens up to 90 mm wide.

- Rollers: Ø30 mm loading and support rollers (customizable).

- Grip Weight: 6.0 kg (upper grip), 36.0 kg (lower grip).

- Working Temperature: Ambient.

- Note: NextGen can provide various loading and support rollers according to client requirements.

Technical Specifications – NGA305A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for metal, alloy, composite, ceramic, construction material etc. |

| Maximum Force Capacity | ≤ 300 kN |

| Connection Type | Upper Grip: Ø18 mm pin Lower Grip: Ø18 mm pin |

| Span (Adjustable) | ≤ 400 mm |

| Overall Height (A) | 156 mm |

| Grip Body Width (B) | 267 mm |

| Overall Width (C) | 500 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 6.0 kg Lower Grip: 36.0 kg |

| Compatible Specimen Width | ≤ 90 mm |

| Loading Roller | Ø30 mm |

| Support Roller | Ø30 mm |

NGA104A – 3-Point Bending Fixture

The NGA104A 3-Point Bending Fixture is a precise and lightweight system developed for low-force bending tests on plastics, alloys, ceramics, and composite materials. With a force capacity of up to 10 kN and an adjustable span up to 200 mm, it is ideal for testing smaller specimens with accuracy. The fixture includes Ø5 mm loading and support rollers and is equipped with a digital indicator to measure specimen deformation during testing. Compact yet capable, the NGA104A is well-suited for research, education, and quality control environments.

The NGA104A 3-Point Bending Fixture is a precise and lightweight system developed for low-force bending tests on plastics, alloys, ceramics, and composite materials. With a force capacity of up to 10 kN and an adjustable span up to 200 mm, it is ideal for testing smaller specimens with accuracy. The fixture includes Ø5 mm loading and support rollers and is equipped with a digital indicator to measure specimen deformation during testing. Compact yet capable, the NGA104A is well-suited for research, education, and quality control environments.

- Application: Bending tests for plastic, alloy, composite, ceramic, and structural materials.

- Maximum Capacity: Up to 10 kN load.

- Connection: Ø10 mm pin mount (upper and lower), suitable for small-frame universal testing machines.

- Dimensions: Height 90 mm; Grip body width 230 mm; Overall width 340 mm.

- Span: Adjustable up to 200 mm.

- Specimen Range: Supports specimens up to 90 mm wide.

- Rollers: Ø5 mm loading and support rollers.

- Grip Weight: 0.5 kg (upper grip), 9.7 kg (lower grip).

- Working Temperature: Ambient.

- Note: Equipped with digital indicator to measure deformation of the specimen during test.

Technical Specifications – NGA104A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for plastic, alloy, composite, ceramic, construction material etc. |

| Maximum Force Capacity | ≤ 10 kN |

| Connection Type | Upper Grip: Ø10 mm pin Lower Grip: Ø10 mm pin |

| Span (Adjustable) | ≤ 200 mm |

| Overall Height (A) | 90 mm |

| Grip Body Width (B) | 230 mm |

| Overall Width (C) | 340 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 0.5 kg Lower Grip: 9.7 kg |

| Compatible Specimen Width | ≤ 90 mm |

| Loading Nose | R5 |

| Support Roller | R5 |

| Additional Feature | Equipped with digital indicator to measure deformation during test |

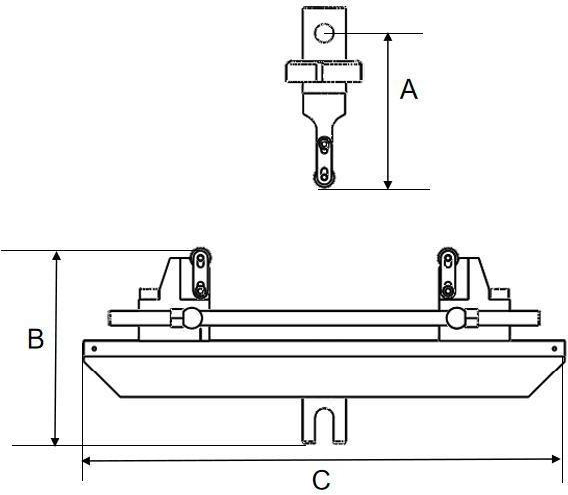

NGA104B – 3-Point Bending Fixture

The NGA104B 3-Point Bending Fixture is specially designed for low-force flexural testing of ceramic tile adhesive specimens. With a load capacity of up to 10 kN and a fixed 200 mm span, it supports standardized evaluation of bonding performance and durability. This fixture accommodates specimens with dimensions commonly used in tile adhesive testing and is equipped with R50×60 mm loading and support rollers to ensure stable and even load application. The NGA104B provides dependable performance in laboratory environments requiring precise mechanical testing of bonding materials.

The NGA104B 3-Point Bending Fixture is specially designed for low-force flexural testing of ceramic tile adhesive specimens. With a load capacity of up to 10 kN and a fixed 200 mm span, it supports standardized evaluation of bonding performance and durability. This fixture accommodates specimens with dimensions commonly used in tile adhesive testing and is equipped with R50×60 mm loading and support rollers to ensure stable and even load application. The NGA104B provides dependable performance in laboratory environments requiring precise mechanical testing of bonding materials.

- Application: Bending tests for adhesive of ceramic tiles.

- Maximum Capacity: Up to 10 kN load.

- Connection: Ø10 mm pin mount (upper and lower), compatible with standard UTMs.

- Dimensions: Height 150 mm; Grip body width 170 mm; Overall width 260 mm.

- Span: Fixed at 200 mm.

- Specimen Size: Supports standard sizes such as 280×45×5 mm and 300×45×3 mm.

- Rollers: R50×60 mm loading and support rollers.

- Grip Weight: 2.6 kg (upper grip), 6.0 kg (lower grip).

- Working Temperature: Ambient.

Technical Specifications – NGA104B 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for adhesive of ceramic tile |

| Maximum Force Capacity | ≤ 10 kN |

| Connection Type | Upper Grip: Ø10 mm pin Lower Grip: Ø10 mm pin |

| Span (Adjustable) | ≤ 200 mm (Fixed span used: 200 mm) |

| Overall Height (A) | 150 mm |

| Grip Body Width (B) | 170 mm |

| Overall Width (C) | 260 mm |

| Working Temperature | Ambient |

| Grip Weight | Upper Grip: 2.6 kg Lower Grip: 6.0 kg |

| Specimen Size | 280×45×5 mm and 300×45×3 mm (L×W×T) |

| Loading Nose | R50×60 mm |

| Support Roller | R50×60 mm |

| Span | 200 mm |

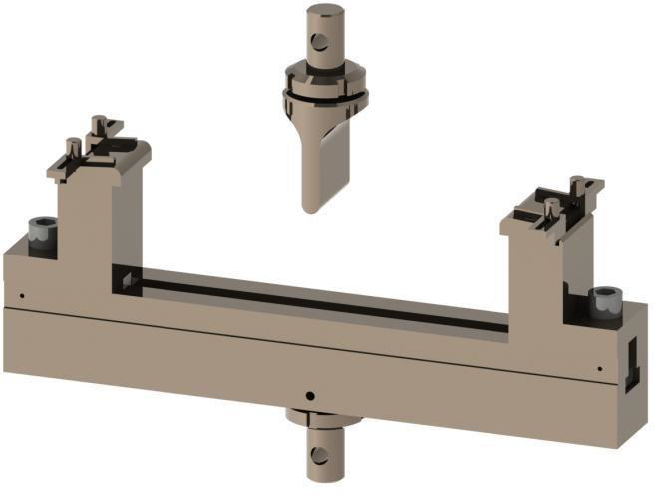

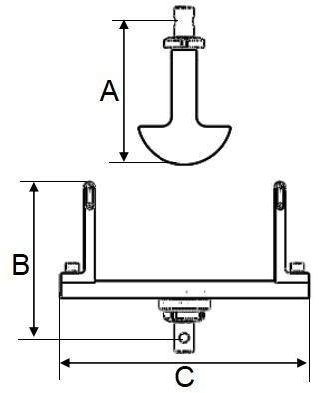

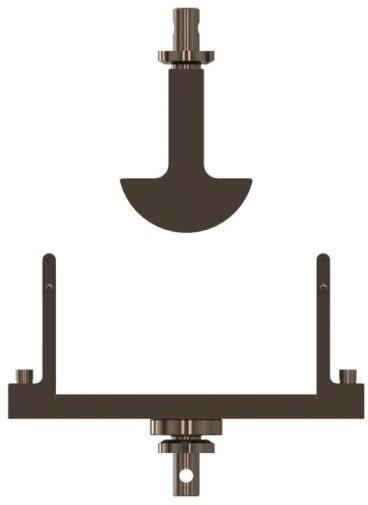

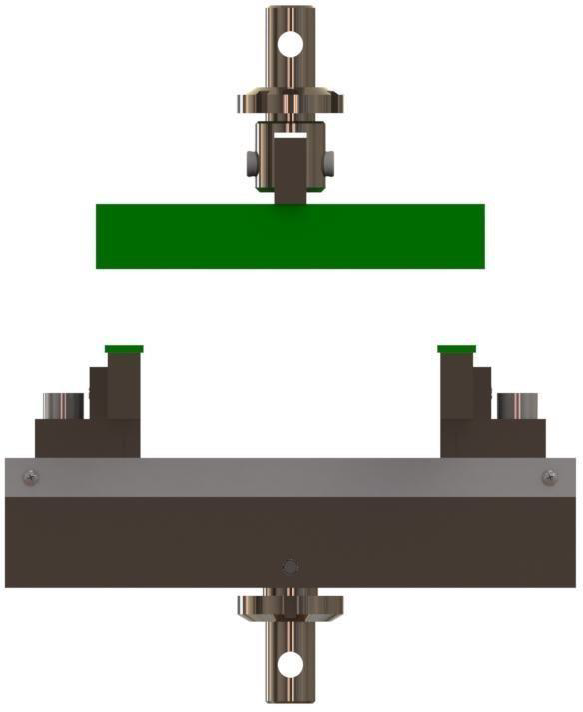

NGA204A – Marker Bending Fixture

The NGA204A Marker Bending Fixture is purpose-built for the mechanical evaluation of raised pavement markers. With a load capacity of up to 20 kN and an adjustable span up to 200 mm, it enables reliable flexural testing of roadway safety products. Its dual-height and dual-width design ensures compatibility with a wide range of marker sizes. The fixture features a sturdy construction and is suitable for standard universal testing machines in laboratory environments focused on transportation and infrastructure material performance.

The NGA204A Marker Bending Fixture is purpose-built for the mechanical evaluation of raised pavement markers. With a load capacity of up to 20 kN and an adjustable span up to 200 mm, it enables reliable flexural testing of roadway safety products. Its dual-height and dual-width design ensures compatibility with a wide range of marker sizes. The fixture features a sturdy construction and is suitable for standard universal testing machines in laboratory environments focused on transportation and infrastructure material performance.

- Application: Bending tests for raised pavement markers.

- Maximum Capacity: Up to 20 kN load.

- Connection: Ø10 mm pin mount (upper and lower), compatible with standard UTM systems.

- Span: Adjustable up to 200 mm.

- Height: 85 mm (upper grip), 120 mm (lower grip).

- Width: 150 mm (upper grip), 220 mm (lower grip).

- Grip Weight: 6.5 kg.

- Working Temperature: Ambient.

Technical Specifications – NGA204A Marker Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for raised pavement markers |

| Maximum Force Capacity | ≤ 20 kN |

| Connection Type | Upper Grip: Ø10 mm pin Lower Grip: Ø10 mm pin |

| Span (Adjustable) | ≤ 200 mm |

| Height | Upper Grip (A): 85 mm Lower Grip (B): 120 mm |

| Width | Upper Grip (C): 150 mm Lower Grip (D): 220 mm |

| Working Temperature | Ambient |

| Grip Weight | 6.5 kg |

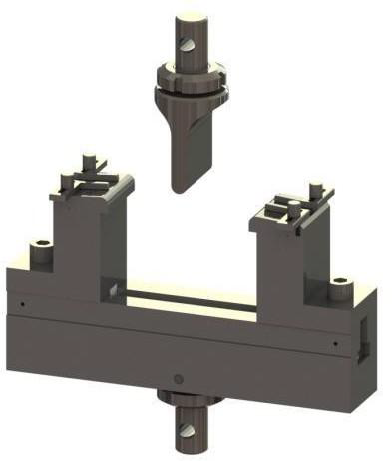

NGA104G – 3-Point Bending Fixture

The NGA104G 3-Point Bending Fixture is designed for flexural testing of plastics, composites, and ceramic construction materials under extreme temperature conditions. Supporting a wide temperature range from -70 °C to +350 °C, it is ideal for thermal performance evaluation and environmental simulation. With a 90 mm adjustable span and compact footprint, this fixture features precision-aligned R5 loading and support rollers for smooth, consistent load distribution. NGA104G is the preferred solution for material testing in research labs and thermal chambers.

The NGA104G 3-Point Bending Fixture is designed for flexural testing of plastics, composites, and ceramic construction materials under extreme temperature conditions. Supporting a wide temperature range from -70 °C to +350 °C, it is ideal for thermal performance evaluation and environmental simulation. With a 90 mm adjustable span and compact footprint, this fixture features precision-aligned R5 loading and support rollers for smooth, consistent load distribution. NGA104G is the preferred solution for material testing in research labs and thermal chambers.

- Application: Bending tests for plastic, composite, and ceramic materials.

- Maximum Capacity: Up to 10 kN load.

- Connection: Ø10 mm pin mount (upper and lower), compatible with most UTMs.

- Span: Adjustable up to 90 mm.

- Height: 86 mm (upper grip), 157 mm (lower grip).

- Base Width: 190 mm.

- Specimen Range: Supports specimens up to 30 mm wide.

- Rollers: R5 loading roller; R5 and R2 support rollers (customizable).

- Grip Weight: 0.4 kg (upper grip), 5.2 kg (lower grip).

- Working Temperature: -70 °C to +350 °C.

- Note: NextGen can provide various loading and support rollers according to client requirements.

Technical Specifications – NGA104G 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for plastic, composite, ceramic construction material etc. |

| Maximum Force Capacity | ≤ 10 kN |

| Connection Type | Upper Grip: Ø10 mm pin Lower Grip: Ø10 mm pin |

| Span (Adjustable) | ≤ 90 mm |

| Height | Upper Grip (A): 86 mm Lower Grip (B): 157 mm |

| Base Width (C) | 190 mm |

| Working Temperature | -70 °C to +350 °C |

| Grip Weight | Upper Grip: 0.4 kg Lower Grip: 5.2 kg |

| Compatible Specimen Width | ≤ 30 mm |

| Loading Roller | R5 |

| Support Roller | R5, R2 |

NextGen’s complete bending fixture line ensures compatibility with universal testing machines while providing consistent performance in flexural testing. Whether for industrial QA or academic research, each fixture meets strict ISO and ASTM standards. Contact NextGen for expert assistance in selecting the right fixture for your testing system or to request a formal quotation.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.