Metal Testing Equipment

Standards

Description

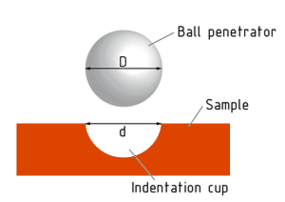

BrinGen 3000 - Digital Brinell Hardness Tester is designed to test the resistance of a metal specimen for indentation. A fixed force (load) is applied against the specimen by an indenter to determine the material hardness. The smaller the indentation, the stronger the specimen is. According to the ASTM E-10 BrinGen - Digital Brinell Hardness Tester is commonly used on surfaces of materials that are too rough to be tested by any other test method. Learn all about the Brinell Hardness Testing System here.

The test load ranges are from 62.5kgf to 3000kfg. BrinGen 3000 Series - Digital Brinell Hardness Testing system is equipped with a closed loop system for the absolute highest accuracy load control. Closed loop driven system provides precise control of test force application.

BrinGen 3000 Series - Digital Brinell Hardness Testing systems are standalone units that can easily be upgraded to include the NG-Scope - Brinell Hardness Image Automatic Measuring system - for the most accurate results through an optical Analysis Software.

Digital Brinell and Automatic Brinell Hardness Tester Features

- BrinGen is engineered to obtain highly sensitive and accurate readings

- Direct Digital Reading

- Perfect for laboratories, workshops, tool rooms, inspection labs, etc.

- BrinGen's test process eliminates room for all human error for maximum accuracy.

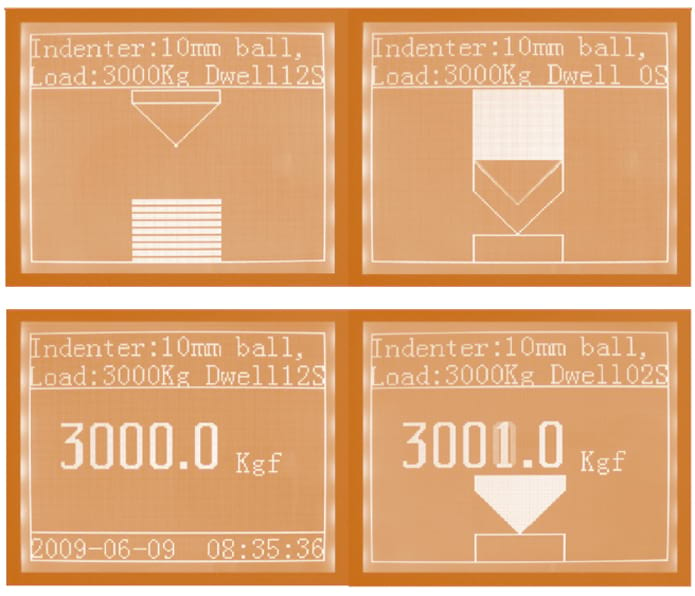

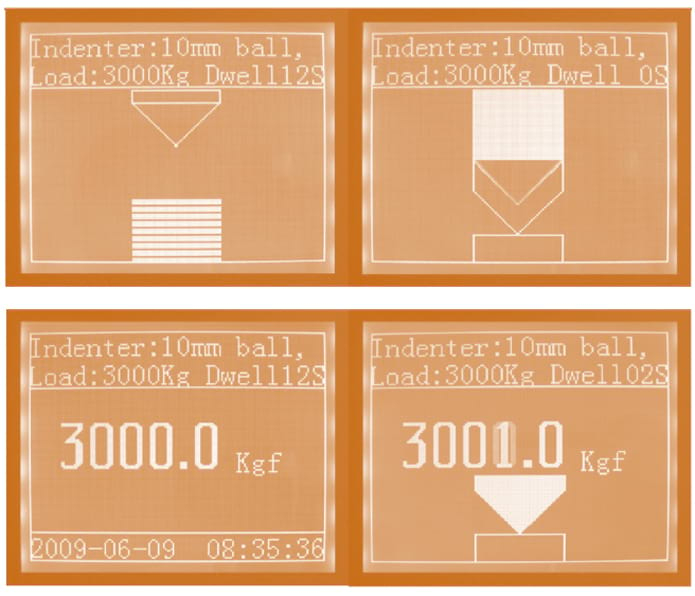

- It is equipped with a large LCD display screen with a user friendly interface.

- Most commonly, BrinGen is used to test the hardness of unquenched steel, cast iron, non-ferrous metals, soft bearing alloys, etc.

- Equipped with a 20X optical microscope to measure the diameter of Brinell indention

- Resolution capability of the microscope: 0.005mm

- The tester weight is 50% less than the traditional dead weights type tester

- Test load selection by keyboard and LCD screen

- Fully automatic test cycles. The Brinell hardness Tester features a fully automatic test cycle, load application, holding, and unloading, is performed fully automatically. This greatly improves reproducibility of test results since operator influence is eliminated

- Selectable dwell times by screen. The indenter, load, and other test information are shown clearly on the large LCD screen

- Brinell Hardness Calculator (BHC) make the hardness value calculation easier and convenient

Digital Brinell and Automatic Brinell Hardness Tester Technical Specifications

| BrinGen – 3000M | |

|---|---|

| Brinell Scale | HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW5/125, HBW5/250, HBW5/750, HBW10/100, HBW10/1500, HBW10/3000, HBW10/250, HBW10/500, HBW10/1000 |

| Test Force | 62.5kgf(612.9N), 100kgf(980.7N), 125kgf(1226N), 187.5kgf(1839N), 250kgf(2452N), 500kgf(4903N), 750kgf(7355N), 1000kgf(9807N), 1500kgf(14710N), 3000kgf(29420N) |

| Test Space (HxD) | 9x6.1" (230x155mm) |

| Measure Resolution | 0.5% |

| Test Force Accuracy | 62.5-250Kgf ≤ 1%; 500-3000Kgf ≤ 0.5% |

| Dwell Time | 1-60s |

| Test Range | 8-650HBW |

| Microscope | 20X |

| Standard | BSEN 6506, ISO 6506, ASTM E10, GB/T231 |

| Data Display | LCD touch screen |

| Power Supply | AC110 V or AC220 ±5%, 50-60Hz |

| Dimension | Machine: 21.6x7.5x29.5" (540x190x750mm); Shipping Package: 28.7x17.7x38.6" (730x450x980mm) |

| Weight | Net weight: 220lbs (100kg) Gross weight: 286lbs (130kg) |

Hardness Value Reference for Various Materials

| Material | Hardness |

|---|---|

| Softwood (e.g., pine) | 1.6 HBS 10/100 |

| Hardwood | 2.6–7.0 HBS 1.6 10/100 |

| Lead | 5.0 HB (pure lead; alloyed lead typically can range from 5.0 HB to values in excess of 22.0 HB) |

| Pure Aluminium | 15 HB |

| Copper | 35 HB |

| Mild steel | 120 HB |

| 18–8 (304) stainless steel annealed | 200 HB |

| Glass | 1550 HB |

| Hardened tool steel | 600–900 HB (HBW 10/3000) |

| Rhenium diboride | 4600 HB |

| NOTE: Based on standard test conditions unless otherwise stated | |

FAQs

The flexible Austenitic Stainless Steel (Chrome-Nickel base, often known as 18/8 Steel) alloy 304 offers a number of important characteristics and advantages. 304 offers good corrosion resistance and is non-magnetic, making it perfect for use in a variety of applications.

It is ideal for many different sectors and may be used both indoors and outdoors. It is simple to construct and machine. It's a wonderful option for food service and healthcare settings because it's also fairly simple to maintain.

Different kinds of AISI 304 Stainless Steel (18-8 Stainless Steel) are available, and this material has various material parameters. AISI 304 is most frequently found in sheet form, but it is also offered in pipe, tube, bar, rod, and wire forms.

The low-temperature limit of AISI 304 stainless steel (18-8 stainless steel), commonly known as Cryogenic Stainless Steel, is 320°F (-195.5°C). This indicates that 304 can be utilized in a variety of applications that call for low temperatures. Cryogenic storage tanks, refrigeration coils, and kitchen appliances are a few examples of popular applications.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester Hardness Value Reference for 18–8 (304) stainless steel annealed is 200 HB.

Click here to obtain a personalized quote!

A substantial indentation test is a Brinell test. It is ideal for a large plate, bars, rods, forgings, etc., but not for thin strips or wire. The indenter is a ball made of either tungsten carbide or hardened steel (results identified by HBS) (results designated by HBW). This test results in huge indentations, which makes it far less sensitive to local microstructural changes. This makes it perfect for microstructures that contain big particles, such as those in copper-nickel silicon chromium alloys. However, only materials thicker than 0.125 inches may be subjected to Brinell testing (3.2 mm).

Depending on the alloy, temper (hardness), and part thickness, a variety of hardness tests are suitable for copper beryllium, copper nickel tin, and other high-performance copper alloys. For thorough details on test techniques and equipment calibration, consult the relevant ASTM standard.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester Hardness Value Reference for Copper is 35 HB.

Click here to obtain a personalized quote!

Any carbon steel or alloy that is particularly well suited to being produced into tools and tooling, such as cutting tools, dies, hand tools, knives, and other items, is referred to as "tool steel." Their characteristic hardness, resistance to abrasion and deformation, and capacity to maintain a cutting edge at high temperatures are what make them suitable. Tool steels are, therefore suitable for shaping other materials through processes like cutting, machining, stamping, or forging.

Metals and other materials can be cut, pressed, extruded, and coined using tool steels. Their use in tooling is crucial; for example, injection molds need tool steels because of their resistance to abrasion, a crucial factor in mold longevity that allows for hundreds of thousands of molding operations over the course of a mold's lifetime.

The most used system for classifying different tool steel grades is the AISI-SAE scale. A number is assigned to each alloy within a grade, such as A2, O1, etc.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester Hardness Value Reference for Hardened Tool Steel is 600–900 HB (HBW 10/3000)

Click here to obtain a personalized quote!

ReB2 is a synthetic superhard material made of rhenium diboride. It was first created in 1962 and has recently been synthesized again in the hopes of obtaining a high hardness that is equivalent to diamond's. Although this is a matter of definition, the claimed ultrahigh hardness has been contested because rhenium diboride was able to scratch the diamond in the initial test.

This material's production process does not use high pressures like that of other hard synthetic materials, including cubic boron nitride, which lowers the cost of manufacture. Rhenium, however, is a pricey metal in and of itself.

Rhenium, known for its tolerance to high pressure, and boron, which forms quick, powerful covalent bonds with rhenium, combine to produce the combination.

At standard atmospheric pressure, ReB2 can be produced by at least three separate processes: solid-state metathesis, melting in an electric arc, and direct heating of the elements.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester Hardness Value Reference for Rhenium Diboride is 4600 HB

Click here to obtain a personalized quote!

Shippers need to be aware of a serious safety concern with regard to the accuracy of cargo containers, as well as individual skids and crates. In most cases, weight directly affects how much freight costs. It is common for shippers to mistakenly estimate a shipment's weight lower than it actually is. For instance, it is rather typical for shippers to estimate the size of their cargo based on the product data and omit to account for the weight of the shipping package. Usually not a problem, but if there are multiple shipments in a container, the bulk shipment may be extremely overweight, endangering the safety of vehicles, ships, and aircraft.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester has the following dimensions and weight:

Machine: 21.6x7.5x29.5" (540x190x750mm);

Shipping Package: 28.7x17.7x38.6" (730x450x980mm)

Net weight: 220lbs (100kg)

Gross weight: 286lbs (130kg)

Click here to obtain a personalized quote!

In order to verify that the hardness tester's loading device is stationary and that the load being applied to the material is static, dwell time is required. Dynamic loads—which result from movement—can unintentionally be applied during testing if the indentor is moving too quickly. These loads will increase the apparent load on the material, which will increase the size of the indent and produce a reading of hardness that suggests the material is softer than it actually is.

The dwell time for the test force is typically between 10 and 15 seconds (nominal time duration 14 s). If the dwell time is any longer, the hardness value must also include the length in seconds, for example: 610 HV 10/30. (dwell time of 30 s).

In conclusion, the dwell time exists to guarantee the hardness test's accuracy.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester has the following dwell time range: 1-60s.

Click here to obtain a personalized quote!

When charged electrons (current) are forced through a conducting loop by the pressure of an electrical circuit's power source, they can perform tasks like lighting a lamp.

In a nutshell, voltage equals pressure and is expressed in volts (V).

Early on, voltage was referred to as electromotive force (emf). This is the reason why the symbol E is used to denote voltage in equations like Ohm's Law.

Most troubleshooting issues are approached by technicians with an understanding of how a circuit should normally operate.

Energy is delivered to a load using circuits, which can be anything from a small gadget to a home appliance to an industrial motor. Nameplates that list the standard electrical reference values of a load, such as voltage and current, are common. Some manufacturers offer a thorough schematic (technical diagram) of a load's circuitry in place of a nameplate. Standard values may be included in manuals.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester has the following power supply: AC110 V or AC220 ±5%, 50-60Hz

Click here to obtain a personalized quote!

A type of flat panel display known as an LCD (Liquid Crystal Display) operates primarily using liquid crystals. Since they are frequently used in cellphones, televisions, computers, and instrument panels, LEDs offer a wide range of applications for consumers and enterprises.

When compared to the technologies they replaced, such as light-emitting diode (LED) and gas-plasma displays, LCDs represented a significant advancement. Compared to cathode ray tube (CRT) technology, LCDs permitted screens to be far thinner. As opposed to LED and gas-display displays, LCDs operate on the idea of blocking light rather than emitting it, which results in a significant reduction in power consumption. The liquid crystals in an LCD use a backlight to form an image where an LED emits light.

LCDs started to be superseded by new display technologies like OLEDs as they took the place of earlier display technologies.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester is equipped with an LCD Touch Screen.

Click here to obtain a personalized quote!

NextGen offers a BrinGen Scope, a CCD optical camera optional accessory for NextGen’s Hardness Testers.

A Brinell Auto scanning system is BrinGen Scope. It is made to work with a computer or laptop to speed up and improve the quality of your testing program. Real-time result assistance is provided.

Features:

- Choose BrinGen Scope when you require a Brinell Hardness testing solution that yields consistent, accurate, and repeatable test results.

- The automeasurement, result, tolerance values, and other information are displayed here on the screen.

- Hardness is automatically and precisely measured with a single button press.

- Human error is completely eliminated from test results by the BrinGen Scope.

- Supports measuring by hand.

Click here to obtain a personalized quote!

The functionality, accuracy, and conformance to standards of the hardness testing apparatus and all measurement-related components must be guaranteed when pertinent measurements are conducted on components. There are specific guidelines for how this must be proved and tracked in the hardness testing standards (ISO, ASTM). Every test technique and loading level must comply with this monitoring criterion.

Calibration of a hardness tester is necessary to perform an initial accuracy check, for instance, on new equipment or after modifications.

Even after calibration, the hardness testing device's accuracy needs to be periodically reviewed as part of a recurring daily or weekly test. For each test method and series of standards, the manner in which these tests are conducted and the permitted variances of the results are explicitly described (ASTM, ISO).

For the purpose of monitoring the hardness tester, all standard-compliant tests must be recorded.

NextGen's BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester test force accuracy is 62.5-250Kgf ≤ 1%; 500-3000Kgf ≤ 0.5%.

Click here to obtain a personalized quote!

The Brinell scale determines the indentation hardness of materials by measuring the depth of penetration of an indenter placed onto a material test piece. There are several ways to define hardness in the study of materials.

The standard test uses a steel ball with a diameter of 10 mm (0.39 in) as the indenter and applies a force to it of 3,000 kgf (29.42 kN; 6,614 lbf). For softer materials, a smaller force is used, and for harder materials, a tungsten carbide ball is used in place of the steel ball.

The Brinell hardness number (BHN, or more commonly, HB) must be quoted with the test circumstances that were used to calculate it. The "HBW 10/3000" example serves as an example of how tests should be specified using the accepted format. In contrast to "HBS," which indicates the use of a hardened steel ball, the designation "HBW" specifies the use of a tungsten carbide ball indenter. The "10" is the diameter of the ball in millimetres. The kilos of force are represented by the number "3000."

Here are Brinell Scales applicable to NextGen's BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester: HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW5/125, HBW5/250, HBW5/750, HBW10/100, HBW10/1500, HBW10/3000, HBW10/250, HBW10/500, HBW10/1000

Click here to obtain a personalized quote!

A flexible hardness test technique, the Vickers hardness test is used to measure both macro and micro hardness. It is appropriate for a variety of applications and materials and has a wide load range.

Many people believe that the Vickers hardness test is simpler to use than other hardness tests: The procedure can be carried out using a universal or micro hardness tester, the calculations necessary are independent of the indenter size, and the same indenter (a pyramidal diamond) can be used for all materials, regardless of hardness.

Vickers hardness tests are typically used to assess the hardness of materials within the micro hardness test load range. To assess the hardness of thin layers, such as coatings, or to avoid cracking in brittle materials, the Knoop hardness test is frequently employed.

When deciding between various forms of hardness tests, you should take into account both the customary criteria and pertinent requirements.

NextGen's BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester available test load: 62.5kgf(612.9N), 100kgf(980.7N), 125kgf(1226N), 187.5kgf(1839N), 250kgf(2452N), 500kgf(4903N), 750kgf(7355N), 1000kgf(9807N), 1500kgf(14710N), 3000kgf(29420N)

Click here to obtain a personalized quote!

Closed-loop tester systems provide unsurpassed performance reliability, stability, and flexibility when compared to dead weight-type hardness testers. Additionally, the components employed in a closed-loop system naturally lend themselves to a considerably simpler design than a dead-weight system, allowing it to continuously measure the test force applied. As was already established, in order for dead-weight systems to operate well, they need levers, pivots, and other parts that cause friction. The weights themselves are separated from the indenter, the only component of the system in touch with the test sample, by levers, pivots, etc.

For instance, the load cell won't report the right force if the actuator's friction is so high that the appropriate force is not applied to the indenter. As a result, the system will stop the test rather than output a false positive. In this approach, the system constantly verifies that it is only applying the appropriate test forces to the indenter. The feedback loop makes it simple to control the actuator's mass.

NextGen’s BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester is equipped with a closed loop system.

Click here to obtain a personalized quote!

The ISO develops and publishes standards for a wide range of products, parts, and processes. There are over 24,362 standards in the ISO Standards database, broken up into areas like healthcare technology, railway engineering, jewelry, clothing, metallurgy, weaponry, paint, civil engineering, agriculture, and aircraft. In addition to standards, the ISO also releases technical reports, publicly available specifications, technical corrigenda, and guidelines. Global Experts in linked sectors have endorsed the ISO standards. Manufacturers, sellers, buyers, customers, trade organizations, users, or regulators are examples of people who are knowledgeable of the requirements of their industries. ISO 6506 specifies the Brinell hardness test for metallic materials.

It can be used with both stationary and mobile hardness testing equipment.

There are certain International Standards (like ISO 4498) that apply to certain materials and/or products that make reference to this International Standard.

BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester – Closed Loop System complies with ISO 6506

Click here to obtain a personalized quote!

A metal specimen's resistance to being indented is tested with the BrinGen 3000 - Digital Brinell Hardness Tester. An indenter presses a preset force (load) against the specimen to ascertain the hardness of the material.

The main features of BrinGen 3000 - Digital Brinell Hardness Tester:

- BrinGen is designed to produce extremely precise and sensitive measurements.

- Direct digital readout

- Perfect for workshops, tool rooms, inspection labs, and other similar spaces.

- For optimal precision, BrinGen's testing procedure completely eliminates room for human error.

- It has a sizable LCD display panel with an intuitive user interface.

- BrinGen is most frequently used to test the hardness of materials such as soft bearing alloys, cast iron, non-ferrous metals, unquenched steel, etc.

- 20X optical microscope to measure the Brinell indention's diameter.

- The microscope has a resolution of 0.005mm.

- Compared to the conventional dead weight type testing, the tester weighs 50% less.

- Test the keyboard and LCD screens for load selection.

- Complete automation of test cycles. The load application, holding, and unloading phases of the Brinell hardness tester's test cycle are all totally automatic. Since operator influence is avoided, this considerably enhances the reproducibility of test results.

- Each screen has selectable dwell periods The wide LCD screen clearly displays the information on the indenter, load, and other test parameters.

- The Brinell Hardness Calculator (BHC) makes it convenient and easier to calculate hardness values.

Click here to obtain a personalized quote!

All NextGen's Metal hardness testers including the Digital Brinell hardness Testing System come with standard configurations that include the certified test blocks and indenters. This allows for a simple plug and play solution of your digital Brinell hardness testing system. Upon ordering the machine, we ask that you provide us with the hardness value of your desired block and the test loads that you will be using on the material in order to provide you with a NIST Certified test block. This allows your Digital Brinell Hardness Testing system to be calibrated within minutes for your long-term quality control operations. Additional test blocks, indenters and carbide balls for your digital Brinell hardness testing system can be purchased from NextGen at a later time. Contact us today to learn more.

For larger, heavy, and unusually shaped specimens we would recommend to look into the Portable Brinell Hardness Tester options. Commonly, our LeebGen 3000 - Leeb Rebound Portable Hardness Tester for Brinell Hardness Testing equivalent is the go to instrument for the job. The unit is capable of performing indentation on virtually any type of material from any angle. The supporting impact devices that can be requested during the acquisition of this portable Brinell hardness tester equivalent will allow you to measure flat or curved surfaces as needed. Contact us today to learn more about the right portable Brinell hardness tester solution for you.

Every Brinell Hardness Tester including the Analogue and Digital Brinell hardness testing systems comply with the ASTM E10 standard. The hardness tester comes certificate of calibration as well as NIST traceable hardness test blocks allowing you to confirm the hardness reading and operate the Brinell hardness tester from day 1. Request quote today to receive your certified Brinell Hardness Testing System.

The unique value proposition of NextGen's Brinell Hardness Tester is a combination of state-of-the-art engineering, user-friendly software, robust & ergonomic design and exceptional accuracy. The machine is a plug-and-play unit which requires very minimal engineering experience to set up. The manual is simple to follow for the other 10% set up. Experience the difference by requesting your quotation today.

Prior to dispatch, all Brinell Hardness Testers are calibrated in accordance with ASTM E10. The certificate of calibration can be found along with the main instrument upon arrival to your facility. Additional calibration and related inquiries can be submitted to [email protected]

NextGen Material Testing, Inc. offers a wide range of Brinell Hardness Testing Systems custom made for your unique specimen sizes. Whether your specimens are long, thick or heavy, we got you covered! All custom made Brinell Systems with elongated throats, deeper widths and larger anvils are manufactured according to the latest industry standards. Request a quotation today.

Related Products

BrinGen Scope - Optically Advanced CCD Brinell Measuring Scope for Manual or Digital Brinell Hardness Testing System

BrinGen Scope - is a Optically Advanced CCD Brinell Measuring Scope for Manual or Digital designed as Brinell Hardness Testing automatic scanning system. It is engineered to work with a computer or a laptop to make your testing program faster and more accurate. The Optical Brinell Scope is equipped with real-time result support.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.