Metal Testing Equipment

Standards

Description

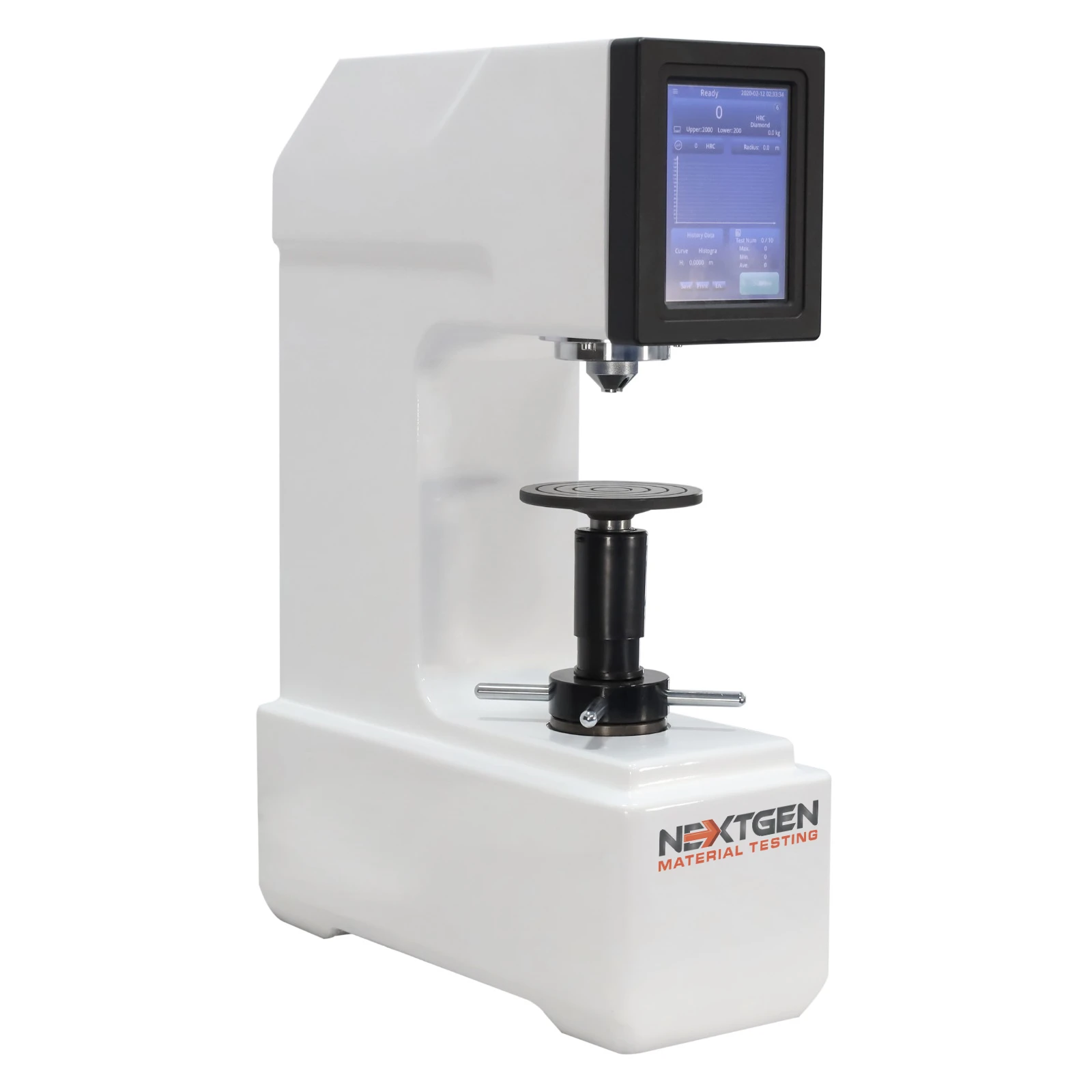

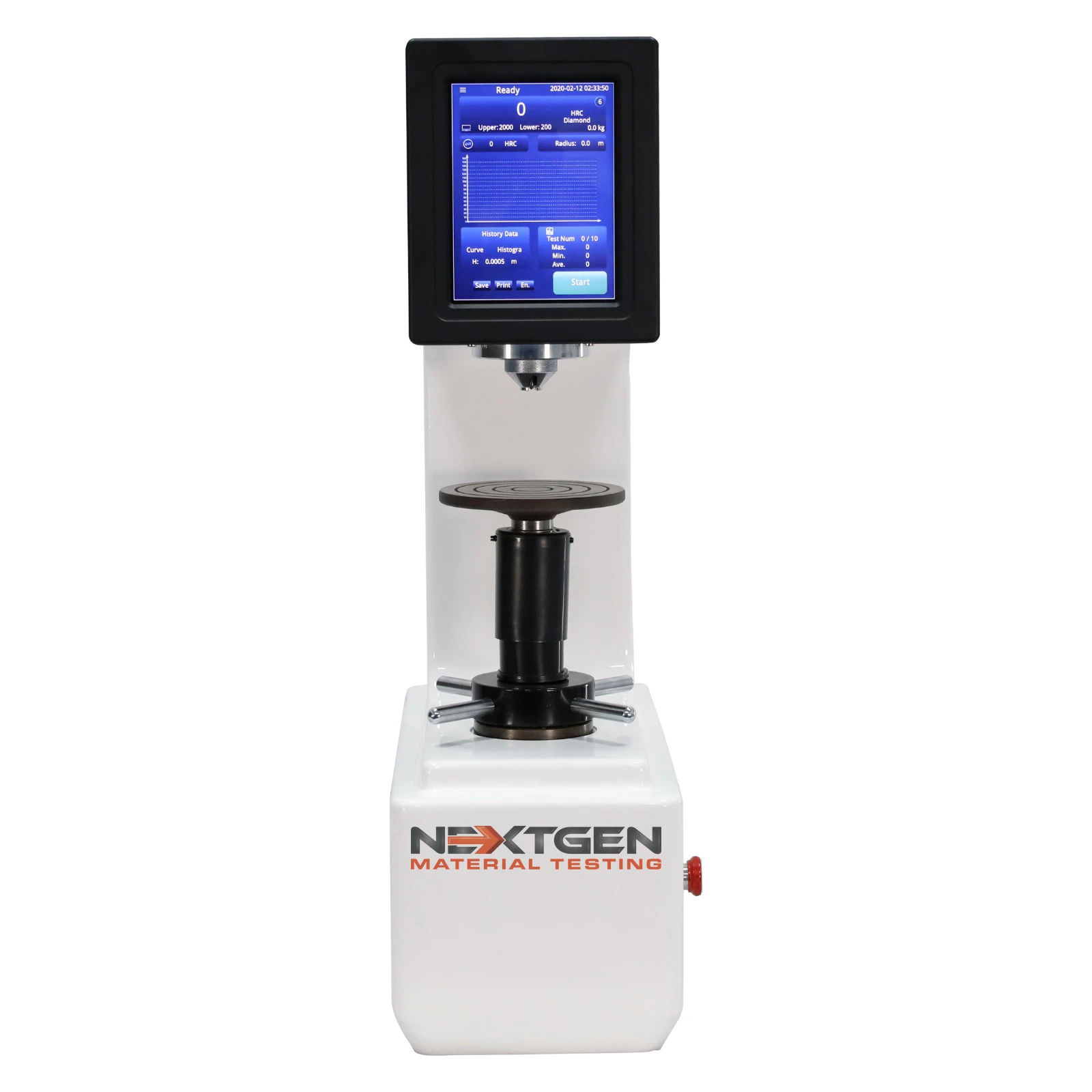

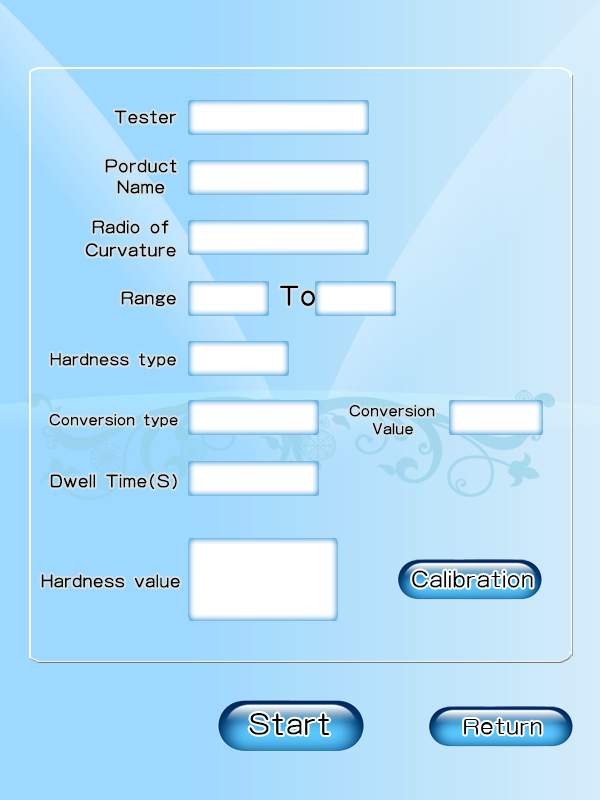

The NG-RockGen - Digital Rockwell Hardness Tester is designed to test the hardness of metals by determining the depth of penetration of an indenter under a large load compared to the penetration made by a preload according to the Rockwell scale. There are variations of the RockGen DGEN - Digital Rockwell Hardness Tester system for Rockwell Regular scales, Superficial scales as well as a TWIN scales system is capable of both regular and superficial scales. With an easy to navigate operational menu, the RockGen DGEN - Digital Rockwell Hardness Tester provides the solution for any Rockwell testing requirements. With a resolution of 0.001, the system will provide you with the absolute highest accuracy on the market. Learn everything you need to know about the Rockwell Hardness Test here.

2024 Model Introduction Video

Main Function and Features of RockGen DGEN

- High gloss and scratch resistance surface allows the unit to maintain a brand new look even after many years of use

- Large LCD Display for clear visibility of your hardness readings. Removes all aspects of human error.

- Automatic Testing procedures. System will make the indentation and provide the reading automatically.

- The DGEN system provides a high level of repeatability when testing any parts for Rockwell hardness.

Main Application

Chilled steel, hardened and tempered steel, annealed steel, casting, malleable cast, hard alloy, hardened steel plate, aluminum alloy, bearings steel.

2024 Model with Indenter Protector

Technical Specifications

| Model | RockGen R-DGEN | RockGen S-DGEN | RockGen TWIN-DGEN |

|---|---|---|---|

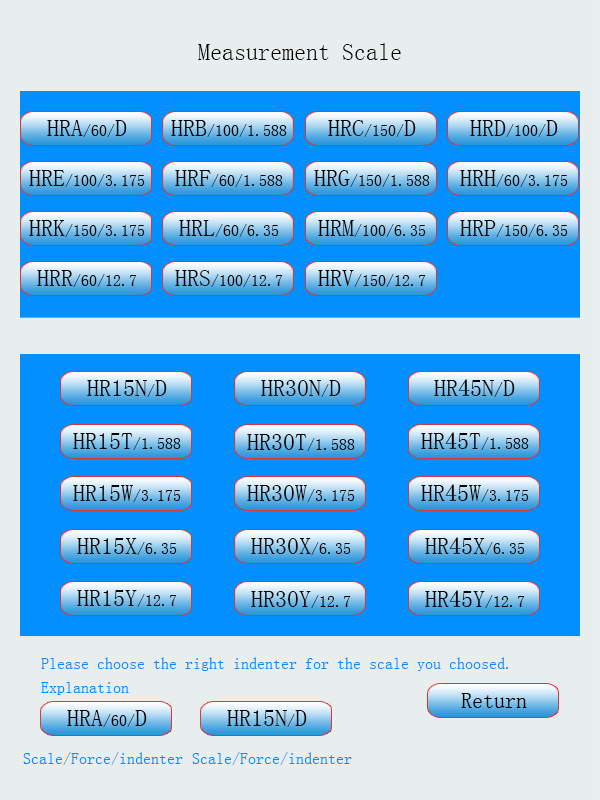

| Rockwell Scales | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRR, HRL, HRM and HRK. | HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HRD, HRE, HRF, HRG, HRH, HRR, HRL, HRM and HRK | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Conversion Scales | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, H15N, H30N, H45N, H15T, H30T, H45T | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, H15N, H30N, H45N, H15T, H30T and H45T | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, H15N, H30N, H45N, H15T, H30T, H45T |

| Preliminary Test Force | 10kg (98N) | 3Kg (29.42N) | 10Kg(98.0N), 3Kg (29.42N) |

| Total Test Force | 60kg (588N), 100kg (980N), 150kg (1471N) | 15Kg(147.1N), 30Kg(294.2N), 45Kg(441.3N) | 60Kg (588N), 100Kg (980N), 150Kg (1471N), 15Kg(147.1N), 30Kg(294.2N), 45Kg(441.3N) |

| Hardness Data Read | Digital LCD Display | ||

| Data Output | Built in Printer and RS-232 Port | ||

| Maximum Specimen Height | 8.5" (21.6cm) Extension Model Available upon Request up to 15.5" (40cm) |

||

| Throat Depth (cm) | 15 | ||

| Dwell Time (sec) | 1 – 60 | ||

| Power Supply | 110V/60Hz or 220V/50Hz | ||

| Instrument Size (cm) (L x W x H) |

18 x 6.2 x 26" (45.7 x 15.7 x 66) |

||

| Instrument Weight | 188 lbs (85 kgs) |

||

| Hardness Value Range | HRA: 20-88, HRB:20-100, HRC:20-70 | HR15N:70-91, HR30N:42-80, HR45N:20-70, HR15T:73-93, HR30T:43-82, HR45T:12-72 | HRA:20-88, HRB:20-100, HRC:20-70, HR15N:70-91, HR30N: 42-80, HR45N:20-70, HR15T:73-93, HR30T:43-82 HR45T:12-72 |

| Reference Standard | ASTM E18 and ISO 6508 | ||

| Standard Accessories | Main Hardness Tester, Diamond HRC Rockwell Indenter, HRB 1/16" Diameter Hard Alloy Steel Ball Indenter, Large Testing Flat Anvil, Medium Testing Anvil and V-shaped Testing Anvil (Medium sized), Standard Hardness Blocks x3, Accessory Case, Dust-Proof Cover, Instruction Manual and Certification/Warranty card | ||

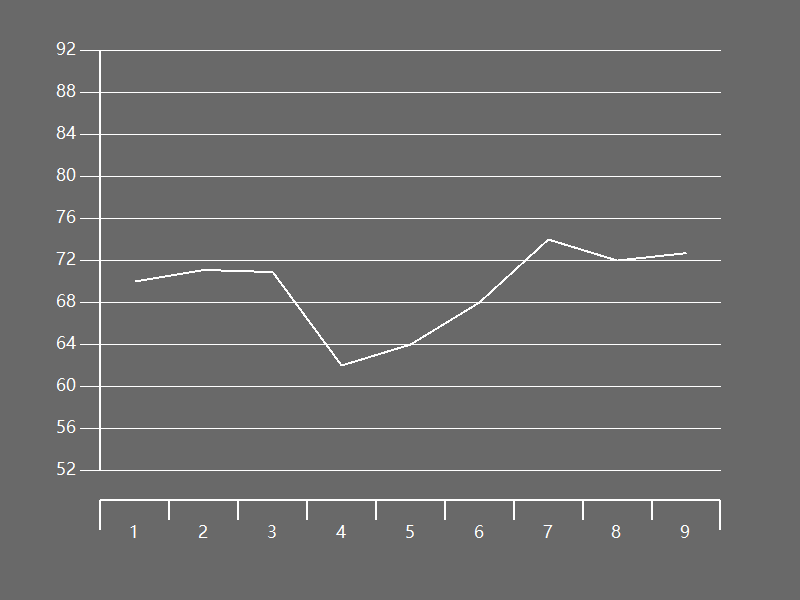

Hardness Test Report

| Tester | Date | 2021/01/09 | |||||

| Part Name | Part # | ||||||

| Part Size | Test Standard | ||||||

| Quality UL | Quality UL | ||||||

| Test Result | |||||||

| # | Hardness | Hardness Type | |||||

| 1 | 70.1 | HRC | |||||

| 2 | 71.2 | HRC | |||||

| 3 | 71.0 | HRC | |||||

| 4 | 62.1 | HR30TW | |||||

| 5 | 64.1 | HR30TW | |||||

| 6 | 68.1 | HR30TW | |||||

| 7 | 74.1 | HRC | |||||

| 8 | 72.1 | HRC | |||||

| 9 | 72.8 | HRC | |||||

FAQs

Sometimes, gauging the strength of materials through Rockwell Hardness Tester is preferable. This is due to a number of advantages.

The sample material for several tests needs to be polished, ground, broken up, and buffed to obtain the most accurate readings. In essence, tests like the Knoop and Vickers method require that the sample surface be as flat and variable-free as feasible.

Since the Rockwell method measures the indentation depth, the sample does not need to go through further processing for the test to be accurate. This is also why unprocessed commodities like ore are tested using the Rockwell method.

Since most hardness testers that employ the Rockwell method don't use diagonal scales to measure hardness, the hardness value is easily readable. This is definitely the case if you use a digital Rockwell Hardness tester, as the results are shown on the screen right away after a little processing period.

The lack of visual examination significantly decreases the likelihood of an operator reading error.

Click here to obtain a personalized quote for yours NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester.

Depending on the tester's application on various materials, the Rockwell Hardness Tester has a wide range of scales. For hardness testing and determining hardness value, a total of 30 Rockwell hardness scales are provided. The principal load for the Rockwell Regular Scales Testing is either 50kgf, 100kgf, or 150kgf, with a preload of 10kgf. The Superficial Rockwell scales are used for materials with a thickness as thin as 0.15mm, or 0.0006 inches, and they employ a 3kgf preload and one of 15kgf, 30kgf, or 45kgf as the principal loads.

The Rockwell Testing systems depend on the material being tested, including its hardness, thickness, indentation placement, and scale restrictions. The material being tested must have a thickness that is at least ten times greater than what the Rockwell indentation will be when manufactured of the material is.

The Rockwell Hardness Testers from NextGen are among the top Rockwell Manufacturing equipment. They can give you all the choices your business requires, including the Rockwell Twin Digital Testing equipment. One of our most well-liked products is the Twin model, which enables the user to test both the Rockwell regular and Rockwell superficial scales on a single instrument.

NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester weights 188 lbs or 85kgs.

Click here to obtain a personalized quote.

The RockGen Rockwell Hardness Testing System was created to determine the hardness of metal based on the indentation they left on a material under test. The device can measure a material's resolution down to 0.001 inches. The accuracy of NextGen's Rockwell hardness testers is guaranteed to be among the greatest on the market. The preliminary force test, also known as a preload, is initially applied for a predetermined amount of time, or dwell time before the Rockwell Hardness Testing measurement is calculated.

The major load, which is an additional load, will be administered after the predetermined amount of time. Following the application of the complete force, measurements of the indentation's depth are made from the reference point to the penetrator's final depth after the major load has been applied. The Rockwell Hardness Values are the distances between the two imprints.

NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester throat depth is 15cm.

Click here to obtain a personalized quote.

In that strength is determined by applying load to a material, the Rockwell hardness test is fundamentally similar to other approaches. However, the Rockwell test does this differently.

The surface is first subjected to a light load to establish the zero position. A heavier major load is then applied to the material that creates the depression once the zero position has been established.

While the test is running, the minor load is kept constant. In some test versions, the principal load must stay on the material until a sufficient indentation has been formed.

The penetration depth starting from the zero point is then measured after removing the main load. The strength of the material is inversely correlated to the amount of damage it endured, as is the case with all hardness tests. As a result, according to the Rockwell method, materials tend to rate harder if the indentation made on them is closer to the surface.

NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester has a Digital LCD Display to read hardness data.

Click here to obtain a personalized quote.

The Rockwell Hardness test's basic idea is the same as that of its equivalents. The sample material is fed into a manual or digital Rockwell hardness tester, which drops a predetermined load and leaves an indenter on the surface. The type of indentation that is made on the sample will then reveal the material's strength.

However, there is one area where the Rockwell approach significantly differs from the Knoop, Vickers, and Brinell procedures. The Rockwell method evaluates strength by depth as opposed to the other methods, which measure strength by the size or width of the depression left. The Rockwell technique is based on the idea that a material's capacity to maintain structural integrity in the face of damage that is more than just visible is a better indicator of its durability. This is why the technique is frequently employed in the domains of engineering and metallurgy, where it is difficult to determine a material's integrity by surface-level inspection.

NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester uses built in Printer and RS-232 Port for data output.

Click here to obtain a personalized quote.

Manufacturing professionals are well-versed in the idea that an item is only as excellent as the components it is built of. To ensure the strength and durability of a given machine or device, manufacturing professionals must ensure that every component, material, and material treatment is employed in its construction.

The Rockwell Hardness test can be used in this situation because it was created expressly to gauge a material's endurance. The system is made to be tested using the ASTM E18 standard. But there are a few things about the test that you need to grasp before you decide to invest in a Rockwell Hardness Tester.

The Rockwell Hardness Test is just one of several assessments used to determine whether a material is suitable for use as a component of an object based on its strength and durability. The Knoop, Brinell, and Vickers procedures are some of the other tests in the series.

The maximum specimen height of NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester is 8.5" (21.6cm) with available extension model up to 15.5" (40cm) upon request.

Click here to obtain a personalized quote.

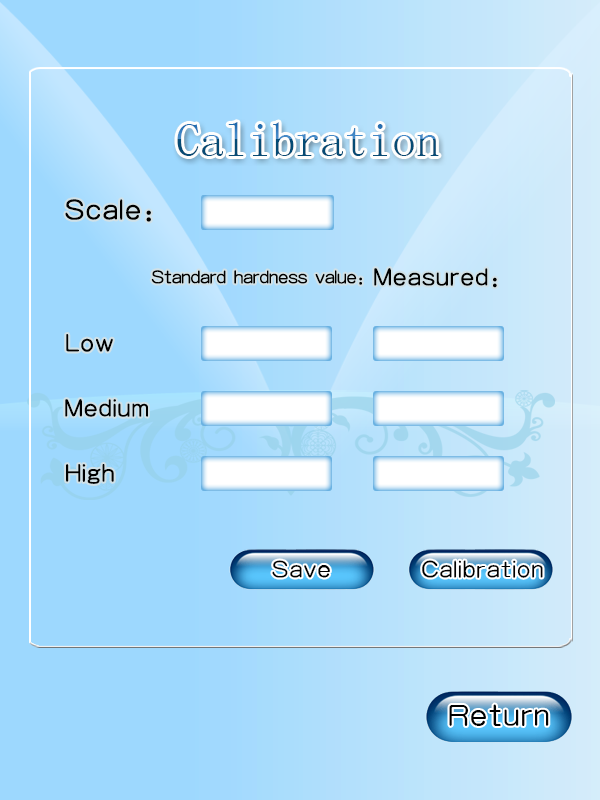

The RockGen DGEN - Digital Rockwell Hardness Tester offers the answer to all Rockwell testing needs with an intuitive operational menu. The system will provide you with the highest precision possible on the market with a resolution of 0.001.

NextGen’s RockGen DGEN Series – Digital Rockwell Hardness main functions:

- Even after many years of usage, the unit may maintain a brand-new appearance because of its high gloss and scratch-resistant surface.

- Clear visibility of your hardness readings thanks to a large LCD display. Eliminates the potential for human error.

- Techniques for automatic testing. The system will automatically create the indentation and deliver the reading.

- When checking the Rockwell hardness of any part, the DGEN system offers a high degree of repeatability.

NextGen’s RockGen DGEN Series – Digital Rockwell Hardness main application:

- Chilled steel

- Hardened and tempered steel

- Annealed steel

- Casting

- Malleable cast

- Hard alloy

- Hardened steel plate

- Aluminum alloy

- Bearings steel

Click here to obtain a personalized quote.

The NG-RockGen - Digital Rockwell Hardness Tester is made to measure the depth of penetration of an indenter under a heavy load in comparison to the penetration made by a preload in accordance with the Rockwell scale in order to test the hardness of metals. The RockGen DGEN - Digital Rockwell Hardness Tester system comes in many configurations. A TWIN scales system is capable of both regular and superficial scales, as well as regular and superficial scales.

Here is the list of standard accessories for NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester:

- Main Hardness Tester

- Diamond HRC Rockwell Indenter

- HRB 1/16" Diameter Hard Alloy Steel Ball Indenter

- Large Testing Flat Anvil

- Medium Testing Anvil and V-shaped Testing Anvil (Medium sized)

- Standard Hardness Blocks x3

- Accessory Case

- Dust-Proof Cover

- Instruction Manual and Certification/Warranty card

Click here to obtain a personalized quote.

Under two different force levels and predetermined circumstances, an indenter of a given size, shape, and material is pressed into the surface of a test specimen. A predetermined extra force is then applied and then removed, returning to the stated preliminary force, after which the initial indentation depth is measured. After measuring the final indentation depth, the Rockwell hardness value is calculated using the two constants N and S, as well as the difference, h, between the final and beginning indentation depths.

A spheroconical diamond indenter that complies with ISO 6508-2:2015 must have a radius of curvature at the tip of 0.2 mm and an included angle of 120°. Only the superficial Rockwell diamond scales, the regular Rockwell diamond scales, or the regular and superficial Rockwell diamond scales may be measured using diamond indenters that have received certification.

Ball indenter, shall be tungsten carbide composite in accordance with ISO 6508-2:2015, with a diameter of 1,587 5 mm or 3,175 mm

NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester complies with ISO 6508 standard.

Click here to obtain a personalized quote.

The Rockwell hardness test is an indentation hardness test that involves forcing a tungsten carbide (or steel) ball indenter or a diamond spheroconical indenter into the surface of the material being tested under specific conditions. The indentation depth is then measured as the indenter's force is increased from a predetermined preliminary test force to a predetermined total test force and then decreased to the predetermined preliminary test force.

An empirical indentation hardness test that can reveal important details about metallic materials is the Rockwell hardness test. This knowledge could be connected to tensile strength, wear resistance, ductility, and other physical properties of metallic materials, and it could be helpful for material selection and quality control.

For acceptance testing of commercial shipments, Rockwell hardness tests are deemed sufficient. Except as otherwise specified, adherence to this standard test technique ensures traceability to national Rockwell hardness requirements.

NextGen’s RockGen DGEN Series – Digital Rockwell Hardness Tester complies with ASTM E-18 standard.

Click here to obtain a personalized quote.

NextGen's RockGen DGEN Series - Digital Rockwell Hardness Tester for regular, superficial and twin scales options. The digital Rockwell hardness tester comes standard with all of your required test blocks and indenters for a long-term operation. We pride ourselves in delivering metal testing systems as a plug-and-play unit to your facility. This allows you to swiftly and effortlessly install the digital Rockwell hardness tester and use it for a long time. Learn more about our Rockwell regular scales, Rockwell superficial scales and Rockwell twin scales by submitting your quote today.

The Rockwell Hardness Testing Systems found at NextGen are manufactured for both regular scales, superficial scales and both. The regular scale Rockwell hardness testing systems have a few models based on your laboratories needs. Analogue Rockwell hardness tester, digital Rockwell hardness tester and advanced semi or fully automatic Rockwell hardness testing systems are here for you. All Rockwell regular scales testing comes with a full range of regular scales including: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRR, HRL, HRM and HRK. All Rockwell superficial scales testing comes with a full range of superficial scales including: HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HRD, HRE, HRF, HRG, HRH, HRR, HRL, HRM and HRK. All Rockwell twin digital scale models include: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T. Learn more about the right Rockwell Hardness Tester for you and submit your request today.

There are two key options for accurate Rockwell hardness testing systems that will surely fit your quality control requirements. RockGen-DGEN Series - Digital Rockwell Hardness Testing Systems for Regular and Superficial scales are an affordable, accurate Rockwell hardness testing solution. The unit allows the operator to experience superior level of accuracy and is extremely easy to operate. The other option includes our semi- or fully-automatic GenRock NG-150 Series - Advanced Digital Rockwell Hardness Testing System. This Rockwell hardness testers is German engineered to deliver the highest accuracy and flexibility. The unit is fully customizable to meet advanced quality control requirements. The accommodated software, Hardwin XL allows you to measure indentation automatically, with the one and only optical magnification zoom, in the thousands. This state of the art unit is there to save you time and money for decades to come. Request your quotation today and our qualified consultants will be happy to match you with your Rockwell hardness testing needs.

Every Rockwell Hardness Tester including the Analogue and Digital Rockwell hardness testing systems comply with the ASTM E18 standard. The hardness tester comes certificate of calibration as well as NIST traceable hardness test blocks allowing you to confirm the hardness reading and operate the Rockwell hardness tester from day 1. Request quote today to receive your certified Rockwell Hardness Testing System.

We are very familiar with Rockwell Hardness Testing of large specimens in-house. Abnormally shaped metal samples are part of structural milestones of railroad, oil and other industries. Our Rockwell Hardness Tester - NG-RockGen DGEN Regular and/or Superficial scales has your covered. Each unit can be pre-ordered with an elongated throat height or extended anvil depth. The units are robust with anvil capabilities of handling up to 500lb. Custom solutions are available based on request. Request a quote today with your technical specifications to acquire the ultimate Rockwell Hardness Tester solution.

The Rockwell Twin Digital Testing system offered by NextGen is the ultimate solution for your lab's tech requirements. By choosing the Twin Digital Testing model NG-RockGen DGEN Regular and Superficial, you will cover the entire spectrum

of your HR requirements including: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T. We offer both analogue and digital models to suit your best needs. Reach out to our technical

consultants today to learn more about your perfect Rockwell Twin Digital Testing solution.

NextGen's Digital Rockwell Hardness Testing Systems are all designed with the end-user in mind. Our goal is to ensure that the user-friendly interface and the simplicity of the instructional manual will help anyone become an expert in minutes! Request a quote today to learn more.

Related Products

NG-RockGen - Analogue Series Rockwell Hardness Tester - Manual and Electronic Models

The NG-RockGen Analogue Rockwell Hardness Tester is designed to test the hardness of metals by determining the depth of penetration of an indenter under a large load compared to the penetration made by a preload according to the Rockwell regular scales.

GenRock NG-150 Series - Advanced Rockwell Hardness Tester - Manual and Automatic Rockwell Hardness Testing System

The NG150 GenRock system can be equipped with a variety of accessories to meet all of your hardness testing requirements. A fully motorized stage, Jominy accessories and a wide variety of specimen fixtures are available to configure the NG150 RockGen system to meet your application.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.