The NG-HDT is configured so that HDT and Vicat specimens can be placed in the same heated oil bath at the same time. Each test station is equipped with its own loading system and deformation sensor, while all stations share the controlled bath environment. With programmable cycles, the software manages both procedures in parallel, allowing laboratories to obtain HDT and Vicat results in a single run. This setup shortens testing time and raises throughput without sacrificing measurement accuracy.

Plastic Testing Equipment

Standards

ISO 2507, ISO 75, ISO 306, ASTM D648, ASTM D1525, GB/T 8802, GB/T 1633, GB/T 1634

Description

The NG-HDT HDT/Vicat testing machine is designed to measure heat deflection temperature under load (HDT) and Vicat softening temperature (VST) for thermoplastics, including pipes and fittings. It runs these methods under a constant load with a controlled linear heating rate, which fits routine QA/QC work and material development.

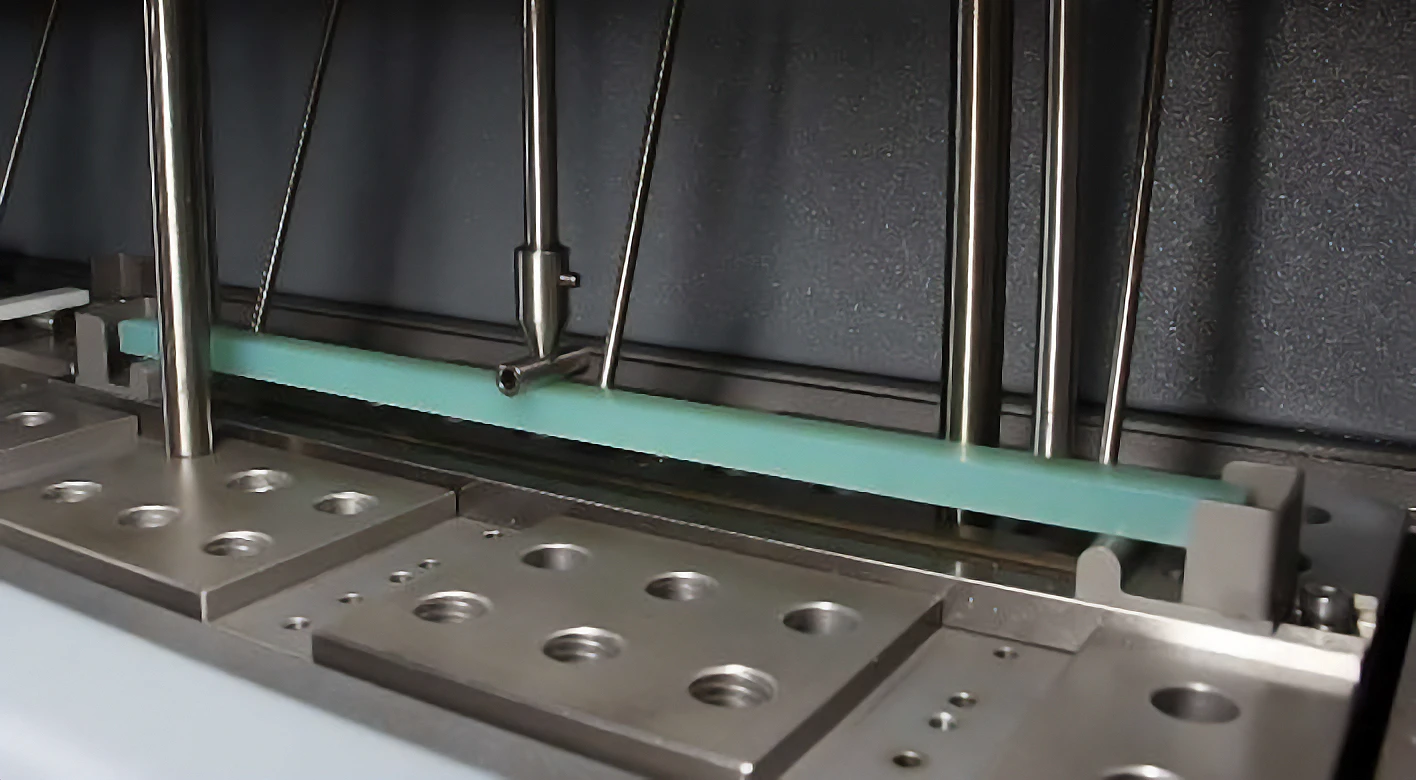

The platform is offered in 3-station and 6-station configurations and uses a built-in touchscreen industrial PC to run the test sequence from loading and measurement through unloading and cooling. Measurement is based on Class A temperature sensing and LVDT displacement measurement, with an oil bath rated up to 300°C. The bath design includes turbulence suppression and cyclic heating functions to support steady heating conditions during the ramp.

Test data can be reviewed and exported over Ethernet. The system can also be paired with options such as a chiller for faster cooldown and an external oil-vapor extraction and filtration unit for high-temperature operation.

Materials and Specimen Types This Machine Supports

This system is used for thermoplastic materials, including plastic pipes and fittings, where HDT and Vicat (VST) values are part of product qualification, incoming inspection, or material comparison work. It supports both test types on the same platform, so labs can cover common thermal performance checks without switching equipment.

Supported Specimen Sizes

For Vicat (VST), the maximum specimen size is 50 × 16 × 6.5 mm. For HDT, the maximum specimen size is 130 × 15 × 13 mm. A long-span option is available for ISO 75-3 / GB/T 1634.3 methods and supports specimens up to 260 × 15 × 13 mm, with a maximum span of 210 mm.

Standards and Test Methods You Can Run (ISO / ASTM / GB/T)

NG-HDT supports a broad set of HDT and Vicat (VST) methods used in plastics testing, including the most commonly referenced standards in North America and internationally, such as the ones listed below:

NG-HDT supports a broad set of HDT and Vicat (VST) methods used in plastics testing, including the most commonly referenced standards in North America and internationally, such as the ones listed below:

- ASTM D648: Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position - North American reference method for HDT. Used to compare how plastics deform under a specified flexural stress while temperature increases.

- ASTM D1525: Standard Test Method for Vicat Softening Temperature of Plastics - North American reference method for VST. Measures the temperature at which a specified needle penetration occurs under defined load and heating conditions.

- ISO 75-1: Plastics - Determination of temperature of deflection under load - Part 1: General test method - The general ISO framework for HDT style testing, including the overall procedure and common test setup.

- ISO 75-2: Plastics - Determination of temperature of deflection under load - Part 2: Plastics and ebonite - The commonly used ISO part for most plastics, defining standard condition sets (including the A/B/C stress conditions).

- ISO 75-3: Plastics - Determination of temperature of deflection under load - Part 3: High-strength thermosetting laminates and long-fibre-reinforced plastics - Used when the material category and setup fall under high-strength laminates or long-fibre reinforced plastics.

- ISO 306: Plastics - Thermoplastic materials - Determination of Vicat softening temperature (VST) - The ISO Vicat method, including the standard A50/B50/A120/B120 condition sets (load and heating rate combinations).

- ISO 2507 (series): Thermoplastics pipes and fittings - Vicat softening temperature - Vicat test method and conditions written specifically for pipe and fitting samples. (Often referenced alongside ISO 306 when the product is pipe-based.)

- GB/T 1634.1: Plastics - Determination of temperature of deflection under load - Part 1: General test method - Adoption aligned to the ISO 75-1 structure for HDT style testing.

- GB/T 1634.2: Plastics - Determination of Temperature of Deflection under Load - Part 2: Plastics, Ebonite and Long-fibre-reinforced Composites - Adoption aligned to ISO 75-2 for standard DTUL/HDT condition sets.

- GB/T 1634.3: Plastics - Determination of temperature of deflection under load - Part 3: High-strength thermosetting laminates - Part focused on high-strength thermosetting laminates (paired conceptually with ISO 75-3 use cases).

- GB/T 1633: Plastics - Thermoplastic materials - Determination of Vicat softening temperature (VST) - Vicat method aligned to the same test concept as ISO 306 / ASTM D1525 (needle penetration under controlled conditions).

- GB/T 8802: Thermoplastics pipes and fitting - Determination of vicat softening temperature - Vicat method written for thermoplastic pipes and fittings (pipe QC and product qualification use).

Automated Test Sequence: Loading, Heating, Measurement, Unloading, Cooling

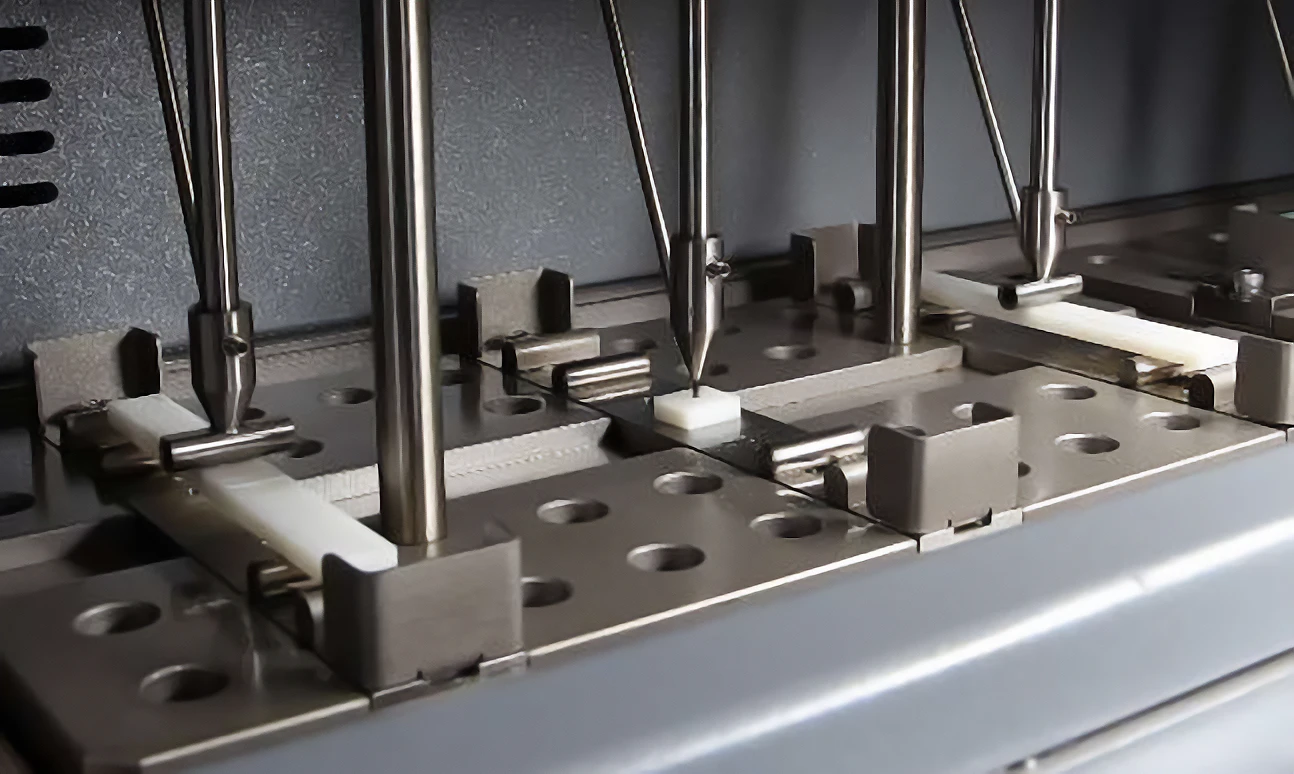

NG-HDT is built around a hands-off test sequence that follows the same order labs run every day: bring the bath to the starting condition, apply the required load, ramp temperature at the selected rate, record displacement or penetration, then unload and cool down. For HDT, the setup uses the support span and loading nose to track deflection under flexural stress. For Vicat, the needle applies the specified load and the system tracks penetration as temperature increases. Once a run is complete, the unit moves into the cooling step so the next test can be set up.

NG-HDT is built around a hands-off test sequence that follows the same order labs run every day: bring the bath to the starting condition, apply the required load, ramp temperature at the selected rate, record displacement or penetration, then unload and cool down. For HDT, the setup uses the support span and loading nose to track deflection under flexural stress. For Vicat, the needle applies the specified load and the system tracks penetration as temperature increases. Once a run is complete, the unit moves into the cooling step so the next test can be set up.

Preset Standards + Custom Methods (Touchscreen Control)

The built-in touchscreen industrial PC lets operators select preset methods based on common ISO, ASTM, and GB/T standards, or create custom methods when a lab needs a specific combination of load and heating rate. During operation, the system monitors key checks at startup such as oil level, sensor status, and door-lock state, and it assumes control of the run without manual step-by-step intervention. Test data can be saved for later review, searched as history, and exported over Ethernet when the unit is connected to a network.

Class A Temperature Sensing + LVDT Displacement Measurement

NG-HDT uses a Class A PT100 temperature sensor package and an LVDT displacement sensor system to capture the two signals that define HDT and Vicat testing: bath temperature and specimen movement. Temperature control is tied to the oil-bath layout and control parameters so the bath stays uniform during the ramp, while the displacement system tracks deflection or penetration without relying on operator interpretation.

Key displacement specs:

- Displacement resolution: 0.001 mm

- Displacement accuracy: better than 0.01 mm

- Displacement measurement range: 15 mm

Cooling Options and Oil-Consumption Reduction

NG-HDT uses an immersion oil bath and supports water cooling as the standard cooling method. For labs that need shorter turnaround between runs, the system can be configured with an external chiller to speed up cooldown after a test. The platform also supports optional nitrogen protection on the oil surface, which helps reduce silicone oil consumption over time in higher-temperature, high-usage workflows.

With a chiller installed, typical cooling time is 45 minutes from 200°C down to 23°C.

Safety Systems That Prevent Overheat, Spills, and Damage

NG-HDT is designed around a closed test chamber that separates operators from the hot oil bath during a run. The protective shield stays closed for testing, and the door is locked while the program is active to reduce the chance of accidental contact or splashing. The system also checks basic conditions at startup, including oil level, sensor status, and door-lock state, and flags abnormal conditions before the test proceeds.

Closed Shield + Auto Door Lock During Testing

A fully enclosed protection shield is used for testing, and the chamber door locks automatically during operation.

Overheat Cut-Off + Oil Level Monitoring + Overflow Protection

The unit includes dual overtemperature protection that cuts heating and triggers an alarm if limits are exceeded. Oil level monitoring works with an overflow port and automatic stop logic to prevent heater damage when the oil level is low and to handle overflow conditions during use.

Designed for Fast Cleaning and Easy Calibration

The test area is set up for routine lab maintenance, with a modular specimen rack that can be removed without tools. This makes it easier to clear fragments if a specimen drops and to keep the chamber clean between runs. The open-type oil tank uses quick-release knobs and can be cleaned in about five minutes. A dedicated calibration interface is built in to support quick checks with an external thermometer, without improvised setups.

The test area is set up for routine lab maintenance, with a modular specimen rack that can be removed without tools. This makes it easier to clear fragments if a specimen drops and to keep the chamber clean between runs. The open-type oil tank uses quick-release knobs and can be cleaned in about five minutes. A dedicated calibration interface is built in to support quick checks with an external thermometer, without improvised setups.

To protect contact parts during day-to-day handling, the Vicat needle is kept suspended when not in use, and separating pliers are included to help remove specimens without damaging the needle or pin.

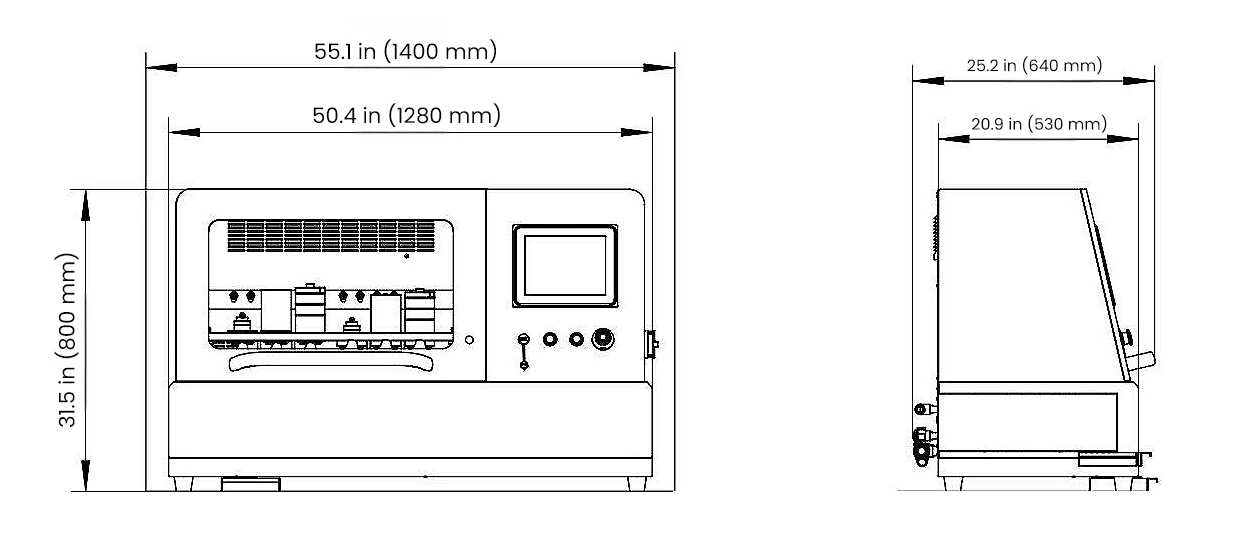

Models and Technical Specifications

In the table below, you’ll find the available model configurations and the full technical specifications for the NG-HDT HDT/Vicat testing machine, including key performance parameters, supported test setups, utilities, and dimensions.

| Specification | NG-HDT300 | NG-HDT600 |

| Test stations | 3 | 6 |

| Temperature range | Ambient to 300 °C (572 °F) | |

| Heating rate | 120 ± 10 °C/h (216 ± 18 °F/h) 50 ± 5 °C/h (90 ± 9 °F/h) | |

| Displacement resolution | 0.001 mm | |

| Displacement accuracy | Better than 0.01 mm | |

| Displacement measurement range | 15 mm | |

| HDT test span | 2.52 in (64 mm) (GB/T 1634.2, ISO 75-2) 3.94 in (100 mm), 4.00 in (101.6 mm) (ASTM D648, optional) | |

| HDT stress | 1.80 MPa, 0.45 MPa, 8.00 MPa (GB/T 1634.2) 0.455 MPa, 1.82 MPa (ASTM D648) Custom (GB/T 1634.3, ISO 75-3) | |

| VST load | 10 ± 0.2 N, 50 ± 1.0 N | |

| VST maximum specimen size | 1.97 x 0.63 x 0.26 in (50 x 16 x 6.5 mm) | |

| HDT maximum specimen size | 5.12 x 0.59 x 0.51 in (130 x 15 x 13 mm) 9.06 x 0.50 x 0.28 in (230 x 12.8 x 7 mm) (optional for GB/T 1634.3, ISO 75-3) | |

| Bath volume | 18 L | |

| Temperature sensor | PT100 | |

| Cooling time | 45 min (200 °C to 23 °C / 392 °F to 73 °F) with chiller | |

| Cooling method | Water cooling | |

| Loading type | Electric | |

| Communication port | LAN + 2 x USB 2.0 | |

| Power consumption | 3.5 kW | |

| Power supply | 1-phase, 220 V AC ± 10%, 50 Hz ± 2% | |

| Weight | 353 lb (160 kg) | |

| Dimensions | 50.4 x 20.9 x 31.5 in (1280 x 530 x 800 mm) (L x W x H) | 50.4 x 24.4 x 49.6 in (1280 x 620 x 1260 mm) (L x W (door open) x H (door open)) |

Standard Configuration and Optional Accessories

Below is an overview of what ships with the NG-HDT system as standard, plus the optional add-ons that can be supplied based on your lab setup. Quantities for station-specific items differ between the 3-station and 6-station configurations.

Standard Сonfiguration

This table lists the components supplied with the system. Items marked 3/6, 4/7, etc. depend on whether the unit is configured with 3 or 6 test stations.

| Name | Description | QTY |

| Test stations | 3/6 | |

| Support span | 2.52 in (64 mm) (ISO 75) 4.00 in (101.6 mm) (ASTM D648, Method A) 3.94 in (100 mm) (ASTM D648, Method B) | 3/6 |

| Immersion bath | 1 | |

| Temperature sensor | PT100, Class A | 4/7 |

| Displacement sensor | 3/6 | |

| Computer | Built-in 10.4" industrial PC, capacitive touch screen | 1 |

| HDT loading nose | R = 0.12 in (3.0 ± 0.2 mm) | 3/6 |

| VST needle | Cross-section area 1.000 mm² ± 0.015 mm² | 3/6 |

| Universal weight set | Combined load up to 12.1 lb (5500 g). All loads from 1 g to 5500 g are possible in 1 g steps. | 3/6 |

| Test software | GenTest, English version | 1 |

| Test accessories | Tweezers, specimen scissors, specimen separating pliers, specimen box, wrenches (1.5 mm and 2.5 mm), oil filling funnel, inlet and outlet water pipes (rated to 300 °C / 572 °F), 78.7 in (2 m) length | 1 |

| Calibration accessories | Gauge blocks (2 mm, 3 mm, 2 x 4 mm) Temperature calibration hole (Φ 3.2 mm) | 1 |

| Quality certificate | 1 | |

| Operation manual | USB drive | 1 |

Optional Accessories

Optional items can be supplied to match your workflow, cooling requirements, or test method needs.

| Name | Description |

| Universal weight set | Combined load up to 12.1 lb (5500 g). All loads from 1 g to 5500 g are possible in 1 g steps. |

| Vicat weight set | 10 N and 50 N in accordance with ISO 306 and ASTM D1525 (one set required per measuring station) |

| HDT loading nose | R = 0.12 in (3.0 ± 0.2 mm) |

| VST needle | Cross-section area 1.000 mm² ± 0.015 mm² |

| Work bench | 55.1 x 25.6 x 29.1 in (1400 x 650 x 740 mm) |

| Chiller | 2.2 kW |

| Oil-vapor purifier | 80 W, 3-layer filter, 51.2 in (1.3 m) pipe 16.7 x 9.8 x 16.1 in (425 x 250 x 410 mm) |

| Filter set (for oil-vapor purifier) | First layer: 5 pcs Second layer: 2 pcs Third layer: 1 pc |

| Adjustable-span support | Meets GB/T 1634.3 and ISO 75-3 Maximum span: 8.27 in (210 mm) Maximum specimen: 10.24 x 0.59 x 0.51 in (260 x 15 x 13 mm) |

Have Questions or Need to Confirm a Detail?

If you’re not sure which method you need to run, what station count fits your workload, or whether you need options like a chiller or oil-vapor purifier, send us a quick request online. Share your material type, applicable standard (ISO/ASTM), and specimen size, and we’ll get back to you as soon as possible with clear answers and the right configuration for your lab.

FAQs

The NG-HDT is a thermal analysis instrument developed for plastics and polymers. It performs both Heat Deflection Temperature (HDT) and Vicat Softening Temperature (VST) tests, giving data on how materials behave when exposed to rising heat under load. These values are critical for qualifying polymers, comparing formulations, and checking if materials meet regulatory or customer specifications. The system is applied in quality control labs, production environments, and R&D to confirm product reliability and to support material development.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT uses test stations built from Invar steel, a low-expansion alloy that keeps dimensional stability even when exposed to high heat. This material choice minimizes thermal deformation, so measurements remain consistent up to 300 °C. Stable load fixtures hold specimens firmly, preventing shifts that could affect deflection readings. Critical components such as displacement sensors and temperature probes are selected for high-temperature tolerance, allowing the system to deliver precise results over repeated heating cycles.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT covers the main global methods for HDT and Vicat testing. It supports ISO 75 for heat deflection, ISO 306 for Vicat softening, ASTM D648 for HDT, ASTM D1525 for Vicat, ISO 2507 for thermoplastic pipes and fittings, as well as GB/T 1633, GB/T 1634, and GB/T 8802. With this range, users can run tests that match the requirements of international product certification and industry regulations.

Click here to learn more about the product or here to receive a personalized quote.

In the Vicat method, a flat-ended needle is pressed into the surface of a plastic specimen under a defined load. The sample is heated at a uniform rate, and the test ends once the needle penetrates to a depth of 1 mm. The recorded temperature is the Vicat softening temperature, showing the point where the material transitions from rigid to softened under heat.

Click here to learn more about the product or here to receive a personalized quote.

In the HDT method, a specimen is placed on a three-point bending fixture and subjected to a constant load. The surrounding bath is then heated at a controlled rate. The test records the temperature at which the specimen bends to a defined deflection under the applied stress. This temperature is known as the heat deflection temperature, and it indicates the upper service limit of plastics when carrying mechanical loads in heated environments.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT is built for thermal analysis of thermoplastics and engineering plastics, covering both unfilled and reinforced grades. It handles general-purpose polymers such as polyethylene, polypropylene, and PVC, as well as engineering materials like polyamides, polyacetals, and polycarbonates. Filled plastics with glass or mineral reinforcement can also be tested to evaluate how additives affect heat resistance. In addition, the system supports composites and specialty polymers, giving laboratories a way to compare different formulations and confirm material suitability for demanding applications.

Click here to learn more about the product or here to receive a personalized quote.

HDT/VICAT machines are applied wherever thermoplastics and polymers must be verified for performance under heat. Plastics manufacturers rely on them to qualify raw materials and finished goods. The pipe and profile industry uses them to certify pressure pipes and structural profiles before distribution. Automotive suppliers apply HDT and Vicat tests to evaluate polymers used in under-the-hood parts, housings, and interior components. In construction, the method helps validate plastic pipes, fittings, and panels for long-term service. Research and development laboratories use these tests for new material formulations and compliance studies.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT has a footprint of approximately 32 × 24.5 × 28.5 inches (815 × 620 × 725 mm). The smaller configurations, such as the 3- and 4-station models, weigh about 253 lbs (115 kg), while the larger 6-station system reaches around 617 lbs (280 kg). This compact yet solid construction allows the unit to fit into standard laboratory spaces while offering the stability required for high-precision thermal testing.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT requires a three-phase 220 V, 50/60 Hz power connection to operate. Its maximum heating power is rated at 5000 W, giving it enough capacity to maintain stable high-temperature conditions even when running multiple test stations in parallel. A dedicated three-phase line is recommended in laboratories to handle the load safely and prevent voltage fluctuations during testing.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT supports several cooling approaches. For standard use, natural cooling can be applied once the heating cycle is finished. For faster cycles, water cooling is available when the bath temperature is below 150 °C. In addition, the system can be paired with an external chiller, which lowers the oil temperature to below 25 °C, shortens turnaround times, and keeps results within the limits defined by ISO and ASTM requirements.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT uses Swiss-made micrometers with a resolution of 0.001 mm and a measurement accuracy of ±0.003 mm. This level of precision allows laboratories to detect very small changes in specimen deflection under load, which is critical when determining HDT and Vicat softening points.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT system uses either methyl silicon oil or transformer oil as the heat transfer medium. For silicon oil, a viscosity grade of about 300 cSt (for example, Dow Corning PMX-200 or KF96-300) is recommended to achieve stable thermal performance. The bath requires a volume of 22 liters, giving enough capacity to keep temperature gradients low during long test cycles. Using these oils provides consistent heating and cooling.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT immersion bath works from ambient levels (around 20 °C) up to 300 °C. Temperature stability is maintained within ±0.5 °C across the entire range, which is critical for reliable HDT and Vicat testing. The bath uses 22 liters of silicone or transformer oil as the heat transfer medium, providing uniform heating and minimizing thermal gradients. This capacity and control allow consistent evaluation of thermoplastics, pipes, and engineering polymers that require precise high-temperature testing.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT system provides two standard loading options with 10 N and 50 N dead weights, covering both HDT and Vicat methods. The machine features an automatic loading and lifting mechanism that removes the need for manual weight handling, making the operation faster and reducing operator fatigue. Fixtures are designed to hold specimens securely during heating.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT series is offered in three versions: a 3-station unit, a 4-station unit, and a 6-station unit. This flexibility allows laboratories to choose a setup that matches their workload. Multi-station configurations make it possible to run several specimens in parallel, improving throughput and reducing overall testing time.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT machine integrates multiple safeguards to keep both operators and samples protected. It has overload protection to prevent mechanical strain, temperature limit controls to avoid overheating, and an automatic shutdown system that activates in case of abnormal operation. The test chamber is enclosed in a stable structure that shields users from heat exposure while keeping specimens in controlled conditions. Together, these measures provide safe day-to-day use in research and quality control labs.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HDT machine is supplied with warranty coverage for both mechanical and electrical components, giving users confidence in long-term operation. Technical service is available to assist with installation, training, and troubleshooting. Spare parts are kept in stock for fast replacement, and calibration services are offered to keep the system performing to standard requirements

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-HDT is designed to follow ISO 2507, which specifies how to determine the Vicat softening temperature of thermoplastic pipes and fittings. This test identifies the temperature at which the material begins to soften under a defined load and heating rate.

For plastic pipe manufacturers and quality control labs, ISO 2507 is a key benchmark. It helps confirm whether pipes and fittings can handle the thermal stress they will face during installation and service. By applying this method on the NG-HDT, users can verify compliance with product standards and demonstrate durability for building and infrastructure applications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-HDT supports ISO 75, the standard that defines how to measure the heat deflection temperature (HDT) of plastics. The test records the temperature at which a plastic sample bends under a specified load.

ISO 75 is important for pipe makers, construction material suppliers, and plastic processors, as it shows how materials behave under mechanical stress at elevated temperatures. Using the NG-HDT, labs can follow this method to check whether plastics maintain their strength and shape within the required temperature range.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-HDT machine is designed to perform tests according to ISO 306, which specifies the Vicat softening temperature (VST) of plastics. This method measures the temperature at which a flat-ended needle penetrates the specimen to a standard depth under a defined load, providing a benchmark of when a plastic starts to soften.

ISO 306 is widely applied across the plastics and polymer industry, especially for materials used in construction, piping, insulation, and consumer goods, where heat resistance is a critical property. Running ISO 306 on the NG-HDT system gives manufacturers and laboratories reliable data on material performance, enabling material comparison, product development, and compliance with international requirements.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-HDT system supports ASTM D648, the standard test method for determining the heat deflection temperature (HDT) of plastics under flexural load. In this method, a specimen is placed under a specified stress, heated at a controlled rate, and the temperature at which it reaches a set deflection is recorded.

ASTM D648 is one of the most frequently applied standards in plastics, pipe manufacturing, and engineering design, since it provides a clear measure of how materials behave under mechanical stress at elevated temperatures. By working in line with ASTM D648, the NG-HDT allows laboratories and production facilities to qualify materials for high-temperature use, compare grades of thermoplastics, and validate performance for regulatory and customer specifications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-HDT complies with ASTM D1525, the international standard for determining the Vicat softening temperature of plastics. This method uses a needle-shaped indenter under a constant load to measure the temperature at which the material begins to soften.

ASTM D1525 is widely used in quality control and material selection because it helps manufacturers evaluate the heat resistance of thermoplastics. It is especially relevant in industries such as construction, automotive, and electrical applications, where materials must maintain integrity when exposed to elevated temperatures. With compliance to ASTM D1525, the NG-HDT provides reliable data for certifying materials and comparing them with results obtained under ISO 306 or GB/T 8802 procedures.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-HDT system conforms to GB/T 8802, a standard that specifies the method for determining the Vicat softening temperature (VST) of plastics. This procedure measures the temperature at which a flat-ended needle penetrates a plastic specimen to a set depth under a defined load, helping evaluate material softening behavior under heat.

The Vicat softening point is an important benchmark for comparing different thermoplastics and for selecting materials suitable for high-temperature environments such as hot water piping, electrical housings, and automotive components.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-HDT is built to meet GB/T 1633, a standard that defines the method for determining the heat deflection temperature (HDT) of plastics. The test measures the temperature at which a plastic specimen deforms under a specified load, providing a critical parameter for assessing thermal performance.

This standard is essential for evaluating the service temperature limits of thermoplastics used in construction, piping, automotive, and electrical applications. With GB/T 1633 compliance, the NG-HDT allows laboratories and manufacturers to confirm material reliability, align with national regulations, and generate data directly comparable to other global HDT methods such as ISO 75 and ASTM D648.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-HDT is fully compliant with GB/T 1634, a standard that specifies the method for determining the Vicat softening temperature (VST) of plastics. This procedure measures the temperature at which a standard needle penetrates a plastic specimen to a defined depth under a specified load, giving a clear benchmark for material softening under heat.

GB/T 1634 is widely used by plastic manufacturers, quality control laboratories, and research institutes in China to qualify materials for piping, automotive parts, and consumer products. By following this method on the NG-HDT, companies can verify that thermoplastics meet national compliance requirements, compare the softening behavior of different product batches, and support certification processes for both domestic and export markets.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

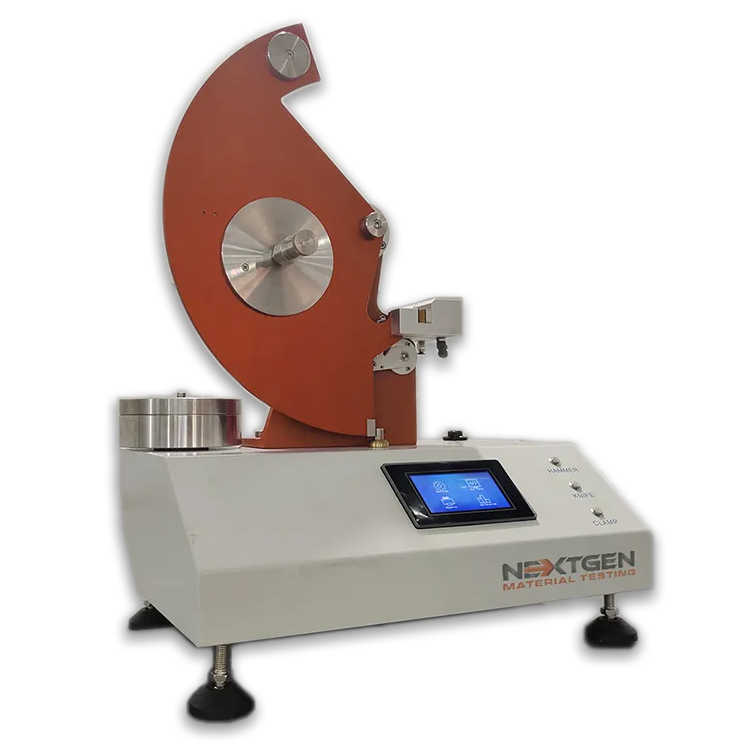

GenElm Series Elmendorf Tearing Tester – 64N and 128N Models

The GenElm Series Elmendorf Tearing Tester is designed for precise measurement of tear strength in fabrics, plastic films, paper, nonwovens, and technical textiles. Available in 64 N and 128 N models, it complies with ASTM, ISO, and DIN standards to provide accurate and comparable results across laboratories. The system features a touch-screen interface, pneumatic clamping, automatic specimen cutting, and data export via RS232, combining usability with consistent performance.

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.