Metal Testing Equipment

Overview of Snubbing Grips for Tensile Testing of Wires, Cables, Ropes, and Geogrids

Snubbing grips (also known as capstan grips) are designed to secure challenging specimens like steel wires, wire ropes, fiber ropes, textile strips, and geogrids during tensile testing. They work by wrapping the specimen around curved surfaces to increase friction and prevent slippage under load. This makes them ideal for high-strength materials that tend to slip or break at the grips in standard clamps. The NextGen snubbing grip range (compatible with most universal testing machines) covers a variety of specimen types and sizes – from fine metal wires and braided cables to broad textile webbings (seat belts) and polymer geogrids used in civil engineering. Each grip in this series is engineered with robust materials and a precise clamping mechanism to ensure accurate alignment, even force distribution, and repeatable results in accordance with relevant test standards. Below is a detailed overview of each snubbing grip model, including their technical specifications and suitable applications.

Snubbing grips (also known as capstan grips) are designed to secure challenging specimens like steel wires, wire ropes, fiber ropes, textile strips, and geogrids during tensile testing. They work by wrapping the specimen around curved surfaces to increase friction and prevent slippage under load. This makes them ideal for high-strength materials that tend to slip or break at the grips in standard clamps. The NextGen snubbing grip range (compatible with most universal testing machines) covers a variety of specimen types and sizes – from fine metal wires and braided cables to broad textile webbings (seat belts) and polymer geogrids used in civil engineering. Each grip in this series is engineered with robust materials and a precise clamping mechanism to ensure accurate alignment, even force distribution, and repeatable results in accordance with relevant test standards. Below is a detailed overview of each snubbing grip model, including their technical specifications and suitable applications.

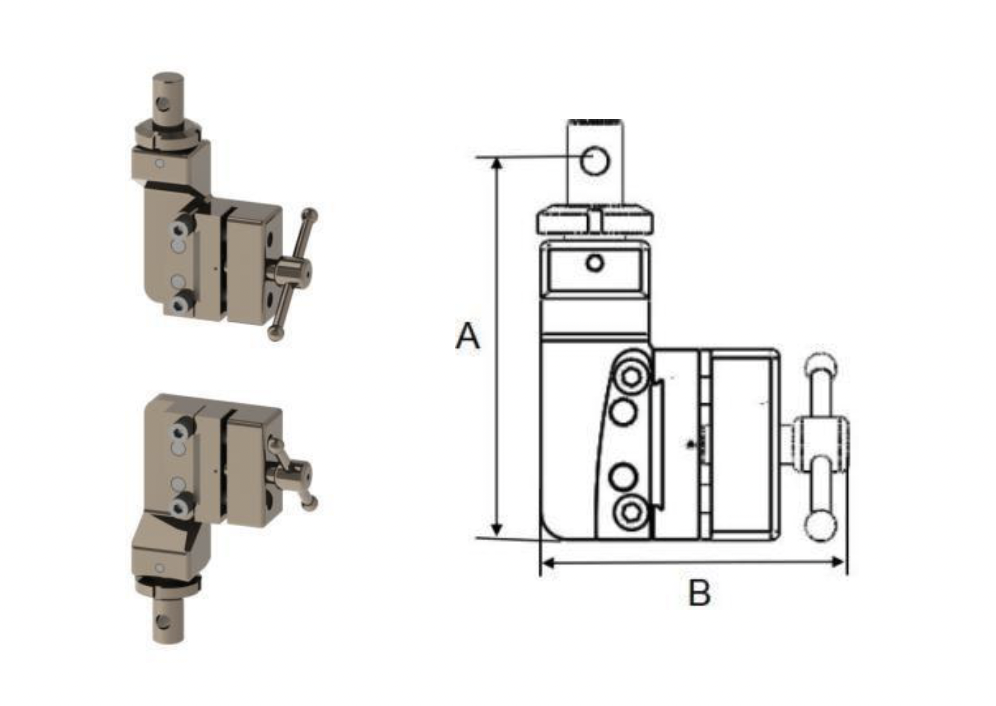

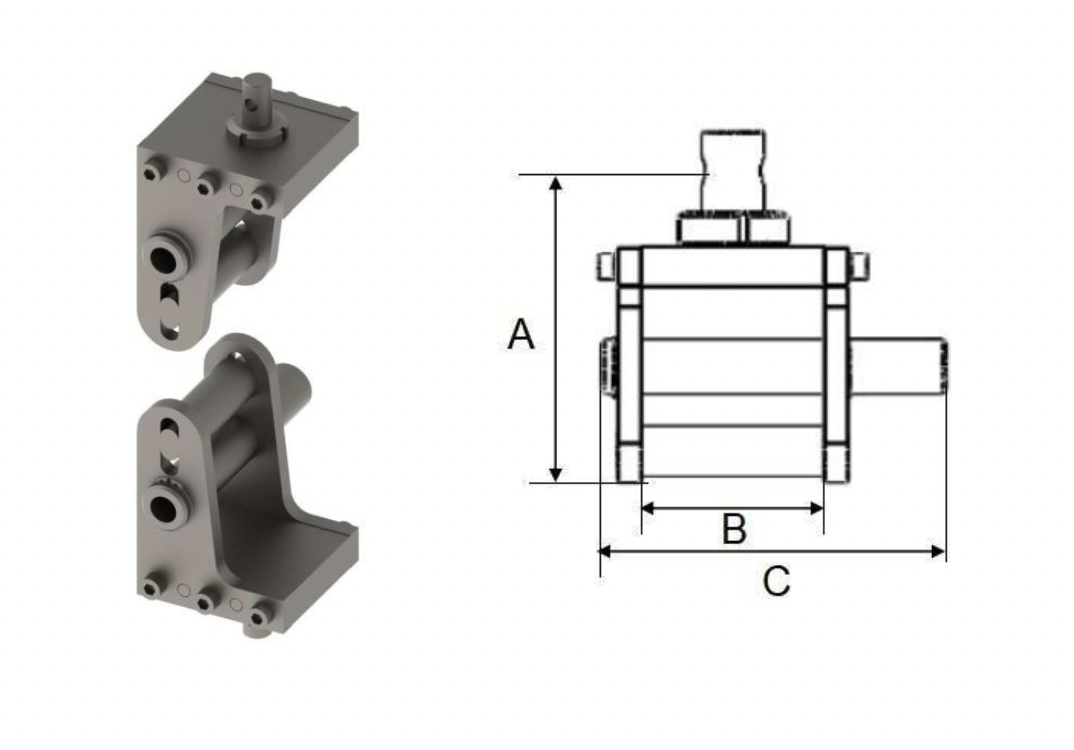

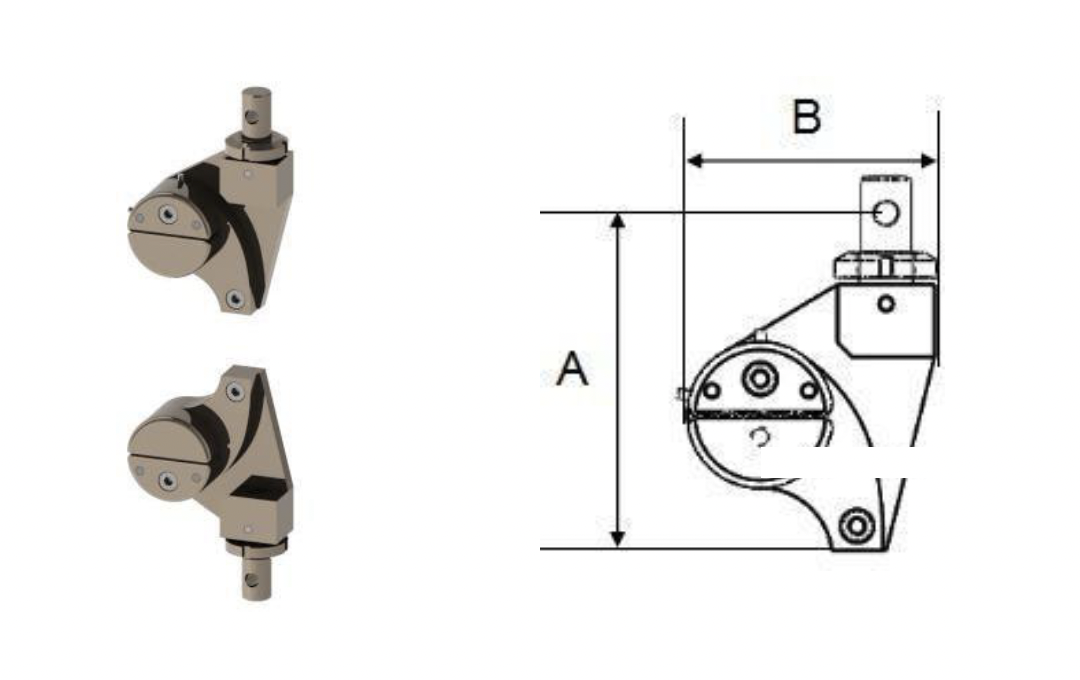

WCA203B – Steel Wire Snubbing Grip

The WCA203B Steel Wire Snubbing Grip is a specialized grip for tensile testing of fine steel wires. It features a wrap-around snubbing design to prevent slippage of thin wire specimens during high-stress testing. Despite its compact size, this grip securely holds very small diameter wires for accurate strength measurements. Key technical parameters for the WCA203B are:

- Application: Tension tests for steel wires (e.g. piano wire, small cable strands).

- Maximum Capacity: Up to 2 kN load.

- Clamping Range: Accommodates wire diameters from 0.5 mm to 1.5 mm (Φ0.5–Φ1.5 mm).

- Connection: Φ10 mm pin coupling on upper and lower grip, for easy mounting to the UTM crossheads.

- Dimensions: Height approximately 145 mm; grip body width approximately 110 mm (compact form factor for small specimens).

- Grip Mechanism: Wrap-around snubbing capstan design (no separate jaw faces needed for smooth wire).

- Grip Weight: Approximately 1.99 kg each (upper and lower grip halves).

- Working Temperature: Ambient conditions (standard room temperature testing).

Technical Specifications – WCA203B Wire and Cable Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tensile testing of steel wire |

| Maximum Force Capacity | ≤ 2 kN |

| Connection Type |

Upper Grip: Ø10 mm pin |

| Overall Height (A) | 145 mm |

| Grip Body Width (B) | 110 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 1.99 kg |

| Compatible Specimen Diameter | Ø0.5 – Ø1.5 mm |

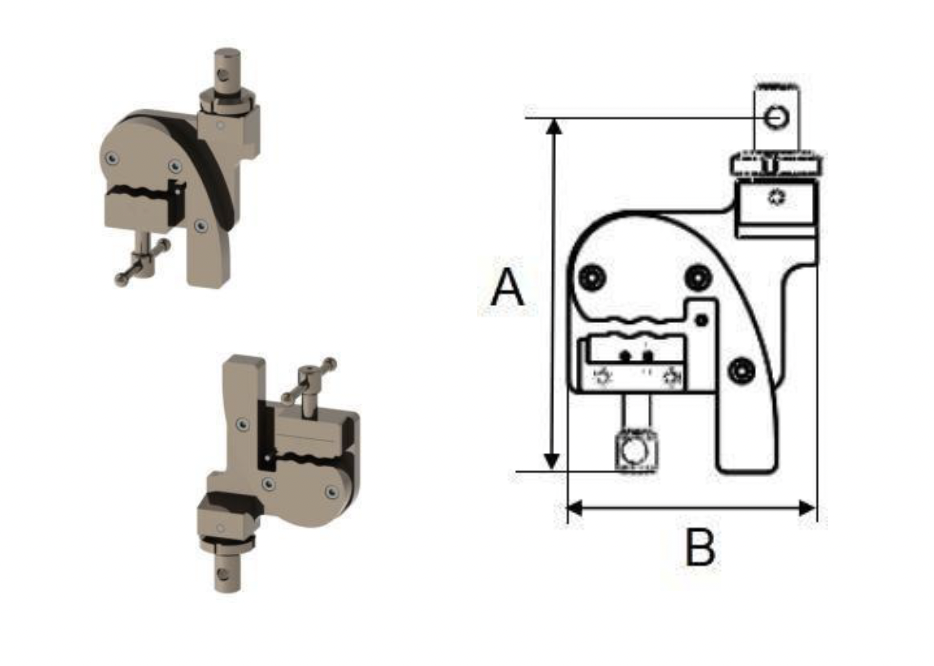

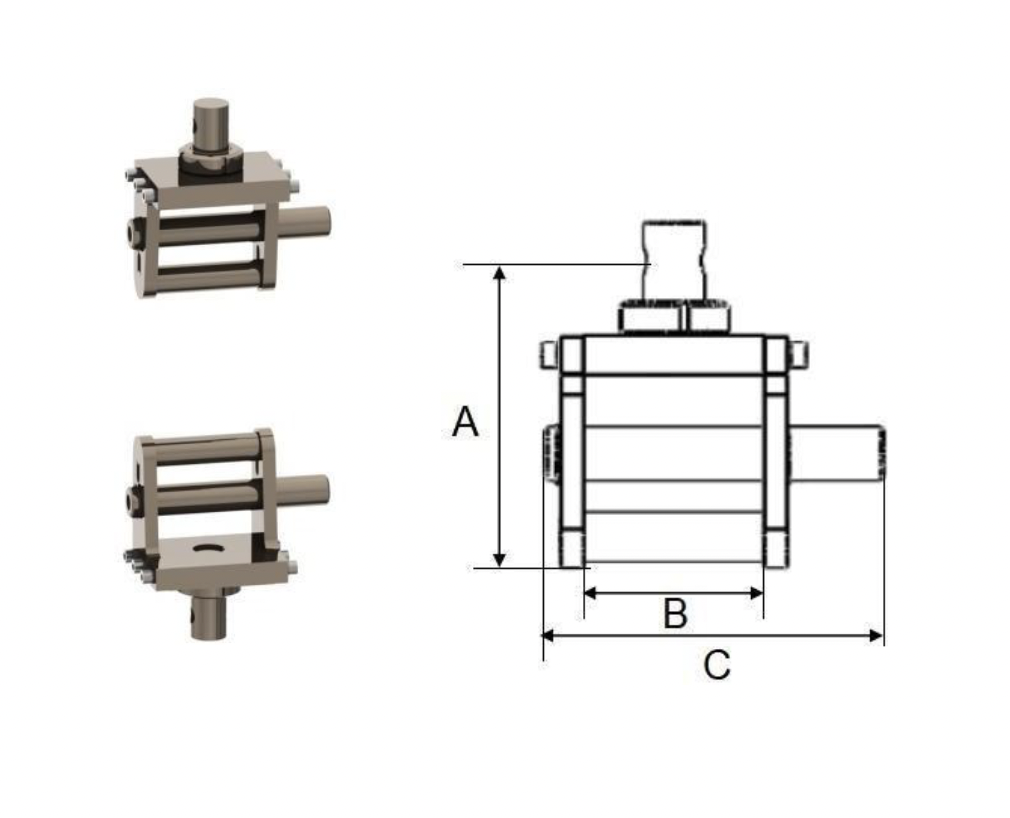

WCA503C – Wire & Rope Snubbing Grip

The WCA503C Wire & Rope Snubbing Grip is a versatile grip intended for small ropes, cable strands, and bundled yarns. It uses wave-profile jaws in a snubbing configuration to securely hold flexible fiber or wire rope specimens without slippage. This grip is well-suited for medium-force tests on cords and rope-like materials. Its technical details include:

- Application: Tension tests for glass fiber yarn bundles and small ropes/cables (e.g. fiber cords, wire strands).

- Maximum Capacity: Up to 5 kN load.

- Clamping Range: Handles specimens up to 8 mm diameter (rope or bundle diameter ≤ Φ8 mm).

- Connection: Φ10 mm pin mount (upper and lower), compatible with standard UTM fittings.

- Dimensions: Height 165 mm; Grip body width 120 mm for a stable clamping area.

- Jaw Faces: Wave-profile clamping faces, sized 46 mm (H) × 18 mm (W), which conform around the rope to increase friction.

- Grip Weight: Approximately 2.02 kg each for upper and lower grip.

- Working Temperature: Ambient conditions.

Technical Specifications – WCA503C Snubbing Grip for Glass Fiber Yarn Bundles and Ropes

| Parameter | Specification |

|---|---|

| Application | Tensile testing of glass fiber yarn bundles and ropes |

| Maximum Force Capacity | ≤ 5 kN |

| Connection Type |

Upper Grip: Ø10 mm pin |

| Overall Height (A) | 165 mm |

| Grip Body Width (B) | 120 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 2.02 kg |

| Wave-Profile Jaw Face Dimensions | 46 mm (H) × 18 mm (W) |

| Compatible Specimen Diameter | ≤ Ø8 mm |

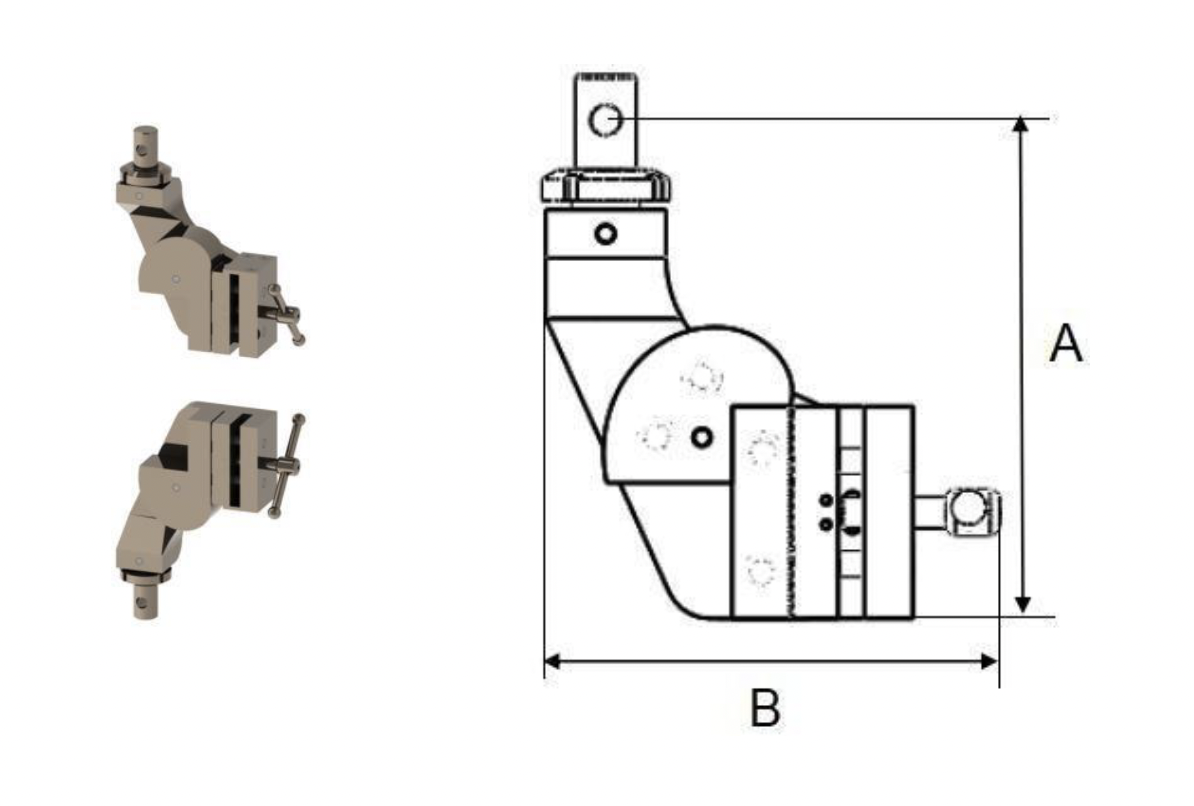

WCA503D – Strip Snubbing Grip

The WCA503D Strip Snubbing Grip is designed for tensile testing of wide strip specimens such as geogrid strips or flat tapes. It features a diamond-pattern jaw surface and a snubbing clamp configuration to hold flat specimens without tearing. This model is optimized for moderate loads on relatively narrow strips of stiff materials (like fiber-reinforced polymer strips used in geogrids). Key specs are:

- Application: Tension tests for glass fiber type geogrids and other wide strip specimens (e.g. narrow strips of geotextiles).

- Maximum Capacity: Up to 5 kN load.

- Clamping Range: Suitable for strip specimens up to about 30 mm wide (e.g. one or two ribs of a geogrid) for effective clamping.

- Connection: Φ10 mm pin attachment (both ends).

- Dimensions: Height 170 mm; Grip body width 150 mm – providing a larger jaw surface for strip samples.

- Jaw Faces: Diamond-pattern jaws, size 70 mm (H) × 30 mm (W), to bite into and hold flat strips securely without slippage.

- Grip Weight: Approximately 2.79 kg (upper grip) and 2.90 kg (lower grip) – slight difference due to the clamping mechanism components.

- Working Temperature: Ambient conditions.

Technical Specifications – WCA503D Snubbing Grip for Glass Fiber Geogrids and Wide Strip Specimens

| Parameter | Specification |

|---|---|

| Application | Tensile testing of glass fiber geogrids and wide strip specimens |

| Maximum Force Capacity | ≤ 5 kN |

| Connection Type |

Upper Grip: Ø10 mm pin |

| Overall Height (A) | 170 mm |

| Grip Body Width (B) | 150 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 2.79 kg |

| Diamond Jaw Face Dimensions | 70 mm (H) × 30 mm (W) |

| Compatible Specimen Diameter | ≤ Ø 30 mm |

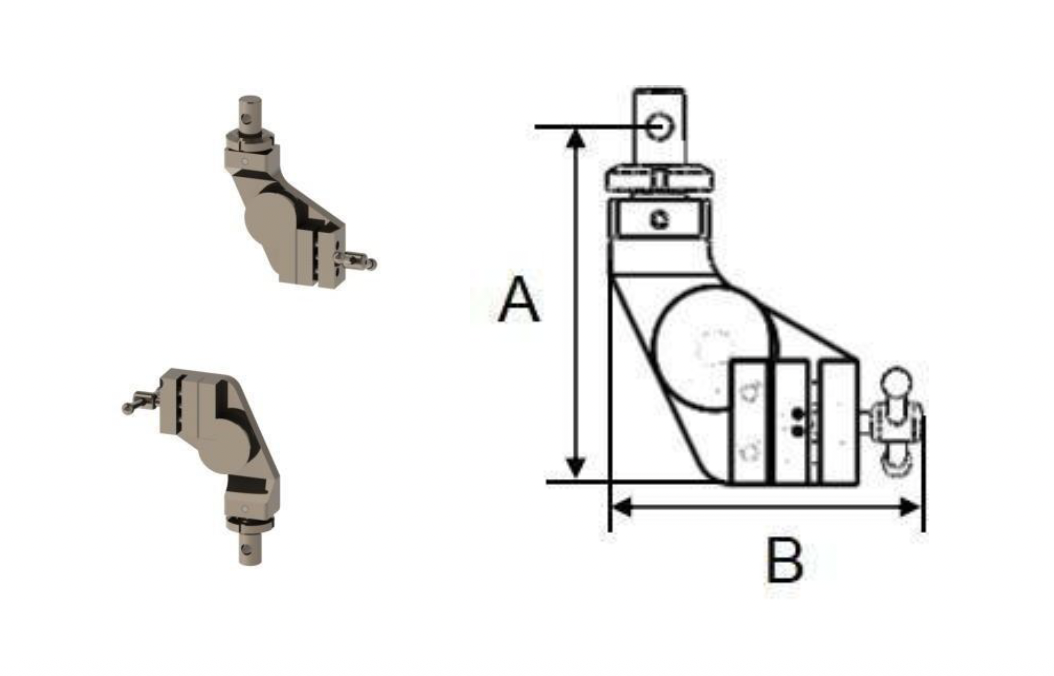

WCA503E – Strip Snubbing Grip

The WCA503E Strip Snubbing Grip is a lighter, compact variant for similar applications as the WCA503D. It is used for wide strip geogrid or geotextile specimens, especially where a smaller grip is sufficient. With a slightly lower profile, it accommodates moderate strip widths at the same 5 kN capacity. Its specifications are:

- Application: Tension tests for glass fiber geogrids and other wide strip specimens (similar use as NGA503D, for slightly narrower or thinner strips).

- Maximum Capacity: Up to 5 kN load.

- Clamping Range: Optimized for strip specimen widths in the order of a few centimeters (exact width capacity is similar to or slightly less than NGA503D, suitable for typical geogrid strip samples).

- Connection: Φ10 mm pin (upper and lower connections).

- Dimensions: Height 140 mm; Grip body width 125 mm – a more compact form to fit smaller frames or specimen sizes.

- Jaw Faces: Hardened jaw faces 50 mm (H) × 15 mm (W), providing a reliable grip on the specimen. (This model’s jaw width is narrower, focusing clamping force on a smaller area for thin strips.)

- Grip Weight: 1.45 kg (upper) and 1.45 kg (lower) – lightweight design for ease of handling.

- Working Temperature: Ambient conditions.

Technical Specifications – WCA503E Snubbing Grip for Glass Fiber Geogrids (Narrow Strip)

| Parameter | Specification |

|---|---|

| Application | Tensile testing of glass fiber geogrids and wide strip specimens |

| Maximum Force Capacity | ≤ 5 kN |

| Connection Type |

Upper Grip: Ø10 mm pin |

| Overall Height (A) | 140 mm |

| Grip Body Width (B) | 125 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 1.45 kg |

| Jaw Face Dimensions | 50 mm (H) × 15 mm (W) |

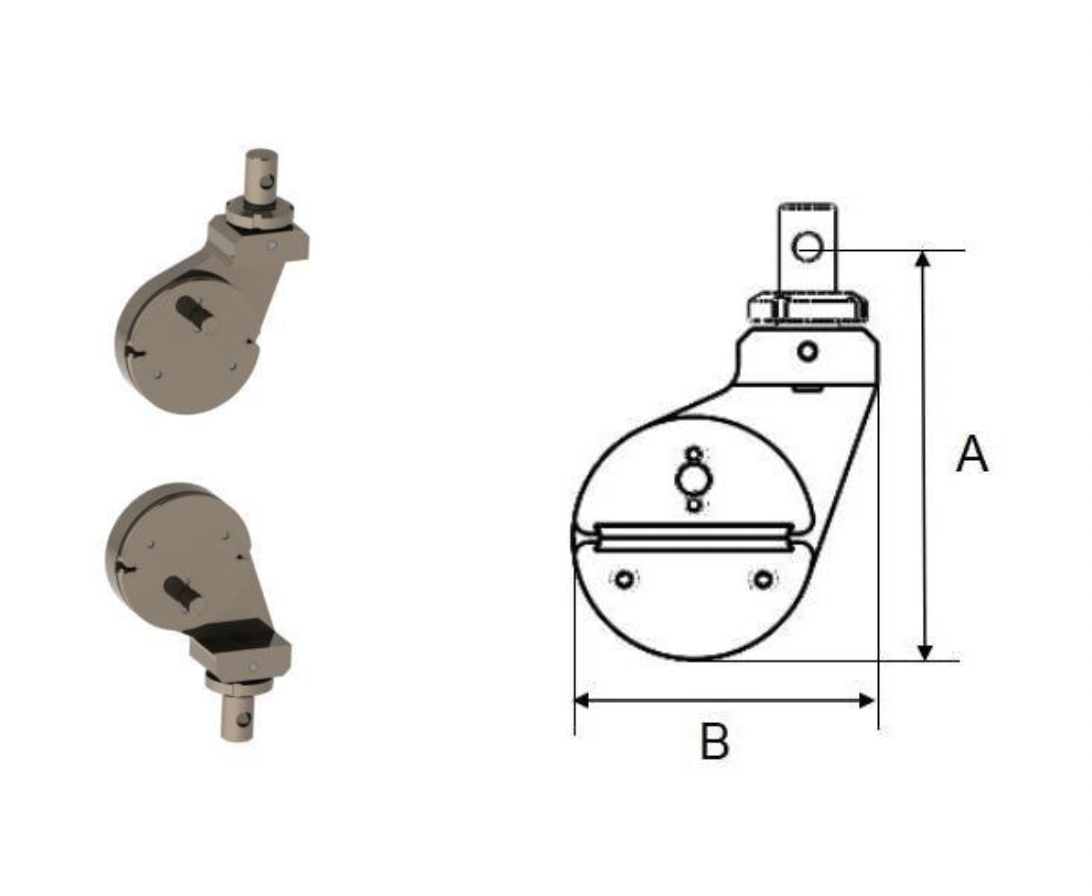

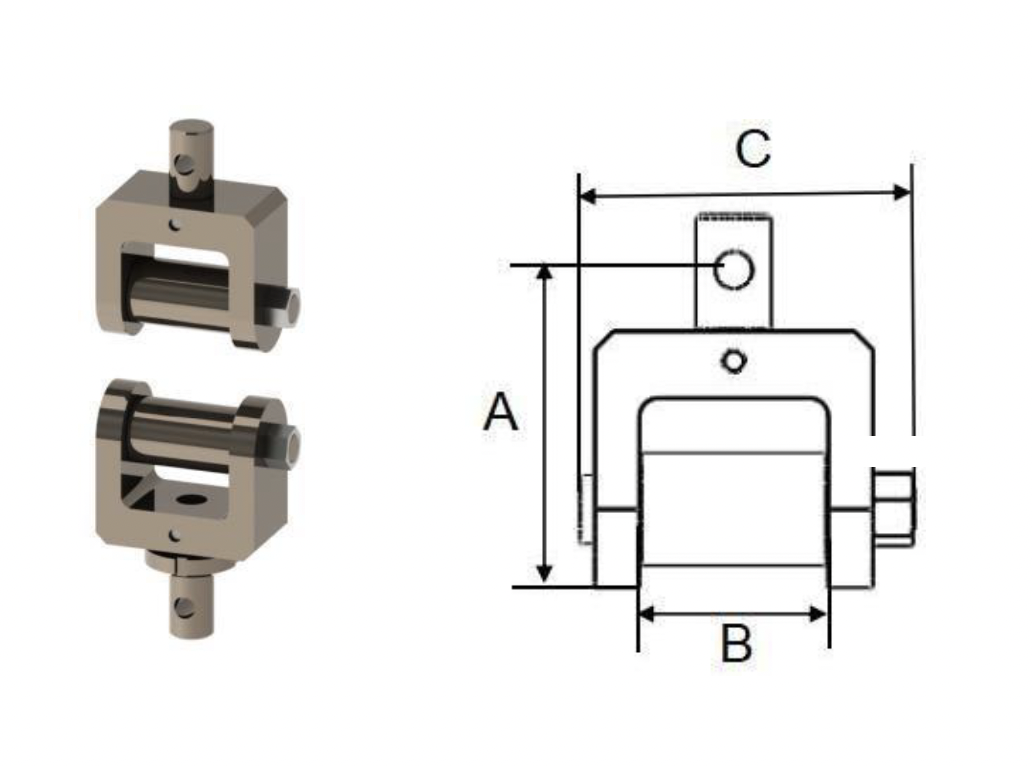

WCA304C – Strip Snubbing Grip

The WCA304C Strip Snubbing Grip is a heavy-duty grip for broad fabric straps and belts. It is commonly used for testing items like seat belts, safety harness webbing, and braided straps. The grip has a larger clamping surface and higher load capacity, using a snubbing roller design to distribute the force over a wide area and avoid stress concentrations. Key technical details:

- Application: Tension tests for seat belt webbing, cargo straps, braided tapes and similar wide, flat specimens.

- Maximum Capacity: Up to 30 kN load, accommodating high-strength webbing materials.

- Clamping Range: Capable of gripping strap specimens up to 85 mm wide and 0.5–4 mm thick. This covers standard seat belt widths (typically 46–50 mm) with ample margin for broader straps.

- Connection: Φ10 mm pin mount on both grip halves (suitable for load frames in this capacity range).

- Dimensions: Height 180 mm; Grip body width 85 mm; Overall width 184 mm – the overall width includes the extended snubbing path to wrap the strap around.

- Grip Mechanism: Snubbing capstan with a wide profile – wraps the strap around a curved surface to evenly distribute clamping pressure.

- Grip Weight: 7.75 kg each (upper and lower), reflecting its robust steel construction for high loads.

- Working Temperature: Ambient conditions.

Technical Specifications – WCA304C Strip Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tensile testing of seat belts and braided straps |

| Maximum Force Capacity | ≤ 30 kN |

| Connection Type |

Upper Grip: Ø10 mm pin |

| Overall Height (A) | 180 mm |

| Grip Body Width (B) | 85 mm |

| Overall Width (C) | 184 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 7.75 kg |

| Compatible Specimen Width | ≤ 85 mm |

| Compatible Specimen Thickness | 0.5 – 4 mm |

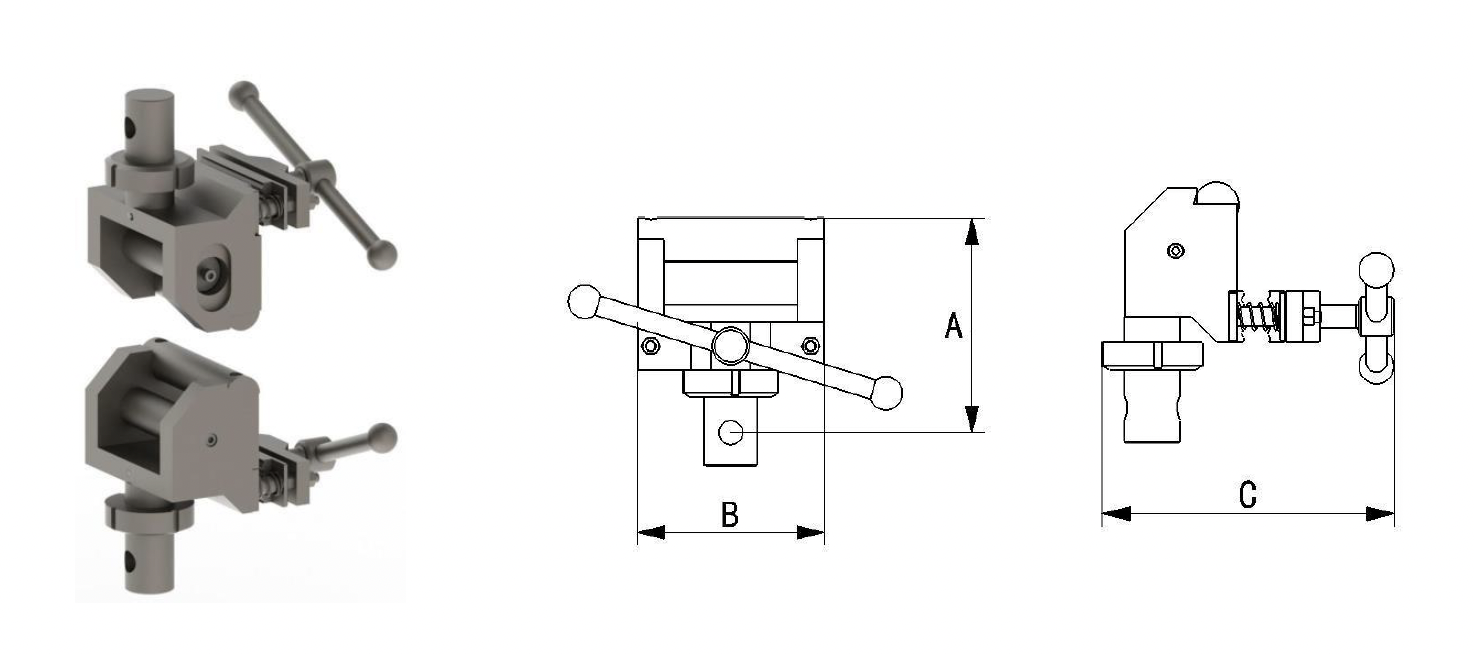

WCA504D – Strip Snubbing Grip

The WCA504D Strip Snubbing Grip is the highest-capacity strip grip in this series, made for very wide and strong straps or belts. It can handle larger specimen widths and forces, making it suitable for industrial belting, heavy webbing, and high-strength geotextile strips. This model uses a larger pin connection to withstand its 50 kN capacity. Main specifications are:

- Application: Tension tests for seat belts, industrial straps, and braided belts requiring extended width clamping (similar to WCA304C but for larger/stronger specimens).

- Maximum Capacity: Up to 50 kN load.

- Clamping Range: Grips specimen widths up to 120 mm and thickness 0.5–4 mm , allowing testing of extra-wide webbing or multiple layers.

- Connection: Φ18 mm pin coupling (upper and lower) for compatibility with high-capacity load cells and machines.

- Dimensions: Height 200 mm; Grip body width 120 mm; Overall width 225 mm – providing a broad clamping surface and snubbing wrap for wide samples.

- Grip Mechanism: Large-radius snubbing curve for uniform tension distribution across very wide specimens.

- Grip Weight: 7.75 kg each (upper and lower grip), built for durability under high loads.

- Working Temperature: Ambient conditions.

Technical Specifications – WCA504D Strip Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tensile testing of seat belts and braided straps |

| Maximum Force Capacity | ≤ 50 kN |

| Connection Type |

Upper Grip: Ø18 mm pin |

| Overall Height (A) | 200 mm |

| Grip Body Width (B) | 120 mm |

| Overall Width (C) | 225 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 7.75 kg |

| Compatible Specimen Width | ≤ 120 mm |

| Compatible Specimen Thickness | 0.5 – 4 mm |

WCB503A – Rope Snubbing Grip

The WCB503A Rope Snubbing Grip is a grip for thin ropes, cords, and small-diameter wire ropes. It’s ideal for materials like nylon cords, small-diameter steel rope (steel cord), and other flexible rods that require gentle but firm clamping. The grip employs flat-faced jaws and a snubbing loop to secure very thin specimens without breaking them at the grip. Key parameters include:

- Application: Tension tests for nylon rope, polyester cord, and small steel cords (e.g. rope diameter < 2 mm).

- Maximum Capacity: Up to 5 kN load.

- Clamping Range: Suitable for rope/cord diameters from 0.5 mm to 1.5 mm (Φ0.5–Φ1.5 mm) – covering very fine cables and cords.

- Connection: Φ10 mm pin mount (top and bottom).

- Dimensions: Height 110 mm; Grip body width 70 mm – a compact size for lower-force applications.

- Jaw Faces: Flat jaws, size 68 mm (H) × 10 mm (W), with smooth or lightly textured surface to grip tiny ropes without cutting them. The flat, narrow jaw prevents stress concentration on the slender specimen.

- Grip Mechanism: Snubbing wrap combined with flat clamp faces; the rope is wrapped and then clamped flat to maximize grip.

- Grip Weight: Approximately 1.79 kg each (upper and lower).

- Working Temperature: Ambient conditions.

Technical Specifications – WCB503A Rope Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tensile testing of nylon rope and steel cord |

| Maximum Force Capacity | ≤ 5 kN |

| Connection Type |

Upper Grip: Ø10 mm pin |

| Overall Height (A) | 110 mm |

| Grip Body Width (B) | 70 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 1.79 kg |

| Flat Jaw Face Dimensions | 68 mm (H) × 10 mm (W) |

| Compatible Specimen Diameter | Ø 0.5 – Ø 1.5 mm |

WCC504A – Geogrid Snubbing Grip

The WCC504A Geogrid Snubbing Grip is a specialized heavy-duty grip for geogrids and other high-strength grid or mesh materials. It is engineered to test large polymer geogrids used in geotechnical reinforcement by gripping one or multiple ribs of the grid. The grip’s design prevents the thin ribs from slipping or being damaged by distributing the load. Its major features are:

- Application: Tension tests for geogrids (e.g. polypropylene or polyester geogrid specimens) and similar high-strength open-mesh materials.

- Maximum Capacity: Up to 50 kN load, to handle the high tensile forces required to break geogrid specimens.

- Clamping Range: Ideal for one or several geogrid ribs or strips, typically gripping specimens with rib thickness around 0.5–1.5 mm (approximately Φ0.5–Φ1.5 mm). This allows secure clamping of the thin, flat bars of a geogrid.

- Connection: Φ18 mm pin attachment (upper and lower) to fit high-capacity UTM adapters.

- Dimensions: Height 161 mm; Grip body width 120 mm; Overall width 190 mm – providing a broad, stable gripping area for wide specimens.

- Grip Mechanism: Snubbing with a contoured clamping surface tailored for geogrid geometry, ensuring even load on the grid’s ribs.

- Grip Weight: 9.37 kg each (upper and lower), built to withstand heavy loads and frequent testing.

- Working Temperature: Ambient conditions.

Technical Specifications – WCC504A Geogrid Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tensile testing of geogrids |

| Maximum Force Capacity | ≤ 50 kN |

| Connection Type |

Upper Grip: Ø18 mm pin |

| Overall Height (A) | 161 mm |

| Grip Body Width (B) | 120 mm |

| Overall Width (C) | 190 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 9.37 kg |

| Compatible Specimen Diameter | Ø0.5 – Ø1.5 mm |

WCR104B – Rope Snubbing Grip

The WCR104B Rope Snubbing Grip is a mid-range rope grip for testing medium-diameter ropes (such as marine ropes, climbing cords, or utility ropes). It provides a higher force capacity than WCB503A, with wave-profile jaws to securely hold ropes a few millimeters thick. This grip is often used for synthetic ropes or small steel ropes where a 10 kN capacity is sufficient. Key specs:

- Application: Tension tests for ropes and cords (natural or synthetic fiber ropes, small steel wire ropes) in the mid-diameter range.

- Maximum Capacity: Up to 10 kN load.

- Clamping Range: Supports rope diameters roughly 2 mm to 5 mm (Φ2–Φ5 mm). This covers common utility rope sizes.

- Connection: Φ10 mm pin coupling (upper/lower).

- Dimensions: Height 135 mm; Grip body width 105 mm; Overall width 190 mm – a larger format to accommodate bigger rope loops.

- Jaw Faces: Wave-profile jaws, size 60 mm (H) × 20 mm (W), which press into the rope’s surface to enhance grip while distributing pressure.

- Grip Mechanism: Snubbing wrap around a curved block plus wave-profile clamping for maximum friction on the rope.

- Grip Weight: Approximately 1.85 kg each (upper and lower).

- Working Temperature: Ambient conditions.

Technical Specifications – WCR104B Rope Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tensile testing of rope |

| Maximum Force Capacity | ≤ 10 kN |

| Connection Type |

Upper Grip: Ø10 mm pin |

| Overall Height (A) | 135 mm |

| Grip Body Width (B) | 105 mm |

| Overall Width (C) | 190 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 1.85 kg |

| Wave-Profile Jaw Face Dimensions | 60 mm (H) × 20 mm (W) |

| Compatible Specimen Diameter | Ø2 – Ø5 mm |

WCR304B – Rope Snubbing Grip

The WCR304B Rope Snubbing Grip is a compact, high-strength grip for steel ropes and braided ropes in the intermediate diameter range. Despite its relatively small size, it is rated for 30 kN, making it useful for steel cable testing (such as aircraft cable or winch rope) up to 8 mm diameter. This model’s design focuses on maximizing grip strength in a short grip length. Its specifications are:

- Application: Tension tests for ropes (steel wire ropes or heavy braided fiber ropes) requiring up to 30 kN force.

- Maximum Capacity: Up to 30 kN load.

- Clamping Range: Suitable for rope diameters approximately 4 mm to 8 mm (Φ4–Φ8 mm).

- Connection: Φ10 mm pin (upper and lower) attachment.

- Dimensions: Height 90 mm; Grip body width 50 mm; Overall width 90 mm – a very compact footprint given its load capacity. The short height is advantageous when machine space is limited.

- Grip Mechanism: Snubbing capstan with high-friction surface to hold short length of rope under high tension.

- Grip Weight: Approximately 1.29 kg each (upper and lower).

- Working Temperature: Ambient conditions.

Technical Specifications – WCR304B Rope Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tensile testing of rope |

| Maximum Force Capacity | ≤ 30 kN |

| Connection Type |

Upper Grip: Ø10 mm pin |

| Overall Height (A) | 90 mm |

| Grip Body Width (B) | 50 mm |

| Overall Width (C) | 90 mm |

| Working Temperature | Ambient |

| Grip Weight |

Upper Grip: 1.29 kg |

| Compatible Specimen Diameter | Ø4 – Ø8 mm |

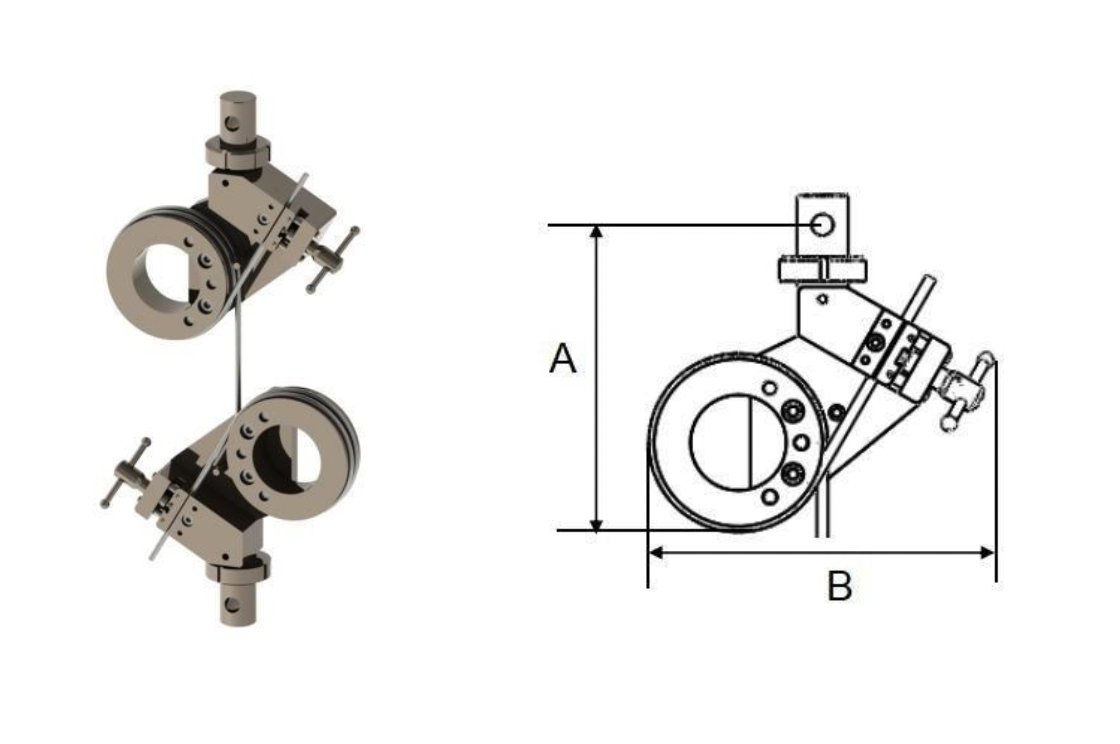

NGC504A – Rope Snubbing Grip

The NGC504A Rope Snubbing Grip is a heavy-duty snubbing grip for steel wire rope and large braided rope specimens. (Note: This model code also appears in the geogrid grip above, but here it refers to the configuration for rope testing.) It is built to handle high loads and relatively large rope diameters with minimal slippage. The grip includes large, robust components to sustain repeated tests at 50 kN. Key specifications:

- Application: Tension tests for steel wire ropes and braided fiber ropes (e.g. wire rope cables, towing ropes) of moderate size.

- Maximum Capacity: Up to 50 kN load.

- Clamping Range: Designed for rope diameters up to 8 mm (≤ Φ8 mm) – suitable for typical steel ropes used in elevators, winches, etc.

- Connection: Φ18 mm pin (upper and lower) for mounting in high-capacity test machines.

- Dimensions: Height 240 mm; Grip body width 290 mm – this large width provides an extended snubbing path for the rope. (Note: The overall width is integrated in the grip body width here.)

- Grip Mechanism: Heavy-duty snubbing drum and clamping system that can accommodate steel rope without slippage or wire damage.

- Grip Weight: 9.37 kg each (upper and lower), reflecting a solid steel construction.

- Working Temperature: Ambient conditions.

Technical Specifications – NGC504A Rope Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tensile testing of steel wire rope and braided rope |

| Maximum Force Capacity | ≤ 50 kN |

| Connection Type | Upper Grip: Ø18 mm pin connection Lower Grip: Ø18 mm pin connection |

| Grip Height (A) | 240 mm |

| Grip Body Width (B) | 290 mm |

| Operating Temperature | Ambient |

| Grip Mass | Upper Grip: 9.37 kg Lower Grip: 9.37 kg |

| Compatible Specimen Diameter | ≤ Ø8 mm |

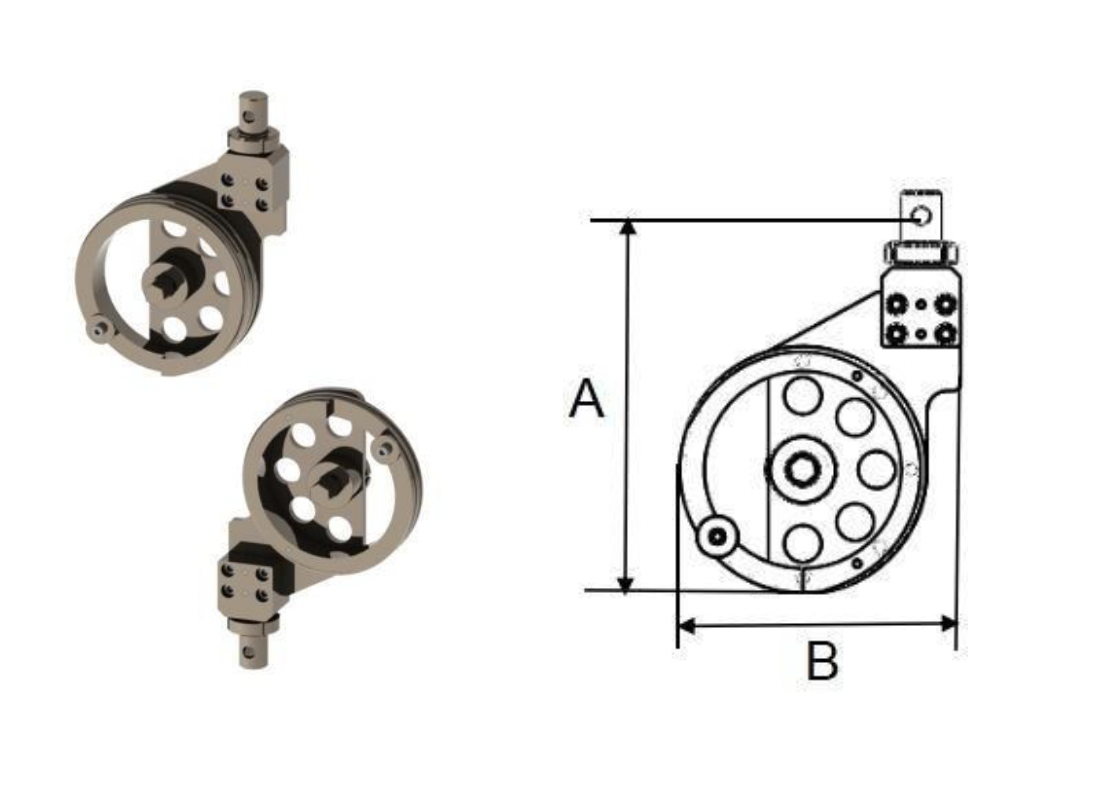

NGC105A – Rope Snubbing Grip

The NGC105A Rope Snubbing Grip is the highest-capacity snubbing grip in this lineup, intended for large-diameter ropes and cables. It can test steel rope up to 10 mm in diameter at forces up to 100 kN. This grip is built with a long grip length and high-strength materials, and it even supports elevated temperature testing for special applications. Its main technical parameters are:

The NGC105A Rope Snubbing Grip is the highest-capacity snubbing grip in this lineup, intended for large-diameter ropes and cables. It can test steel rope up to 10 mm in diameter at forces up to 100 kN. This grip is built with a long grip length and high-strength materials, and it even supports elevated temperature testing for special applications. Its main technical parameters are:

- Application: Tension tests for steel wire ropes and heavy braided ropes (e.g. large hoisting cables, industrial ropes) requiring very high tensile loads.

- Maximum Capacity: Up to 100 kN load.

- Clamping Range: Suitable for rope diameters from 3 mm up to 10 mm (Φ3–Φ10 mm).

- Connection: Φ18 mm pin (upper and lower), to attach securely to 100 kN-class test machines.

- Dimensions: Height 370 mm; Grip body width 190 mm – an extended length grip to allow multiple wraps of the rope for maximum friction.

- Grip Mechanism: Large snubbing drum and clamp assembly capable of holding very high tensile forces. Often used with auxiliary rope termination devices if required.

- Grip Weight: 15.31 kg each (upper and lower), utilizing high-strength alloy steel components.

- Working Temperature: Ambient to +150 °C – this grip is rated for an extended temperature range, allowing testing of rope specimens at elevated temperatures (e.g. to simulate high-heat conditions or to use in environmental chambers).

Technical Specifications – NGC105A Rope Snubbing Grip

| Parameter | Specification |

|---|---|

| Application | Tension testing of steel rope and braided rope |

| Maximum Force | ≤100 kN |

| Connection Type | Upper grip: Ø18 mm pin Lower grip: Ø18 mm pin |

| Overall Height (A) | 370 mm |

| Grip Body Width (B) | 190 mm |

| Working Temperature | Ambient to +150 °C |

| Grip Weight | Upper grip: 15.31 kg Lower grip: 15.31 kg |

| Specimen Diameter | Ø3 mm to Ø10 mm |

| Grip Mass | Upper Grip: 9.37 kg Lower Grip: 9.37 kg |

| Compatible Specimen Diameter | ≤ Ø8 mm |

Relevant ISO, ASTM, and DIN Standards for Wire, Rope, Strip, and Geogrid Tensile Testing

Testing wires, cables, textiles, and geogrids with the above grips should be done in accordance with established standards to ensure valid results. Below is a list of key international standards (ISO, ASTM, and related DIN/EN equivalents) that pertain to tensile testing of wires, ropes, strips/webbings, and geogrid materials:

- Metal Wires and Metallic Materials: ASTM E8 (Standard Test Methods for Tension Testing of Metallic Materials) and ISO 6892 (Metallic Materials – Tensile Testing) are general standards for tensile testing of metals (including metal wires). These define specimen preparation and testing procedures for wire samples to determine yield and tensile strength. (DIN EN ISO 6892 is the German adoption of ISO 6892.)

- Steel Wire Ropes and Stranded Cables: ASTM A931 (Standard Test Method for Tension Testing of Wire Ropes and Strand) specifically addresses tensile testing of full wire rope assemblies , measuring breaking strength and elongation. ISO 10425 (Steel wire ropes – Tensile strength tests) provides an equivalent international method for determining the tensile strength of steel wire ropes. ISO 2307 (Fibre ropes – Determination of certain physical and mechanical properties) is used for establishing breaking force and other properties of fiber ropes (and includes guidelines for tensile testing of rope materials). (DIN EN 12385-1 covers safety requirements and minimum breaking forces for steel wire ropes, referencing these test methods.)

- Textile Strips, Webbing, and Fabric: ASTM D6775 (Standard Test Method for Breaking Strength and Elongation of Textile Webbing, Tape and Braided Material) is used for seat belt webbing and similar narrow fabrics under a split-drum or snubbing grip method. General textile fabric strip tests are covered by ASTM D5035 and ISO 13934-1 (Textiles – Tensile properties of fabrics – Part 1: Determination of breaking force and elongation, Strip method), which specify using a 50 mm wide strip in tensile clamps. These standards ensure consistent tensile results for flexible strip materials. (DIN EN ISO 13934-1 is the European equivalent for fabric strip testing.)

- Geotextiles and Geogrids: ASTM D4595 (Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method) and its counterpart ISO 10319 (Geosynthetics – Wide-width tensile test) are the key standards for tensile testing of geotextile fabrics and geogrid materials. They involve using wide specimens (typically 200 mm wide) and clamping them in specialized grips to measure tensile strength and elongation. For geogrids specifically, ASTM D6637 (Standard Test Method for Tensile Properties of Geogrids – Single or Multi-Rib Specimen) is used, which covers testing strips of geogrid of varying widths under tension. These standards ensure that the snubbing grips (or other grips) apply the load uniformly so that the strength of the geosynthetic material is measured accurately without slippage.

Many of these standards have equivalent DIN or EN versions (for example, DIN EN ISO 6892 for metals, DIN EN ISO 10319 for geotextiles), underscoring their international acceptance. Using the appropriate standard for each material type guarantees that the testing performed with NextGen’s wire and cable snubbing grips yields accurate, industry-recognized results. Each snubbing grip listed above is designed to meet or exceed the gripping requirements specified in these standards, providing reliable performance for compliance testing and research applications.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.