Metal Testing Equipment

Precision Clamping Solutions with Compressed-Air Actuation from NextGen

NextGen's pneumatic grips are engineered for precise, high-throughput testing applications using universal testing machines (UTMs). These air-actuated systems ensure uniform clamping pressure, reduced operator fatigue, and faster sample mounting, ideal for quality control and R&D environments. Our pneumatic grips are designed to accommodate a wide range of specimen geometries and test types—including side-action, wedge-action, and snubbing—meeting or exceeding global testing standards such as ASTM D638, ASTM E8, ISO 6892, and DIN 51221. Whether you’re evaluating tensile properties of wires, composites, or polymers, these robust grips provide secure, repeatable holding force during critical tensile and compression procedures.

NextGen's pneumatic grips are engineered for precise, high-throughput testing applications using universal testing machines (UTMs). These air-actuated systems ensure uniform clamping pressure, reduced operator fatigue, and faster sample mounting, ideal for quality control and R&D environments. Our pneumatic grips are designed to accommodate a wide range of specimen geometries and test types—including side-action, wedge-action, and snubbing—meeting or exceeding global testing standards such as ASTM D638, ASTM E8, ISO 6892, and DIN 51221. Whether you’re evaluating tensile properties of wires, composites, or polymers, these robust grips provide secure, repeatable holding force during critical tensile and compression procedures.

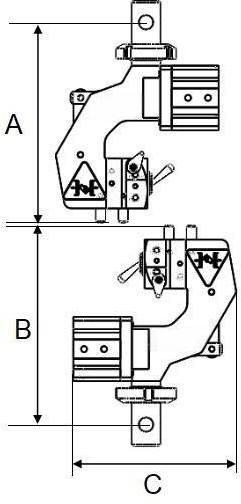

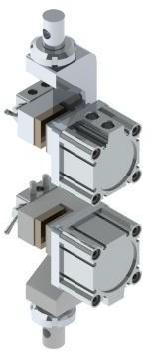

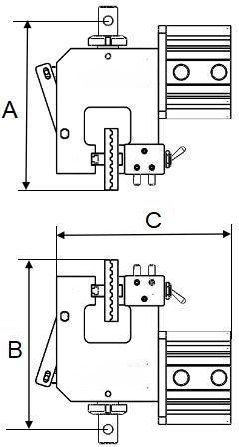

WCQA502A – Pneumatic Snubbing Tensile Grip

The WCQA502A Pneumatic Tensile Grip is engineered for filament testing under low-force tensile conditions. Utilizing a snubbing mechanism, it offers superior hold on delicate filament materials without introducing stress concentrations. Designed to support specimens up to 1.5 mm in diameter, this grip operates at forces up to 500 N. Pneumatic actuation ensures uniform clamping pressure, while Ø10 mm pin connections allow seamless integration with universal testing systems. Ideal for textile, fiber, or fine wire testing, the WCQA502A provides consistent and repeatable results in ambient laboratory environments.

The WCQA502A Pneumatic Tensile Grip is engineered for filament testing under low-force tensile conditions. Utilizing a snubbing mechanism, it offers superior hold on delicate filament materials without introducing stress concentrations. Designed to support specimens up to 1.5 mm in diameter, this grip operates at forces up to 500 N. Pneumatic actuation ensures uniform clamping pressure, while Ø10 mm pin connections allow seamless integration with universal testing systems. Ideal for textile, fiber, or fine wire testing, the WCQA502A provides consistent and repeatable results in ambient laboratory environments.

- Application: Tension test for fine filament and fiber materials.

- Maximum Capacity: Up to 500 N load.

- Connection: Ø10 mm pin (upper and lower), compatible with most standard UTMs.

- Height: 140 mm (upper and lower grips).

- Width: 115 mm.

- Specimen Size: ≤ 1.5 mm diameter.

- Grip Weight: 0.56 kg (upper and lower grips).

- Working Temperature: Ambient.

Technical Specifications – WCQA502A Pneumatic Snubbing Grip for Filament Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for filament |

| Maximum Force Capacity | ≤ 500 N |

| Upper Grip Weight | 0.56 kg |

| Lower Grip Weight | 0.56 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 140 mm |

| Lower Grip Height (B) | 140 mm |

| Width (C) | 115 mm |

| Specimen Size | ≤ 1.5 mm diameter |

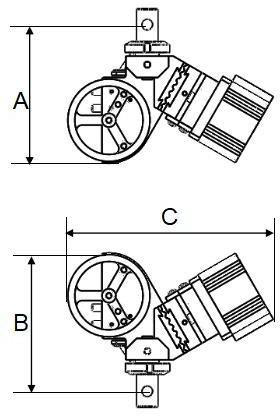

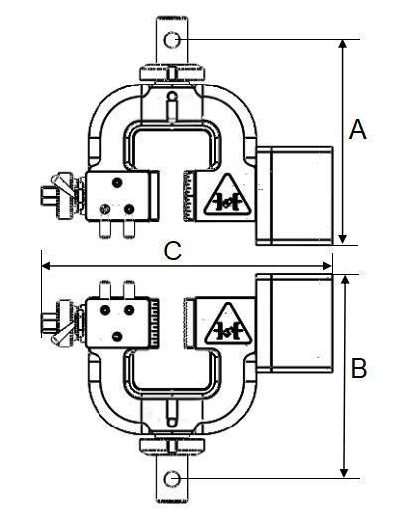

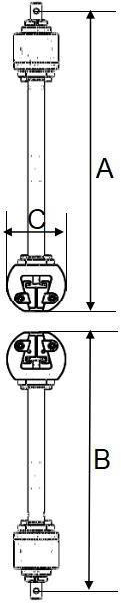

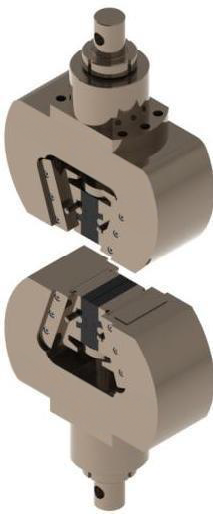

WCQA203A – Pneumatic Snubbing Tensile Grip

The WCQA203A Pneumatic Tensile Grip is designed for tensile testing of textile ropes and similar flexible materials. This grip features a pneumatic clamping mechanism combined with a snubbing design that securely holds specimens ranging from 1 mm to 3 mm in diameter. Its wave-profile jaw face enhances friction while minimizing slippage and damage. With a force capacity of up to 2 kN and standard Ø10 mm pin connections, WCQA203A ensures repeatable test performance and is well-suited for laboratory use in ambient conditions.

The WCQA203A Pneumatic Tensile Grip is designed for tensile testing of textile ropes and similar flexible materials. This grip features a pneumatic clamping mechanism combined with a snubbing design that securely holds specimens ranging from 1 mm to 3 mm in diameter. Its wave-profile jaw face enhances friction while minimizing slippage and damage. With a force capacity of up to 2 kN and standard Ø10 mm pin connections, WCQA203A ensures repeatable test performance and is well-suited for laboratory use in ambient conditions.

- Application: Tension test for textile ropes and soft cord-like materials.

- Maximum Capacity: Up to 2 kN load.

- Connection: Ø10 mm pin (upper and lower), standard UTM-compatible.

- Height: 130 mm (upper and lower grips).

- Width: 192 mm.

- Specimen Size: Ø1–3 mm.

- Jaw Face: Wave-profile, 50 mm (H) × 10 mm (W).

- Grip Weight: 1.42 kg (upper and lower grips).

- Working Temperature: Ambient.

Technical Specifications – WCQA203A Pneumatic Snubbing Grip for Textile Rope Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for textile rope |

| Maximum Force Capacity | ≤ 2 kN |

| Upper Grip Weight | 1.42 kg |

| Lower Grip Weight | 1.42 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 130 mm |

| Lower Grip Height (B) | 130 mm |

| Width (C) | 192 mm |

| Specimen Size | Ø1–3 mm |

| Wave-Profile Jaw Face | 50 mm (H) × 10 mm (W) |

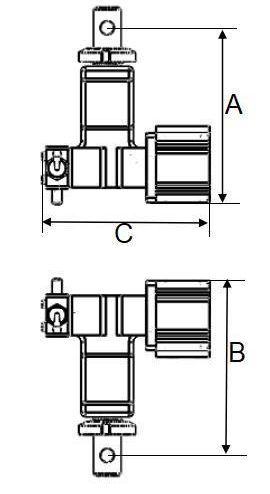

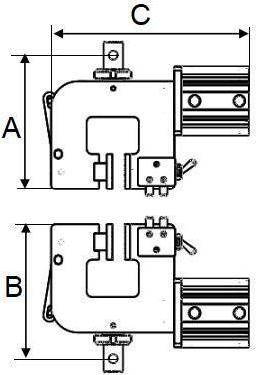

NGA502A – Pneumatic Side Action Tensile Grip

The NGA502A Pneumatic Tensile Grip is specifically designed for low-force testing of rubber, plastic films, and other thin, flexible materials. Its side-action clamping mechanism provides even pressure distribution across the specimen surface, minimizing slippage and specimen distortion. With a force capacity of up to 500 N, standard Ø10 mm pin connections, and compact dimensions, this grip is ideal for light-duty universal testing machines. It accommodates specimens up to 8 mm thick and is fitted with 30 × 25 mm jaws for secure, consistent gripping.

The NGA502A Pneumatic Tensile Grip is specifically designed for low-force testing of rubber, plastic films, and other thin, flexible materials. Its side-action clamping mechanism provides even pressure distribution across the specimen surface, minimizing slippage and specimen distortion. With a force capacity of up to 500 N, standard Ø10 mm pin connections, and compact dimensions, this grip is ideal for light-duty universal testing machines. It accommodates specimens up to 8 mm thick and is fitted with 30 × 25 mm jaws for secure, consistent gripping.

- Application: Tension testing of plastic film and rubber.

- Maximum Capacity: Up to 500 N load.

- Connection: Ø10 mm pin (upper and lower), compatible with compact UTMs.

- Height: 132 mm (upper and lower grips).

- Width: 124 mm.

- Specimen Thickness: ≤ 8 mm.

- Jaw Face Dimensions: 30 mm (H) × 25 mm (W).

- Grip Weight: 0.7 kg (upper and lower grips).

- Working Temperature: Ambient.

Technical Specifications – NGA502A Pneumatic Side Action Grip for Plastic Film and Rubber

| Parameter | Specification |

|---|---|

| Application | Tension test for plastic film and rubber |

| Maximum Force Capacity | ≤ 500 N |

| Upper Grip Weight | 0.7 kg |

| Lower Grip Weight | 0.7 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 132 mm |

| Lower Grip Height (B) | 132 mm |

| Width (C) | 124 mm |

| Jaw Face | 30 mm (H) × 25 mm (W) |

| Specimen Thickness | ≤ 8 mm |

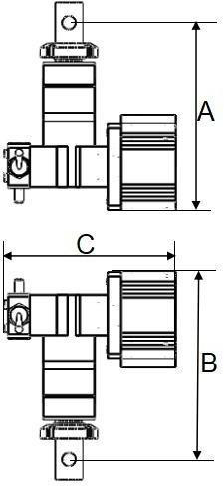

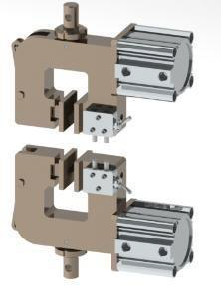

NGA103A – Pneumatic Side Action Tensile Grip

The NGA103A Pneumatic Tensile Grip is built for accurate and controlled testing of plastic film, rubber, and other soft sheet materials. With a maximum tensile load of 1 kN and 30 × 30 mm jaws, this fixture applies uniform clamping pressure via a side-action pneumatic mechanism. The grip accommodates specimens up to 6 mm thick and is equipped with Ø10 mm pin connections for seamless integration with universal testing systems. Ideal for quality control, research, and film testing labs, NGA103A ensures repeatable results in ambient conditions.

The NGA103A Pneumatic Tensile Grip is built for accurate and controlled testing of plastic film, rubber, and other soft sheet materials. With a maximum tensile load of 1 kN and 30 × 30 mm jaws, this fixture applies uniform clamping pressure via a side-action pneumatic mechanism. The grip accommodates specimens up to 6 mm thick and is equipped with Ø10 mm pin connections for seamless integration with universal testing systems. Ideal for quality control, research, and film testing labs, NGA103A ensures repeatable results in ambient conditions.

- Application: Tension testing of plastic film and rubber.

- Maximum Capacity: Up to 1 kN load.

- Connection: Ø10 mm pin (upper and lower), compatible with tabletop and benchtop UTMs.

- Height: 140 mm (upper and lower grips).

- Width: 128 mm.

- Specimen Thickness: ≤ 6 mm.

- Jaw Face Dimensions: 30 mm × 30 mm.

- Grip Weight: 0.9 kg (upper and lower grips).

- Working Temperature: Ambient.

Technical Specifications – NGA103A Pneumatic Side Action Grip for Plastic Film and Rubber

| Parameter | Specification |

|---|---|

| Application | Tension test for plastic film and rubber |

| Maximum Force Capacity | ≤ 1 kN |

| Upper Grip Weight | 0.9 kg |

| Lower Grip Weight | 0.9 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 140 mm |

| Lower Grip Height (B) | 140 mm |

| Width (C) | 128 mm |

| Jaw Face | 30 mm × 30 mm |

| Specimen Thickness | ≤ 6 mm |

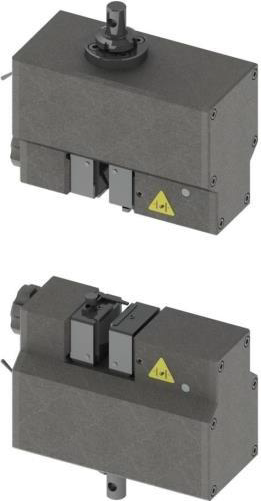

NGA103C – Pneumatic Side Action Tensile Grip

The NGA103C Pneumatic Tensile Grip is engineered for versatile tension testing of textile fabrics, plastic sheets, rubber, and films. With a load capacity of up to 1 kN and dual jaw face options—serrated for cloth, rubber, and plastic sheet, and rubber-coated for film—this grip ensures secure, application-specific clamping. Its robust frame, 32 × 32 mm jaw faces, and support for specimen thicknesses up to 14 mm make it ideal for both quality control and R&D environments. Standard Ø10 mm pin connections enable integration with most universal testing machines.

The NGA103C Pneumatic Tensile Grip is engineered for versatile tension testing of textile fabrics, plastic sheets, rubber, and films. With a load capacity of up to 1 kN and dual jaw face options—serrated for cloth, rubber, and plastic sheet, and rubber-coated for film—this grip ensures secure, application-specific clamping. Its robust frame, 32 × 32 mm jaw faces, and support for specimen thicknesses up to 14 mm make it ideal for both quality control and R&D environments. Standard Ø10 mm pin connections enable integration with most universal testing machines.

- Application: Tension tests for textile fabric, plastic sheet, rubber, and films.

- Maximum Capacity: Up to 1 kN load.

- Connection: Ø10 mm pin (upper and lower), UTM-compatible.

- Height: 135 mm (upper and lower grips).

- Width: 190 mm.

- Specimen Thickness: ≤ 14 mm.

- Jaw Face Options:

- Serrated: 32 mm × 32 mm (for cloth, plastic sheet, rubber)

- Rubber-coated: 32 mm × 32 mm (for plastic film)

- Grip Weight: 2.61 kg (upper and lower grips).

- Working Temperature: Ambient.

Technical Specifications – NGA103C Pneumatic Side Action Grip for Textile, Rubber & Film Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for textile fabric, plastic sheet, film, rubber etc. |

| Maximum Force Capacity | ≤ 1 kN |

| Upper Grip Weight | 2.61 kg |

| Lower Grip Weight | 2.61 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 135 mm |

| Lower Grip Height (B) | 135 mm |

| Width (C) | 190 mm |

| Serrated Jaw Face | 32 mm × 32 mm (cloth, plastic sheet, rubber) |

| Rubber-Coated Jaw Face | 32 mm × 32 mm (plastic film) |

| Specimen Thickness | ≤ 14 mm |

NGA503A – Pneumatic Side Action Tensile Grip

The NGA503A Pneumatic Tensile Grip is a high-capacity fixture designed for tensile testing of waterproof rolls, heavy textile cloth, and similar wide, flexible materials. With a force capacity of up to 5 kN, this side-action grip provides stable and uniform clamping pressure for specimens up to 20 mm thick. Its robust 225 mm wide body and 150 mm height allow for handling large samples, making it ideal for industrial and construction material testing. Equipped with standard Ø10 mm pin connections, NGA503A integrates easily into universal testing machines.

The NGA503A Pneumatic Tensile Grip is a high-capacity fixture designed for tensile testing of waterproof rolls, heavy textile cloth, and similar wide, flexible materials. With a force capacity of up to 5 kN, this side-action grip provides stable and uniform clamping pressure for specimens up to 20 mm thick. Its robust 225 mm wide body and 150 mm height allow for handling large samples, making it ideal for industrial and construction material testing. Equipped with standard Ø10 mm pin connections, NGA503A integrates easily into universal testing machines.

- Application: Tension test for waterproof roll materials and heavy textile cloth.

- Maximum Capacity: Up to 5 kN load.

- Connection: Ø10 mm pin (upper and lower), compatible with universal testing systems.

- Height: 150 mm (upper and lower grips).

- Width: 225 mm.

- Specimen Thickness: ≤ 20 mm.

- Grip Weight: 4.35 kg (upper and lower grips).

- Working Temperature: Ambient.

Technical Specifications – NGA503A Pneumatic Side Action Grip for Waterproof Rolls & Textiles

| Parameter | Specification |

|---|---|

| Application | Tension test for waterproof roll, textile cloth etc. |

| Maximum Force Capacity | ≤ 5 kN |

| Upper Grip Weight | 4.35 kg |

| Lower Grip Weight | 4.35 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 150 mm |

| Lower Grip Height (B) | 150 mm |

| Width (C) | 225 mm |

| Specimen Thickness | ≤ 20 mm |

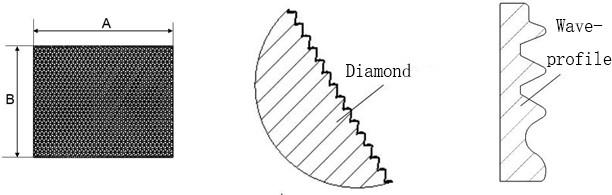

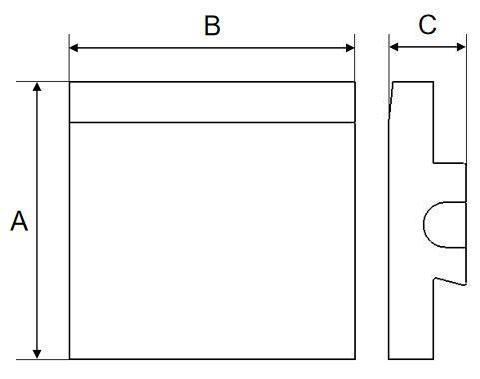

Optional Jaw Faces for NGA503A Pneumatic Grip

The NGA503A Pneumatic Grip supports interchangeable jaw faces to suit a variety of specimen types and surface conditions. Available in both diamond and wave-profile configurations, these jaw faces enhance grip performance and minimize slippage based on the material tested. Users can choose from different widths and heights for optimized contact area, depending on whether the specimen is textile-based or a heavier waterproof roll.

The NGA503A Pneumatic Grip supports interchangeable jaw faces to suit a variety of specimen types and surface conditions. Available in both diamond and wave-profile configurations, these jaw faces enhance grip performance and minimize slippage based on the material tested. Users can choose from different widths and heights for optimized contact area, depending on whether the specimen is textile-based or a heavier waterproof roll.

Available options:

| No. | Width (A) | Height (B) | Jaw Type | Recommended Specimen |

|---|---|---|---|---|

| NGA503A-07 | 50 mm | 40 mm | Diamond | Textile fabric |

| NGA503A-10 | 60 mm | 30 mm | Diamond | Textile fabric |

| NGA503A-11 | 100 mm | 35 mm | Wave-profile | Waterproof roll |

- Diamond jaws offer a serrated surface ideal for holding flexible and textured materials such as textile fabric.

- Wave-profile jaws are better suited for thick, coated, or layered materials such as waterproof rolls, offering increased surface contact.

NGA503G – Pneumatic Side Action Tensile Grip

The NGA503G Pneumatic Tensile Grip is a heavy-duty fixture designed for high-force testing of waterproof rolls, thick textiles, and coated materials. With a maximum force capacity of 5 kN and a wide 65 × 60 mm sawtooth jaw face, this grip ensures firm and stable clamping of demanding specimens. Its rugged construction, 180 mm grip height, and Ø10 mm pin compatibility make it ideal for large-scale sample testing in production and R&D settings. The wide sawtooth design is especially effective for preventing slippage during the testing of waterproof and laminated materials.

The NGA503G Pneumatic Tensile Grip is a heavy-duty fixture designed for high-force testing of waterproof rolls, thick textiles, and coated materials. With a maximum force capacity of 5 kN and a wide 65 × 60 mm sawtooth jaw face, this grip ensures firm and stable clamping of demanding specimens. Its rugged construction, 180 mm grip height, and Ø10 mm pin compatibility make it ideal for large-scale sample testing in production and R&D settings. The wide sawtooth design is especially effective for preventing slippage during the testing of waterproof and laminated materials.

- Application: Tension test for waterproof roll materials and heavy textile cloth.

- Maximum Capacity: Up to 5 kN load.

- Connection: Ø10 mm pin (upper and lower), suitable for high-strength testing machines.

- Height: 180 mm (upper and lower grips).

- Width: 185 mm.

- Specimen Thickness: 10 mm.

- Jaw Face Type: Wide sawtooth – 65 mm (H) × 60 mm (W).

- Grip Weight: 7.12 kg (upper and lower grips).

- Working Temperature: Ambient.

Technical Specifications – NGA503G Pneumatic Side Action Grip for Waterproof Rolls

| Parameter | Specification |

|---|---|

| Application | Tension test for waterproof roll, textile cloth etc. |

| Maximum Force Capacity | ≤ 5 kN |

| Upper Grip Weight | 7.12 kg |

| Lower Grip Weight | 7.12 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 180 mm |

| Lower Grip Height (B) | 180 mm |

| Width (C) | 185 mm |

| Jaw Face | Wide sawtooth – 65 mm (H) × 60 mm (W) |

| Specimen Thickness | 10 mm |

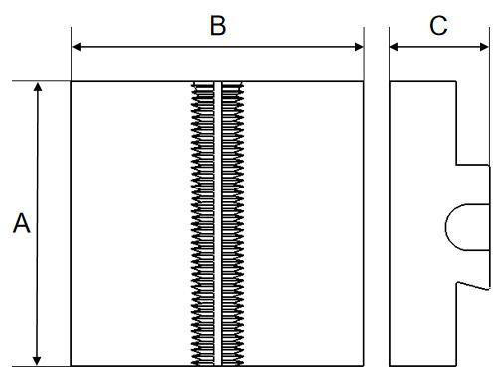

Optional Jaw Faces for NGA503A/G Pneumatic Grips

The NGA503A and NGA503G pneumatic grips support a range of interchangeable jaw faces, enabling users to match jaw surfaces to specific specimen types. Whether you're testing textile cloth or coated fabrics, these options ensure optimal grip, reduce slippage, and preserve specimen integrity. Available in sawtooth and flat types, all jaws feature the same 40 mm width but vary in length and surface pattern.

Available options:

| No. | Jaw Type | Length (A) | Width (B) | Recommended Specimen |

|---|---|---|---|---|

| NGA503A-08/09 | Sawtooth | 50 mm | 40 mm | Textile cloth |

| NGA503A-10/11 | Sawtooth | 80 mm | 40 mm | Textile cloth |

| NGA503A-12/13 | Flat | 80 mm | 40 mm | Textile cloth |

| NGA503A-14/15 | Flat | 50 mm | 40 mm | Textile cloth |

- Sawtooth jaws are ideal for woven or textured textiles requiring higher gripping strength.

- Flat jaws are better suited for delicate or laminated cloth materials that could be damaged by serration.

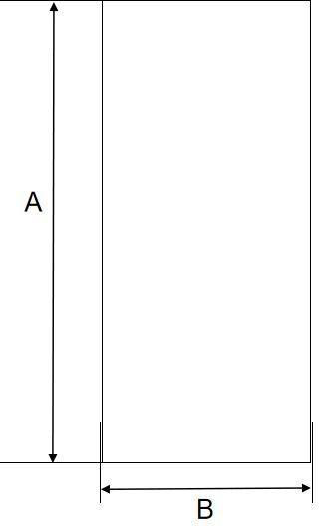

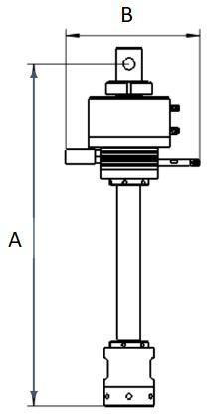

NGB104A – Pneumatic Side Action Tensile Grip

The NGB104A Pneumatic Tensile Grip is a high-capacity fixture designed for tensile testing of both metallic and non-metallic flat specimens. With a force capacity of up to 10 kN and a serrated jaw face measuring 50 × 45 mm, this grip provides superior holding strength for flat test samples. Its robust construction and weight make it ideal for demanding test applications in industrial or research environments. The NGB104A uses Ø10 mm pin connections for compatibility with a wide range of universal testing machines.

The NGB104A Pneumatic Tensile Grip is a high-capacity fixture designed for tensile testing of both metallic and non-metallic flat specimens. With a force capacity of up to 10 kN and a serrated jaw face measuring 50 × 45 mm, this grip provides superior holding strength for flat test samples. Its robust construction and weight make it ideal for demanding test applications in industrial or research environments. The NGB104A uses Ø10 mm pin connections for compatibility with a wide range of universal testing machines.

- Application: Tension test for metallic and non-metallic flat specimens.

- Maximum Capacity: Up to 10 kN load.

- Connection: Ø10 mm pin (upper and lower), UTM-compatible.

- Height (A): 210 mm.

- Width (B): 247 mm.

- Jaw Face Type: Serrated – 50 mm (H) × 45 mm (W).

- Grip Weight: 10.7 kg (upper and lower grips).

- Working Temperature: Ambient.

Technical Specifications – NGB104A Pneumatic Side Action Grip for Flat Specimen Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for metallic and non-metallic flat specimen |

| Maximum Force Capacity | ≤ 10 kN |

| Upper Grip Weight | 10.7 kg |

| Lower Grip Weight | 10.7 kg |

| Working Temperature | Ambient |

| Connection Type | Ø10 mm pin (upper and lower) |

| Height (A) | 210 mm |

| Width (B) | 247 mm |

| Serrated Jaw Face | 50 mm (H) × 45 mm (W) |

NGC204A – Pneumatic Wedge Action Tensile Grip

![]() The NGC204A Pneumatic Wedge Action Grip is designed for high-force tensile testing of round and flat specimens made from metal and plastic. Engineered to support loads up to 20 kN, this grip offers exceptional thermal range performance from –73 °C to +315 °C. The wedge-action mechanism provides self-tightening grip under load, while optional flat jaws in 0–6 mm and 6–12 mm ranges allow for flexible specimen dimensions. Ideal for materials with tensile strengths below 600 MPa and hardness below 30 HRC, NGC204A is suited for research and quality assurance in metal, plastic, and composite testing environments.

The NGC204A Pneumatic Wedge Action Grip is designed for high-force tensile testing of round and flat specimens made from metal and plastic. Engineered to support loads up to 20 kN, this grip offers exceptional thermal range performance from –73 °C to +315 °C. The wedge-action mechanism provides self-tightening grip under load, while optional flat jaws in 0–6 mm and 6–12 mm ranges allow for flexible specimen dimensions. Ideal for materials with tensile strengths below 600 MPa and hardness below 30 HRC, NGC204A is suited for research and quality assurance in metal, plastic, and composite testing environments.

- Application: Tension testing for round and flat metal/plastic specimens.

- Maximum Capacity: Up to 20 kN load.

- Connection: Ø10 mm pin (upper and lower), compatible with heavy-duty UTMs.

- Height: 568 mm (upper grip), 488 mm (lower grip).

- Width: 110 mm.

- Grip Weight: 7.73 kg (upper grip), 7.39 kg (lower grip).

- Jaw Options: Flat jaws – 0–6 mm or 6–12 mm.

- Working Temperature: –73 °C to +315 °C.

- Note: For specimens with hardness <30 HRC and tensile strength <600 MPa.

Technical Specifications – NGC204A Pneumatic Wedge Action Grip

| Parameter | Specification |

|---|---|

| Application | Tension test for round and flat specimen of metal and plastic |

| Maximum Force Capacity | ≤ 20 kN |

| Upper Grip Weight | 7.73 kg |

| Lower Grip Weight | 7.39 kg |

| Working Temperature | –73 °C to +315 °C |

| Connection Type | Ø10 mm pin (upper and lower) |

| Upper Grip Height (A) | 568 mm |

| Lower Grip Height (B) | 488 mm |

| Width (C) | 110 mm |

| Flat Jaw Options | 0–6 mm; 6–12 mm |

| Specimen Condition Note | Hardness < 30 HRC; Tensile strength < 600 MPa |

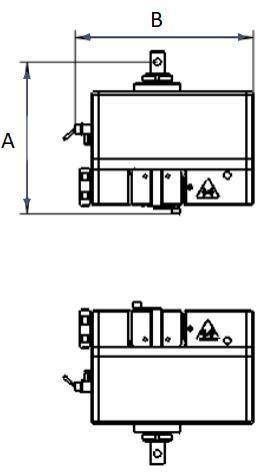

NGC504A – Pneumatic Wedge Action Tensile Grip

The NGC504A Pneumatic Wedge Action Grip is designed for heavy-duty tensile testing of flat and round metallic specimens. With a robust load capacity of up to 50 kN and a wide thermal operating range from –73 °C to +315 °C, this grip is ideal for applications requiring consistent clamping under extreme conditions. Featuring Ø18 mm pin connections and compatibility with specimens from Ø5 mm to Ø20 mm, it is commonly used in advanced material testing where reliability and performance are critical. The grip is suitable for specimens with hardness below 30 HRC and tensile strength below 600 MPa.

The NGC504A Pneumatic Wedge Action Grip is designed for heavy-duty tensile testing of flat and round metallic specimens. With a robust load capacity of up to 50 kN and a wide thermal operating range from –73 °C to +315 °C, this grip is ideal for applications requiring consistent clamping under extreme conditions. Featuring Ø18 mm pin connections and compatibility with specimens from Ø5 mm to Ø20 mm, it is commonly used in advanced material testing where reliability and performance are critical. The grip is suitable for specimens with hardness below 30 HRC and tensile strength below 600 MPa.

- Application: Tension test for flat and round metal specimens.

- Maximum Capacity: Up to 50 kN load.

- Connection: Ø18 mm pin (upper and lower), compatible with high-force testing machines.

- Height: 534 mm.

- Width: 208 mm.

- Specimen Size Range: Ø5 mm – Ø20 mm.

- Grip Weight: 13.97 kg (upper and lower grips).

- Working Temperature: –73 °C to +315 °C.

- Note: For specimen hardness <30 HRC and tensile strength <600 MPa.

Technical Specifications – NGC504A Pneumatic Wedge Action Grip for Metal Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal |

| Maximum Force Capacity | ≤ 50 kN |

| Upper Grip Weight | 13.97 kg |

| Lower Grip Weight | 13.97 kg |

| Working Temperature | –73 °C to +315 °C |

| Connection Type | Ø18 mm pin (upper and lower) |

| Height (A) | 534 mm |

| Width (B) | 208 mm |

| Specimen Size | Ø5 mm – Ø20 mm |

| Note | Specimen hardness <30 HRC; Tensile strength <600 MPa |

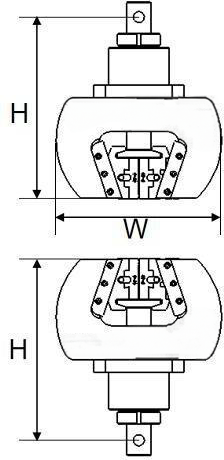

NGD105D – Pneumatic Wedge Action Tensile Grip

The NGD105D Pneumatic Wedge Action Grip is designed for high-load tensile testing of both flat and round specimens made from metal, composites, and rigid plastics. With an impressive capacity of up to 100 kN, this grip delivers reliable self-tightening performance under load. Equipped with Ø18 mm pin connections and a durable structure, it is ideal for advanced testing applications requiring large grip dimensions. The system is intended for materials with hardness values below 30 HRC and tensile strength under 600 MPa, making it a powerful option for quality assurance in structural materials.

The NGD105D Pneumatic Wedge Action Grip is designed for high-load tensile testing of both flat and round specimens made from metal, composites, and rigid plastics. With an impressive capacity of up to 100 kN, this grip delivers reliable self-tightening performance under load. Equipped with Ø18 mm pin connections and a durable structure, it is ideal for advanced testing applications requiring large grip dimensions. The system is intended for materials with hardness values below 30 HRC and tensile strength under 600 MPa, making it a powerful option for quality assurance in structural materials.

- Application: Tension test for flat and round specimens of metal, composite, and rigid plastic.

- Maximum Capacity: 100 kN.

- Connection: Ø18 mm pin (upper and lower), compatible with high-capacity universal testing machines.

- Height: 299 mm.

- Width: 270 mm.

- Grip Weight: 30 kg (upper and lower grips).

- Working Temperature: Ambient.

- Note: Suitable for specimens with hardness below 30 HRC and tensile strength below 600 MPa.

Technical Specifications – NGD105D Pneumatic Wedge Action Grip for Metal and Composite Testing

| Parameter | Specification |

|---|---|

| Application | Tension test for flat and round specimen of metal, composite, rigid plastic |

| Maximum Force Capacity | 100 kN |

| Upper Grip Weight | 30 kg |

| Lower Grip Weight | 30 kg |

| Working Temperature | Ambient |

| Connection Type | Ø18 mm pin (upper and lower) |

| Height (H) | 299 mm |

| Width (W) | 270 mm |

| Note | Specimen hardness <30 HRC; Tensile strength <600 MPa |

Optional Jaw Faces for NGD105D Pneumatic Grip

The NGD105D Wedge Action Grip supports a series of interchangeable jaw faces designed to accommodate a wide range of specimen shapes and sizes. Both flat and Vee-type jaws are available, allowing the grip to handle flat metal, composites, and round specimens with diameters up to Φ26 mm. These hardened jaws maintain stable clamping and consistent load transfer during testing under forces up to 100 kN.

The NGD105D Wedge Action Grip supports a series of interchangeable jaw faces designed to accommodate a wide range of specimen shapes and sizes. Both flat and Vee-type jaws are available, allowing the grip to handle flat metal, composites, and round specimens with diameters up to Φ26 mm. These hardened jaws maintain stable clamping and consistent load transfer during testing under forces up to 100 kN.

Available options:

| No. | Jaw Type | Specimen Size | Jaw Face A (mm) | Jaw Face B (mm) | Jaw Face C (mm) |

|---|---|---|---|---|---|

| NGD105D-02 | Flat | 0–10 mm | 68 | 70 | 24 |

| NGD105D-03 | Flat | 10–20 mm | 68 | 70 | 19 |

| NGD105D-04 | Vee | Φ5–Φ12 mm | 68 | 70 | 24 |

| NGD105D-05 | Vee | Φ12–Φ19 mm | 68 | 70 | 24 |

| NGD105D-06 | Vee | Φ19–Φ26 mm | 68 | 70 | 24 |

- Flat jaws are ideal for rigid plastics and flat metals.

- Vee jaws are recommended for round specimens of varying diameters.

NextGen’s pneumatic grips are ideal for users seeking efficient, safe, and standardized tensile and compression testing solutions. Fully compatible with NG-EML and NG-SHM UTMs, these grips offer unmatched speed, repeatability, and ergonomic advantage. Whether you’re upgrading your test lab or configuring a new system, our pneumatic grip lineup ensures optimal performance across a broad spectrum of materials. Contact NextGen for expert assistance in selecting the right configuration for your testing needs.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.