Metal Testing Equipment

Precision 3-Point and 4-Point Bending Fixtures for NextGen Universal Testing Machines

NextGen’s bending fixtures are precision-engineered to enable accurate flexural testing of various materials, including metals, ceramics, composites, concrete, bricks, and construction products. These accessories are optimized for seamless integration with NG-EML and other universal testing machines in our product line, ensuring compatibility, durability, and repeatable results. All fixtures are compliant with international testing standards such as ASTM C1609, ASTM C78, ASTM C293, ISO 178, and EN 12808, ensuring they are suitable for both R&D and quality control environments.

NextGen’s bending fixtures are precision-engineered to enable accurate flexural testing of various materials, including metals, ceramics, composites, concrete, bricks, and construction products. These accessories are optimized for seamless integration with NG-EML and other universal testing machines in our product line, ensuring compatibility, durability, and repeatable results. All fixtures are compliant with international testing standards such as ASTM C1609, ASTM C78, ASTM C293, ISO 178, and EN 12808, ensuring they are suitable for both R&D and quality control environments.

Each fixture is designed for specific bending test applications such as 3-point or 4-point configurations, enabling laboratories to meet the most demanding flexural strength, deformation, and modulus testing requirements.

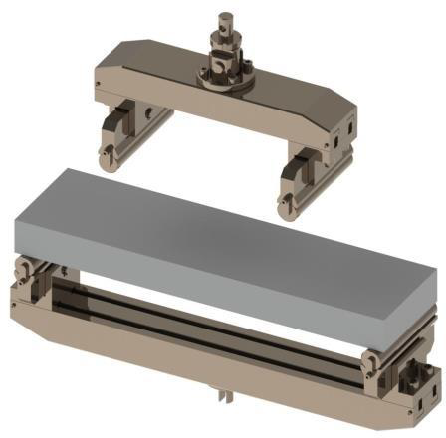

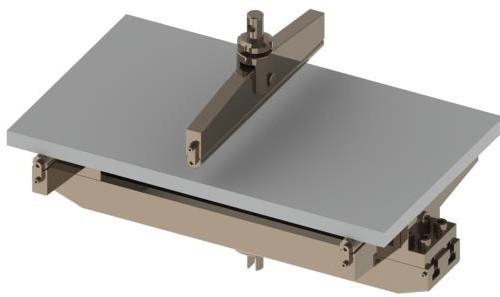

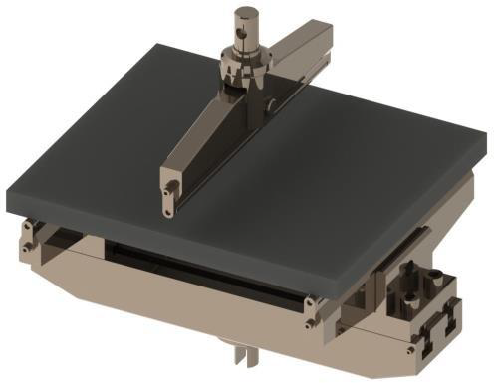

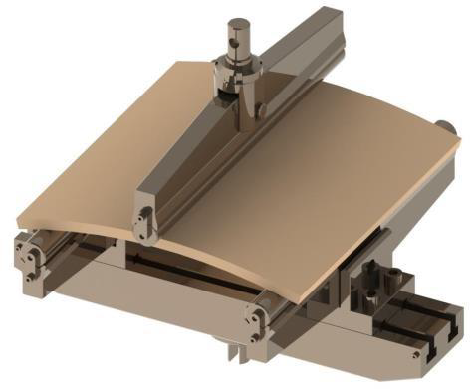

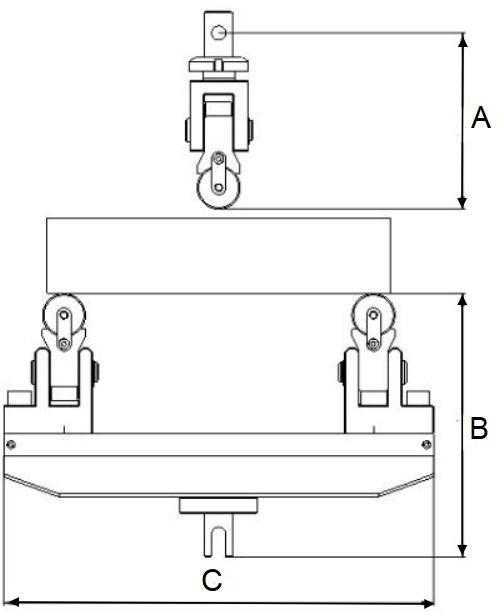

NGB304 – Bending Fixture

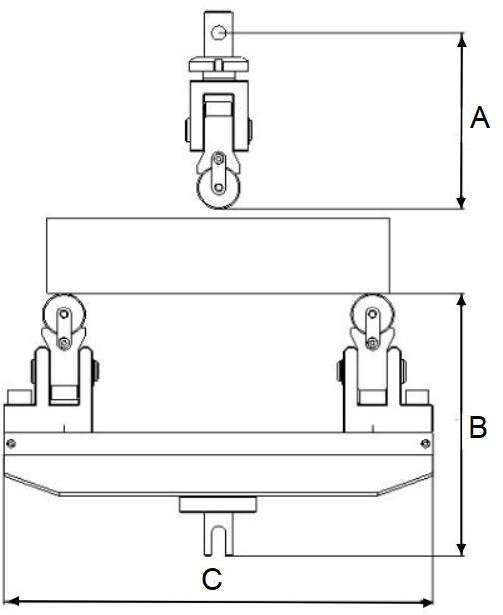

The NGB304 Bending Fixture series is designed for accurate 4-point bending tests on natural stone, ceramics, and composite materials. With three model variations—NGB304A, NGB304B, and NGB304C—this system accommodates a wide range of specimen sizes and load requirements. Each fixture includes adjustable upper and lower spans, precision rollers, and is compatible with standard UTM systems.

The NGB304 Bending Fixture series is designed for accurate 4-point bending tests on natural stone, ceramics, and composite materials. With three model variations—NGB304A, NGB304B, and NGB304C—this system accommodates a wide range of specimen sizes and load requirements. Each fixture includes adjustable upper and lower spans, precision rollers, and is compatible with standard UTM systems.

- Application: 4-point bending tests on natural stone, ceramic, and composite materials.

- Maximum Capacity: ≤ 30 kN.

- Grip Weight:

- NGB304A: Upper 15 kg / Lower 24 kg

- NGB304B: Upper 19 kg / Lower 35 kg

- NGB304C: Upper 22 kg / Lower 47.5 kg

- Connection: Φ10 mm pin (upper and lower), UTM compatible.

- Adjustable Span:

- Upper: ≤ 250 mm (A), ≤ 400 mm (B), ≤ 500 mm (C)

- Lower: ≤ 500 mm (A), ≤ 800 mm (B), ≤ 1000 mm (C)

- Max Specimen Width: 160 mm

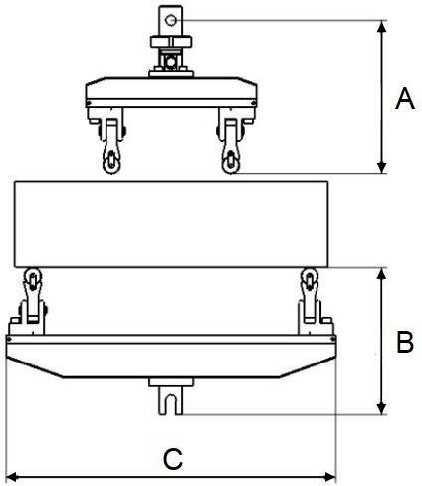

- Dimensions:

- Upper Grip Height (A): 218 mm / 218 mm / 223 mm

- Lower Grip Height (B): 185 mm / 195 mm / 205 mm

- Base Width (C): 600 mm / 900 mm / 1100 mm

- Roller Diameter: Φ25 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGB304 4-Point Bending Fixture

| Parameter | NGB304A | NGB304B | NGB304C |

|---|---|---|---|

| Application | - Bending test for natural stone, ceramic, composite materials | ||

| Maximum Force Capacity | ≤ 30 kN | ≤ 30 kN | ≤ 30 kN |

| Upper Grip Weight | 15 kg | 19 kg | 22 kg |

| Lower Grip Weight | 24 kg | 35 kg | 47.5 kg |

| Working Temperature | Ambient | ||

| Connection – Upper Grip | Φ10 mm pin | Φ10 mm pin | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin | Φ10 mm pin | Φ10 mm pin |

| Upper Span (Adjustable) | ≤ 250 mm | ≤ 400 mm | ≤ 500 mm |

| Lower Span (Adjustable) | ≤ 500 mm | ≤ 800 mm | ≤ 1000 mm |

| Maximum Specimen Width | 160 mm | 160 mm | 160 mm |

| Upper Grip Height (A) | 218 mm | 218 mm | 223 mm |

| Lower Grip Height (B) | 185 mm | 195 mm | 205 mm |

| Base Width (C) | 600 mm | 900 mm | 1100 mm |

| Roller Diameter | Φ25 mm | Φ25 mm | Φ25 mm |

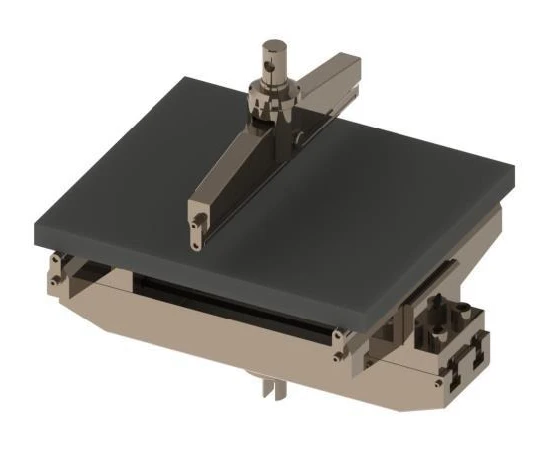

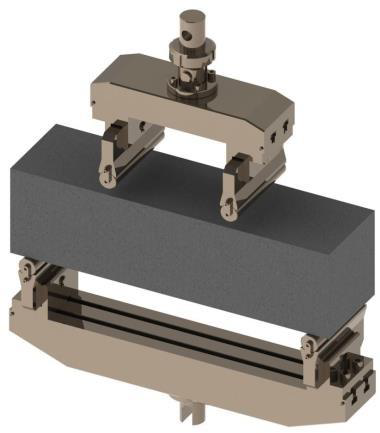

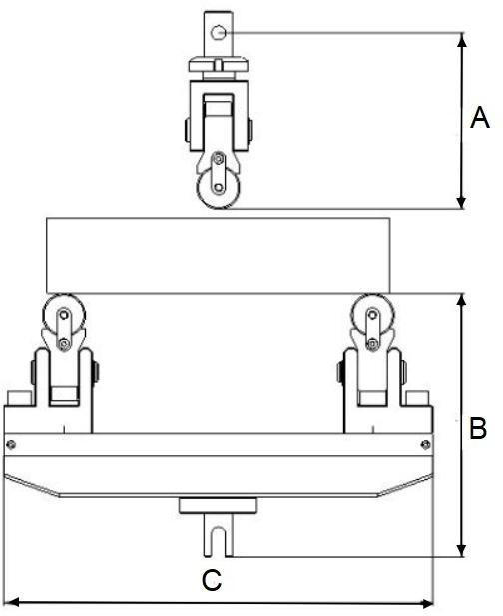

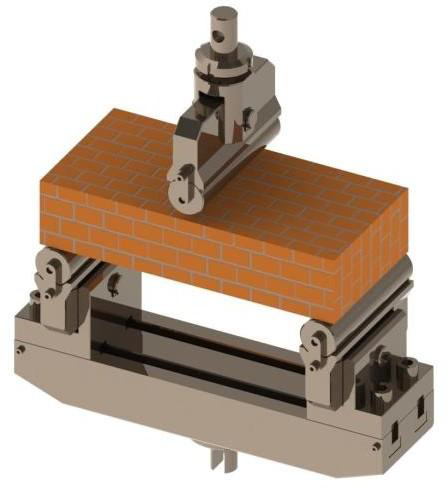

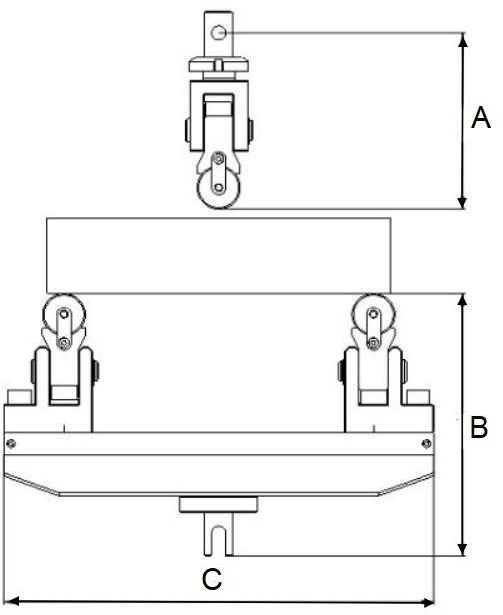

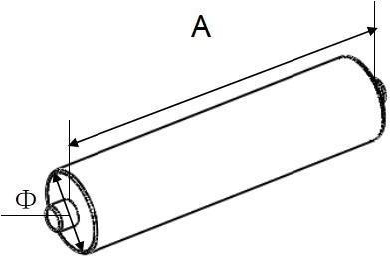

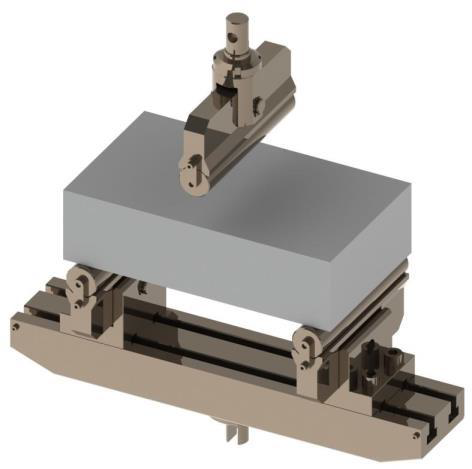

NGB105A – Bending Fixture

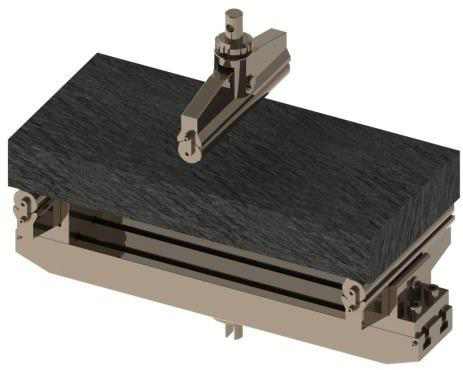

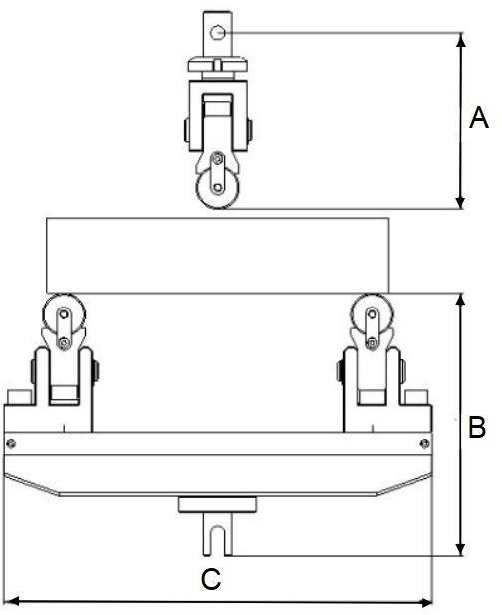

The NGB105A Bending Fixture is engineered for high-capacity 4-point bending tests on ordinary concrete, metal, ceramic, and composite specimens. With robust Φ18 mm pin connections and a 100 kN force capacity, this fixture is well-suited for laboratories performing strength analysis on large structural materials. It supports both standard and non-standard specimen sizes.

The NGB105A Bending Fixture is engineered for high-capacity 4-point bending tests on ordinary concrete, metal, ceramic, and composite specimens. With robust Φ18 mm pin connections and a 100 kN force capacity, this fixture is well-suited for laboratories performing strength analysis on large structural materials. It supports both standard and non-standard specimen sizes.

- Application: Bending tests for ordinary concrete, metal, ceramic, and composite.

- Maximum Capacity: ≤ 100 kN.

- Grip Weight: 21.3 kg (Upper Grip), 38.9 kg (Lower Grip).

- Connection: Φ18 mm pin (upper and lower), compatible with large-scale testing frames.

- Adjustable Span:

- Upper: ≤ 200 mm

- Lower: ≤ 480 mm

- Maximum Specimen Width: 160 mm

- Dimensions:

- Upper Grip Height (A): 270 mm

- Lower Grip Height (B): 259 mm

- Base Width (C): 580 mm

- Roller Diameter: Φ30 mm

- Working Temperature: Ambient conditions.

- Standard Specimen: 150 mm × 150 mm × 600/550 mm

- Non-standard Specimen: 100 mm × 100 mm × 400 mm

Technical Specifications – NGB105A 4-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for ordinary concrete, metal, ceramic, composite |

| Maximum Force Capacity | ≤ 100 kN |

| Upper Grip Weight | 21.3 kg |

| Lower Grip Weight | 38.9 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ18 mm pin |

| Connection – Lower Grip | Φ18 mm pin |

| Upper Span (Adjustable) | ≤ 200 mm |

| Lower Span (Adjustable) | ≤ 480 mm |

| Maximum Specimen Width | 160 mm |

| Upper Grip Height (A) | 270 mm |

| Lower Grip Height (B) | 259 mm |

| Base Width (C) | 580 mm |

| Roller Diameter | Φ30 mm |

| Standard Specimen | 150 mm × 150 mm × 600/550 mm |

| Non-standard Specimen | 100 mm × 100 mm × 400 mm |

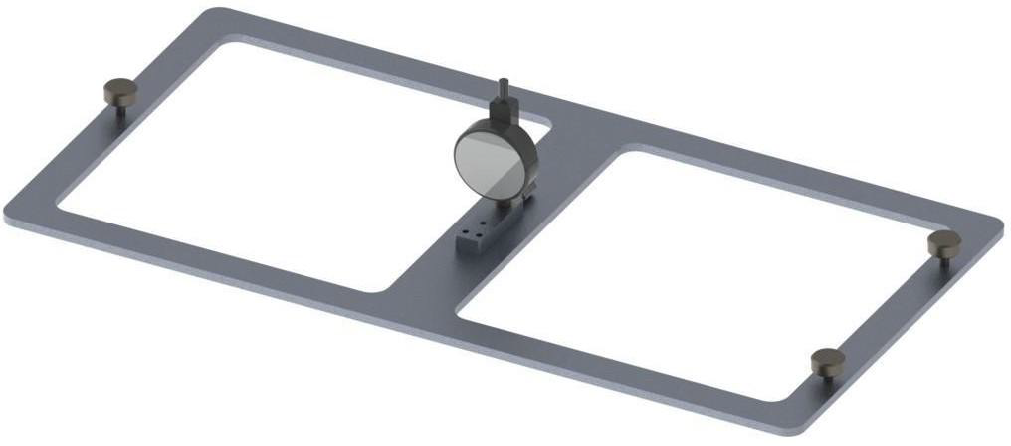

Optional Accessories – NGB105A Bending Fixture

Deformation Measurement Device (Optional)This device allows real-time monitoring of specimen deformation during 4-point bending tests. It collects bending displacement data and enables calculation of the elastic modulus of the specimen for accurate mechanical property evaluation.

Deformation Measurement Device (Optional)This device allows real-time monitoring of specimen deformation during 4-point bending tests. It collects bending displacement data and enables calculation of the elastic modulus of the specimen for accurate mechanical property evaluation.

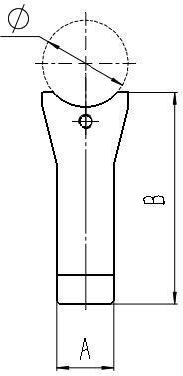

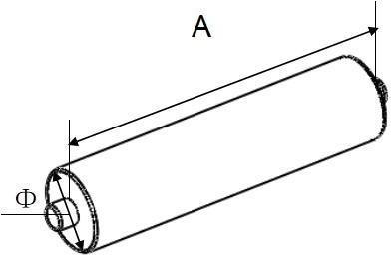

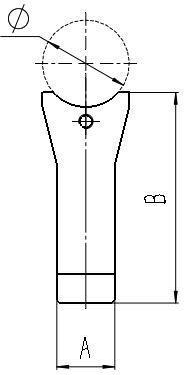

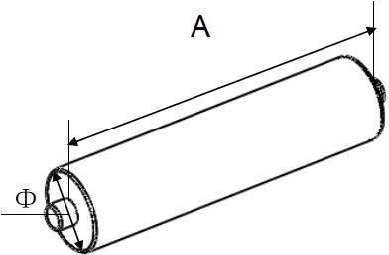

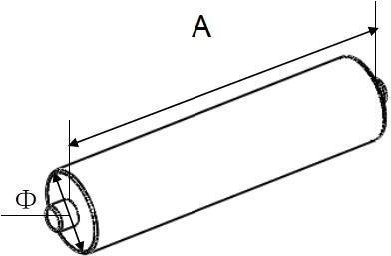

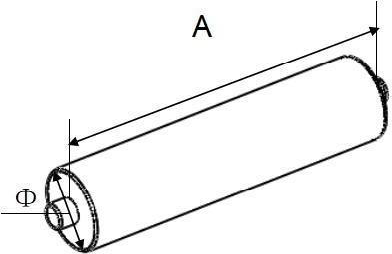

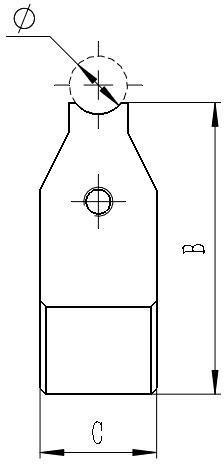

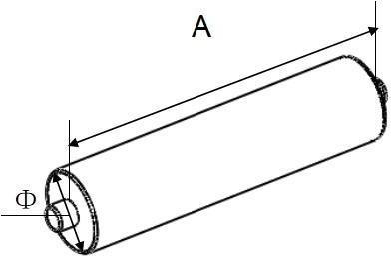

Roller (Optional)

| No. | Diameter (mm) | Width A (mm) |

|---|---|---|

| NGB105A-12 | 30 | 160 |

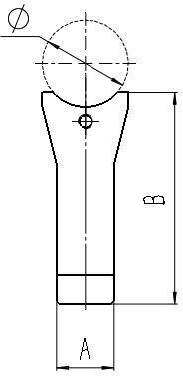

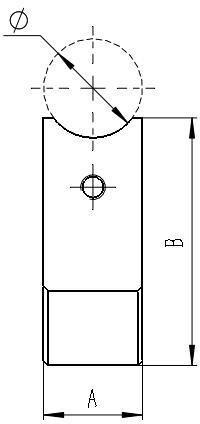

Roller Support (Optional)

| No. | Diameter (mm) | Width A (mm) | Height B (mm) |

|---|---|---|---|

| NGB105A-05 | 3 | 20 | 73 |

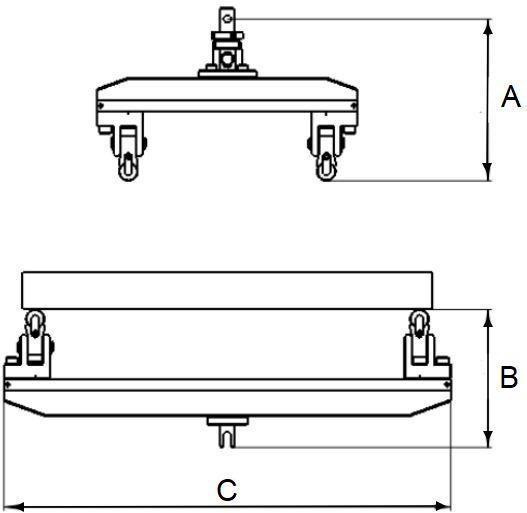

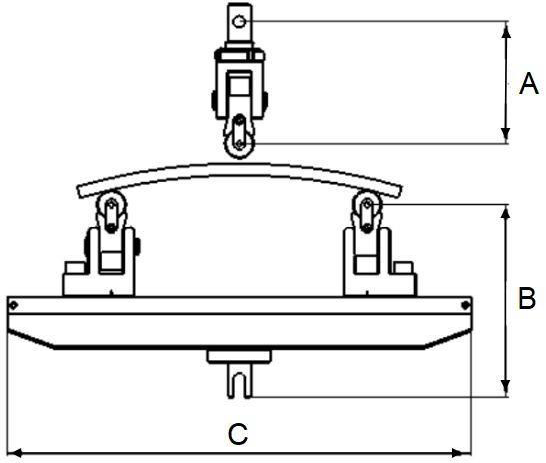

NGD204A – Bending Fixture

The NGD204A 3-Point Bending Fixture is specifically developed for testing wall bricks, metal, ceramics, and composite materials under flexural load. Its compact form and adjustable span up to 200 mm make it ideal for laboratories conducting strength evaluation of structural and brittle materials. The fixture supports both small and medium-sized specimens and operates under ambient temperature.

The NGD204A 3-Point Bending Fixture is specifically developed for testing wall bricks, metal, ceramics, and composite materials under flexural load. Its compact form and adjustable span up to 200 mm make it ideal for laboratories conducting strength evaluation of structural and brittle materials. The fixture supports both small and medium-sized specimens and operates under ambient temperature.

- Application: Bending tests for wall bricks, metal, ceramic, and composite materials.

- Maximum Capacity: ≤ 20 kN.

- Grip Weight: 3.2 kg (Upper Grip), 12.7 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), UTM-compatible.

- Span (Adjustable): ≤ 200 mm.

- Maximum Specimen Width: 90 mm.

- Dimensions:

- Upper Grip Height (A): 123 mm

- Lower Grip Height (B): 184 mm

- Base Width (C): 300 mm

- Roller Diameter: Φ30 mm

- Standard Specimens:

- 190 mm × 35 mm × 90 mm

- 240 mm × 115 mm × 53 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGD204A 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for wall bricks, metal, ceramic, composite |

| Maximum Force Capacity | ≤ 20 kN |

| Upper Grip Weight | 3.2 kg |

| Lower Grip Weight | 12.7 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Span (Adjustable) | ≤ 200 mm |

| Maximum Specimen Width | 90 mm |

| Upper Grip Height (A) | 123 mm |

| Lower Grip Height (B) | 184 mm |

| Base Width (C) | 300 mm |

| Roller Diameter | Φ30 mm |

| Standard Specimen | 190 mm × 35 mm × 90 mm 240 mm × 115 mm × 53 mm |

Optional Accessories – NGD204A Bending Fixture

Optional Accessories – NGD204A Bending Fixture

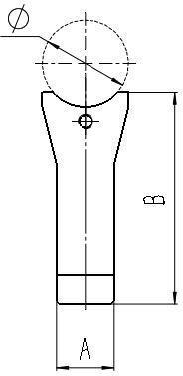

Roller (Optional)

| No. | Diameter (mm) | Width A (mm) |

|---|---|---|

| WZWD204A-03 | 30 | 120 |

Roller Support (Optional)

| No. | Diameter (mm) | Width A (mm) | Height B (mm) |

|---|---|---|---|

| NGD204A-04 | 30 | 20 | 50 |

NGD204B – Bending Fixture

The NGD204B 3-Point Bending Fixture is optimized for testing precast concrete paving bricks as well as metals, ceramics, and composite materials. With a span adjustable up to 400 mm and a high-strength lower grip, it accommodates larger specimens under medium-load bending. Its structure ensures stability and compatibility with standard UTM systems.

The NGD204B 3-Point Bending Fixture is optimized for testing precast concrete paving bricks as well as metals, ceramics, and composite materials. With a span adjustable up to 400 mm and a high-strength lower grip, it accommodates larger specimens under medium-load bending. Its structure ensures stability and compatibility with standard UTM systems.

- Application: Bending tests for precast concrete paving bricks, metal, ceramic, and composite materials.

- Maximum Capacity: ≤ 20 kN.

- Grip Weight: 3.2 kg (Upper Grip), 20 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), UTM-compatible.

- Span (Adjustable): ≤ 400 mm.

- Maximum Specimen Width: 123 mm.

- Dimensions:

- Upper Grip Height (A): 185 mm

- Lower Grip Height (B): 500 mm

- Base Width (C): 90 mm

- Roller Diameter: Φ30 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGD204B 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for precast concrete paving bricks, metal, ceramic, composite |

| Maximum Force Capacity | ≤ 20 kN |

| Upper Grip Weight | 3.2 kg |

| Lower Grip Weight | 20 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Span (Adjustable) | ≤ 400 mm |

| Maximum Specimen Width | 123 mm |

| Upper Grip Height (A) | 185 mm |

| Lower Grip Height (B) | 500 mm |

| Base Width (C) | 90 mm |

| Roller Diameter | Φ30 mm |

Optional Accessories – NGD204B Bending Fixture

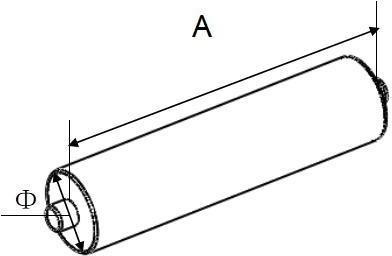

Roller (Optional)

| No. | Diameter (mm) | Width A (mm) |

|---|---|---|

| WZWD204B-02 | 30 | 210 |

Roller Support (Optional)

| No. | Diameter (mm) | Width A (mm) | Height B (mm) |

|---|---|---|---|

| NGD204B-01 | 30 | 20 | 50 |

NGD204C – Bending Fixture

The NGD204C 3-Point Bending Fixture is designed for flexural strength testing of gypsum plasterboard, metal, ceramics, and composite materials. Featuring a wide specimen compatibility (up to 310 mm) and lightweight upper grip, this fixture is ideal for testing fragile and large-format specimens under low to medium force. Its compact roller system and stable base design ensure reliable and repeatable results.

The NGD204C 3-Point Bending Fixture is designed for flexural strength testing of gypsum plasterboard, metal, ceramics, and composite materials. Featuring a wide specimen compatibility (up to 310 mm) and lightweight upper grip, this fixture is ideal for testing fragile and large-format specimens under low to medium force. Its compact roller system and stable base design ensure reliable and repeatable results.

- Application: Bending tests for gypsum plasterboard, metal, ceramic, and composite materials.

- Maximum Capacity: ≤ 20 kN.

- Grip Weight: 3.4 kg (Upper Grip), 20 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), UTM-compatible.

- Span (Adjustable): ≤ 400 mm.

- Maximum Specimen Width: 310 mm.

- Dimensions:

- Upper Grip Height (A): 114 mm

- Lower Grip Height (B): 176 mm

- Base Width (C): 350 mm

- Roller Diameter: Φ20 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGD204C 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for gypsum plasterboard, metal, ceramic, composite |

| Maximum Force Capacity | ≤ 20 kN |

| Upper Grip Weight | 3.4 kg |

| Lower Grip Weight | 20 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Span (Adjustable) | ≤ 400 mm |

| Maximum Specimen Width | 310 mm |

| Upper Grip Height (A) | 114 mm |

| Lower Grip Height (B) | 176 mm |

| Base Width (C) | 350 mm |

| Roller Diameter | Φ20 mm |

Optional Accessories – NGD204C Bending Fixture

Optional Accessories – NGD204C Bending Fixture

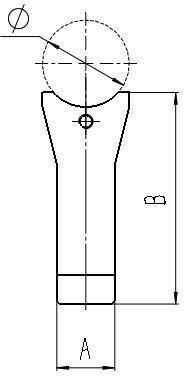

Roller (Optional)

| No. | Diameter (mm) | Width A (mm) |

|---|---|---|

| NGD204C-02 | 20 | 310 |

Roller Support (Optional)

| No. | Diameter (mm) | Width A (mm) | Height B (mm) |

|---|---|---|---|

| NGD204C-01 | 20 | 20 | 50 |

NGD204D – Bending Fixture

The NGD204D 3-Point Bending Fixture is engineered for testing fiber cement products, metals, ceramics, and composite materials. It supports specimen widths up to 260 mm and features a compact roller system. With a lightweight upper grip and a strong base, it provides a stable and efficient setup for mid-range bending applications in ambient conditions.

The NGD204D 3-Point Bending Fixture is engineered for testing fiber cement products, metals, ceramics, and composite materials. It supports specimen widths up to 260 mm and features a compact roller system. With a lightweight upper grip and a strong base, it provides a stable and efficient setup for mid-range bending applications in ambient conditions.

- Application: Bending tests for fiber cement products, metal, ceramic, and composite materials.

- Maximum Capacity: ≤ 20 kN.

- Grip Weight: 2.3 kg (Upper Grip), 14.4 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), UTM-compatible.

- Span (Adjustable): ≤ 240 mm.

- Maximum Specimen Width: 260 mm.

- Dimensions:

- Upper Grip Height (A): 106 mm

- Lower Grip Height (B): 168 mm

- Base Width (C): 350 mm

- Roller Diameter: Φ10 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGD204D 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for fiber cement products, metal, ceramic, composite |

| Maximum Force Capacity | ≤ 20 kN |

| Upper Grip Weight | 2.3 kg |

| Lower Grip Weight | 14.4 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Span (Adjustable) | ≤ 240 mm |

| Maximum Specimen Width | 260 mm |

| Upper Grip Height (A) | 106 mm |

| Lower Grip Height (B) | 168 mm |

| Base Width (C) | 350 mm |

| Roller Diameter | Φ10 mm |

Optional Accessories – NGD204D Bending Fixture

Optional Accessories – NGD204D Bending Fixture

Roller (Optional)

| No. | Diameter (mm) | Width A (mm) |

|---|---|---|

| NGD204D-02 | 10 | 260 |

Roller Support (Optional)

| No. | Diameter (mm) | Width A (mm) | Height B (mm) |

|---|---|---|---|

| NGD204D-01 | 10 | 20 | 50 |

NGD204E – Bending Fixture

The NGD204E 3-Point Bending Fixture is designed for testing fired roofing tiles, metals, ceramics, and composite materials. With a wide specimen accommodation of up to 350 mm and durable Φ10 mm pin-mounted grips, this fixture is ideal for evaluating the flexural strength of brittle and structural materials under ambient conditions.

The NGD204E 3-Point Bending Fixture is designed for testing fired roofing tiles, metals, ceramics, and composite materials. With a wide specimen accommodation of up to 350 mm and durable Φ10 mm pin-mounted grips, this fixture is ideal for evaluating the flexural strength of brittle and structural materials under ambient conditions.

- Application: Bending tests for fired roofing tiles, metal, ceramic, and composite materials.

- Maximum Capacity: ≤ 20 kN.

- Grip Weight: 4.3 kg (Upper Grip), 19.5 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), compatible with standard UTM systems.

- Span (Adjustable): ≤ 300 mm.

- Maximum Specimen Width: 350 mm.

- Dimensions:

- Upper Grip Height (A): 105 mm

- Lower Grip Height (B): 168 mm

- Base Width (C): 400 mm

- Roller Diameter: Φ20 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGD204E 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for fired roofing tiles, metal, ceramic, composite |

| Maximum Force Capacity | ≤ 20 kN |

| Upper Grip Weight | 4.3 kg |

| Lower Grip Weight | 19.5 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Span (Adjustable) | ≤ 300 mm |

| Maximum Specimen Width | 350 mm |

| Upper Grip Height (A) | 105 mm |

| Lower Grip Height (B) | 168 mm |

| Base Width (C) | 400 mm |

| Roller Diameter | Φ20 mm |

Optional Accessories – NGD204E Bending Fixture

Roller (Optional)

| No. | Diameter (mm) | Width A (mm) |

|---|---|---|

| NGD204C-04 | 25 | 350 |

Roller Support (Optional)

| No. | Diameter (mm) | Width A (mm) | Height B (mm) |

|---|---|---|---|

| NGD204C-01 | 25 | 20 | 50 |

NGD204F – Bending Fixture

The NGD204F 3-Point Bending Fixture is optimized for evaluating the flexural behavior of inorganic rigid thermal insulation foam, metals, ceramics, and composite materials. With a medium-width capacity and balanced grip design, it provides accurate and reliable support for low-to-medium force bending tests under ambient conditions.

The NGD204F 3-Point Bending Fixture is optimized for evaluating the flexural behavior of inorganic rigid thermal insulation foam, metals, ceramics, and composite materials. With a medium-width capacity and balanced grip design, it provides accurate and reliable support for low-to-medium force bending tests under ambient conditions.

- Application: Bending tests for inorganic rigid thermal insulation foam, metal, ceramic, and composite materials.

- Maximum Capacity: ≤ 20 kN.

- Grip Weight: 2.7 kg (Upper Grip), 16.3 kg (Lower Grip).

- Connection: Φ10 mm pin (upper and lower), compatible with standard UTM systems.

- Span (Adjustable): ≤ 300 mm.

- Maximum Specimen Width: 160 mm.

- Dimensions:

- Upper Grip Height (A): 123 mm

- Lower Grip Height (B): 185 mm

- Base Width (C): 400 mm

- Roller Diameter: Φ30 mm

- Working Temperature: Ambient conditions.

Technical Specifications – NGD204F 3-Point Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for inorganic rigid thermal insulation foam, metal, ceramic, composite |

| Maximum Force Capacity | ≤ 20 kN |

| Upper Grip Weight | 2.7 kg |

| Lower Grip Weight | 16.3 kg |

| Working Temperature | Ambient |

| Connection – Upper Grip | Φ10 mm pin |

| Connection – Lower Grip | Φ10 mm pin |

| Span (Adjustable) | ≤ 300 mm |

| Maximum Specimen Width | 160 mm |

| Upper Grip Height (A) | 123 mm |

| Lower Grip Height (B) | 185 mm |

| Base Width (C) | 400 mm |

| Roller Diameter | Φ30 mm |

Optional Accessories – NGD204F Bending Fixture

Optional Accessories – NGD204F Bending Fixture

Roller (Optional)

| No. | Diameter (mm) | Width A (mm) |

|---|---|---|

| NGD304A-09 | 30 | 160 |

Roller Support (Optional)

| No. | Diameter (mm) | Width A (mm) | Height B (mm) |

|---|---|---|---|

| NGD304A-06 | 30 | 20 | 50 |

NextGen’s wide array of bending fixtures allows laboratories and manufacturers to conduct standardized flexural testing across a range of materials and specimen geometries. Whether you need a compact solution for classroom training or a robust fixture for industrial-grade testing, we offer the right product for your universal testing machine. All bending fixtures are precision-calibrated, quality-verified, and available with rapid shipping across North America.

Contact our team today to request a quote, verify compatibility with your system, or schedule a demonstration.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.