Universal hardness testers are built for professionals who need one instrument to cover multiple testing methods. Instead of operating separate machines for Rockwell, Brinell, Vickers, or Knoop, a universal system brings them together in a single unit.

This approach is practical for engineers, QA managers, and laboratories handling different specimen sizes and materials. Rockwell is used for quick routine checks, Brinell for coarse structures, and Vickers or Knoop for thin layers and micro-scale features. A universal tester makes it possible to switch between these methods without changing equipment, saving time and maintaining consistency.

These machines are valued for their versatility. One system can evaluate hardened steels, cast irons, aluminum alloys, or coatings with precision while meeting ASTM, ISO, JIS, and EN standards. For many facilities, it is the most efficient way to achieve reliable results across different projects with one compact solution.

Universal Hardness Testers from NextGen

Universal hardness testers from NextGen are designed to carry out Rockwell, Brinell, Vickers, and Knoop methods in one system. They are practical for both laboratories and production sites where several testing techniques are required.

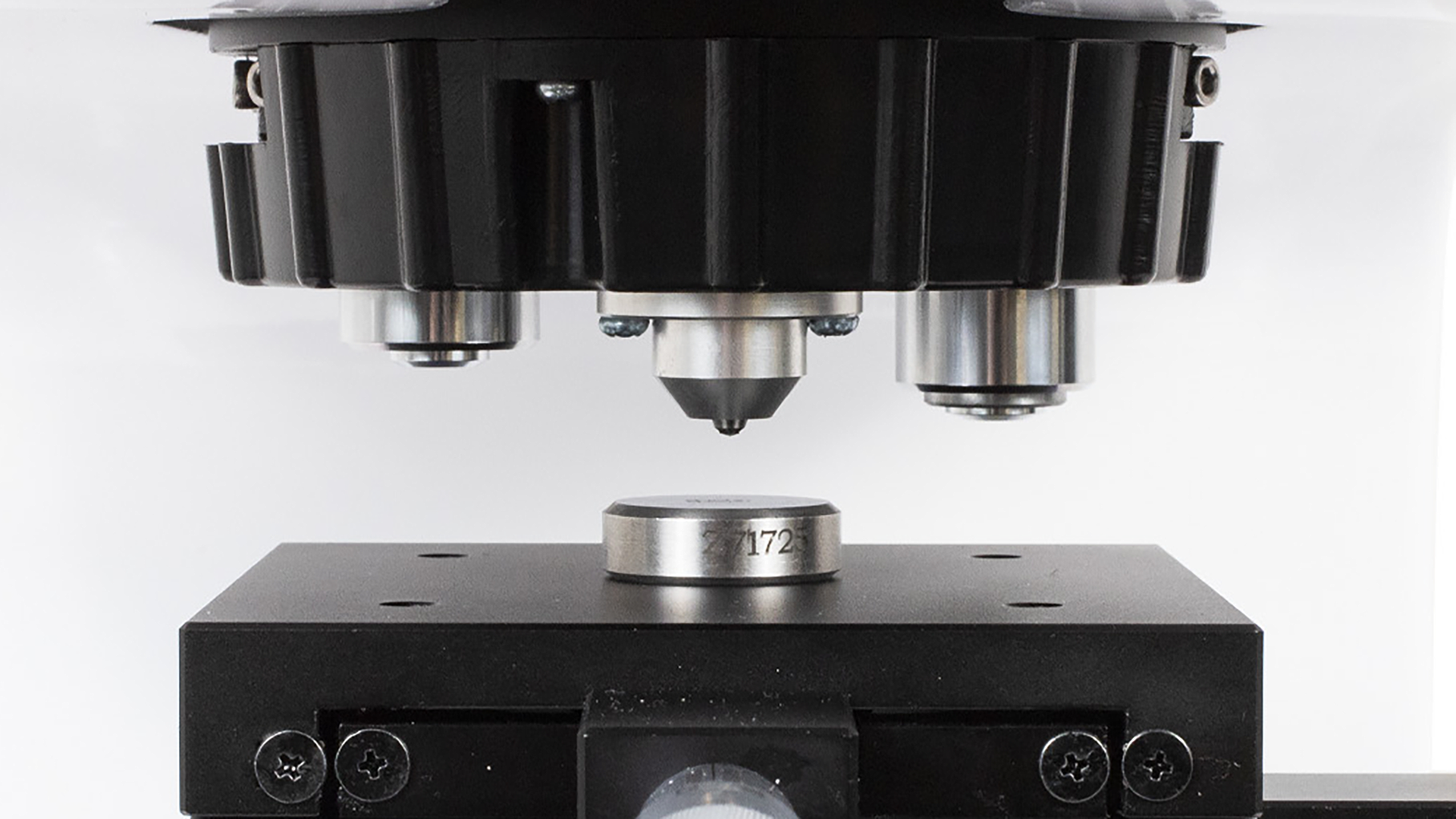

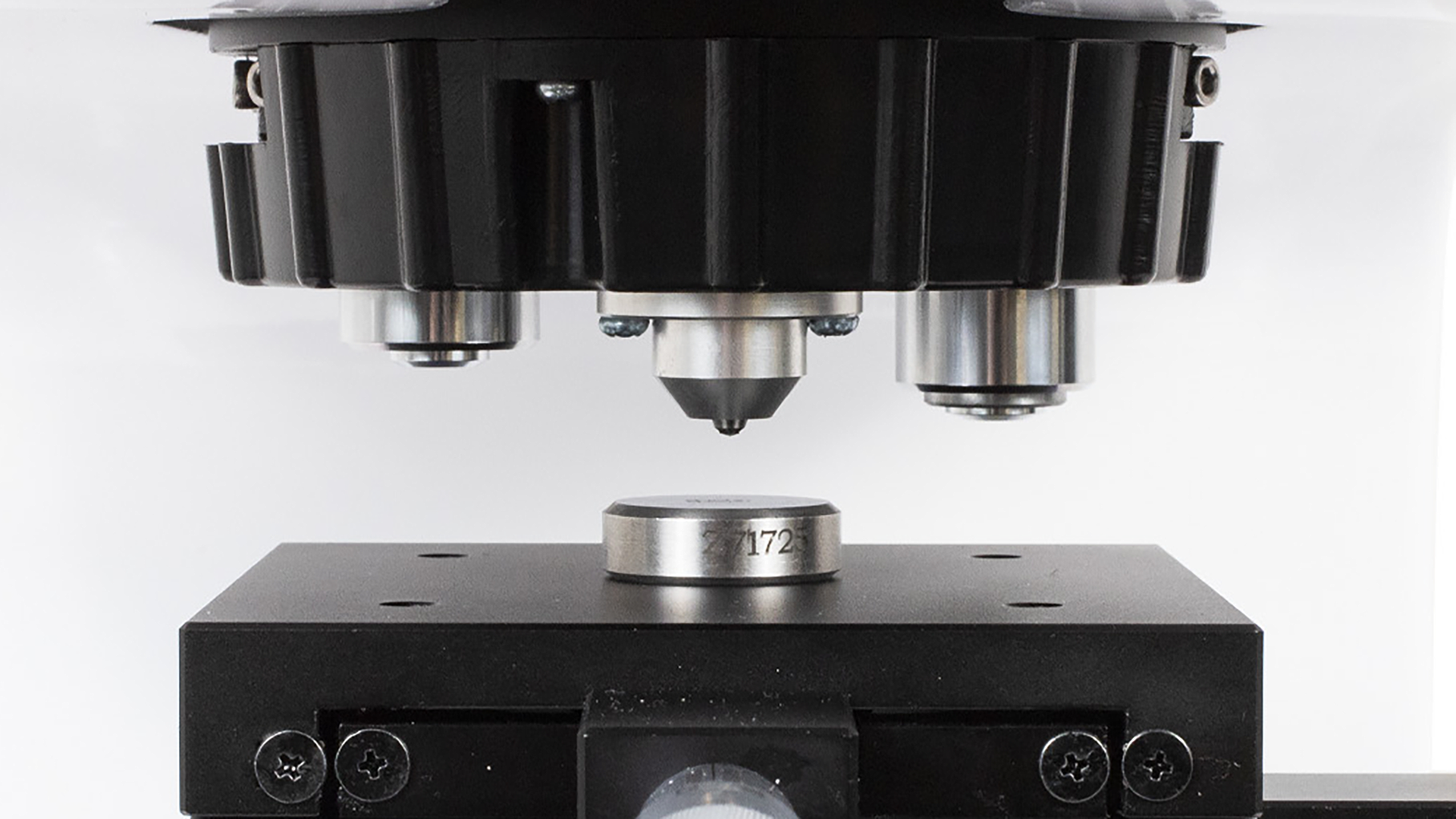

The machines operate on a closed-loop load cell system, which keeps the applied force stable and gives consistent readings. A touch-screen interface together with optical lenses and a digital camera allows the indentation to be measured directly on screen, reducing operator error. The available scales cover Rockwell A through V, Brinell from HBW1/5 to HBW2.5/187.5, and Vickers from low force up to HV120.

Specimens of different sizes can be tested, with vertical space up to 220 mm and horizontal clearance of 200 mm. Force correction is automatic, holding times are adjustable, and results can be saved in digital formats for later use.

One example is the UniGen Series, which integrates all three major hardness testing methods in a single platform. It is suitable for tasks ranging from routine checks of steel parts to detailed evaluations of coatings and alloys in R&D environments.

All NextGen universal hardness testers are supplied in compliance with international standards such as ISO 6506, ISO 6507, ISO 6508, ASTM E10, ASTM E18, ASTM E92, ASTM E384, and JIS equivalents. This means results can be used directly for both internal quality control and external certification.

Methods and Their Applications

Universal hardness testers bring several techniques into one system, but it is important to understand what each method offers and where it is most effective. Below are the main approaches that such equipment covers.

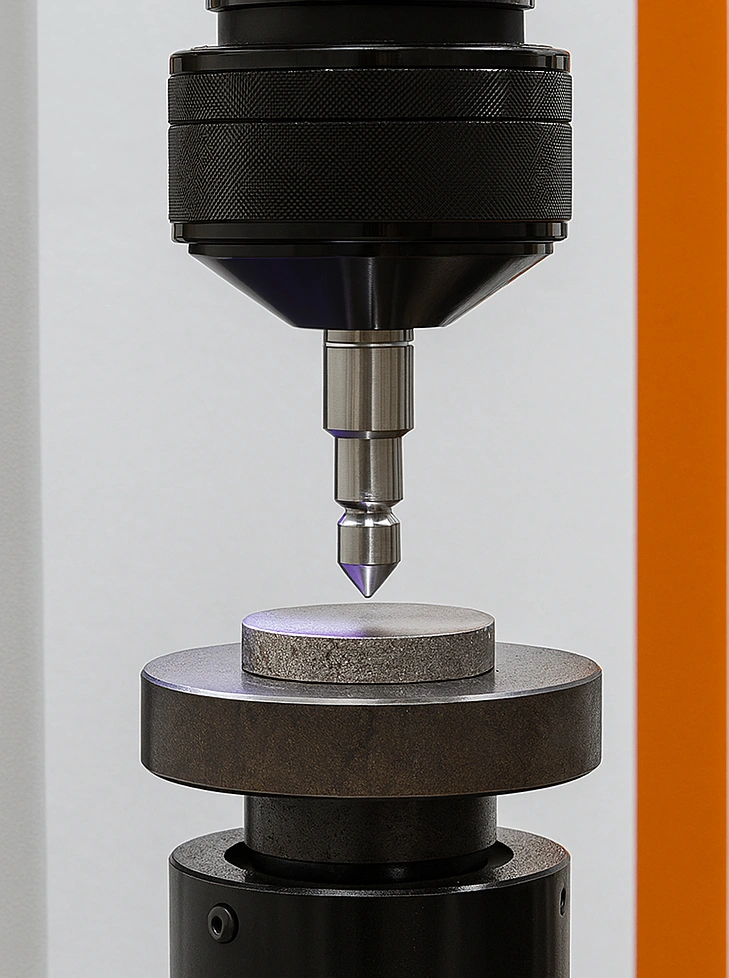

Vickers & Knoop

These two methods are used when high accuracy is required on small or delicate areas. Vickers applies a diamond pyramid indenter and can measure loads from very low micro ranges up to macro levels. It is well suited for case depth studies, coatings, and thin cross-sections. Knoop uses an elongated diamond shape that spreads the impression, making it valuable for very thin layers or brittle materials such as ceramics. Together, they provide precise data for microstructures that cannot be tested with larger-scale methods.

Rockwell

Rockwell is known for its speed and simplicity. It measures indentation depth under load, making it effective for routine checks on steels, non-ferrous alloys, and even some plastics. The method is widely used in production quality control, where quick verification is needed without complex preparation. Its wide set of scales allows testing from soft materials to hardened steels, which is why it remains one of the most common hardness tests worldwide.

Brinell

Brinell uses a hardened ball to create a relatively large indentation. This makes it suitable for coarse-grained or non-uniform materials such as castings and forgings. By averaging over a bigger surface area, Brinell reduces the effect of local irregularities and provides a reliable picture of overall hardness. It is often chosen for heavy manufacturing sectors where parts are large and microstructural variations are common.

Why Combine Methods in One Machine

Having all three methods in a single universal tester gives engineers the ability to match the method to the task without switching equipment. It saves laboratory space, simplifies training, and reduces the number of instruments that need calibration. More importantly, it enables cross-validation: the same part can be checked under different methods for a broader understanding of its properties. This flexibility supports both research and daily production quality assurance, making universal testers a practical choice for organizations that work with diverse materials and testing needs.

International Standards for Universal Hardness Testing

Because universal hardness testers support Brinell, Vickers, Knoop, and Rockwell methods, they are built to comply with multiple international standards that regulate testing steps, verification, and reporting. Shown below are the main standards that define the operation of these testers worldwide.

Because universal hardness testers support Brinell, Vickers, Knoop, and Rockwell methods, they are built to comply with multiple international standards that regulate testing steps, verification, and reporting. Shown below are the main standards that define the operation of these testers worldwide.

- ISO 6506 – Metallic Materials – Brinell Hardness Test

Defines the Brinell test method using a carbide ball and fixed loads, including procedure, indentation measurement, and reporting rules.

- ASTM E10 – Standard Test Method for Brinell Hardness of Metallic Materials

U.S. standard for Brinell testing, widely applied to castings, forgings, and coarse-grained metals. Equivalent in scope to ISO 6506.

- ISO 6507 – Metallic Materials – Vickers Hardness Test

Details the Vickers test across micro, low-force, and standard ranges with a diamond pyramid indenter. Includes procedures for load application and indentation measurement.

- ASTM E92 – Standard Test Method for Vickers Hardness and Knoop Hardness of Metallic Materials

U.S. reference for macro and low-force Vickers and Knoop tests, often cited alongside ISO 6507.

- ASTM E384 – Standard Test Method for Microindentation Hardness of Materials

Focused on microhardness testing with Vickers and Knoop, typically used for thin coatings, films, and microstructures.

- ISO 4545-2 – Metallic Materials – Knoop Hardness Test – Part 2: Verification and Calibration

Specifies machine verification, indenter checks, and calibration for Knoop testing systems.

- ISO 6508 – Metallic Materials – Rockwell Hardness Test

Defines the Rockwell and Superficial Rockwell methods, indentation depth measurement, and verification of test machines.

- ASTM E18 – Standard Test Methods for Rockwell Hardness of Metallic Materials

U.S. standard equivalent to ISO 6508, widely used in both laboratories and production QA.

- JIS Z2245 – Rockwell Hardness Test – Test Method

Japanese Industrial Standard aligned with ISO 6508 for Rockwell procedures.

- JIS Z2243 – Brinell Hardness Test – Test Method

Japanese Industrial Standard for Brinell hardness testing, commonly paired with ISO 6506 in specifications.

- JIS Z2244 – Vickers Hardness Test – Test Method

Japanese Industrial Standard based on ISO 6507, covering load ranges and indentation measurement.

- GB/T 230.2 – Metallic Materials – Rockwell Hardness Test – Verification and Calibration

National standard defining requirements for verifying Rockwell machines and indenters.

- GB/T 231.2 – Metallic Materials – Brinell Hardness Test – Verification and Calibration

National standard specifying verification steps for Brinell machines and reference blocks.

- GB/T 4340.2 – Metallic Materials – Vickers Hardness Test – Verification and Calibration

National standard that complements ISO 6507, covering calibration of Vickers testers.

Close-up of Vickers hardness tester applying load on a thin metal sample during microhardness testing

Applications & Benefits of Universal Hardness Testers

Universal hardness testers are used in settings where fast transitions between different test methods are required. Below are practical examples showing how these systems serve engineers, QA managers, and researchers.

Industry Sectors

In aerospace and automotive, universal systems evaluate gears, shafts, fasteners, and landing gear parts. Operators can switch between Rockwell for fast checks and Vickers for accurate case depth analysis without changing machines.

In heavy manufacturing, castings, forgings, and welded joints often require Brinell testing because of coarse grain structures. Universal testers make it possible to perform these evaluations directly on the same unit.

Research and development labs often rely on Vickers and Knoop methods for thin coatings, experimental alloys, and microstructures. Having all methods in one system allows researchers to expand testing without additional equipment.

Sample Types

These systems are widely applied to weld zones, gear teeth, cast components, and thin films. The ability to test such varied samples with a single platform reduces preparation time and improves throughput.

Materials and Loads

Universal hardness testers cover a broad force range, from low loads for soft alloys and thin coatings to higher loads for hardened steels and bulk metals. This flexibility makes them suitable for both routine QA and specialized investigations.

Benefits at a Glance

Of course, as a universal solution, this equipment comes with clear advantages. Benefits:

- Efficiency: One machine covers multiple hardness methods, saving floor space and speeding up test cycles.

- Repeatability: Closed loop force application delivers stable and consistent results across different scales.

- Traceability: Digital output and data storage allow straightforward integration into reports and audits.

- Adaptability: A wide range of loads and indenter types supports everything from soft non-ferrous metals to hardened steels.

Find Out More About the UniGen Series

If you are looking for a universal solution for hardness testing, we invite you to explore the UniGen Series on our product page. This line of systems integrates Vickers, Knoop, Rockwell, and Brinell methods into one reliable platform, giving you a complete tool for both production and research needs.

Should you have specific requirements, questions about capabilities, or need guidance on possible modifications, you can reach us directly or submit a request for a quote online. Our team will respond quickly, provide clear information, and guide you toward the most suitable configuration for your work.

Because universal hardness testers support Brinell, Vickers, Knoop, and Rockwell methods, they are built to comply with multiple international standards that regulate testing steps, verification, and reporting. Shown below are the main standards that define the operation of these testers worldwide.

Because universal hardness testers support Brinell, Vickers, Knoop, and Rockwell methods, they are built to comply with multiple international standards that regulate testing steps, verification, and reporting. Shown below are the main standards that define the operation of these testers worldwide.