Metal Testing Equipment

Metallographic sample preparation equipment is used to prepare metal and alloy specimens for structural examination under optical or electron microscopes. The goal of preparation is to produce a surface that accurately reflects the internal structure of the material without introducing artifacts or damage.

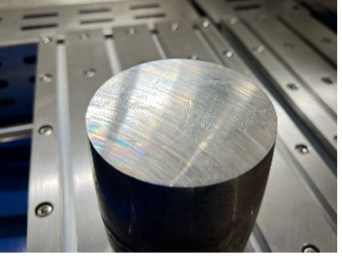

The process typically includes several stages. Cutting is required to extract a representative section of the bulk material. Grinding removes irregularities and deformations caused during cutting. Polishing produces a smooth and reflective surface that allows microscopic details to be observed clearly. Mounting is often applied to stabilize small or irregular specimens, making them easier to handle during preparation. In some cases, etching is performed as a final step to reveal grain boundaries or specific structural features.

The process typically includes several stages. Cutting is required to extract a representative section of the bulk material. Grinding removes irregularities and deformations caused during cutting. Polishing produces a smooth and reflective surface that allows microscopic details to be observed clearly. Mounting is often applied to stabilize small or irregular specimens, making them easier to handle during preparation. In some cases, etching is performed as a final step to reveal grain boundaries or specific structural features.

Without proper preparation, the true microstructure of the material cannot be evaluated. Surface scratches, heat damage, or deformation can mask important details such as grain size, inclusions, or phase distribution. Accurate metallographic analysis therefore depends directly on the quality of the preparation process and the equipment used.

Sub-categories

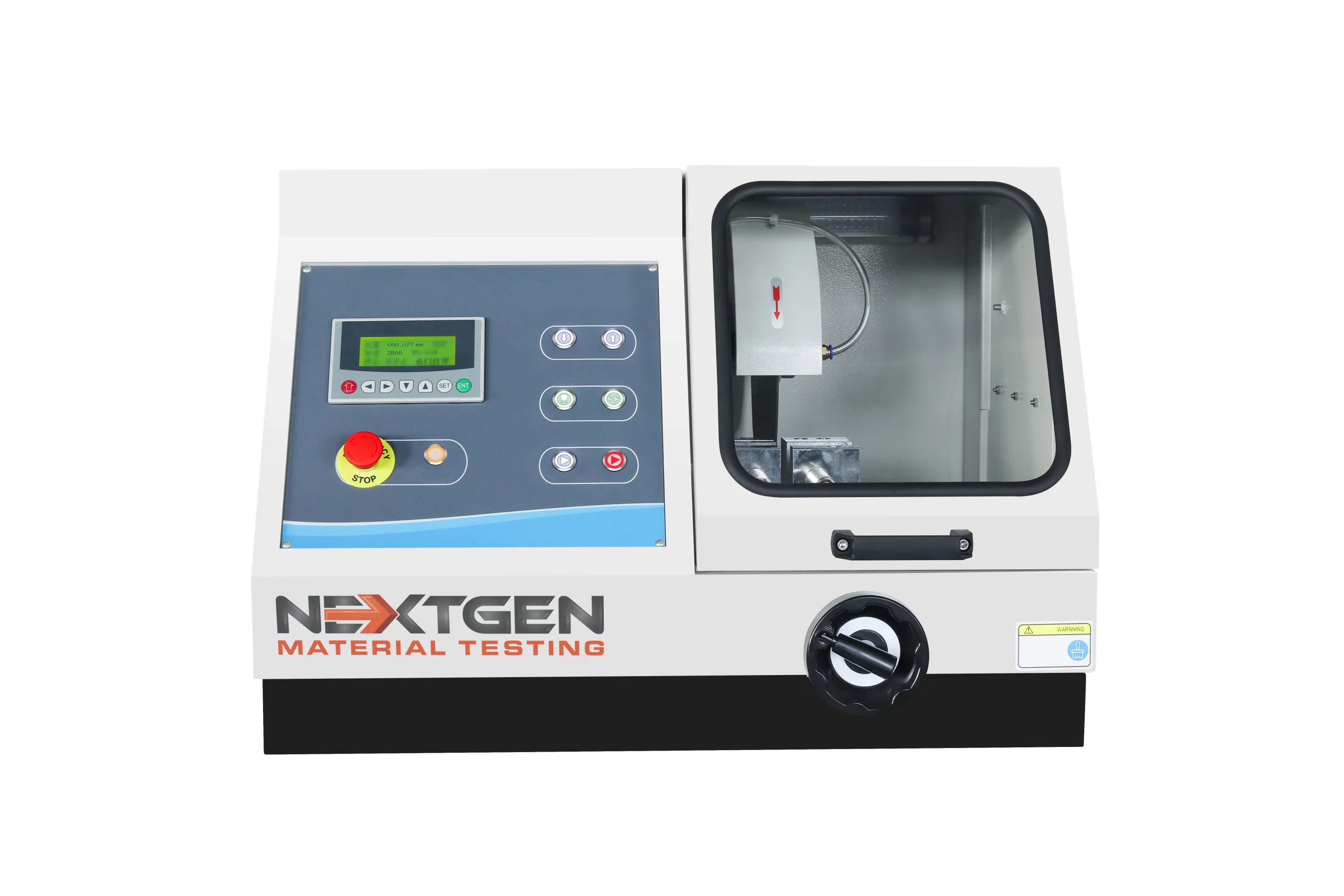

Abrasive Metallographic Cutting Equipment

NextGen offers a full scope of manual and automatic abrasive metallographic cutting machines

Grinding and Polishing Equipment

NextGen specializes in an extensive range of metallographic polishers and grinders for all possible user applications.

Mounting Press System for Metallography

The GenPress Series - Mounting Press Systems is designed to alleviate the user from the challenge of handling difficult specimen shapes and sizes during sample preparation procedures. The equipment is also used to protect the edges and any other defects found on the surface of the samples.

Precision Metallographic Cutting Equipment

NextGen offers a full scope of manual and automatic precision metallographic cutting machines

Products

G-800E Trinocular Metallurgical Microscope

This inverted metallurgical trincoular microscope is ideal for both industrial or educational metallurgy applications.

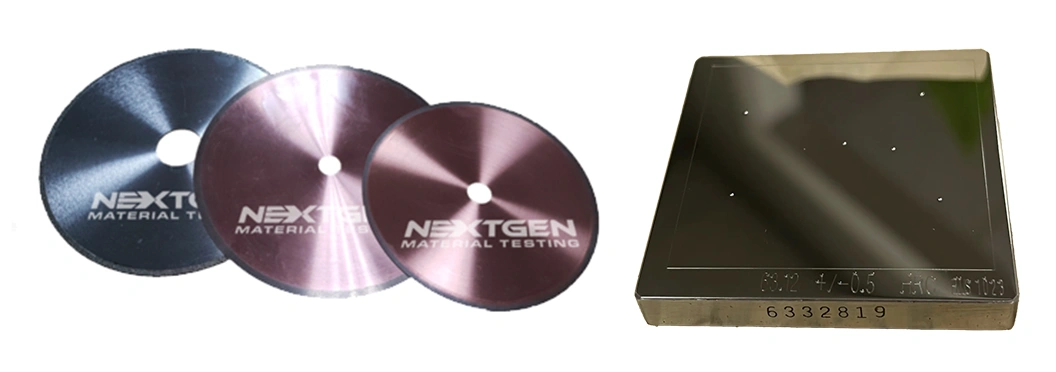

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.

FAQs

The main difference between the precision and abrasive cutters for metallography equipment is the delicacy of the cut. Metallographic precision cutters are designed to provide a high quality finish for delicate materials for ease of sample preparation needs. Metallographic abrasive cutters are more focused on sectioning larger parts into smaller parts as fast and as efficiently as possible. NextGen can supply your facility with a wide range of metallographic precision and abrasive cutters for all of your cutting needs. Request a quote today to learn more.

It is difficult to estimate the precise time that it takes to cut a specific type of material with abrasive cutter machines. There are few factors responsible for the variance in time. These factors include the type of material, material hardness, and the structure of the sample. These three factors must be evaluated in synergy to identify the most accurate estimate for your metallographic abrasive cut. Contact us today to help identify the right abrasive cut off solution for you.

NextGen is proud of the ability to create custom solution for various metallographic abrasive cutting needs. Our custom clamps are the secret. If require a custom solution for your abrasive metallographic cutting needs, we are here to help. Upon placing your order, the abrasive machines will be manufactured with your custom clamps and final tests with your specimens will take place in our facility to insure the optimal time / speed of cut for the optimal results. Learn more by contacting us today.

When it comes to harder metals and alloys, consider our GenCut Series - Precision and Abrasive Metallographic Cutters. These metallography precision cutter and metallography abrasive cutter line-up are capable of cutting soft, hard, and irregular types of specimens. Our quality consultants will be able to find the correct precision or abrasive sectioning saw for your metallographic sample preparation requirements. Contact us today.

There is a number of factors that determine whether you require a precision cutter on an abrasive cutter for your metallographic sample preparation. These factors include the type of material, the quality of the cut, the shape of the sample and more. Our GenCut Series - Precision and Abrasive Metallographic Cutters has all the precision cutters and abrasive cutters that you need for a wide variety of metallographic sample preparation purposes. Request a quote today and our technical team will be happy to identify the metallographic cutter that fits your laboratory best.

Metallographic specimen preparation is guided by a wide set of international and regional standards. NextGen equipment complies with these requirements from the start, so specimens can be prepared and analyzed without additional certification under normal conditions.

Metallographic specimen preparation is guided by a wide set of international and regional standards. NextGen equipment complies with these requirements from the start, so specimens can be prepared and analyzed without additional certification under normal conditions.