Metal Testing Equipment

Description

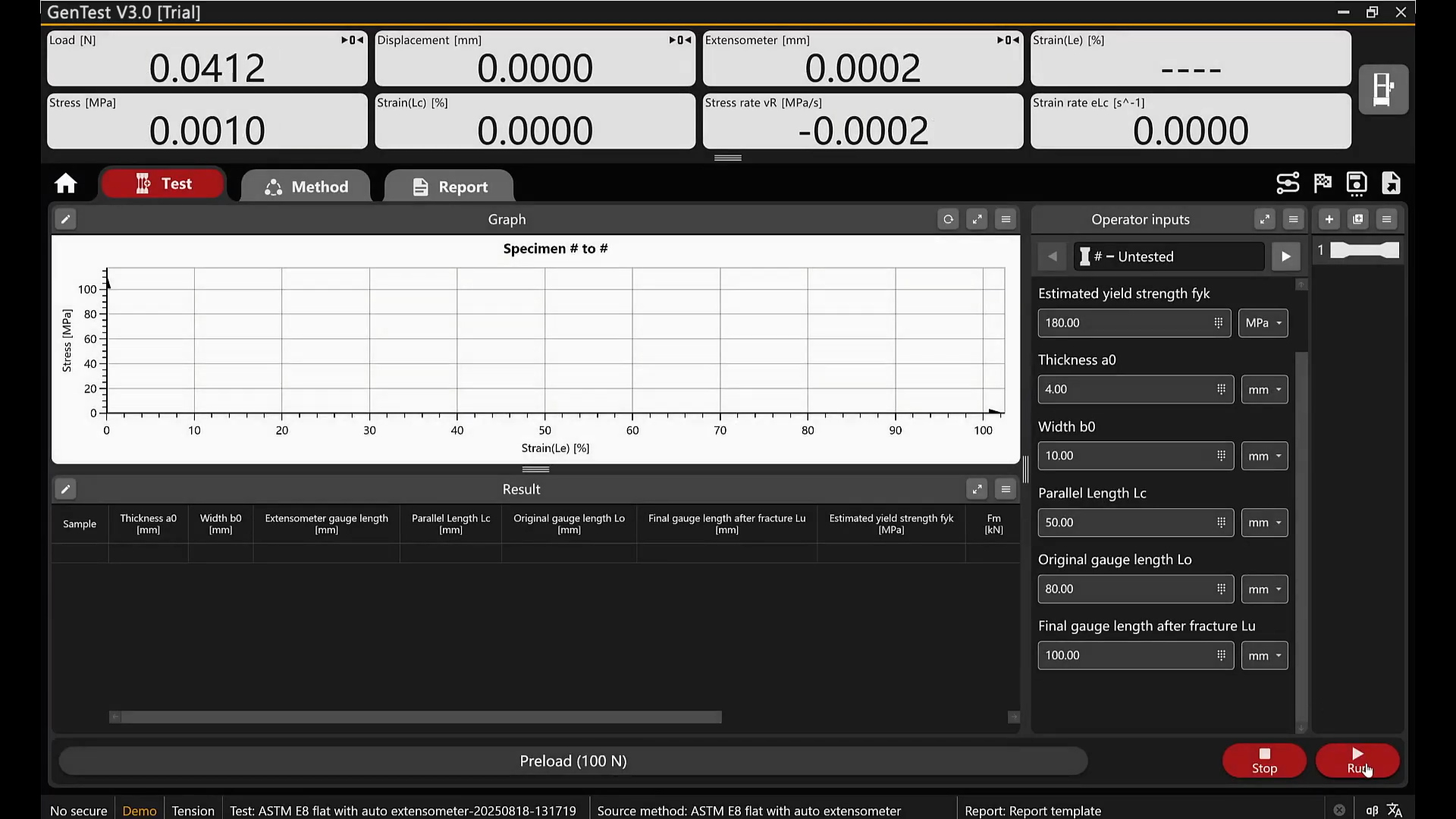

GenTest is NextGen’s data acquisition and test control software for universal testing machines, developed as the standard software environment for NG-EML Series electromechanical UTMs. It is built around a method-driven workflow: the test method defines the control steps, the live channels and curves, the calculation rules, and the report output. This keeps setup parameters, operator inputs, recorded data, calculated results, and reporting tied to the same test record.

GenTest is used in QA/QC and laboratory environments where repeatability, traceability, and consistent documentation matter. It supports real-time monitoring during the run, built-in calculation of common mechanical properties, flexible unit systems, and export-ready reporting. A dedicated GenTest v3.0 build is also available for NextGen servo-hydraulic UTMs for metal testing applications.

Supported Test Types

GenTest supports the core UTM workflows used in routine and standards-based testing:

- Tensile testing

- Compression testing

- Bending / flexure testing

- Shear testing

Depending on your configuration and accessories, the method library may also include application-specific groups (for example peel-style workflows shown in the method group structure).

Typical Applications

GenTest is intended for daily testing programs where the lab needs controlled execution and repeatable reporting:

- Incoming inspection and batch verification

- Routine QC across shifts and lots

- Supplier qualification and material comparisons

- R&D comparisons, process changes, and heat treatment checks

- Metals, polymers, composites, construction materials, and biomedical product testing environments

Key Features of the GenTest Software

GenTest includes a practical set of features that support the full testing workflow for the test types it runs. The main benefits come from:

- Method-Driven Workflow: Tests run from defined methods, keeping setup parameters, recorded data, calculations, and report output tied to the same test record.

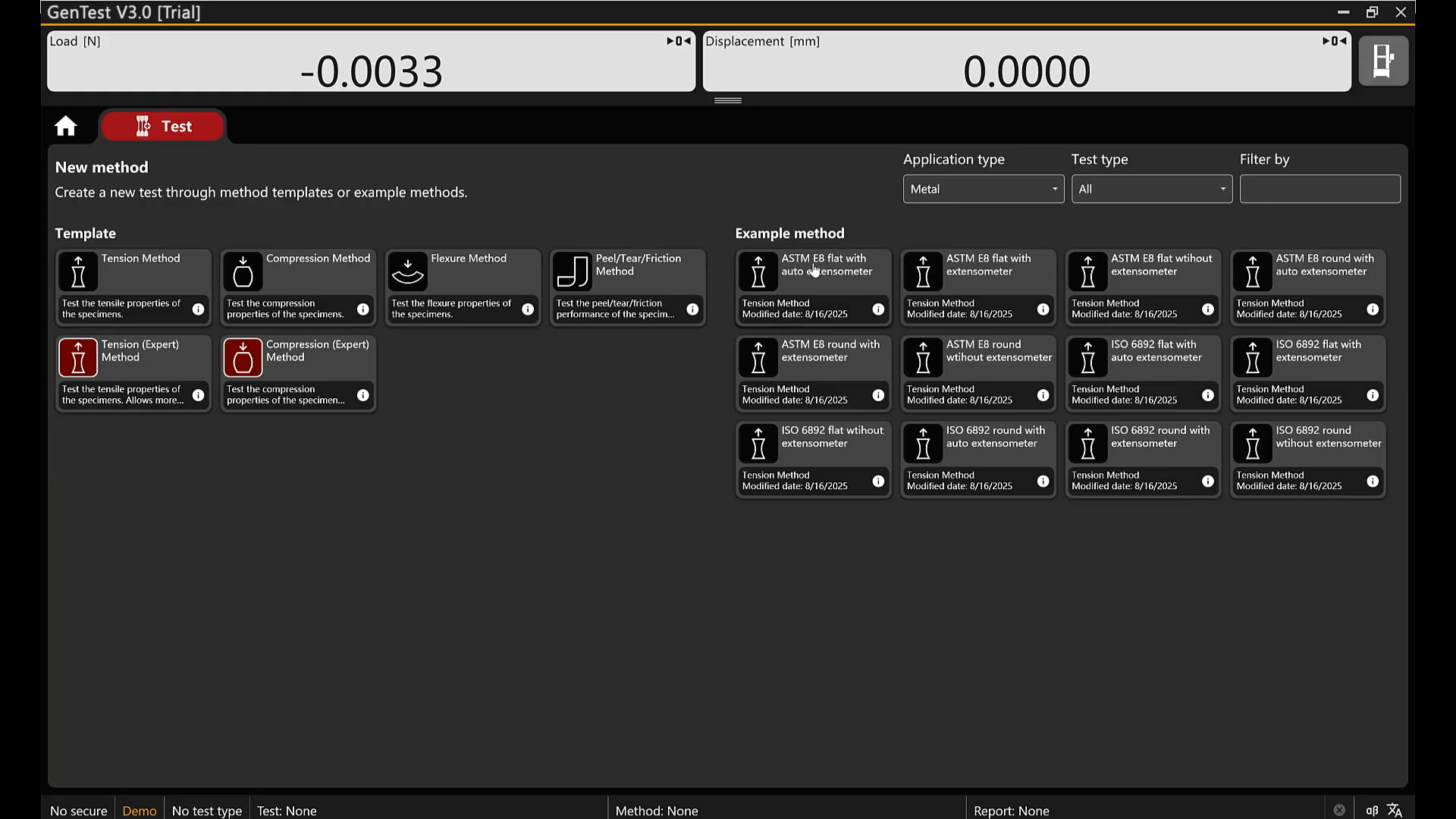

- Templates And Standards-Based Methods: Create methods from normal or expert templates, or start from example methods aligned with common standards-based workflows.

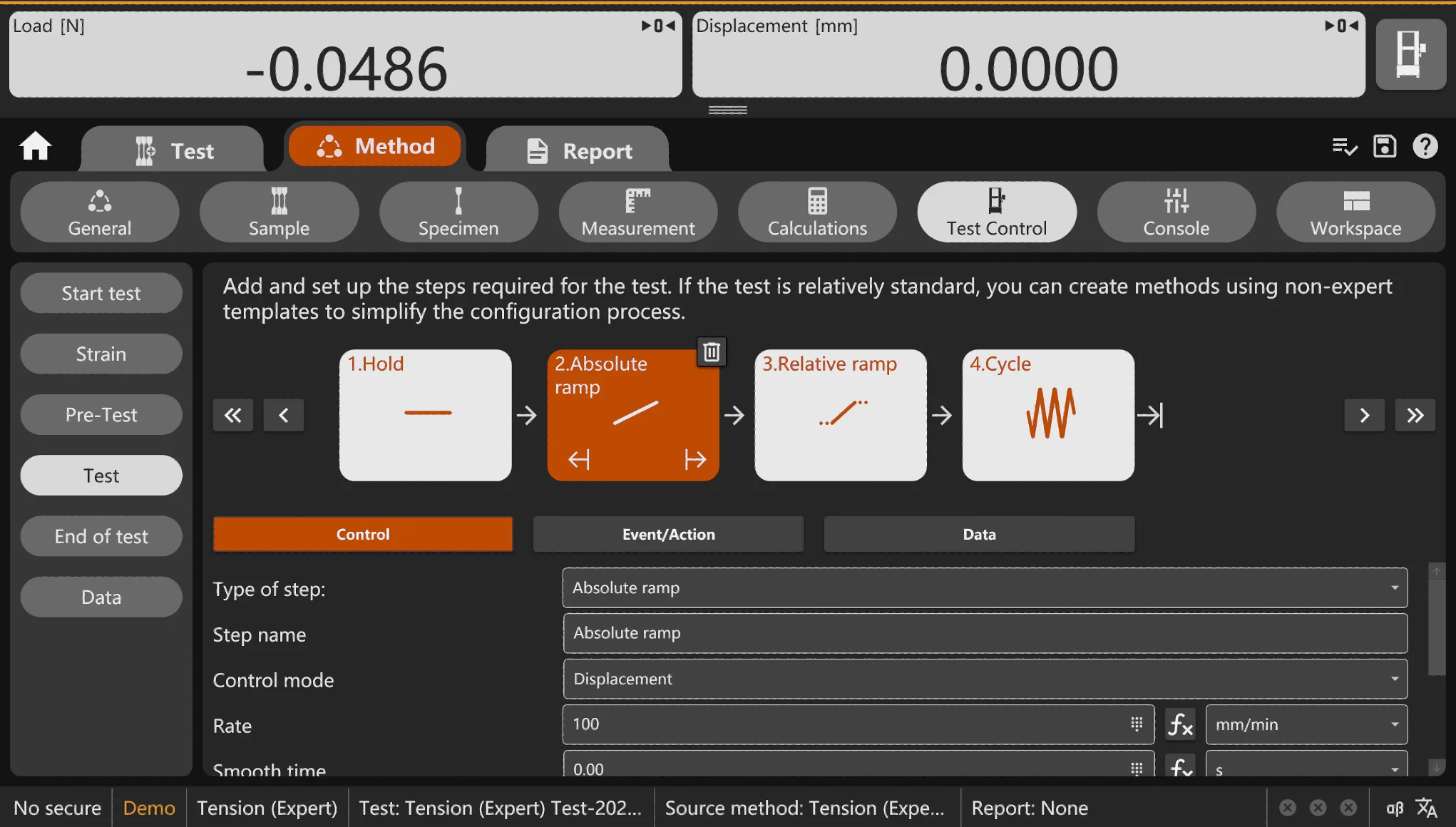

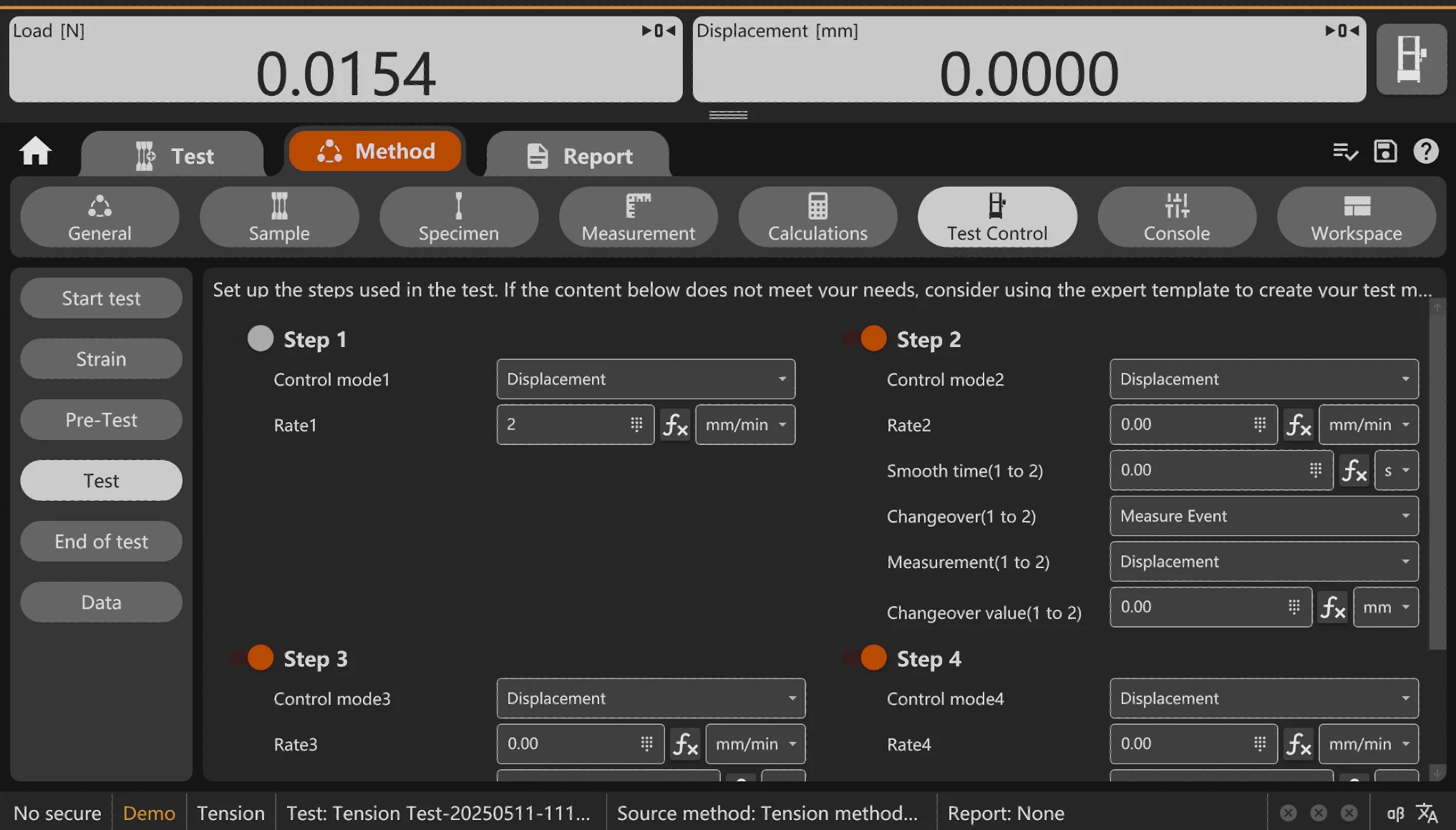

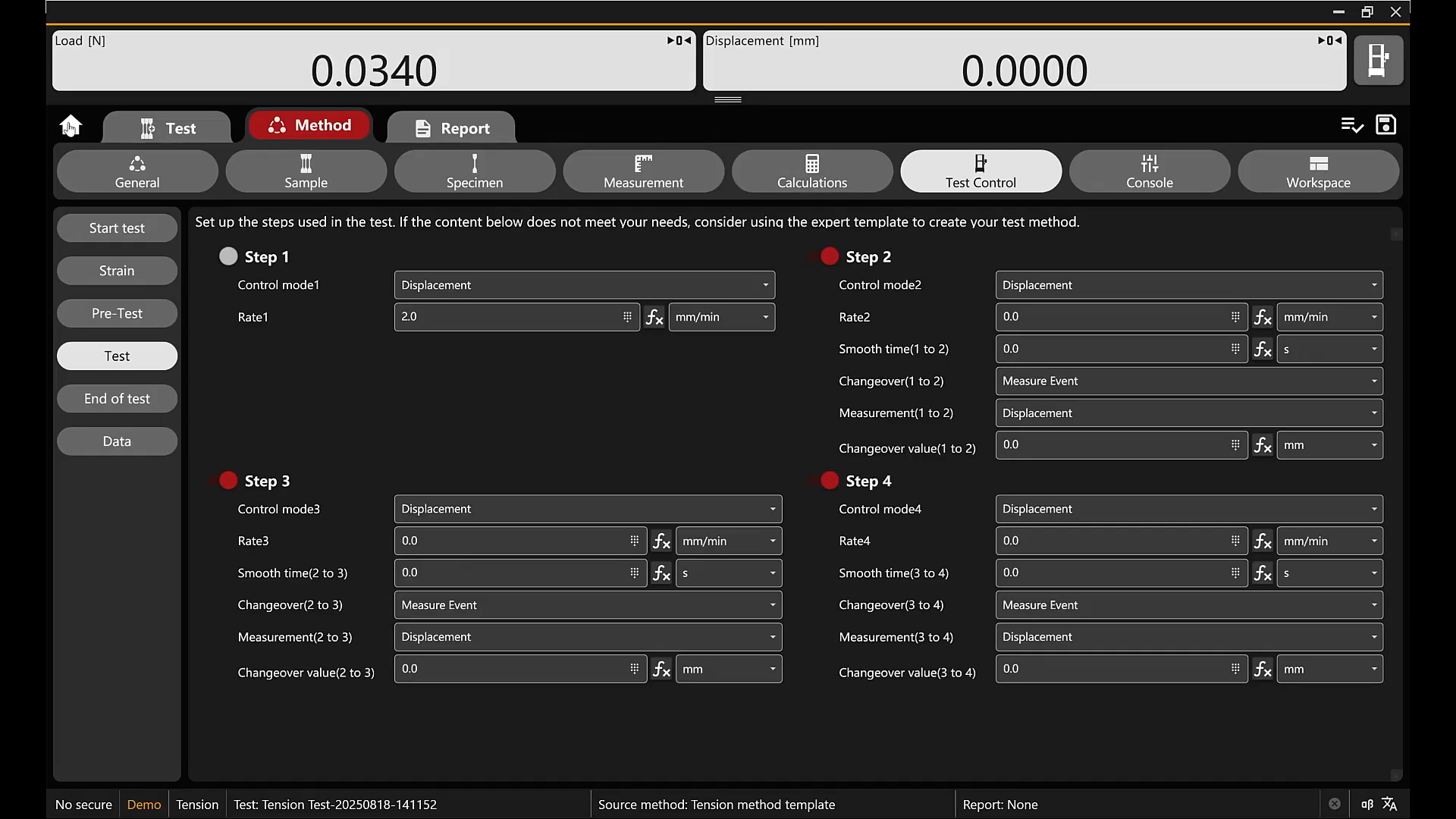

- Step-Based Test Control: Build methods as multi-step sequences (Step 1–Step 4) with configurable control logic and changeover conditions for consistent execution.

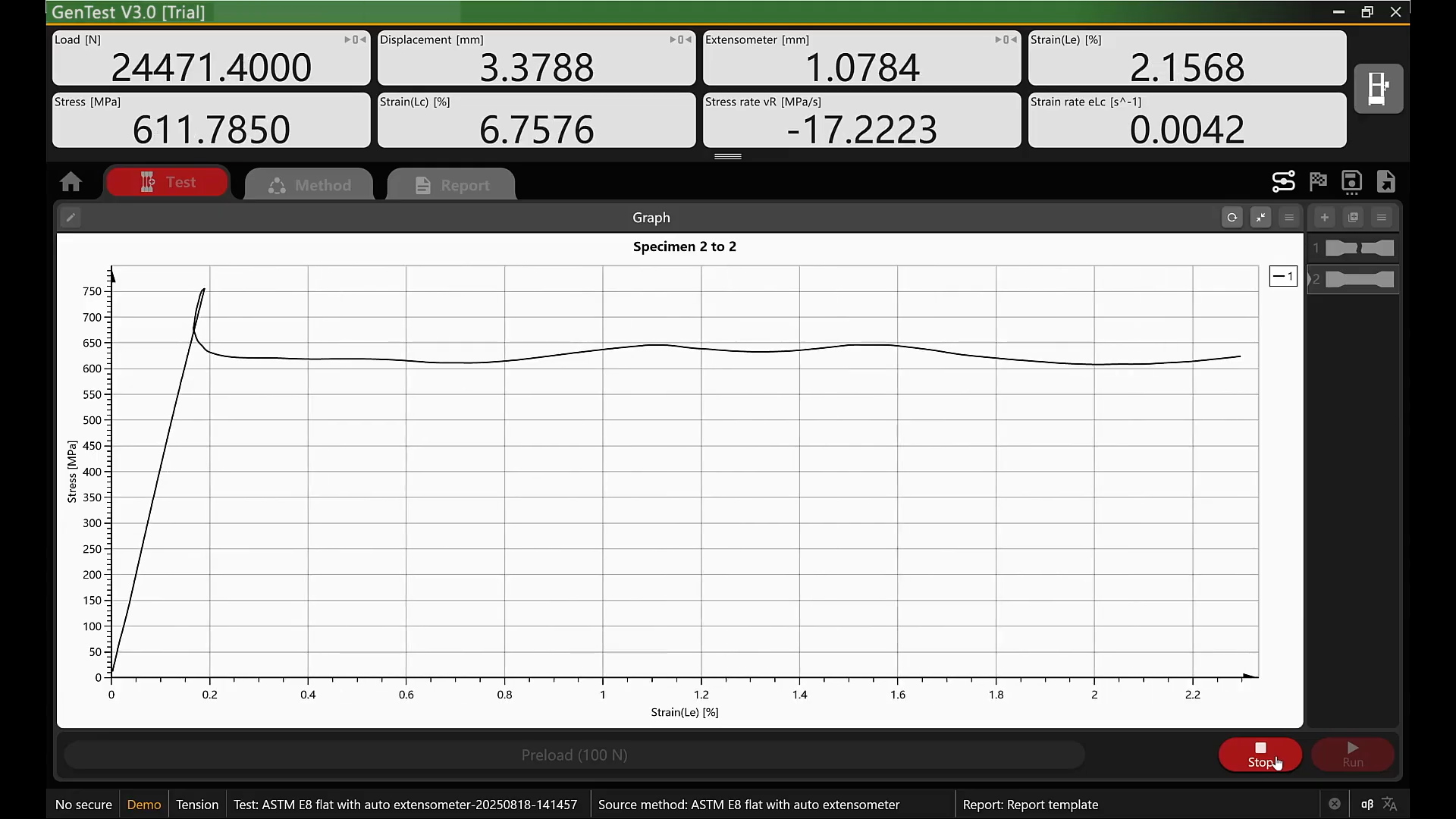

- Real-Time Curves And Monitoring: Monitor tests during the run using common views such as stress–strain, displacement–load, load–time, and strain–time.

- Built-In Calculations: Calculate key mechanical results such as UTS, yield strength (ReL/ReH/Rp), elongation, and modulus of elasticity (when configured by the method).

- Flexible Units And Formulas: Work in N, kN, kgf, lbf, MPa and apply formula-based expressions for method-specific conversions and outputs.

- Report Templates And Export: Generate standardized reports with tables and graphs, with export options that fit Word/Excel documentation workflows and raw data review.

- Demo Mode And Simulation Files: Train operators and validate methods using simulated runs without connecting to the testing machine.

- User Management And Permissions: Create users, assign roles, and control access to method editing and test operation for QA/QC environments.

Support, Quotes, And Technical Help

If you need help choosing the right GenTest configuration or would like to try the software on your NextGen UTM, our team can help. Contact us or request an online quote for installation guidance, licensing questions, compatibility confirmation for your machine, or any technical support if you already own GenTest, and we’ll respond with clear next steps and make sure you can get up and running quickly.

FAQs

GenTest is a data acquisition and analysis software platform for universal testing machines. It connects to the UTM controller and sensors, collects force, displacement and strain signals in real time, and converts them into mechanical properties that labs use for QA, QC and development work.

The software supports the main mechanical test types run on electromechanical UTMs. This includes tensile testing, compression testing, flexural or bending tests, and many variants defined by ASTM, ISO, DIN, EN and BS standards. With the right accessories and methods, labs can also use GenTest for tests such as shear or cyclic routines that stay within the machine’s capabilities.

Pre configured methods help operators run standard tests with almost no setup, while custom methods allow special internal procedures. In all cases, GenTest records curves, calculates key values like yield, UTS and modulus, and produces reports that can be stored, exported or shared with customers and auditors.

Click here to learn more about the product or here to receive a personalized quote.GenTest is aimed at labs that run routine and advanced mechanical tests on metals, polymers and other structural materials. Typical users include metal producers, automotive and aerospace suppliers, construction material labs, universities and R&D centers, and manufacturers of biomedical components and devices. Anywhere a universal testing machine is part of daily QA or development work, GenTest fits into the workflow.

On the people side, the software is used mainly by QA and QC engineers, lab technicians, test engineers, and R&D specialists who need clean, repeatable data. Lab managers and production or quality managers rely on GenTest reports and statistics to release batches and document compliance with ASTM, ISO, DIN, EN and BS standards.

IT and automation staff may also work with GenTest when connecting it to LIMS or plant systems. Because the interface is simple and method driven, both experienced engineers and newer operators can use the same platform without changing tools between routine and more complex test programs.

Click here to learn more about the product or here to receive a personalized quote.GenTest is built around the main international standards used in mechanical testing, including families of ASTM, ISO, DIN, EN and BS methods. The software includes pre-configured templates for common tensile, compression and flexural tests from these standards. When an operator selects the relevant method, GenTest loads the correct control mode, speeds, gauge length, calculations and result fields that match the chosen document.

Compliance is not just about naming the standard, but about following its exact test sequence and calculation rules. GenTest applies the appropriate formulas for yield, UTS, elongation, modulus and other parameters according to the method definition, so results stay consistent between operators and over time.

When standard bodies release revisions, updated templates can be added so labs keep working in line with the latest requirements without rebuilding methods from scratch. For special variants or internal procedures, users can adjust templates while keeping the standard as a base.

Click here to learn more about the product or here to receive a personalized quote.GenTest is primarily designed to work with NextGen’s own universal testing machines, especially the NG-EML electromechanical series. In this setup, communication with the controller, load cells, extensometers and safety circuits is already matched, so installation is straightforward and all features are available out of the box.

In some cases, integration with third-party systems is technically possible, but it depends on the electronics, communication protocol and available documentation from the machine manufacturer. If the controller can provide stable, documented signals or a suitable interface, a custom connection may be developed.

Because every non-NextGen machine is different, third-party compatibility is not guaranteed as a standard feature and should be evaluated case by case. Labs that want to connect GenTest to an existing UTM are usually asked to provide controller details, wiring information and current software setup so the technical team can confirm what is realistic.

Click here to learn more about the product or here to receive a personalized quote.The pre-configured method library saves time by giving operators ready-to-use templates for the most common ASTM, ISO, DIN, EN, and BS tests. Instead of setting every parameter manually, the operator chooses the material and method, and the software loads all required settings automatically. This includes test speed, control mode, gauge length, break conditions, calculations, and reporting fields.

For routine QA and QC work, this cuts setup time from several minutes to just a few clicks. It also reduces mistakes, since operators do not accidentally edit critical parameters or overlook required settings. Labs that test large batches benefit the most, because the same standardized method can be repeated across multiple samples with perfect consistency.

The library is updated as standards change, so users stay current without rebuilding methods themselves. This keeps daily workflow fast, stable, and easy even for newer operators.

Click here to learn more about the product or here to receive a personalized quote.Yes. GenTest allows operators to build custom methods when the testing requirement does not match any standard template. The process is straightforward: the user selects the basic test type, sets the control mode, defines speeds or load rates, and chooses the calculations needed for the final results. Each step is guided through simple menus, so the operator does not have to work with code or complex configuration files.

Custom methods can include unique naming, special stopping conditions, additional data fields, or alternate reporting formats. This is useful for R&D groups, labs working with new materials, or companies that follow internal specifications. Once saved, the method appears in the same library as the standard tests, so it can be reused by any operator with the right access level.

Because custom methods stay linked to all test data, results remain traceable and easy to review during audits or internal quality checks.

Click here to learn more about the product or here to receive a personalized quote.Real-time data acquisition allows GenTest to capture force, displacement, and strain continuously as the test happens. This gives a complete picture of material behavior rather than relying on a few individual readings. Because the system samples data at short time intervals, it records every critical event, including yield onset, peak load, sudden drops, or changes in slope.

This helps eliminate timing errors that occur when an operator tries to record values manually. It also improves repeatability between tests since the software uses the same sampling and processing rules every time. The operator does not influence the measurement, which is important for QA and audits.

Real-time capture also supports smoother and more accurate stress–strain curves. When the software has detailed data, it can calculate modulus, yield strength, UTS, and elongation with much higher precision. In short, real-time acquisition ensures that both routine testing and high-accuracy work produce consistent, trustworthy results.

Click here to learn more about the product or here to receive a personalized quote.GenTest includes a set of analysis tools that help labs extract all key mechanical properties directly from the recorded data. After the test finishes, the software processes the stress–strain or force–displacement curve and highlights the main calculated points. These tools can determine yield strength, ultimate tensile strength, modulus, elongation, reduction of area, break point values, and other method-specific parameters.

Users can zoom into any part of the curve, view numerical tables, and switch between different curve types depending on the sensors used during the test. Batch comparison tools allow labs to evaluate multiple samples together and see how consistent the results are across a production lot.

For more advanced work, the operator can overlay curves, adjust analysis ranges, or apply custom calculations when the test standard allows it. The goal is to give labs clear, fast, and repeatable results without needing external spreadsheets or manual interpretation.

Click here to learn more about the product or here to receive a personalized quote.Yes. GenTest calculates the main mechanical properties automatically as soon as the test finishes. The software reads the force, extension, and strain data, then applies the rules defined in the selected test method. For yield strength, GenTest supports both offset yield and automatic detection depending on the standard. The calculation follows the exact process required by ASTM or ISO so results stay consistent and repeatable.

Ultimate tensile strength is taken directly from the peak load divided by the original cross-sectional area. Elongation can be calculated from extensometer readings or from overall crosshead displacement if allowed by the method. Modulus is determined from the initial linear portion of the stress–strain curve, using the slope of the elastic region.

These calculations appear instantly on the screen along with the curve. Operators do not need manual spreadsheets or external tools, which reduces errors and speeds up reporting. The results stay linked to the raw data, so labs always have a complete record for QA, QC, or audits.

Click here to learn more about the product or here to receive a personalized quote.GenTest supports several export formats so labs can move test results into their own QA, QC, or LIMS systems without extra steps. The most common option is PDF, which is used for final reports that need a fixed layout with curves, key parameters, and header details. These PDFs can include a logo, sample information, operator details, and any calculations performed during the test.

For labs that work with spreadsheets or need further manipulation, GenTest can export data in Excel or CSV format. These files can contain raw points, processed stress–strain curves, and calculated values. Many laboratories use these exports for batch comparison, statistical review, or custom reporting outside the software.

Raw data exports are also available for users who want full time series or high-speed sampling information. These files make it easy to run custom analysis in MATLAB, Python, or other third-party tools. This flexibility keeps GenTest usable in simple QA environments and advanced R&D workflows.

Click here to learn more about the product or here to receive a personalized quote.GenTest reports are highly flexible, so labs can match them to their internal QA and QC formats. Users can select which parameters appear on the report, such as yield strength, ultimate tensile strength, elongation, modulus, offset values, test speed, machine ID, and operator name. Non-essential fields can be hidden to keep reports short and focused.

Layout options allow labs to include company logos, project details, customer information, or approval signatures. In many cases, labs build separate templates for internal use, customer reports, and regulatory documentation. Charts, tables, and summary sections can be rearranged or resized to highlight what matters most.

Once a template is set up, it can be applied to entire batches of tests, so every report from that method looks the same. This helps standardize documentation across multiple operators and shifts, which is important for audits and long-term record keeping.

Click here to learn more about the product or here to receive a personalized quote.Yes. GenTest is designed to work with instrumented tests that require high-speed sampling, for example when capturing detailed load and extension behavior around yield, necking, or sudden failure. When paired with compatible electronics, the software can record data at short time intervals so that peaks, drops, and transient events are not missed or smoothed out.

High-rate sampling is especially useful for applications such as rapid loading, brittle materials, or tests where fine detail around the maximum load is important for fracture analysis. GenTest can log full time series data and then display it as force–time, force–displacement, or stress–strain curves, depending on the connected sensors.

The exact maximum sampling rate depends on the controller and data acquisition hardware used with the UTM, but the software is built to handle dense datasets, store them reliably, and keep navigation and zooming responsive even with large files.

Click here to learn more about the product or here to receive a personalized quote.Yes. GenTest can be used in a multi-user environment where operators, supervisors, and administrators have different roles. Basic operators typically have access to run approved test methods, view results, and create reports, but cannot change critical calibration data or modify standard methods.

Supervisors or lab managers can manage test libraries, approve new or modified methods, and review results from different operators. Administrator-level users handle tasks such as user management, system configuration, and security settings. This structure helps prevent accidental changes to validated methods and keeps sensitive settings under control.

With separate logins, the system can record who ran each test, when it was performed, and which method was used. This supports accountability, easier troubleshooting, and better documentation during audits.

Click here to learn more about the product or here to receive a personalized quote.GenTest organizes test data around projects, methods, and sample identifiers, so labs can easily find past results. Each test record can include fields such as sample ID, batch number, operator, date, method used, and machine information. This gives a clear audit trail for QA, QC, and external inspections.

Test curves and calculated results are stored together in the software’s database or in structured folders, depending on how the system is installed. Labs can back up these data sets on their own servers or external storage as part of their IT policy. When needed, users can filter by date, material, customer, or work order to locate previous runs and compare them side by side.

Because all key meta-data stays linked to the raw and processed results, GenTest supports traceability from the final report back to the original test conditions and operator actions.

Click here to learn more about the product or here to receive a personalized quote.GenTest supports several options for working with LIMS and other lab management tools. At the basic level, the software can export results in common formats such as CSV, Excel and PDF. Many laboratories use these files to import test data into their existing LIMS or ERP systems using their own internal procedures.

For higher integration, GenTest can be set up to use consistent sample IDs, batch numbers and operator fields that match the structure of the external system. This makes mapping and automated import easier. In some projects, IT teams connect GenTest to LIMS through middleware or custom scripts that watch exported files and push them into the database.

The exact integration level depends on the lab’s infrastructure, but the software is built to support traceable data flow instead of locking test results inside a closed environment.

Click here to learn more about the product or here to receive a personalized quote.GenTest is designed to run on a standard modern Windows PC, so most laboratories do not need special hardware. In a typical setup, a current-generation multi-core processor and at least 8 GB of RAM are recommended. This keeps the interface responsive while collecting and displaying test data in real time, even during long or high-load tests. A stable SSD and a full HD monitor help with quick loading and clear display of curves and results.

For communication with the testing machine, the PC needs the appropriate physical ports, such as USB, Ethernet or serial, depending on the controller and electronics used on the UTM. A reliable power source and a stable local network are also important in multi-station labs. GenTest does not require a high-end graphics card, but the system should be dedicated to lab work as much as possible to avoid conflicts with other heavy software.

Click here to learn more about the product or here to receive a personalized quote.GenTest is designed so new operators can begin running tests with very little training. The interface uses clear menus, simple icons and step-by-step screens that mirror the actual workflow inside the lab. Instead of forcing users to configure every detail manually, the software presents ready test templates for common ASTM and ISO methods. A new operator can select a material type, choose a method and start the test with only a few adjustments.

During the test, all key readings appear in real time, and the layout does not overwhelm the screen with unnecessary data. Once the test finishes, the results and curves appear in a clean, easy-to-read format.

Because the interface hides complex settings until they are needed, new operators avoid mistakes and learn the process naturally while working. This reduces onboarding time and helps labs maintain consistent testing even with inexperienced staff.

Click here to learn more about the product or here to receive a personalized quote.Yes. GenTest includes built-in tools that guide labs through routine calibration and verification steps, so operators do not need separate programs or manual worksheets. The software can communicate with load cells, extensometers and crosshead encoders to check readings and confirm that each sensor responds within acceptable limits. This helps labs keep their UTM aligned with ASTM and ISO requirements, especially during periodic audits.

GenTest also stores calibration records inside the system, so labs can access past dates, operators and results without searching through paper files. When a verification step is due, the software can alert the user and walk them through the proper sequence, such as loading certified weights, checking zero balance or performing a strain verification.

These tools keep the machine ready for daily testing and help labs maintain traceable, reliable documentation for QA, QC or external inspections.

Click here to learn more about the product or here to receive a personalized quote.GenTest provides practical support options that help labs start working with the software quickly. New users receive onboarding assistance that explains setup, method selection, test execution and basic data review. This is usually enough for most QA and QC workflows.

If a lab needs deeper instruction, additional training sessions are available. These cover topics like custom method creation, advanced reporting, data comparison or integrating GenTest with existing lab systems. Training can be delivered remotely or on-site depending on the lab’s requirements.

Support teams are available through email, phone or remote access. They help with installation issues, test method configuration, hardware communication problems or data export questions. Users also receive access to documentation and simple step-by-step guides for daily operations.

Click here to learn more about the product or here to receive a personalized quote.GenTest receives updates several times a year. The schedule depends on two things: changes in international testing standards and new features requested by active laboratories. When ASTM, ISO, DIN or EN publish revisions that affect tensile, compression or flexural procedures, GenTest adds these adjustments quickly so labs stay compliant without rebuilding test methods on their own.

Feature updates arrive when the development team releases improvements like new test templates, better curve analysis, faster sampling or clearer reporting tools. These updates are based on real user feedback from metals, plastics and composite testing facilities.

Smaller maintenance patches are pushed as needed to fix performance issues or improve stability. Labs with active support contracts receive update notifications, release notes and assistance with installation. Overall, GenTest stays current at a steady pace, so long-term users always work with standards-ready and fully supported software.

Click here to learn more about the product or here to receive a personalized quote.Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.