Selecting the right grips and fixtures for a universal testing machine is rarely straightforward. Engineers and quality managers know that a poorly chosen accessory can distort results, damage specimens, or even compromise the testing system itself. This is why the release of NextGen’s updated catalog of grips and fixtures is significant.

The new catalog brings together hundreds of solutions designed for both electromechanical and servo-hydraulic universal testing machines (UTMs). While these accessories are broadly compatible with many systems on the market, they are fully optimized for NextGen UTMs, including the new NG-EML series. Each grip and fixture has been developed with precise applications in mind, covering tensile, bending, compression, shear, peel, and puncture testing.

In this article, you will find a comprehensive overview of the clamping devices and test fixtures presented in NextGen’s updated catalog. Each category is described with details on how it functions in the testing process, the materials it is suited for, the applications it covers, and the relevant standards. This way, you can clearly see which solutions are best aligned with your testing requirements.

Grips and Fixtures: What They Are, Why They Matter, How to Choose

In this section, we break down the fundamentals of grips and fixtures for universal testing machines. From their purpose and functions to standards and applications, the following overview answers practical questions and outlines the key points every testing professional should know.

What are grips and fixtures for universal testing machines?

What are grips and fixtures for universal testing machines?

Grips are devices that hold a specimen during tensile, compression, or flexural loading so force transfers without slip or unintended bending. Common types include wedge, side-action, pneumatic, hydraulic, and application-specific designs for wires, films, and fasteners. Fixtures are test-specific tools for three-point and four-point bending, shear, peel, puncture, and compression that define span, geometry, and load path for a method.

What functions do fixtures and grips perform?

They control alignment and surface contact to avoid specimen slip, jaw-edge damage, and off-axis loading, which directly affects measured properties and curve quality. Choice depends on material and geometry, jaw faces or liners, and required force. Examples include side-action or pneumatic grips with adjustable pressure and interchangeable faces for delicate or thin samples.

Why can’t one grip or fixture handle every testing application?

Materials and specimens differ too much for a single solution. Metals need wedge grips to withstand high strength, thin plastics and films perform better with pneumatic grips, and elastomers require self-tightening grips to stretch without slipping. Brittle samples such as concrete or ceramics need three-point or four-point bending fixtures, while compression tests demand platens that maintain parallel surfaces. Wires and cables are secured with snubbing grips, and bolts or fasteners are tested with threaded grips for alignment. Each material and geometry reacts differently under load, so accurate and repeatable results are only possible when the grip or fixture is matched to the specific test standard and specimen type.

Which materials and applications do they cover?

Catalogs span metals, composites, plastics, elastomers, foams, wires and cables, wood, and brittle materials such as ceramics and concrete, with dedicated bending kits for three- and four-point loading.

What should buyers check when selecting grips and fixtures?

When choosing the right clamping devices and test fixtures, there are several important factors to keep in mind. The most common points to check include:

- Material and geometry. Flat vs round, thin films vs thick sections; match jaw type and alignment features.

- Avoiding damage to soft or thin samples. Prefer pneumatic or side-action grips with suitable liners and controlled pressure.

- Method compliance. Map the test to required span and fixture geometry, for example ASTM E8 for metals tensile or ASTM D790 for plastics flexure.

- Changeover speed. Use modular fixtures and quick-change jaws; some systems center automatically after jaw swaps.

- Capacity and jaw faces. Confirm force range from low-force films to high-capacity metals and select serrated, rubber, or carbide faces as needed.

NextGen Grips and Fixtures for Universal Testing Machines

We have recently expanded our catalog of accessories for universal testing machines, adding a wide selection of grips and fixtures for every major type of test.

In the following section, you will find the main categories of testing accessories and attachments available in our catalog. Each category is explained with its key functions, the types of materials it is suited for, and the applications where it delivers the most value.

Side-Action Tensile Grips

Side-action tensile grips are fixtures that hold specimens from both sides, providing fast and reliable clamping for tension tests. They operate through lever or screw mechanisms that control pressure on the sample, preventing slippage and surface damage. These grips are widely used for films, sheets, textiles, rubbers and other flexible or flat specimens, with standard pin connections for compatibility with UTMs.

Side-action tensile grips are fixtures that hold specimens from both sides, providing fast and reliable clamping for tension tests. They operate through lever or screw mechanisms that control pressure on the sample, preventing slippage and surface damage. These grips are widely used for films, sheets, textiles, rubbers and other flexible or flat specimens, with standard pin connections for compatibility with UTMs.

The range includes models such as NGA201A 20 N for microfibers, NGA501A 50 N for films and thin sheets, NGA502A/B 500 N for films and textiles including temperature testing, NGA503 series 5 kN for membranes, fabrics and rubber sheets, and NGA204C 20 kN for wide geotextiles. Compact models like NGB103A/B 1 kN and NGB303A 3 kN support plastics and fabrics, while NGB503A 5 kN handles stronger textiles and sheets with multiple jaw options.

Materials: plastic films, thin sheets, textiles, rubber sheets, membranes, cords, packaging materials, geotextiles.

Standards: ASTM D3822 (single fibers), ASTM D882 / ISO 527-3 (films and thin sheets), ASTM D5035 / ISO 13934-1 (textiles strip), ASTM D5034 / ISO 13934-2 (textiles grab), ASTM D412 / ISO 37 (rubber), EN 12311-1 (roofing membranes), ASTM D4595 / ISO 10319 (geotextiles).

Snubbing Grips for Wire and Cable Tensile Testing

Snubbing grips, also called capstan grips, are designed for tensile testing of wires, ropes, cords, webbings, and geogrids. They work by wrapping the specimen around a curved surface, increasing friction and preventing slippage under load. This principle makes them suitable for materials that often slip or fail at standard clamps.

Snubbing grips, also called capstan grips, are designed for tensile testing of wires, ropes, cords, webbings, and geogrids. They work by wrapping the specimen around a curved surface, increasing friction and preventing slippage under load. This principle makes them suitable for materials that often slip or fail at standard clamps.

The NextGen range offers solutions for many different testing needs. For very thin steel wires there is the WCA203B at 2 kN, while lighter ropes and cords are covered by several 5 kN models like the WCA503C, WCA503D/E for geogrid strips, and WCB503A for thinner ropes. As the loads increase, options such as the WCR104B at 10 kN for medium ropes and the WCR304B at 30 kN for stronger steel ropes come into play. For wider or heavier samples like seat belt webbings and straps, the WCA304C (30 kN) and WCA504D (50 kN) provide reliable clamping, with the WCC504A designed for geogrids. At the upper end, the NGC504A at 50 kN handles wire ropes, while the NGC105A at 100 kN is built for large steel cables.

Materials: fine steel wires, steel cords and ropes, nylon and polyester ropes, braided cords, webbing, seat belts, cargo straps, geotextile strips, geogrids.

Standards: ASTM E8 / ISO 6892 (metallic wires), ASTM A931 / ISO 10425 (steel ropes and strands), ISO 2307 (fiber ropes), ASTM D6775 (textile webbing), ASTM D5035 / ISO 13934-1 (fabric strips), ASTM D4595 / ISO 10319 (geotextiles), ASTM D6637 (geogrids).

Self-Tightening Grips for Deformable and Elastic Materials

Self-tightening grips are designed for tensile testing of materials that deform or elongate under load, such as elastomers, foams, thin plastics, textiles, and biomedical samples. These grips increase clamping pressure automatically as the specimen stretches, preventing slippage without manual adjustment. Their design makes them especially effective for low-friction or delicate materials, where conventional grips may cause early failure or damage.

The lineup includes NGA203A — 2 kN, suitable for soft plastics and rubbers in small-scale testing, and NG5203A — 5 kN, designed for wider specimens and higher forces. Both models use a self-tightening mechanism that adapts to changes in specimen thickness, offering stable and repeatable results in quality control and R&D environments.

Materials: elastomers, soft plastics, rubber sheets, foams, textiles, biomedical samples.

Standards: ASTM D412 / ISO 37 (rubber tensile properties), ASTM D638 / ISO 527 (plastics), ASTM D3574 (flexible foams), ISO 13934-1 (textiles, strip method).

Eccentric Roller Grips for Thin and Flexible Specimens

Eccentric roller grips are tensile fixtures that clamp from the side using a cam-driven roller that increases friction as load rises. The specimen is drawn around the eccentric roller, which self-energizes under tension to prevent slip while protecting the surface. This design is ideal for thin sheets, films, foils, textiles, and other soft materials that are sensitive to clamp pressure or jaw marks.

Eccentric roller grips are tensile fixtures that clamp from the side using a cam-driven roller that increases friction as load rises. The specimen is drawn around the eccentric roller, which self-energizes under tension to prevent slip while protecting the surface. This design is ideal for thin sheets, films, foils, textiles, and other soft materials that are sensitive to clamp pressure or jaw marks.

Our range includes NGA502A for compact, low-force setups up to 500 N, NGA502B for the same force class with a heavier body for stability on mid-size frames, and NGA103A for up to 1 kN when extra capacity is needed. All models use 10 mm pin connections and are ready for integration with NG-EML and SHM UTMs.

Materials: plastic film, soft plastics, rubber sheet, elastomers, thin composites, paper and paperboard, foils, nonwovens, textiles, laminates.

Standards: ASTM D882 (plastic films, tensile properties), ASTM D412 (vulcanized rubber, tension), ISO 527-3 (plastics films and sheets, tensile), ISO 6892-1 (thin soft metals, general tensile), ISO 13934-1 (textiles, strip method), DIN 51221 (grip safety and testing practice).

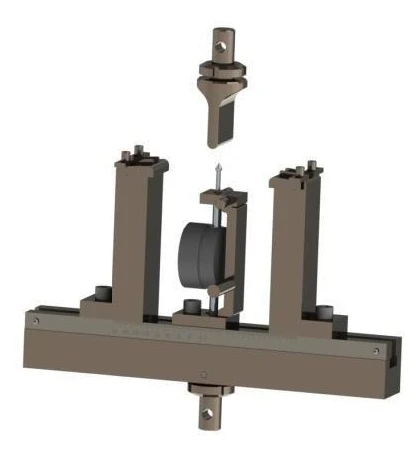

Bending Fixtures for Standard 3-Point Flexural Testing

Bending fixtures are essential accessories for performing flexural tests in a controlled and repeatable way. The classic 3-point bending method applies a central load to a specimen supported at two ends, measuring stiffness, flexural strength, and ductility. These fixtures are widely used with plastics, composites, metals, ceramics, and laminated structures. NextGen’s line is designed for NG-EML and SHM Universal Testing Machines, offering adjustable spans, interchangeable rollers, and precise alignment for compliance with global flexural testing standards.

The line includes NGA204A for general flexural testing up to 20 kN, NGA504A for heavy-duty evaluation at 50 kN, NGA105A for high-capacity testing at 100 kN, and NGA305A for industrial applications up to 300 kN. For low-force applications, NGA104A and NGA104B cover small plastics and adhesives, while NGA104G extends flexural testing into thermal chambers. The NGA204A Marker Bending Fixture is dedicated to roadway marker evaluation.

Materials: plastics, polymers, composites, ceramics, metals, alloys, laminated structures, adhesives, construction materials, roadway markers.

Standards: ASTM D790 (plastics, flexural properties), ISO 178 (plastics, flexural test), ISO 14125 (fiber-reinforced composites), ASTM E290 (metal ductility bend), GB/T 9341 (plastics, flexural properties).

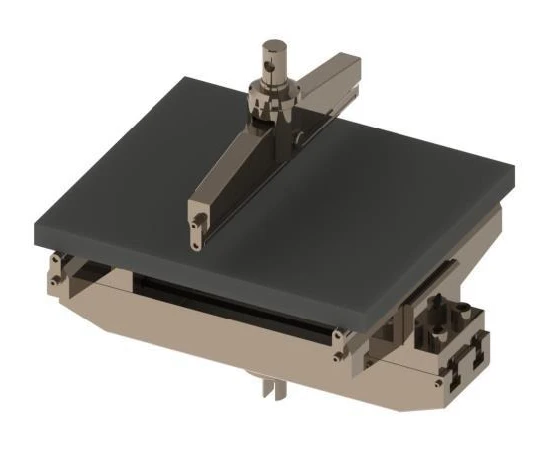

Compression Fixtures for Axial Load Testing of Rigid Samples

Compression fixtures apply vertical force between parallel platens to measure compressive strength, modulus, yield, creep, and crushing behavior. The fixture geometry maintains alignment and distributes load uniformly so rigid and semi-rigid specimens can be tested without bending artifacts. All solutions integrate with our UTMs and support repeatable axial loading for plastics, metals, foams, composites, and construction materials.

Compression fixtures apply vertical force between parallel platens to measure compressive strength, modulus, yield, creep, and crushing behavior. The fixture geometry maintains alignment and distributes load uniformly so rigid and semi-rigid specimens can be tested without bending artifacts. All solutions integrate with our UTMs and support repeatable axial loading for plastics, metals, foams, composites, and construction materials.

Our line includes NGA204 series for general lab work up to 20 kN (Ø100–Ø200 mm platens, optional sphere-seated), NGA105 series for high-force testing up to 100 kN with sphere-seated platens, and NGA305 series for heavy-duty work up to 300 kN with large pins and seated platens. For foams and soft materials, NGB204 covers rigid foam panels (200×200 and 300×300 mm), while NGC203A/B address low-force foam and sponge testing with large-area supports. NGA305B targets concrete and dense construction specimens at 300 kN.

Materials: metals, alloys, engineering plastics, rigid foams, elastomers, fiber-reinforced composites, ceramics, concrete, construction materials, insulation panels.

Standards: ASTM D695 (plastics, compressive properties), ISO 604 (plastics, compressive modulus/strength), ASTM E9 (metals, compression method), GB/T 14485 (foamed plastics, compression).

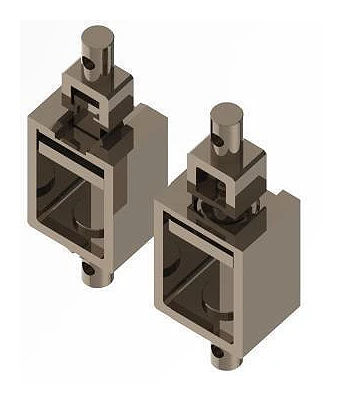

Shoulder Fixtures for Pull-Off and Component Testing

Shoulder fixtures are grips designed to test specimens with shoulder-shaped geometries. They provide accurate alignment and secure clamping during pull-off and tensile tests, preventing uneven stress distribution and specimen slippage. These fixtures are essential for adhesive bond testing, cement mortar evaluation, and other applications where specimens have defined shoulders or bonded surfaces.

Shoulder fixtures are grips designed to test specimens with shoulder-shaped geometries. They provide accurate alignment and secure clamping during pull-off and tensile tests, preventing uneven stress distribution and specimen slippage. These fixtures are essential for adhesive bond testing, cement mortar evaluation, and other applications where specimens have defined shoulders or bonded surfaces.

The range includes NGB203A – 2 kN for cement mortar strength testing, NGC103A – 1 kN and NGC103B – 1 kN for adhesive bonds with substrates up to 75 mm, the modular NGC203 series – 2 kN for adhesives with specimen blocks from 50×50 mm to 200×200 mm, and NGC503A – 5 kN for moderate adhesive bond strength validation. These grips are compact, pin-mounted, and designed for repeatable testing in QC labs and research facilities.

Materials: cement mortar, adhesives, bonded assemblies, polymer composites, machined plastics, metals with shoulder profiles.

Standards: ASTM D638 (tensile properties of plastics), ISO 527 (plastic tensile testing), GB/T 1040 (plastic tensile methods).

Pneumatic Grips for Fast and Repeatable Clamping

Pneumatic grips are air-actuated fixtures that apply uniform, adjustable clamping pressure for rapid, repeatable specimen mounting in UTMs. They improve throughput, reduce operator variability, and maintain alignment across side-action, wedge-action, and snubbing configurations. Suitable for thin films, textiles, wires, ropes, composites, and metals, these grips hold securely as load increases and integrate with NG-EML and SHM frames.

Pneumatic grips are air-actuated fixtures that apply uniform, adjustable clamping pressure for rapid, repeatable specimen mounting in UTMs. They improve throughput, reduce operator variability, and maintain alignment across side-action, wedge-action, and snubbing configurations. Suitable for thin films, textiles, wires, ropes, composites, and metals, these grips hold securely as load increases and integrate with NG-EML and SHM frames.

Our lineup includes WCQA502A for delicate filaments, WCQA203A for small textile ropes, NGA502A and NGA103A for films and rubber sheets, NGA103C for textiles and films with swap jaw faces, NGA503A and NGA503G for waterproof rolls and heavy cloth, NGB104A for flat specimens up to 10 kN, and wedge-action models NGC204A 20 kN, NGC504A 50 kN, NGD105D 100 kN for round and flat metals and composites.

Materials: filaments, fine wires, textile ropes, cords, fabrics, waterproof rolls, plastic films and sheets, rubber, composites, flat metallic specimens, round metallic bars.

Standards: ASTM D638 (plastics tensile), ISO 527 (plastics tensile), ASTM D882 (plastic films), ASTM E8 (metal tensile), ISO 6892 (metal tensile), ASTM D6775 (webbing and straps), DIN 51221 (general tensile guidance).

Wedge Tensile Grips for High-Load Metal and Composite Testing

Wedge tensile grips are self-tightening fixtures that convert axial pull into radial clamping. As load rises, the wedges lock the specimen, reduce slip, and keep alignment stable for repeatable tensile results. They are suited to flat coupons and round bars in metals, rigid plastics, and composites.

Wedge tensile grips are self-tightening fixtures that convert axial pull into radial clamping. As load rises, the wedges lock the specimen, reduce slip, and keep alignment stable for repeatable tensile results. They are suited to flat coupons and round bars in metals, rigid plastics, and composites.

Our range includes NGA204G 20 kN for flat and round specimens with cryogenic to high-heat use, NGA304A 30 kN for mid-range metals and composites, NGA504A 50 kN for higher strength samples, NGA105A 100 kN for heavy lab workloads, and NGA305A 300 kN for structural testing. Compact and specialty options include NGB204A 20 kN, NGB204G 20 kN extended temperature, and NGD104A 10 kN for routine coupon testing.

Materials: metals and alloys, rigid plastics, fiber-reinforced composites, flat tensile coupons, round bars and rods.

Standards: ASTM E8 (metallic tensile), ISO 6892 (metallic tensile), ISO 527 (plastics tensile), DIN 50125 (metal specimen geometries).

3-Point and 4-Point Bending Fixtures for Uniform Moment Flexural Testing

Bending fixtures apply controlled flexural loads using 3-point or 4-point setups to measure strength, stiffness, and deformation of beams, tiles, boards, and structural coupons. They mount to NG-EML and other NextGen UTMs, use precision rollers and adjustable spans, and deliver uniform loading for repeatable flexural modulus and strength results across lab and production testing.

Bending fixtures apply controlled flexural loads using 3-point or 4-point setups to measure strength, stiffness, and deformation of beams, tiles, boards, and structural coupons. They mount to NG-EML and other NextGen UTMs, use precision rollers and adjustable spans, and deliver uniform loading for repeatable flexural modulus and strength results across lab and production testing.

Our lineup includes NGB304A B C 4-point systems for stone, ceramics, and composites, NGB105A 4-point for high load concrete beams, and NGD204A B C D E F 3-point rigs sized for bricks, paving units, plasterboard, fiber cement, roofing tiles, and insulation foam. Each model covers the typical span and width ranges for its application while maintaining quick setup and stable alignment.

Materials: concrete, natural stone, ceramics, bricks and paving blocks, gypsum board, fiber cement, rigid insulation foam, metals, composites.

Standards: ASTM C1609 (fiber reinforced concrete beams), ASTM C78 and ASTM C293 (concrete beam flexure), ISO 178 (plastics flexural properties), EN 12808 (grouts and tile related products), plus related method variants for ceramics and construction products.

Grips and Fixtures for Tensile, Shear, and Flexural Testing of Wood

Grips and fixtures for wood testing secure solid timber, engineered panels, and fastener assemblies for tensile, shear, and flexural methods. Designed for NG-EML and NG-SHM UTMs, they provide stable alignment, uniform load transfer, and repeatable results across QA and R&D, from clear-wood coupons to large panels and fastener withdrawal checks.

Grips and fixtures for wood testing secure solid timber, engineered panels, and fastener assemblies for tensile, shear, and flexural methods. Designed for NG-EML and NG-SHM UTMs, they provide stable alignment, uniform load transfer, and repeatable results across QA and R&D, from clear-wood coupons to large panels and fastener withdrawal checks.

Our wood line includes NGB104B tensile side-action grips for boards and panels, NGB203A shear fixture for adhesive-laminated wood and FRP interlaminar shear, NGH104A internal-bond tensile tool for 50 x 50 mm samples, NGH104B surface bond and soundness tensile tool, NGB502A nail and screw withdrawal fixture, and NGC104C long-span 3- and 4-point bending rig for boards and panels.

Materials and products: solid wood, softwood and hardwood species, plywood, OSB, MDF, particleboard, LVL, glulam, wood-plastic composites, adhesive-bonded laminates, roofing and subfloor panels, nails, screws, wood fastener assemblies.

Standards: ASTM D198 (structural timber bending and tension), ASTM D143 (small clear wood properties), ASTM D1037 (wood-based panel tests), ASTM D1761 (fastener withdrawal and lateral load), ASTM D4761 (lumber mechanical properties), ISO 3349 (MOE in static bending for wood), ISO 3340 (ultimate strength in static bending), EN 310 (panel bending strength and MOE), EN 320 (screw withdrawal from panels), GB/T 1936.1 (wood static bending method).

Composite Grips and Fixtures for Tensile, Shear, and Delamination Test

Composite grips and fixtures are designed for reliable tensile, shear, compression, bending, and delamination testing of fiber-reinforced plastics, laminates, and hybrid materials. They provide stable clamping, precise alignment, and repeatable results, making them essential for both R&D and quality control when working with composites of different geometries and strengths.

Composite grips and fixtures are designed for reliable tensile, shear, compression, bending, and delamination testing of fiber-reinforced plastics, laminates, and hybrid materials. They provide stable clamping, precise alignment, and repeatable results, making them essential for both R&D and quality control when working with composites of different geometries and strengths.

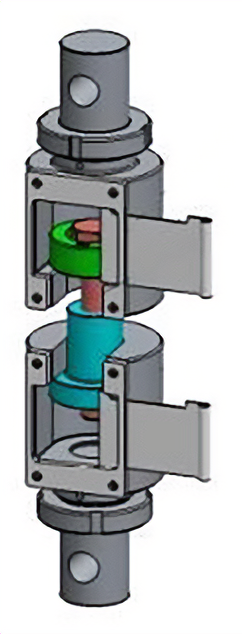

Our range includes NGC105B and NGC105G hydraulic wedge grips for high-capacity tensile testing up to 100 kN, including versions for extreme temperatures, as well as lighter fixtures such as NGA502A for honeycomb core materials, NGB103A for bonded sandwich structures, and NGA104C for flatwise testing of sandwich panels. For interlaminar fracture and delamination, compact options like NGA202A loading block grips are available.

Materials: fiber-reinforced plastics, carbon composites, laminates, honeycomb cores, sandwich panels, hybrid composite structures.

Standards: ASTM D3039 (tensile composites), ISO 527 (plastics and composites), ASTM D2344 / ISO 14125 (short-beam shear and flexural), ASTM C297 (flatwise sandwich tension), ASTM D5528 (interlaminar fracture), DIN EN 2562 (fiber-reinforced plastics tensile).

Specialized Grips and Fixtures for Tear, Peel, and Puncture Testing

Specialized grips and fixtures are engineered for tear, peel, puncture, and shear strength testing of films, textiles, foams, safety nets, and bonded assemblies. They expand the testing scope of universal testing machines by providing precise clamping, stable alignment, and controlled force application.

Specialized grips and fixtures are engineered for tear, peel, puncture, and shear strength testing of films, textiles, foams, safety nets, and bonded assemblies. They expand the testing scope of universal testing machines by providing precise clamping, stable alignment, and controlled force application.

Models in this category: NGB502A side action grips for sponge samples and footwear, NGA502A 90° peeling fixtures for adhesive tapes, NGB103A peeling fixtures for geogrid materials, NGG103A climbing drum peel fixtures for bonded sandwich structures, NGA502A tear fixtures for waterproof rolls, NGA204A grips for safety nets, NGP502A puncture fixtures for plastic films, and NGP103A puncture fixtures for non-woven fabrics. These solutions integrate with NG-EML and SHM UTMs.

Materials: plastic films, non-woven fabrics, geotextiles, waterproof rolls, sponge samples, footwear components, adhesive tapes, bonded sandwich structures, safety nets.

Standards: ASTM D624 (rubber tear strength), ASTM D1004 (plastic film tear resistance), ISO 34 (rubber tear strength), ISO 3303 (film puncture resistance), GB/T 2792 (tape peel test), ISO 29862 (self-adhesive tape peel adhesion).

TestStar® Series Grips and Fixtures for Hydraulic UTM Integration

TestStar® series grips and fixtures are engineered for tensile, compression, bending, shear, and puncture testing across metals, polymers, composites, geotextiles, and other industrial materials. These fixtures integrate with NextGen’s hydraulic and electromechanical universal testing machines, providing stable clamping, controlled alignment, and durability under varying load conditions.

TestStar® series grips and fixtures are engineered for tensile, compression, bending, shear, and puncture testing across metals, polymers, composites, geotextiles, and other industrial materials. These fixtures integrate with NextGen’s hydraulic and electromechanical universal testing machines, providing stable clamping, controlled alignment, and durability under varying load conditions.

Models include NGQA502A pneumatic snubbing grips for delicate filaments up to 500 N, NGH203A manual snubbing grips for glass fiber and cords up to 2 kN, and NGB502B snubbing grips for thin steel wires. For textile and soft material testing, NGSD503A side-action grips handle forces up to 5 kN. High-capacity applications are supported by NGSA105A wedge grips rated to 100 kN and NGSA304A wedge grips for medium-load tests up to 30 kN.

Materials: metals, polymers, composites, filaments, fibers, cords, steel wires, textiles, geotextiles.

Standards: ASTM D638, ISO 6892, DIN 50125, plus related tensile and mechanical testing methods.

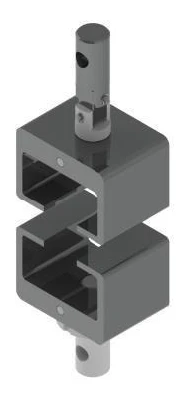

Dual-Action Hydraulic Grips with Wedge Clamping for High-Capacity Tests

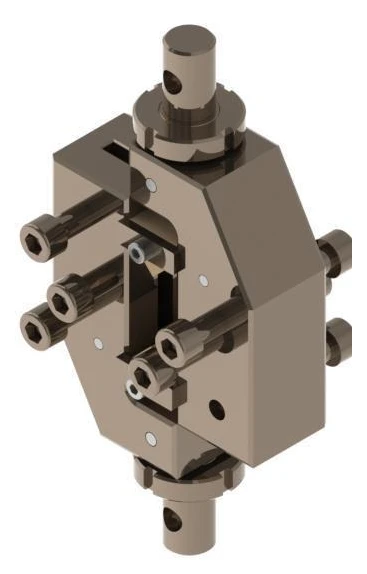

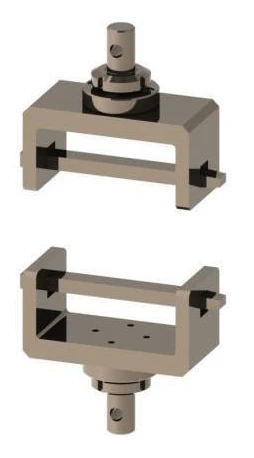

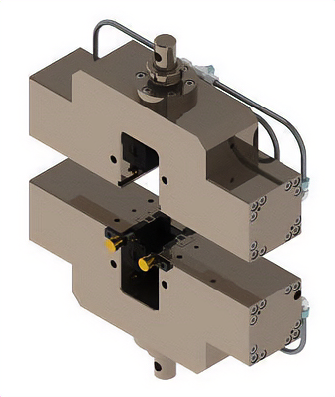

Dual-action hydraulic grips with wedge clamping are designed for high-force tensile testing of flat and round specimens. Hydraulic actuation provides uniform clamping, while the wedge system secures the specimen under increasing load, preventing slip or distortion. These grips are suited for metals, composites, and reinforced plastics tested at very high capacities.

Dual-action hydraulic grips with wedge clamping are designed for high-force tensile testing of flat and round specimens. Hydraulic actuation provides uniform clamping, while the wedge system secures the specimen under increasing load, preventing slip or distortion. These grips are suited for metals, composites, and reinforced plastics tested at very high capacities.

Models in this category cover a wide range of testing capacities. The NGA105B handles 100 kN for standard high-force applications, while the NGA305C extends performance to 300 kN for heavier specimens. The NG605DPS.01 increases capacity to 600 kN, making it suitable for high-strength metals and alloys, and the NG106DPS.01 delivers up to 1000 kN for ultra-heavy-duty testing environments. Each model uses dual side action with wedge clamping to maintain stable alignment and secure specimen engagement under extreme loads.

Materials: metals, alloys, composites, reinforced plastics, structural specimens.

Standards: ASTM E8 (metal tensile), ISO 6892 (metal tensile), DIN 50125 (metal specimen geometry), GB/T standards for hydraulic tensile.

Threaded Grips for Bolt and Nut Tensile Testing

Threaded grips are designed for precise tensile testing of bolts, studs, and nuts, ensuring axial loading without slippage or thread stripping. Built for high-strength fasteners, they maintain secure engagement under heavy loads and comply with major international standards such as ASTM F606, ISO 898, and DIN 50125. Their construction allows repeatable testing across different thread sizes, making them essential for industries that demand reliable fastener validation.

Models in this category cover both medium and high-capacity testing requirements. The NGA105A supports loads up to 100 kN and covers thread sizes from M5 to M18, while the NGA305C extends capacity to 300 kN with compatibility for M3 to M22 fasteners. Both grips feature pin-mounted connections, optional bushings, mandrels, and wedges to handle a wide variety of thread geometries, providing stable alignment and consistent test performance.

Materials and Products: threaded bolts, nuts, studs, automotive fasteners, aerospace fasteners, high-strength structural bolts.

Standards: ASTM F606 (mechanical testing of fasteners), ISO 898 (fastener tensile properties), DIN 50125 (test piece geometries for metals), GB/T 3098.1 / GB/T 3098.2 (mechanical properties of fasteners).

Grips and Fixtures for Hydraulic Universal Testing Machines

Grips and fixtures for hydraulic universal testing machines are built to support high-capacity tensile, shear, proof load, and wedge load applications. They provide strong clamping, prevent slippage, and allow secure axial alignment during demanding tests on bolts, nuts, welded mesh, and other heavy-duty components.

Grips and fixtures for hydraulic universal testing machines are built to support high-capacity tensile, shear, proof load, and wedge load applications. They provide strong clamping, prevent slippage, and allow secure axial alignment during demanding tests on bolts, nuts, welded mesh, and other heavy-duty components.

The selection includes NGA106A for shear testing of welded steel mesh up to 1000 kN, as well as proof load fixtures for nuts such as NGA605A rated to 600 kN and NGA206A rated to 2000 kN. For bolt and nut tensile and wedge load applications, NGB605A with 600 kN capacity and NGB206A with 2000 kN capacity are available. Each system operates with hydraulic clamping, suspended configuration, and offers interchangeable accessories to match a broad range of thread sizes.

Materials: welded steel mesh, threaded bolts, nuts, fasteners, and studs.

Standards: ASTM F606 (mechanical testing of fasteners), ASTM A370 (mechanical testing of steel products), ASTM E8 (tensile testing of metallic materials), ISO 898 (mechanical properties of bolts and nuts), DIN 50125 (specimen geometries for metal tensile testing), GB/T 3098.1 / GB/T 3098.2 (mechanical properties of fasteners), GB/T 1499.3 (testing of welded steel mesh).

Customization of Special Fixtures and Grips Fixtures

Sometimes standard grips and fixtures simply aren’t enough. When you’re working with unique sample shapes, special loading setups, or testing in demanding conditions such as high temperature or corrosion, a tailored solution makes all the difference. To order a tailored solution for your needs, just contact us directly — our team will guide you through the process step by step.

At NextGen, we develop custom fixtures designed specifically for your application. This can include creating a prototype, choosing the right contact surfaces, and confirming everything in actual test runs. All you need to provide is a short description of your material, the shape of your sample, the standard or test method you follow, the expected load range, and any dimension limits. With this information, we can suggest the right fixture that fits your setup perfectly.

The Right Fixtures as the Basis for Accurate UTM Testing

Our catalog brings together a complete range of clamping devices and test fixtures for both hydraulic and electromechanical UTMs. It covers tensile, compression, shear, bending, and fastener testing — all built for reliable daily use and compliant with ASTM, ISO, DIN, JIS, and GB/T standards.

Selecting the right fixture helps you save time, protect your samples, and achieve stable, repeatable results across different materials and geometries. Instead of adjusting tools that were never meant for the task, you can simply choose an option already matched to your testing requirements.

If you have any questions about these grips and fixtures, or if you would like more detailed information, please contact us directly or request a quote. Share your material details, a drawing or photo of your sample, the testing standard you follow, and your load range. We will recommend the fixture set that best supports your application. We’re here to make sure you get exactly what you need.