Plastic Testing Equipment

Standards

ASTM D1424, DIN 53862, ISO 9290, EN ISO 13937-1, ISO 4674-2, M&S P29, NEXT 17, ASTM D1922, ASTM D5734, ASTM D689, ISO 6383-2, ISO 1974, DIN 53128, EN 21974, JIS K 7128-2, JIS L0849, CSA D9, BS 4468, APPITA P 400, NF T54 141, WSP 100.1

Description

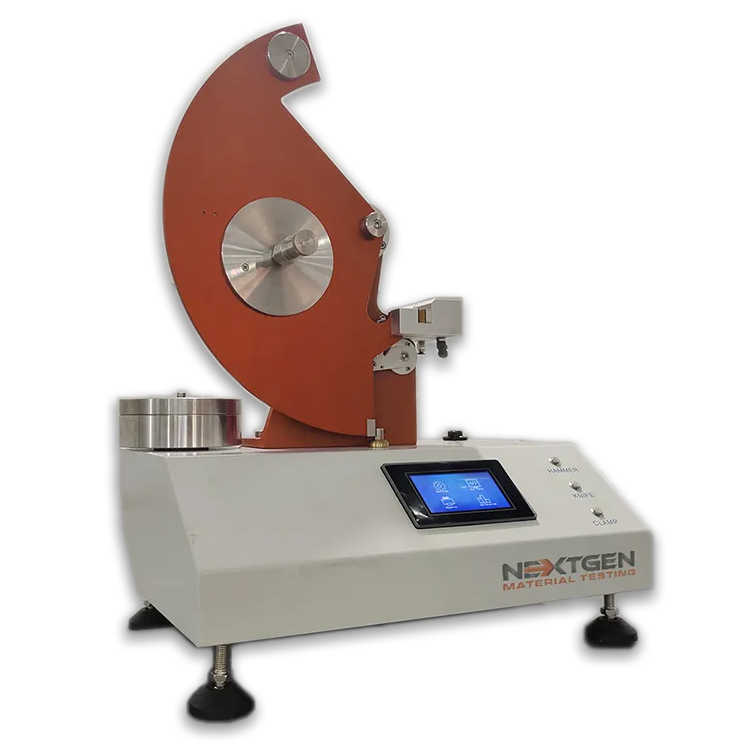

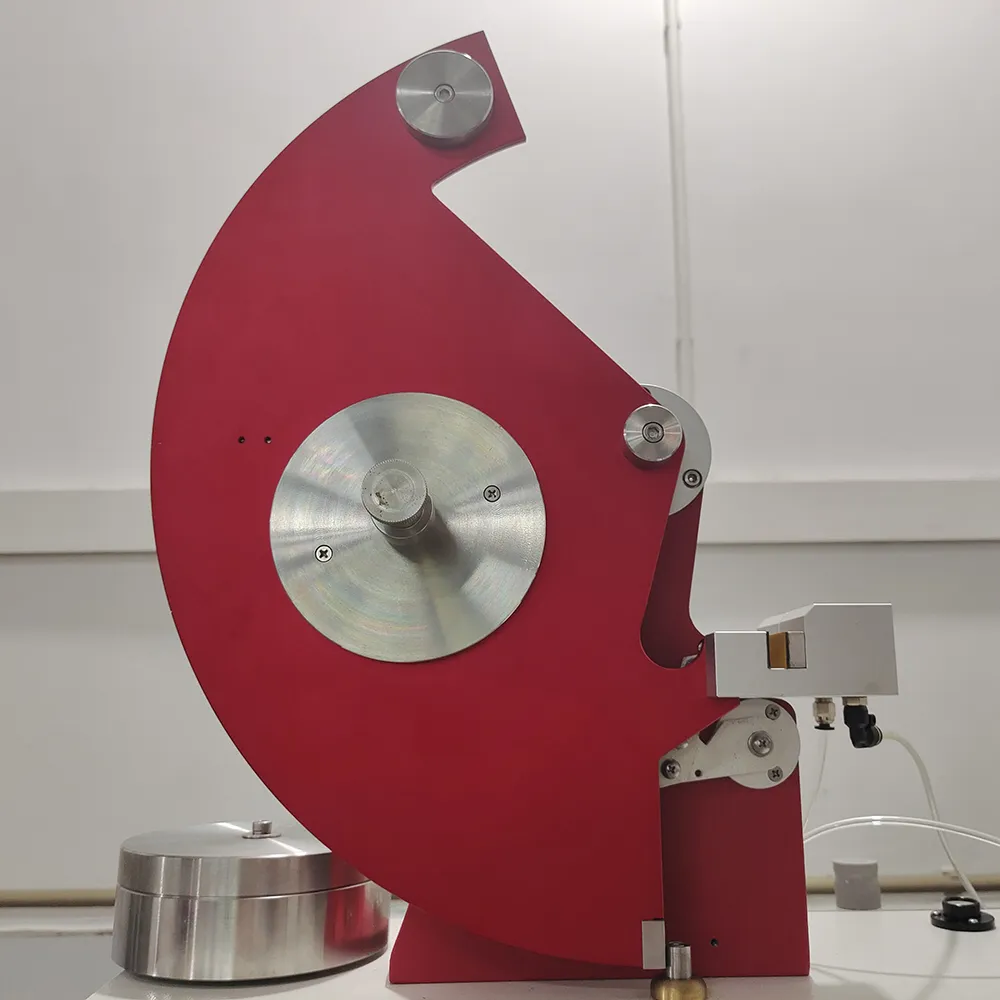

The GenElm Series Elmendorf Tearing Tester is a professional laboratory instrument used to measure the tear resistance of different materials. It follows international standards, including ASTM, ISO, and DIN. The system is based on the pendulum method of testing, giving laboratories clear and precise data for both research and everyday quality control.

This equipment can be applied to many types of materials such as fabrics, plastic films, paper, nonwoven textiles, and thin foils. By testing how a tear develops in these materials, the GenElm Series helps evaluate strength, performance, and compliance with industry requirements. The results are especially valuable for production lines, product testing facilities, and research centers that need dependable measurements of material durability.

This equipment can be applied to many types of materials such as fabrics, plastic films, paper, nonwoven textiles, and thin foils. By testing how a tear develops in these materials, the GenElm Series helps evaluate strength, performance, and compliance with industry requirements. The results are especially valuable for production lines, product testing facilities, and research centers that need dependable measurements of material durability.

The GenElm Series comes with a simple touch-screen interface, automatic specimen cutting, and pneumatic clamping for stable handling of samples. Different pendulum options allow the user to cover several testing ranges, while the built-in system collects and processes the data. This combination of functions makes the instrument practical for everyday laboratory work and a reliable solution for routine testing.

Key Features

The GenElm Series Elmendorf Tearing Tester includes functions that simplify daily use and provide stable test results.

- Automated testing and analysis – the system performs calculations and records results without manual processing.

- Pneumatic clamping and pendulum release – ensures uniform sample holding and a stable start of each test.

Interchangeable pendulums (16 N – 128 N) – covers different load ranges for both light and heavy materials.

Interchangeable pendulums (16 N – 128 N) – covers different load ranges for both light and heavy materials.- Automatic specimen cutting – prepares samples with consistent shape and size for repeatable results.

- Integrated statistics – calculates mean, minimum, maximum, standard deviation, and coefficient of variation directly on the device.

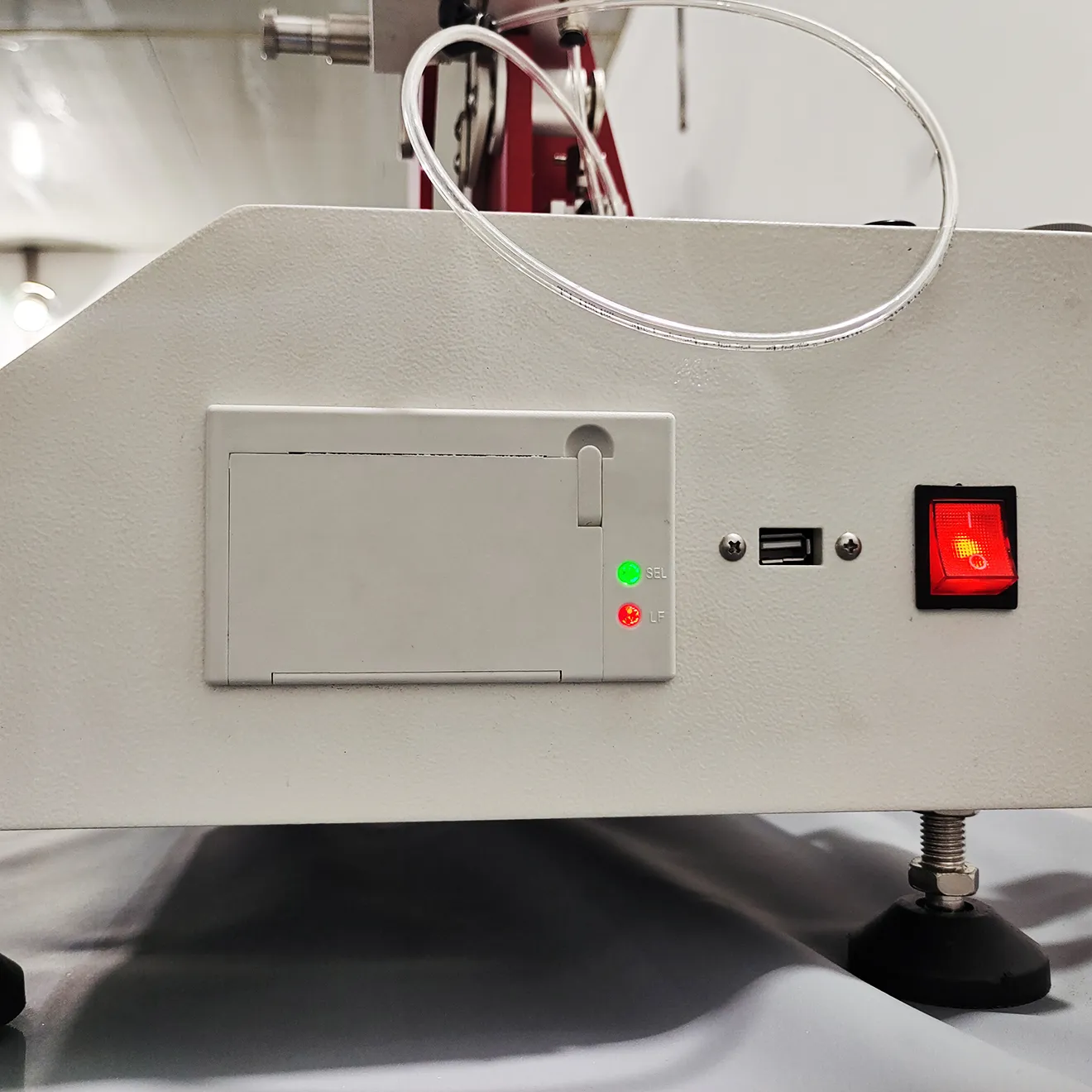

- Data export (RS232) – transfers results to a PC or printer for documentation and reports.

- Multi-language interface – supports different user needs across laboratories.

- Calibration and certificates included – supplied with inspection and calibration documents to confirm compliance with standards.

Compliance with International Standards

The GenElm Series Elmendorf Tearing Tester is supplied from the factory with compliance to all essential international standards. This allows laboratories worldwide to run tests under recognized procedures, compare results, and adapt reporting to regional or industry-specific requirements.

The GenElm Series Elmendorf Tearing Tester is supplied from the factory with compliance to all essential international standards. This allows laboratories worldwide to run tests under recognized procedures, compare results, and adapt reporting to regional or industry-specific requirements.

Below is the list of the main standards supported by the GenElm Series:

- ASTM D1424 – Tearing strength of fabrics using a falling-pendulum (Elmendorf) apparatus.

- ASTM D1922 – Tear resistance of plastic film and thin sheeting by the pendulum method.

- ASTM D5734 – Tear strength of nonwoven fabrics using the trapezoid procedure.

- ASTM D689 – Tearing strength of paper determined by the Elmendorf method.

- ISO 4674-2 – Tear resistance of rubber- or plastics-coated fabrics, Part 2: Elmendorf method.

- ISO 9290 – Tear resistance of plastic film and sheeting using the Elmendorf method.

- ISO 6383-2 – Tear resistance of plastics, film, and sheeting, Part 2: Elmendorf method.

- ISO 1974 – Determination of tearing resistance of paper using the Elmendorf method.

- DIN 53862 – Tearing strength test for textiles by Elmendorf method.

- DIN 53128 – Tearing resistance of paper and board by Elmendorf method.

- EN ISO 13937-1 – Tear properties of textiles, trouser-shaped test specimens.

- EN 21974 – Tearing resistance of paper by Elmendorf method.

- JIS K 7128-2 – Tear resistance of plastic film and sheeting by Elmendorf method.

- JIS L0849 – Tear strength testing of woven fabrics by Elmendorf method.

- CSA D9 – Canadian standard for paper tearing resistance, Elmendorf method.

- BS 4468 – British method for tearing strength of paper and board by Elmendorf method.

- APPITA P 400 – Tear resistance of paper, board, and pulps by Elmendorf method.

- M&S P29 – Fabric tear testing standard used by Marks & Spencer.

- NEXT 17 – Retail and apparel-specific fabric tear testing procedure.

- NF T54 141 – Tear resistance of plastic films and sheets, Elmendorf method.

- WSP 100.1 – Nonwoven fabric standard test methods (INDA/EDANA).

Technical Specifications

The GenElm Series is available in two versions to cover different material testing needs. The 64 N model supports three ranges (0–16 N, 0–32 N, and 0–64 N), making it suitable for textiles, packaging films, and paper products. The 128 N high-energy model extends the capacity up to 128 N, which is required for tougher or more technical materials. Both versions rely on the same pendulum principle, ensuring a unified approach to tear strength measurement.

Despite the difference in maximum load, both models share identical design features and geometry. Each tester is built with a clamp gap of 7.0 ± 0.25 mm, a slit length of 20 ± 0.2 mm, and a tear travel of 43 ± 0.15 mm. In this context, “N” stands for newtons, representing the pendulum capacity. This structure allows laboratories to choose the configuration that matches their materials without compromising consistency across tests.

| Parameter | 64 N Model | 128 N Model |

|---|---|---|

| Measuring Range | 0–16 N, 32 N, 64 N | 0–16 N, 32 N, 64 N, 128 N |

| Measurement Accuracy | ±0.2% F.S. | ±0.2% F.S. |

| Distance Between Clamps | 7.0 ± 0.25 mm | 7.0 ± 0.25 mm |

| Slit Size | 20 ± 0.2 mm | 20 ± 0.2 mm |

| Tearing Distance | 43 ± 0.15 mm | 43 ± 0.15 mm |

| Dimensions | 19.7 × 15.7 × 24.4 in (500 × 400 × 620 mm) | 19.7 × 15.7 × 24.4 in (500 × 400 × 620 mm) |

| Weight | 110–128 lbs (50–58 kg) | 110–128 lbs (50–58 kg) |

| Power Supply | AC220V, 50Hz, 100W | AC220V, 50Hz, 100W |

| Control System | LCD touch panel with microcomputer | LCD touch panel with microcomputer |

| Sample Clamping | Pneumatic, automatic pendulum release | Pneumatic, automatic pendulum release |

| Specimen Cutting | Automatic, consistent sample shape | Automatic, consistent sample shape |

| Data Output | RS232 port to PC and printer | RS232 port to PC and printer |

Applications Across Industries and Materials

The Elmendorf tearing tester is recognized as a practical tool for laboratories and production sites that need to measure how different materials behave when subjected to tearing forces. Its ability to work with textiles, films, papers, and technical fabrics makes it suitable for both research and day-to-day quality control.

Where It Is Used

The instrument is applied in multiple industries where tear resistance is critical for safety, quality, and durability.

- Packaging industry – testing plastic films and sheets to confirm performance during storage, transport, and handling.

- Paper and cardboard – evaluating tissue, printing paper, and packaging board for strength and reliability.

- Textile and nonwoven sectors – measuring tear resistance of woven, knitted, and nonwoven fabrics used in apparel and technical textiles.

- Automotive and upholstery – assessing fabrics and interior materials such as seat covers to ensure durability in use.

- Research and quality control laboratories – providing consistent benchmarks for product development and compliance testing.

Materials Commonly Tested

The system works with a variety of materials, from thin flexible films to heavy technical textiles.

- Plastic films and sheeting

- Paper and cardboard

- Woven textiles

- Knitted fabrics

- Nonwoven fabrics

- Reinforced and industrial fabrics such as canvas

Typical Products Tested

Elmendorf tear testing is also applied to finished or semi-finished products that must meet durability requirements.

- Food, medical, and industrial packaging films

- Tissue, wrapping paper, and printed stock

- Clothing fabrics including sportswear and workwear

- Automotive upholstery and liners

- Disposable nonwoven products such as wipes and filters

- Heavy-duty textiles used in industrial and outdoor applications

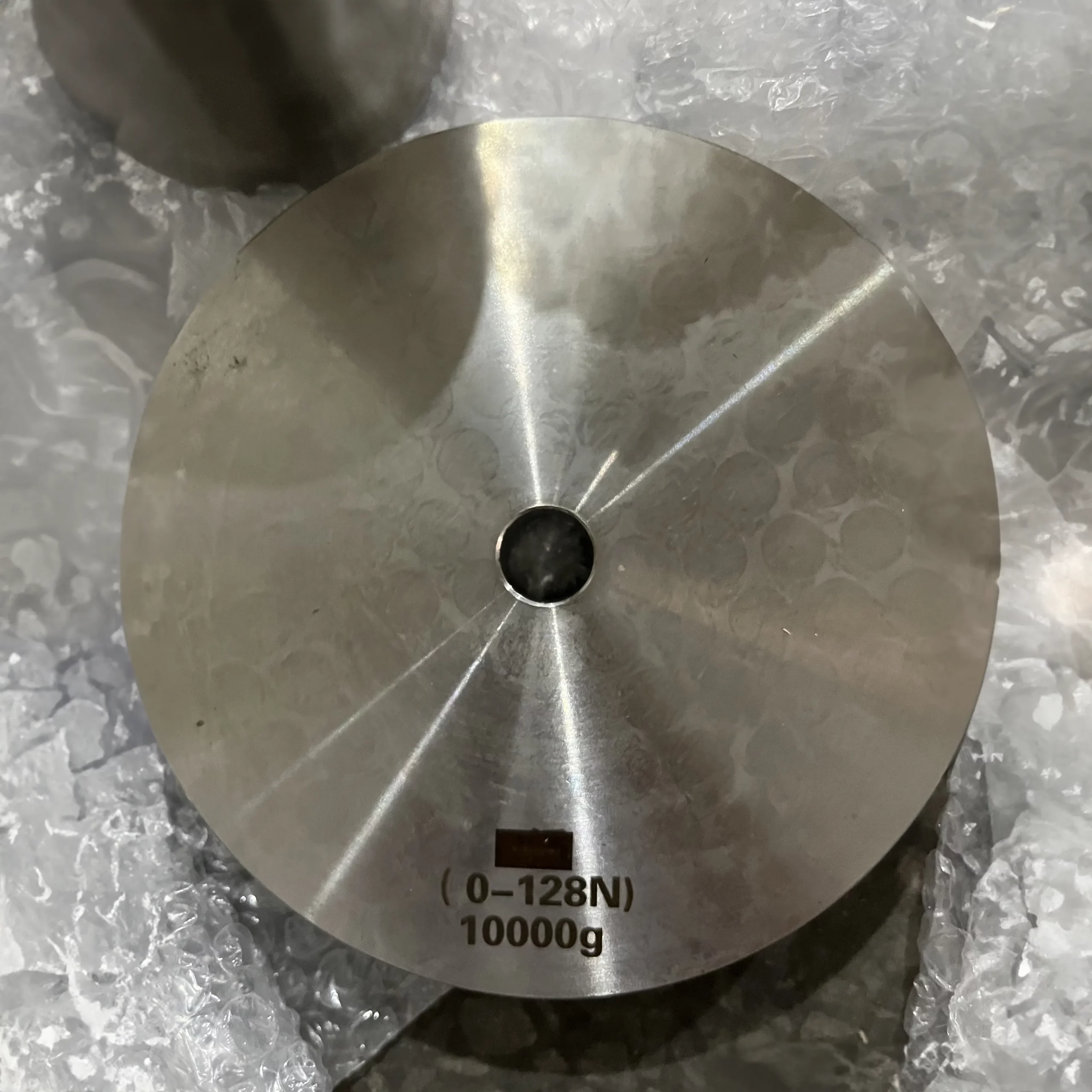

Complete Set of Weights and Tools

The GenElm Series Elmendorf Tearing Tester is supplied with all the required pendulum weights and tools for accurate and repeatable tear strength measurements. Each weight corresponds to a specific test capacity, allowing laboratories to select the right load depending on the type and strength of the material being tested.

With options ranging from low-capacity weights for thin films and paper to high-capacity weights for technical fabrics and industrial materials, the full range is available in the standard package. Alongside the weights, the system is delivered with cutting templates, cables, and adjustment tools.

Get In Touch With Us

If you require this type of equipment for specific testing needs, the GenElm Series can be adapted to meet your requirements. Whether you need clarification on technical details, additional product information, or guidance on how this tester can be integrated into your laboratory, our team is here to assist you.

Please request a quote or contact us directly with your questions. We will provide clear answers and support you in finding the right solution for your testing applications.

FAQs

The GenElm Series Elmendorf Tearing Tester is a laboratory instrument for measuring the tear resistance of flexible materials using the falling pendulum method. It determines the energy required to extend a pre-cut slit and complies with major international standards, including ASTM, ISO, DIN, JIS, EN, CSA, BS, APPITA, NF, and retailer-specific methods.

The tester applies to many material groups: plastic films, laminates, packaging foils, tissue, printing paper, wrapping grades, cartons, boards, woven and knitted fabrics, coated and laminated textiles, upholstery, technical fabrics, and nonwovens such as wipes, filters, geotextiles, and medical disposables.

Two versions are available. The 64 N model is suited for lighter papers, films, and standard textiles, while the 128 N model extends capacity to reinforced and technical fabrics. Both models use fixed geometry with a 7.0 mm clamp gap, 20 mm slit, and 43 mm tear distance to keep results consistent.

Main functions include pneumatic clamping, automatic specimen cutting, interchangeable pendulums, touchscreen control, onboard statistics, and RS232 data export. These features make the GenElm Series practical for quality control, production testing, and research, helping manufacturers validate material durability, compare batches, and comply with industry requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series is designed to work with an extensive variety of materials across paper, plastics, textiles, and technical fabrics. In packaging, it is used for plastic films, sheeting, shrink wraps, pouches, and laminated films that must resist tearing during storage, transport, or handling. In the paper sector, the tester is applied to tissue, printing stock, wrapping paper, corrugated board, coated grades, and recycled papers

In textiles, the instrument covers woven and knitted fabrics, industrial canvases, coated textiles, upholstery materials, sportswear fabrics, protective clothing, and reinforced laminates. It is equally effective for nonwovens, including medical disposables, wipes, geotextiles, filtration products, and hygiene items. Coated fabrics and technical textiles, such as tarpaulins, seat covers, or outdoor performance materials, can also be evaluated under the same system.

Because of this versatility, the GenElm Series is often used in industries that require one platform to cover multiple product categories. A single machine can switch between delicate films, lightweight papers, and heavy-duty reinforced fabrics without compromising test accuracy.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series is supplied ready to meet the requirements of a broad list of international standards. Among them are ASTM D1424 for tearing strength of fabrics, ASTM D1922 for plastic films and sheeting, ISO 1974 for paper, ISO 6383-2 for plastics, EN ISO 13937-1 for textiles, DIN 53862 for fabrics, and JIS K 7128-2 for plastics, along with many others.

Covering standards from ASTM, ISO, DIN, JIS, EN, CSA, BS, APPITA, M&S, NEXT, NF, and WSP means the tester can be applied globally without modifications. This compliance allows laboratories to follow recognized procedures, compare results across markets, and meet the demands of clients or regulatory bodies in packaging, textiles, paper, and nonwovens.

Click here to learn more about the product or here to receive a personalized quote.

The 64 N version is designed for lighter applications such as packaging films, paper products, and standard textiles. It covers three ranges: 0–16 N, 0–32 N, and 0–64 N, which are sufficient for most everyday quality control tasks in these materials.

The 128 N version expands the capacity with an additional high-energy pendulum, allowing tests up to 128 N. This makes it more suitable for reinforced fabrics, coated textiles, technical laminates, and other heavy-duty materials that demand greater tear resistance. Both models share the same construction and control system, so laboratories can choose based on the strength level of the materials they test most often.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series is backed by full after-sales support. Customers can rely on technical assistance for setup and operation, access to spare parts, and scheduled calibration services.

Beyond that, training options, documentation updates, and remote troubleshooting are also offered, helping laboratories keep their equipment running smoothly. This level of service helps maintain accuracy and dependability of the tester throughout its working life.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series can be used for nonwoven fabrics. Standards such as ASTM D5734 and WSP 100.1 outline accepted methods for measuring the tear resistance of nonwovens, and the Elmendorf approach is part of these procedures.

This makes the tester suitable for a broad spectrum of nonwoven products, including wipes, filters, medical disposables, hygiene products, and technical fabrics. Since nonwovens can vary a lot in thickness and structure, having a controlled pendulum method helps laboratories evaluate durability in a consistent way that meets industry requirements.

Click here to learn more about the product or here to receive a personalized quote.

An Elmendorf tear test measures how resistant a material is to the continuation of a tear once it has started. A specimen is prepared with a small slit, clamped into the instrument, and then struck by a pendulum. The pendulum swings through the sample, and the energy it uses to extend the tear is recorded as the tearing strength.

This method is widely used for paper, plastic films, textiles, and nonwovens because it simulates real situations where a small cut or damage can grow under stress. By capturing the force needed to propagate the tear, the test helps manufacturers and labs compare material grades, check product durability, and confirm compliance with international standards.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series can be applied to a very wide range of finished and semi-finished products where tear resistance is critical. In packaging, it covers food wrapping films, medical barrier films, industrial shrink films, plastic bags, pouches, and laminated sheets. In the paper sector, it is used for tissue paper, printing paper, packaging board, kraft paper, wrapping sheets, envelopes, and specialty grades such as coated or recycled paper.

In textiles, the tester handles woven fabrics, knitted fabrics, coated textiles, upholstery materials, industrial canvases, protective clothing fabrics, and sportswear textiles. It also extends to nonwoven disposables like wipes, medical drapes, masks, filters, and geotextiles. For automotive and industrial use, it is applied to seat cover fabrics, interior liners, technical laminates, and heavy-duty outdoor textiles such as tarpaulins and tents. This breadth makes the GenElm Series a versatile choice for manufacturers and labs that deal with multiple material categories in one facility.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series comes with standardized cutting templates that match the requirements set out in ISO and ASTM methods. These templates define the size and shape of each specimen, making sure every sample starts with the same geometry.

The slit length is typically around 20 mm, as specified by international standards. Using the built-in templates reduces variation in preparation, which is critical because even small differences in slit length or sample size can change tear resistance values.

Click here to learn more about the product or here to receive a personalized quote.

Calibration frequency depends on the laboratory’s internal quality system and the standards it follows. Many labs perform a formal calibration annually or semi-annually to stay aligned with ISO or ASTM requirements.

Between these scheduled services, operators often run quick verification checks using the supplied calibration weights. This routine helps confirm that the instrument is holding accuracy during daily use and gives confidence that recorded results remain within tolerance.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series is designed to take most of the manual work out of testing. Once the specimen is clamped and the pendulum is released, the system automatically calculates the tearing force and records the result.

The touchscreen interface shows not only individual values but also built-in statistics such as averages, standard deviation, and coefficient of variation. Results can then be saved, printed, or exported without additional processing. This level of automation helps laboratories run larger test series faster and with fewer errors compared to manual calculations.

Click here to learn more about the product or here to receive a personalized quote.

Elmendorf tear testing uses a pendulum that swings through a pre-cut specimen, and the energy needed to propagate the tear is recorded. It is quick, simple, and ideal for paper, films, and woven fabrics where a sharp tear event is expected.

Trapezoid and trouser tear methods, on the other hand, are performed on a tensile testing machine in a constant-rate-of-extension (CRE) setup. Instead of a pendulum, the sample is pulled apart steadily, and the tearing force is measured throughout the test. These methods are better suited for flexible, elastic, or knitted materials where controlled loading provides more meaningful data.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series includes an automatic specimen cutting function. This feature prepares each sample with the same slit length and geometry, which is critical for repeatable results. Manual preparation often introduces small variations, and those can noticeably affect tear resistance values.

With automatic cutting, laboratories save time on preparation while also reducing the risk of operator error. It is especially useful when running large test series, where consistency across dozens or even hundreds of samples is necessary to compare batches or verify production quality.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series is suitable for testing coated fabrics in line with ISO 4674-2. This standard focuses on materials where a textile base is reinforced with rubber or plastic coatings, which makes them stronger but also changes how they tear.

These types of fabrics are widely used in automotive interiors, protective clothing, and industrial applications. With the GenElm Series, laboratories can measure how resistant such coated textiles are to tearing, helping manufacturers confirm performance and meet the durability requirements of their target markets.

Click here to learn more about the product or here to receive a personalized quote.

Pneumatic clamping applies the same pressure to every specimen, no matter who is operating the tester. This removes differences that can happen if samples are tightened manually, where grip strength and technique often vary from person to person.

The system also links the clamp with an automatic pendulum release. Once the sample is secured, the test begins in the same controlled way every time. Together, these features limit human influence on the process.

Click here to learn more about the product or here to receive a personalized quote.

Conditioning makes sure that paper and textile samples are exposed to stable temperature and humidity before testing. Materials like these absorb and release moisture quickly, which can change their mechanical behavior. If one batch is tested in dry conditions and another in a humid environment, the results may vary even if the materials are identical.

Standards such as ISO 187 specify controlled conditions for this reason. By conditioning specimens, laboratories create a uniform baseline that makes results consistent and comparable between tests, production runs, or even different facilities. This step is especially important when tear resistance data is used for product certification or customer approvals.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series is equipped with both options. A USB port is located on the touchscreen panel, allowing operators to connect external devices for data transfer or updates. In addition, the system can be paired with a printer module, so results can be printed directly without passing through a computer.

These connections are especially useful in quality control settings, where fast documentation is often required. Having both USB and printer output means that test results can be archived digitally, shared within a lab network, or issued as printed reports for audits and compliance checks.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series reports tear strength values in Newtons (N) as the standard unit. For materials where finer resolution is needed, such as thin plastic films, results can also be shown in millinewtons (mN). In paper testing, certain methods present values as force per ply, which makes it easier to compare sheets of different thicknesses.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series is supplied with a full set of pendulums that cover the main testing ranges: 16 N, 32 N, 64 N, and 128 N. Alongside them, the package also includes check weights of 2, 8, 16, and 32 N, which are used to verify calibration before and during operation.

To make specimen preparation consistent, the system comes with cutting templates, as well as the tools needed for setup and maintenance. This means that laboratories receive everything necessary to start testing right away, without having to source accessories separately. The inclusion of both low and high-capacity pendulums makes the instrument suitable for thin films, lightweight papers, and heavy-duty fabrics alike.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series gives several ways to handle test data. Results are shown directly on the touchscreen, where operators can see individual values along with averages, minimums, maximums, and standard deviations. This makes it easy to review outcomes immediately after a test.

For documentation, the system can send results to a connected printer or export them to a computer through the RS232 interface. Many labs use this option to store records digitally or feed them into external software for long-term tracking. Having both on-screen access and external output makes the tester flexible for routine quality checks as well as formal reporting.

Click here to learn more about the product or here to receive a personalized quote.

The GenElm Series follows a fixed geometry to make every test comparable. The clamp gap is set at 7.0 ±0.25 mm, the slit length at 20 ±0.2 mm, and the tear travel at 43 ±0.15 mm. These dimensions are aligned with the requirements of major international standards, which ensures that results can be trusted across different labs.

Keeping these parameters constant is critical because even small variations in slit length or clamp spacing can change how the tear develops. By locking these values into the instrument design, the GenElm Series removes guesswork from specimen preparation and provides a repeatable baseline for testing paper, films, and textiles.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series requires a compressed air supply for its pneumatic clamping system. The air pressure ensures that every sample is held with the same force before the pendulum is released, which removes operator variability and makes the test more reliable.

A standard laboratory air line is usually enough to run the system. Stable pressure is important, since uneven or weak airflow can affect how well the clamps secure the specimen. With proper air support, the instrument maintains consistency across multiple tests, which is a must for both quality control and research environments.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series can be linked to LIMS or ERP systems through its RS232 connection. This port makes it possible to send test results directly to a central database without manual entry.

For many laboratories and production sites, integration means more than just convenience - it helps maintain traceability, reduces errors, and speeds up reporting. By connecting the Elmendorf tester to existing digital workflows, companies can keep material data aligned with broader quality and production records.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series is fully compatible with ISO 6383-2, the international standard that defines the Elmendorf method for determining the tear resistance of plastic films and sheeting. It specifies the slit length, specimen preparation, and pendulum operation needed to measure how a tear propagates under controlled force.

This standard is widely applied in the packaging and polymer industries, where film durability is critical for product safety and performance. By testing according to ISO 6383-2 with the GenElm Series, manufacturers can compare materials across suppliers, qualify new batches, and maintain compliance with international quality benchmarks.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series supports WSP 100.1, the nonwoven fabric test method published by INDA and EDANA. This standard includes the Elmendorf procedure for measuring tear resistance in nonwoven materials, ensuring consistent evaluation across laboratories.

For producers of wipes, filters, and disposable nonwoven products, WSP 100.1 is a common reference point. Using the GenElm Series in line with this method allows manufacturers to assess fabric strength, validate product quality for different end uses, and align with international nonwoven industry practices.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series complies with NF T54 141, the French standard that defines the Elmendorf method for evaluating the tear resistance of plastic films and sheets. It describes how to prepare samples, make the initial slit, and measure the energy required for the tear to propagate.

In France and other regions where NF standards are referenced, NF T54 141 is widely used in the packaging and plastics industries. Applying this method with the GenElm Series helps manufacturers verify product reliability, compare materials across production runs, and demonstrate conformity with regional market expectations.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series is suitable for APPITA P 400, the standard issued by the Technical Association of the Australian and New Zealand Pulp and Paper Industry (APPITA). It outlines the Elmendorf method for determining the tearing resistance of paper, board, and pulps.

For mills and labs across Australia and New Zealand, APPITA P 400 is a primary reference. Running this method on the GenElm Series allows companies to benchmark pulp quality, assess paper performance during development, and maintain regional compliance while aligning with international practices.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series is designed to carry out tests in accordance with BS 4468, the British standard for measuring the tearing strength of paper and board using the Elmendorf method. It specifies procedures for specimen cutting, pendulum operation, and calculation of tear resistance.

This standard has long been recognized in the UK paper and packaging sectors. By applying BS 4468 on the GenElm Series, producers and laboratories can validate the durability of their materials, support compliance with customer requirements, and maintain consistency in product development and quality checks.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series complies with JIS L0849, the Japanese standard for measuring the tearing strength of woven fabrics using the Elmendorf method. It defines how a prepared slit in the fabric should be extended by a pendulum to evaluate material durability.

This standard is often required by textile producers and apparel suppliers working with Japanese markets. Running JIS L0849 on the GenElm Series gives manufacturers a clear way to demonstrate fabric performance, support quality certification, and meet buyer expectations in both domestic and international trade.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series is suitable for JIS K 7128-2, the Japanese standard that defines the Elmendorf method for testing the tear resistance of plastic films and sheeting. It sets procedures for sample cutting, pendulum use, and evaluation of tear propagation under controlled conditions.

In Japan and other regions where JIS standards are required, this method is a reference point for packaging films, industrial plastics, and research applications. Using the GenElm Series for JIS K 7128-2 helps manufacturers validate film durability, meet customer specifications, and ensure smooth entry into markets where compliance with Japanese standards is mandatory.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series complies with EN 21974, a European standard that specifies the Elmendorf method for determining the tearing resistance of paper. It provides clear guidance on specimen dimensions, slit length, and test conditions to ensure uniform measurement across laboratories.

This standard is especially relevant for producers of printing stock, tissue, and packaging paper. By using the GenElm Series in line with EN 21974, companies can verify the mechanical strength of their materials, align with EU quality expectations, and streamline comparisons between different suppliers and product lines.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series supports DIN 53128, the German standard for determining the tearing resistance of paper and board using the Elmendorf method. It outlines the procedure for preparing specimens, applying the pendulum, and calculating the force required to extend a tear.

This standard is widely applied in the paper and packaging industries across Europe. With the GenElm Series, laboratories can follow DIN 53128 directly, making it easier to benchmark different grades of paperboard, compare production batches, and maintain consistency in packaging performance.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series is fully aligned with ISO 1974, the international standard for measuring the tearing resistance of paper using the Elmendorf method. It defines how to prepare the specimen, make the slit, and record the pendulum energy needed to propagate the tear.

For paper mills, packaging companies, and independent test labs, ISO 1974 is a key benchmark in verifying product quality. Running this method on the GenElm Series makes sure that results are directly comparable with global industry expectations.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series meets ASTM D689, the standard for determining the tearing strength of paper using the Elmendorf method. It specifies how to measure the force needed to continue a tear once started, giving a clear picture of paper strength and quality.

Paper mills, packaging producers, and research labs often rely on ASTM D689 as part of routine quality checks. With the GenElm Series, operators can follow the method precisely, using standardized clamping and pendulum ranges to obtain reliable, comparable results across different paper grades.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series is designed to perform tests according to ASTM D5734, which specifies the trapezoid tear method for nonwoven fabrics. Unlike woven textiles, nonwovens have different structures and tear behaviors, and this standard provides a way to measure their resistance to tearing under controlled conditions.

For nonwoven manufacturers, medical textile producers, and quality control labs, ASTM D5734 is an important benchmark. Using the GenElm Series, operators can run these tests with stable clamping, consistent specimen cutting, and accurate data collection.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series supports NEXT 17, a retail-focused standard that defines procedures for measuring the tearing strength of fabrics using the Elmendorf method. It is used by NEXT to ensure that clothing textiles can withstand everyday wear without premature tearing.

For suppliers and textile mills producing for NEXT, meeting this requirement is part of the quality approval process. By using the GenElm Series, labs can carry out the specified tear tests with accuracy and repeatability, helping manufacturers demonstrate compliance and secure product acceptance.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series is suitable for ISO 4674-2, which specifies the Elmendorf method for testing the tear resistance of rubber- or plastics-coated fabrics. This procedure helps determine how well technical textiles and coated materials withstand tearing forces once a cut has been introduced.

For producers of coated fabrics, automotive interiors, and industrial textiles, ISO 4674-2 is a key reference point. Running the test on the GenElm Series gives dependable results with controlled clamping, standard slit preparation, and interchangeable pendulums, making it easier for labs to validate product strength against industry requirements.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenElm Series follows EN ISO 13937-1, which sets the trouser tear method for woven textiles. This standard is widely applied in fabric testing to check how resistant materials are when a tear is initiated in a controlled way.

For apparel brands, textile mills, and certification labs, EN ISO 13937-1 is often requested as proof of fabric durability. The GenElm Series allows these tests to be carried out reliably, with pneumatic clamping and consistent specimen preparation giving results that align with international quality requirements.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series is built to perform tests according to DIN 53862. This standard sets the Elmendorf method for textiles, focusing on how much force is required to extend a tear in fabric under controlled conditions.

For textile producers and testing institutes in Europe, DIN 53862 is a familiar benchmark. With the GenElm Series, labs can follow the prescribed setup exactly, using pneumatic clamping and interchangeable pendulums to keep results consistent across different fabric weights and structures.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenElm Series supports ASTM D1424 out of the box. ASTM D1424 is the Elmendorf method for woven fabrics that measures the force needed to continue a tear from a small pre-cut slit using a falling pendulum.

For textile mills, apparel brands, and test labs, this means you can run fabric durability checks by the required procedure and get clean, comparable numbers. Quick pendulum swaps (16 to 64 N, up to 128 N on the high-energy model), pneumatic clamping, standard cutting templates, and onboard statistics make routine lot release and reporting fast and reliable.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

HDT/VICAT Testing Machine – Thermal Analysis for Plastics NG-HDT

The NG-HDT HDT/Vicat testing machine measures HDT and Vicat softening temperature (VST) for thermoplastics, including pipes and fittings. It supports common ISO, ASTM, and GB/T methods run under constant load with controlled heating. The system is available in 3-station and 6-station configurations with touchscreen control for the full test sequence. Measurement uses Class A PT100 temperature sensing and LVDT displacement monitoring, with an immersion oil bath rated up to 300°C (572°F). Results can be saved and exported over Ethernet, with options such as a chiller and external oil-vapor extraction/filtration.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.