Metal Testing Equipment

Standards

ASTM E8, JIS Z 2241, DIN 50125, ISO 6892-1, ASTM A370, ASTM B557

Description

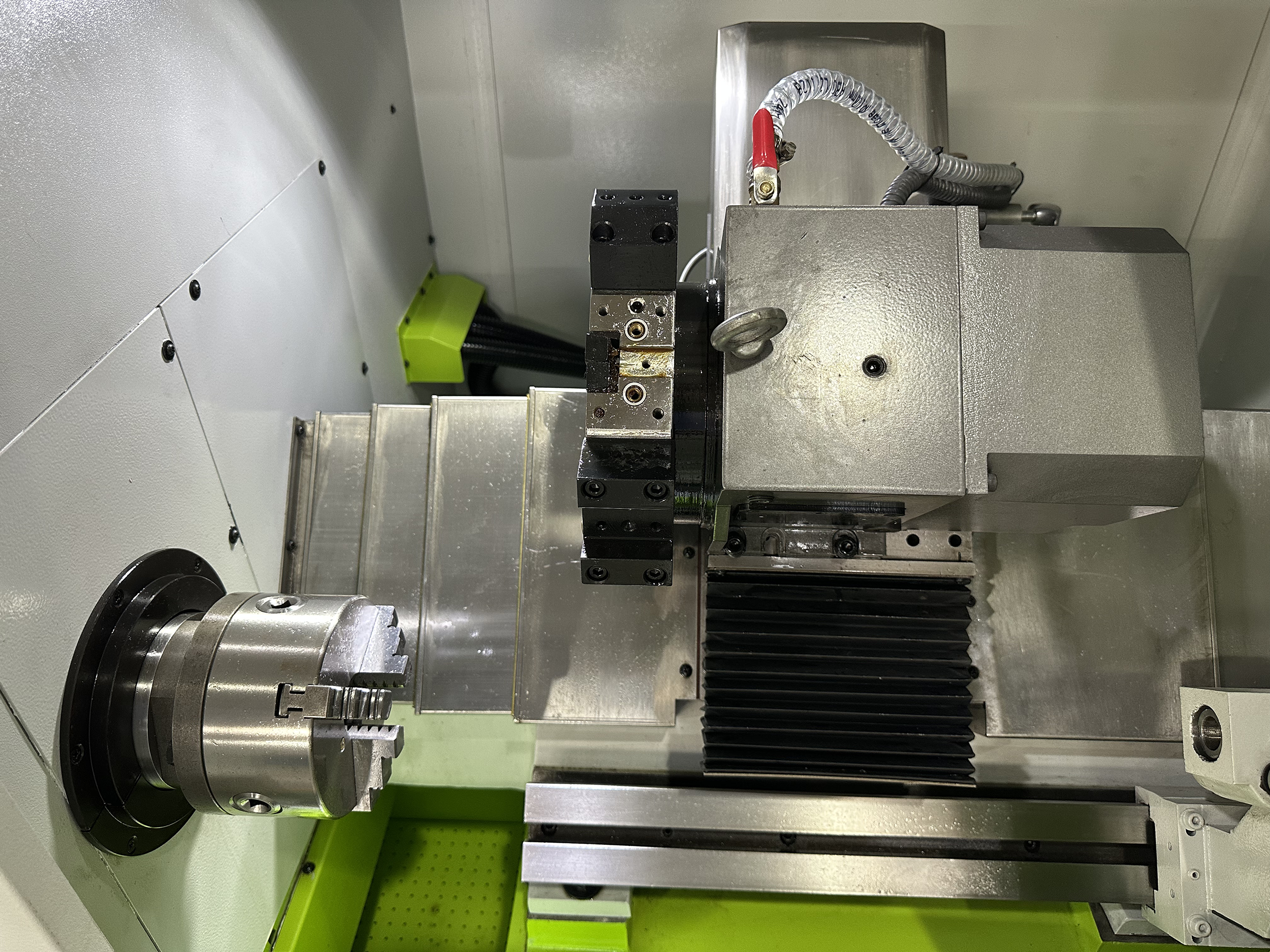

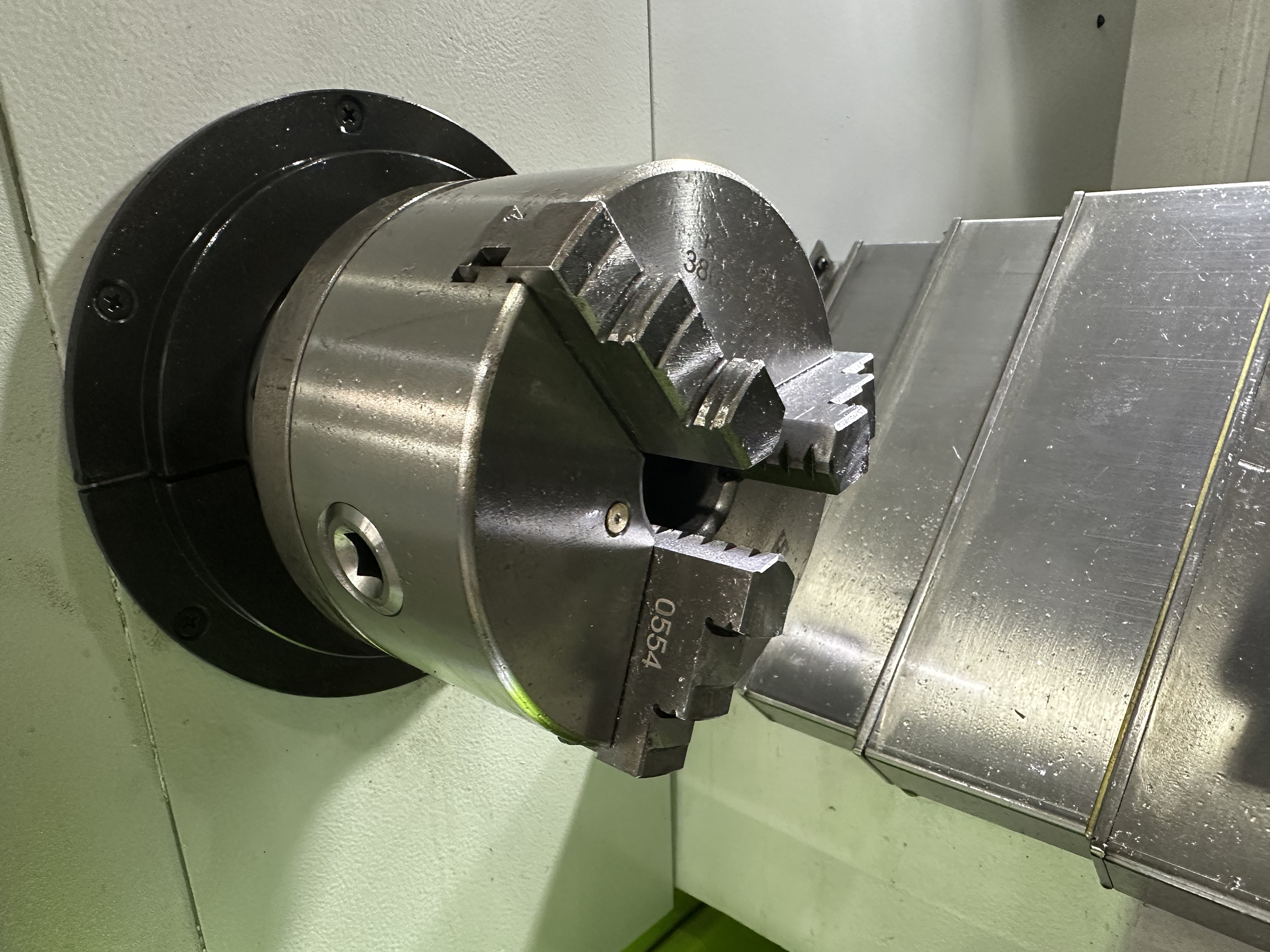

The TensileTurn CNC – Classic Upgrade – Round Tensile Specimen Preparation Machine is a compact CNC lathe designed specifically for accurate and repeatable preparation of round tensile specimens. The system supports specimen diameters up to 1.5" (45 mm) and works confidently with materials up to 55 HRC. For increased throughput, the triple clamping fixture allows preparation of multiple samples in a single setup.

The machine is controlled through the TensileSoft™ 2.0 interface on a 15" touchscreen controller. Operators can select specimen dimensions from a library of common testing standards (ASTM, ISO, DIN, and others) or manually enter custom geometry. This setup enables technicians without machining backgrounds to prepare specimens consistently, while experienced users can access full FANUC CNC controls for general turning tasks when needed.

The Classic Upgrade is suitable for preparing:

- Standard round tensile specimens

- Sub-size specimens

- Threaded-end tensile bars

- Button-head and fatigue specimens

- Samples made from round, square, or irregular stock

The workflow is straightforward: the operator loads the stock, secures it, selects or inputs the specimen parameters, and begins machining. The process takes minutes and fits naturally into laboratory testing routines, helping to avoid delays associated with sending samples to external machine shops. The machine’s stable construction and controlled cutting environment support consistent gauge dimensions and repeatable results across batches.

This model is used in:

- Quality control labs preparing routine test specimens

- Research and development environments requiring versatility

- Production facilities where regular mechanical testing is part of daily workflow

Key Benefits & Working Characteristics

The Classic Upgrade model is built to support stable, predictable specimen preparation workflows inside the laboratory. The system maintains dimensional consistency across batches, which allows mechanical testing results to be compared confidently over time, even when materials, heat treatment conditions, or suppliers change.

In day-to-day operation, the machine helps synchronize specimen preparation with the pace of testing. Instead of scheduling machining work externally, the lab can produce new specimens as soon as they are needed, which stabilizes turnaround time and reduces idle testing periods.

Practical benefits in routine use include:

- Stable geometry across multiple batches, supporting reliable comparison of tensile test data.

- Controlled cutting conditions that minimize variation in the gauge section and shoulder transitions.

- Reduced downtime associated with waiting for machining access or outsourced specimen preparation.

- Flexibility to switch between materials without reconfiguring the entire setup or changing machines.

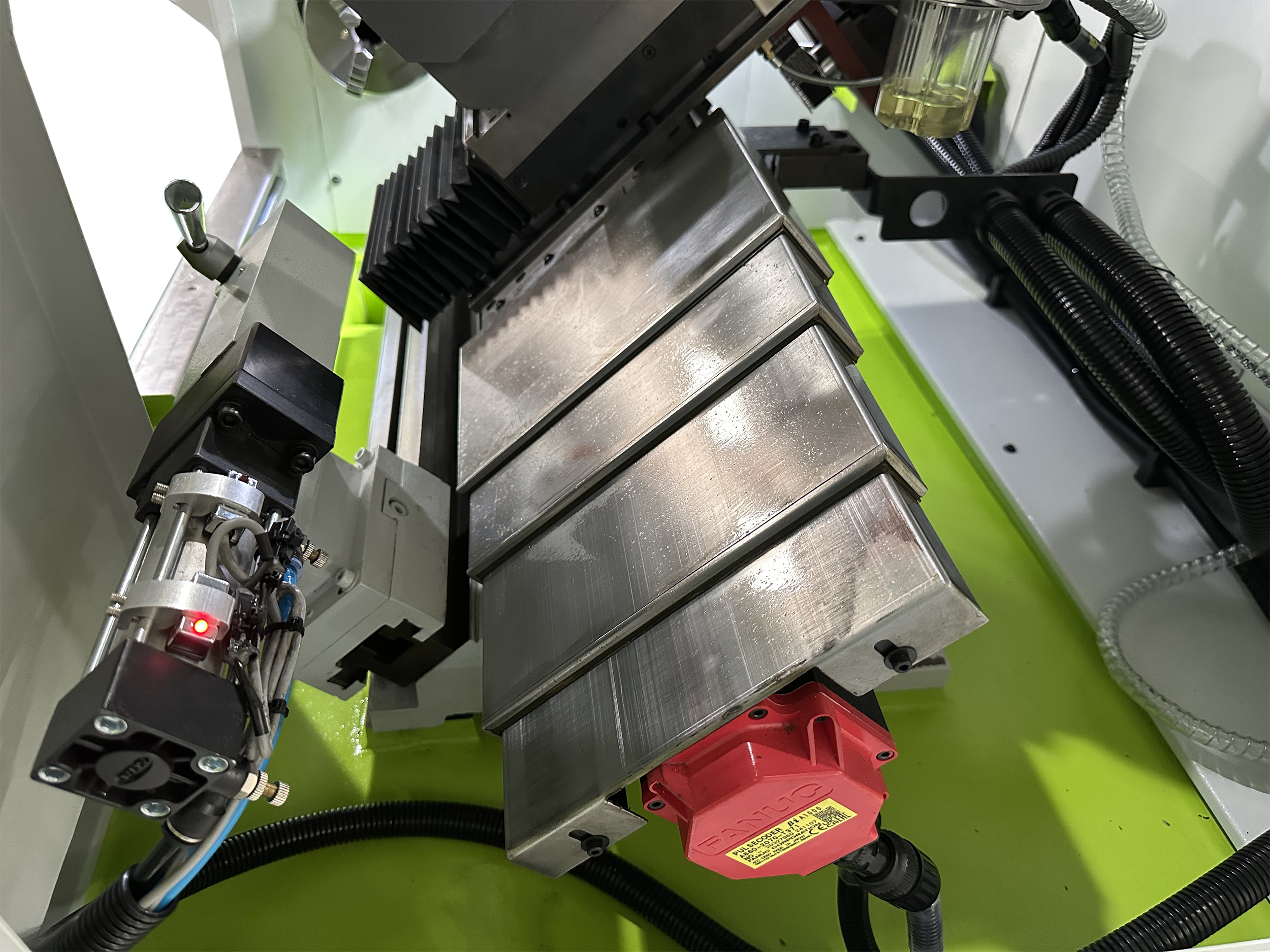

From a workflow perspective, the system is optimized for low-interruption operation:

- clamping methods maintain secure and centered stock positioning

- coolant circulation reduces heat buildup that can distort dimensions

- tool positioning remains stable across repeated cycles

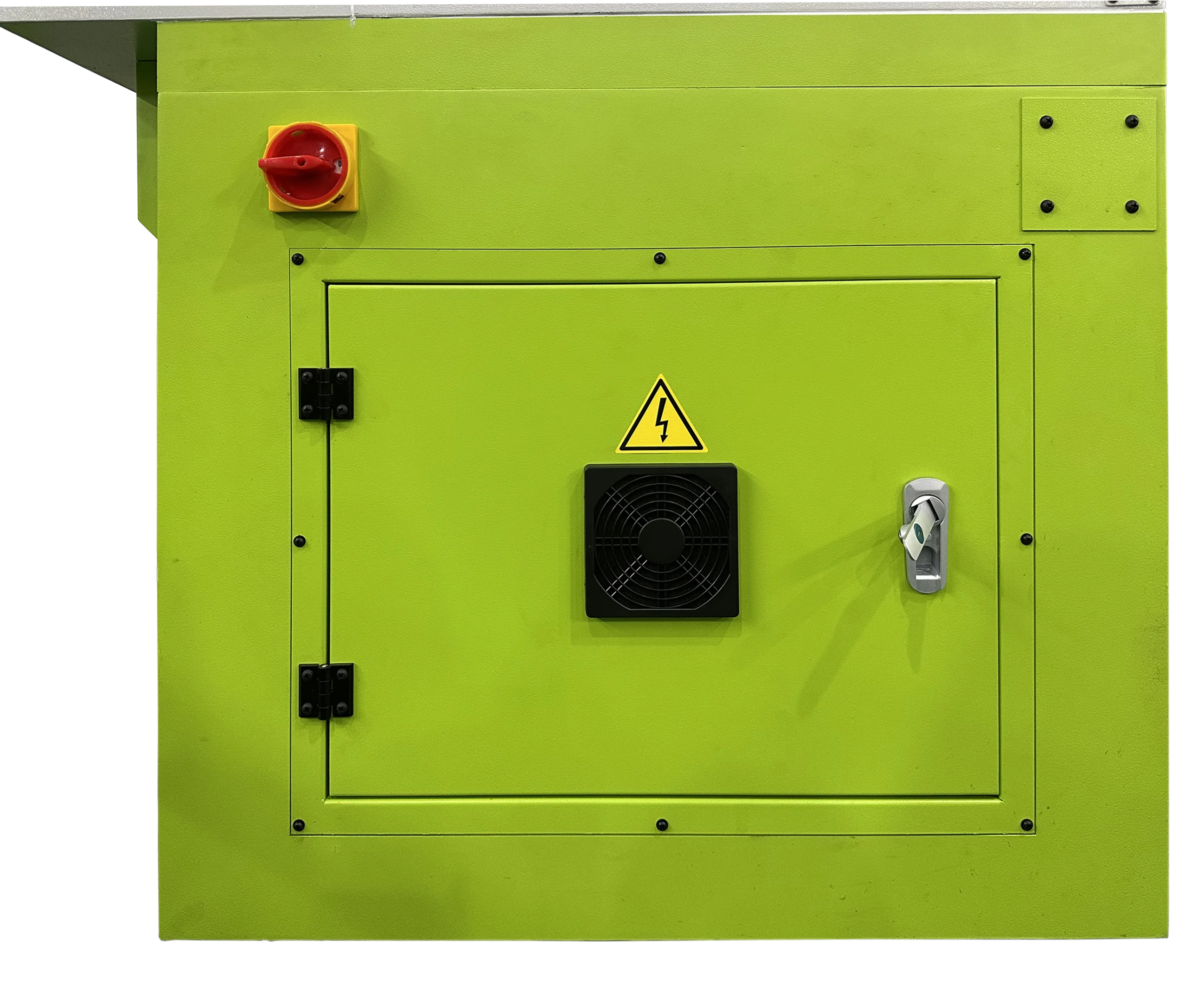

Control System Overview

The system is supplied with a 15" touch-screen controller running a full FANUC CNC environment. This setup provides direct access to both the simplified TensileSoft™ specimen preparation interface and full CNC control functions when needed for general turning operations. The controller includes built-in connectivity and storage resources that support routine operation, file management, and parameter adjustments without additional hardware.

Key controller capabilities include:

- 64 GB storage and 4 GB RAM for program handling and data retention

- Wi-Fi, Ethernet, and USB ports for transferring files and saving settings

- support for Macro B programming, tool offset management, and work coordinate systems

- helical interpolation, drilling cycles, scaling, mirroring, and motion planning functions

Service Plan

The Service Plan supports steady operation of the system over time. It includes scheduled preventive maintenance to help reduce unexpected downtime and maintain stable performance during routine specimen preparation. The plan also covers training and re-training for laboratory personnel, allowing new operators to get up to speed and experienced staff to refine their workflow.

Support can be adapted to:

- onboarding new technicians

- maintaining consistent specimen preparation across shifts

- addressing changes in material types or testing volume

- extending equipment life through regular maintenance checks

This structure helps the laboratory maintain a predictable testing schedule and avoid interruption.

Contact your representative to review available plan options.

Technical Specifications

| Parameter | Value |

|---|---|

| Total Electrical Connection | 3.5 kW |

| Main Motor Power | 2.2 kW |

| Coolant Pump Power | 40 W |

| Input Voltage | 220 V (single phase) |

| Pneumatic Connection Required | Yes |

| Swing Over Bed | Ø11.8" (Ø300 mm) |

| Swing Over Cross Slide | Ø7.8" (Ø200 mm) |

| Center Width | 23.6" (600 mm) |

| Center Height | 5.5" (140 mm) |

| Spindle RPM | 300 |

| Spindle Nose | 1:04 |

| Spindle Taper | MT4 |

| Spindle Bore | Ø1.02" (Ø26 mm) |

| Spindle Speed Range | 30–4000 rpm |

| Lathe Chuck Diameter | Ø4.92" (Ø125 mm) |

| Tool Changer Type | Electric |

| Tool Positions | 4 |

| Max Tool Section Size | 0.47" × 0.47" (12 × 12 mm) |

| X-Axis Travel | 7.1" (180 mm) |

| Z-Axis Travel | 18.3" (465 mm) |

| X-Axis Rapid Feed | 236 in/min (6000 mm/min) |

| Z-Axis Rapid Feed | 315 in/min (8000 mm/min) |

| Position Accuracy (X / Z) | ±0.002" / ±0.001" (±0.05 mm / ±0.03 mm) |

| Repeatability (X / Z) | ±0.0001" / ±0.0001" (±0.02 mm / ±0.02 mm) |

| Tailstock Taper | MT2 |

| Tailstock Sleeve Diameter | Ø1.18" (Ø30 mm) |

| Tailstock Sleeve Travel | 3.15" (80 mm) |

| Machine Dimensions (L × W × H) | 62.5" × 27.75" × 59.65" (1590 × 705 × 1515 mm) |

| Shipping Dimensions (L × W × H) | 72" × 37.2" × 72.65" (1829 × 945 × 1845 mm) |

| Net Weight / Gross Weight | 1873 lb / 850 kg |

| Coolant Tank Capacity | 25 L |

Related Products

TensileTurn CNC – Industrial Upgrade – Round Tensile Sample Preparation Machine

The TensileTurn CNC – Industrial Upgrade Model is a compact round tensile specimen preparation system designed for accurate and repeatable machining results. Operators can select specimen dimensions from preloaded ASTM, ISO, and DIN standard libraries or enter custom parameters directly through the touchscreen interface. The system supports a wide range of materials and specimen types, including standard round bars, button-head samples, and threaded tensile specimens. Its dedicated CNC control environment enables independent sample preparation without relying on external machine shop resources.