Plastic Testing Equipment

Plastic testing equipment is used to evaluate the physical and mechanical behavior of polymers at every stage of production and research. These systems measure tensile strength, impact resistance, hardness, melt flow rate, and other parameters that define the reliability and performance of plastic materials in real applications.

At NextGen Material Testing, we supply a full line of systems designed for different types of plastic evaluation. This includes electromechanical universal testing machines for tensile and elongation checks, Charpy and Izod pendulum impact testers, Shore and IRHD hardness testers, Elmendorf tear strength systems, melt flow indexers for polymer flow behavior, environmental chambers to simulate working conditions, and more.

These solutions allow engineers and researchers to perform tests in line with ASTM, ISO, and DIN standards, making results consistent and comparable across laboratories and production sites. With certified equipment, users reduce the risk of measurement errors and can trust the data that supports both daily quality checks and long-term material development.

Sub-categories

Electromechanical Universal Testing Machines for Plastic Testing

Our NG-EML electromechanical universal testing machines are designed for plastic materials that require accurate tensile, compression and flexural testing. The series includes compact benchtop units and high-capacity floor models, so labs can choose the frame that fits their plastic samples and test loads. Every system runs on GenTest software, giving users ready ASTM and ISO methods and a simple way to manage tests and results. Grips, extensometers and fixtures can be added at any time to match specific sample shapes. This category is made for labs that test films, molded parts, elastomers and other polymer materials in daily production or development work.

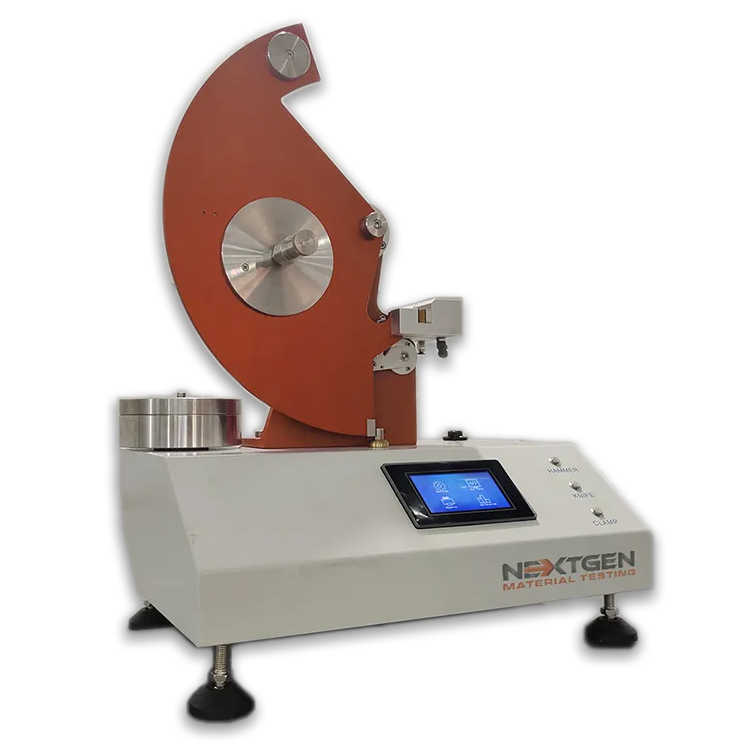

Charpy and Izod Pendulum Impact Testing for Plastic and Rubber Specimens

Pendulum Charpy and Izod Impact Testing for plastic and rubber specimens is a high strain-rate test to determine the amount of energy absorbed by a material during fracture. Impact specimens are of standard or subsize dimensions that can be found in a variety of industry standards including ASTM E23, ASTM A370, EN 10045-1 and ISO 148.

Products

GenElm Series Elmendorf Tearing Tester – 64N and 128N Models

The GenElm Series Elmendorf Tearing Tester is designed for precise measurement of tear strength in fabrics, plastic films, paper, nonwovens, and technical textiles. Available in 64 N and 128 N models, it complies with ASTM, ISO, and DIN standards to provide accurate and comparable results across laboratories. The system features a touch-screen interface, pneumatic clamping, automatic specimen cutting, and data export via RS232, combining usability with consistent performance.

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.

Impact testing systems

Impact testing systems Hardness is one of the key indicators when working with plastics, rubbers, foams, and similar materials. It shows how resistant a sample is to indentation and helps evaluate durability and expected performance in use. Depending on the application, testing can be carried out with automatic systems for high-volume labs, portable durometers for quick checks, or specialized machines for unique sample types.

Hardness is one of the key indicators when working with plastics, rubbers, foams, and similar materials. It shows how resistant a sample is to indentation and helps evaluate durability and expected performance in use. Depending on the application, testing can be carried out with automatic systems for high-volume labs, portable durometers for quick checks, or specialized machines for unique sample types. Tear strength is an important property for thin plastic films, textiles, and similar sheet materials. It shows how well a material resists the spread of a cut or small defect once it has started. Consistent tear strength data helps predict how plastics will perform in packaging, protective layers, or technical applications where durability matters.

Tear strength is an important property for thin plastic films, textiles, and similar sheet materials. It shows how well a material resists the spread of a cut or small defect once it has started. Consistent tear strength data helps predict how plastics will perform in packaging, protective layers, or technical applications where durability matters. The NextGen

The NextGen