Rubber Testing Equipment

Standards

EN ISO 20344, ASTM D813, ASTM D430, ISO 132

Description

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing.

Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Functionality

- Fix the specimen into the movable grips and observe your specimens for their resistance to cracking. The system is equipped with an intelligent testing failure system.

Specifications

| Model | GenFlex-B1 | GenFlex-B2 |

|---|---|---|

| Specimen | 154 x 25 ±1 x 6.3 ±0.15mm | 108 ±0.5 x 70 ±0.5mm |

| Reciprocating Stroke | 57mm | 44mm |

| Maximum Distance Between Fixtures | 75mm | 57mm |

| Testing Speed | 300 ±10cpm | 340-400 ±10cpm |

| Counter | LCD - 0-999,999 | |

| Dimensions (W X D X H) | 35x60x75cm | |

| Weight | 78kg | |

| Power | 110V/60Hz or 220V/50Hz | |

FAQs

The following industry standards are typically followed when testing with the DeMattia Flex Cracking tester:

ISO 132, ISO 6943, ASTM D813, ASTM D430-B and JIS K_6260

Most commonly, rubber sole material is used in a DeMattia Flex tester. Due to the fact that the rubber soles are being used daily and coming into contact with roads, dirt and other elements, they endure the maximum level of flexing. It is the friction from all the flexing that can lead to a surface crack which can lead to failure of the rubber compound.

While rubber has an extremely high strength rating, it also exhibits some faulty characteristics after being exposed to heat, cold weather and humidity/temperature changes. After being exposed to these elements, it is common for a crack to develop on the surface and these cracks have a tendency to continue to grow. DeMattia Flex Cracking can help to estimate the rubbers lifespan after a crack has formed in the materials surface.

Up to 6 specimens can be tested at one time after setting the frequency per your industry standard.

The specimen must first be created in the size required per the industry standard. NextGen can supply the ASTM D430, Method B cutting dies along with the D813 mold required to perform these tests. ISO moulds can also be provided as a custom order.

The DeMattia test allows the operators to analyze the fatigue-cracking properties of the material in question. It provides a picture of the potential lifespan of the material when being used in its service application.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

ICI / Mace Snag Tester

Discover the Fabric Textile ICI / Mace Snag Tester, a reliable tool for assessing fabric snagging under normal wear conditions.

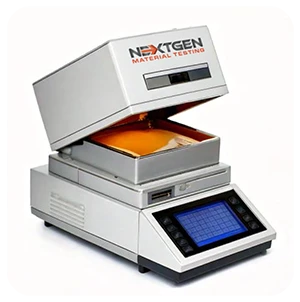

Moving Die Rheometer (MDR)

Introducing the NG-MDR Moving Die Rheometer, your solution for accurately assessing the curing and processing characteristics of vulcanized rubber compounds. Designed for precision, this state-of-the-art rheometer captures the characteristic curve and parameters of rubber vulcanization by measuring the torque applied to the oscillating die.

Aging Oven – High-Temperature Chamber – NG-AGOV-ADV

The NG-AGOV-ADV Aging Oven is designed for high-temperature testing of rubber, plastics, and insulating materials. It features programmable PID control, uniform airflow, and forced convection for stable and repeatable aging cycles. This system supports global testing standards including ISO 188, ASTM D573, and IEC 60216-4-1. With its durable stainless-steel chamber and user-friendly interface, it’s ideal for R&D, quality control, and certification labs.

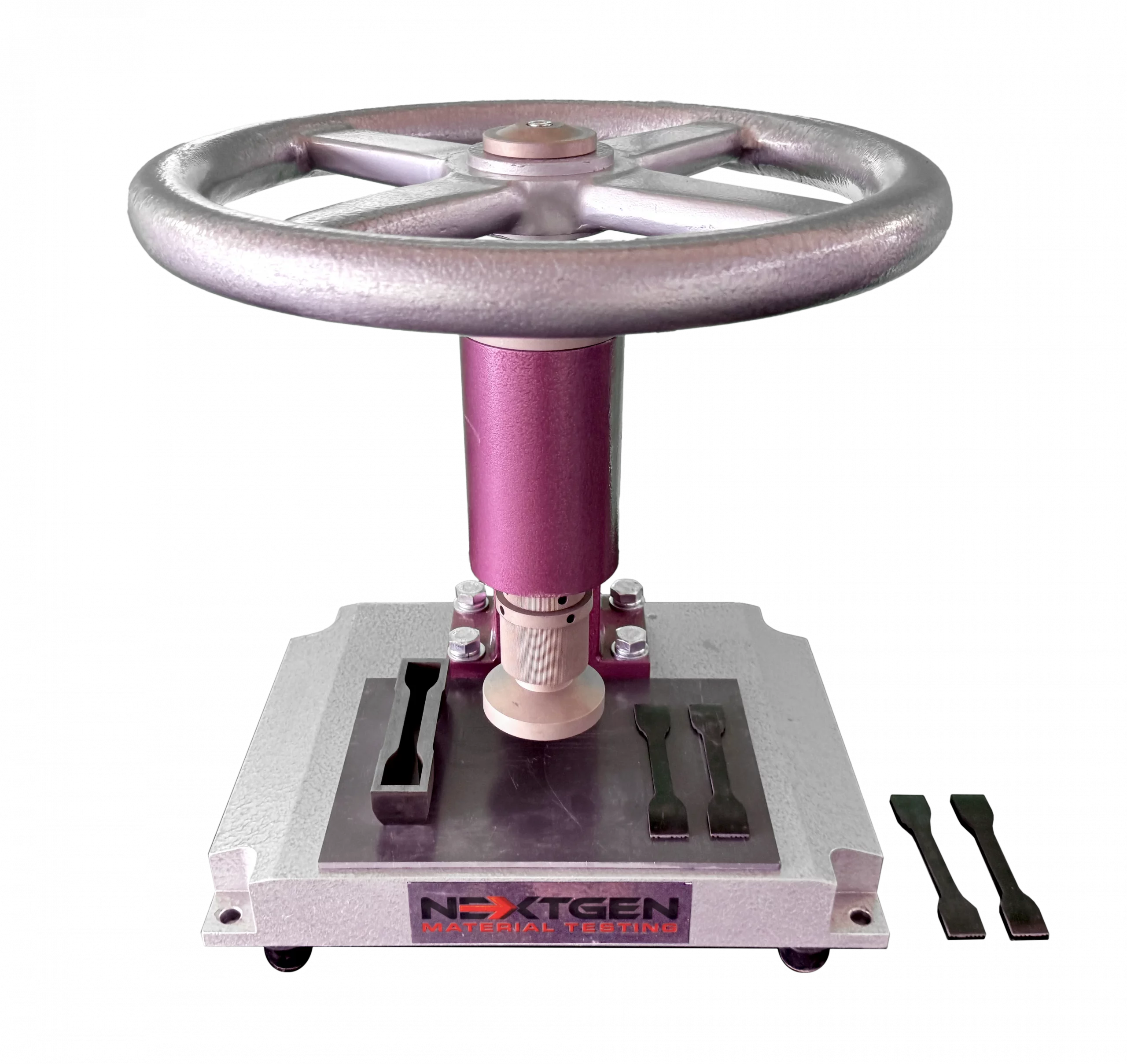

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

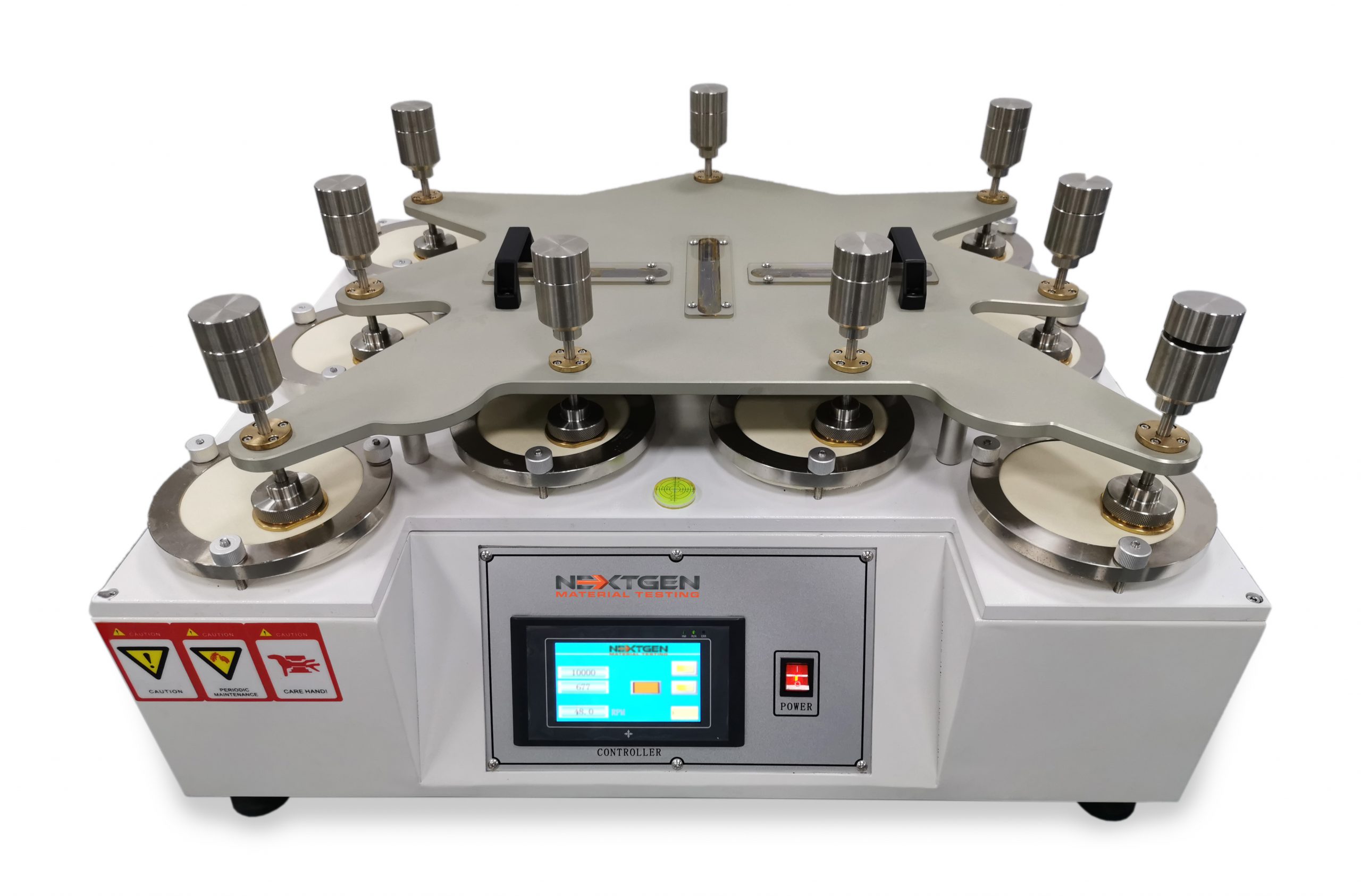

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.