Rubber Testing Equipment

Standards

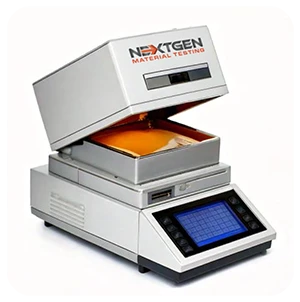

GenBurst is the Burst Strength Tester designed to test anti-rupture strength of variety of materials such as leather, paper and fabric. The unit tests the resistance of specimens to bursting using a hydraulic diaphragm bursting tester.

Burst Strength Tester Technical Specifications

| Type | GenBurst-AD | GenBurst-A |

|---|---|---|

| Sensor | Pressure Transducers | |

| Display Mode | LED | PLC Touch Screen Display |

| Load Resolution | 1/20000 | 1/50000 |

| Capacity | 0-100kgf/cm2 | |

| Oil Pressure Speed | 170±10ml/min | |

| Control Mode | Manual Clutch Control | Automatic measure and return |

| Print Function | n/a | Micro-printer |

| Dimensions (W X D X H) | 45x55x52cm | 55x50x55cm |

| Weight | 60 kg | 50 kg |

| Power | 110V/60Hz or 220V/50Hz | |

FAQs

The Burst Strength Tester for Fabric, or GenBurst, is used to determine the rupture resistance of materials like fabric, leather, and paper. This tester applies hydraulic pressure via a diaphragm until the sample bursts, allowing an accurate assessment of the material's strength under pressure.

This machine is a necessity in industries where fabric or material durability is critical, such as textiles, packaging, and leather goods. By determining how well a material withstands pressure before failing, GenBurst helps manufacturers achieve product reliability and quality.

Complying with ISO 2759 and ASTM D2210 standards, GenBurst provides reliable and consistent results for international quality benchmarks. Available in two models, GenBurst-AD and GenBurst-A, it offers both manual and automatic options with varying control and display types to suit different testing environments.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Burst Strength Tester for Fabric (GenBurst) complies with ISO 2759. This international standard describes the method for determining the bursting strength of paper, board, and similar materials by applying hydraulic pressure. ISO 2759 is particularly relevant for materials that need to withstand pressure without rupturing, as it sets guidelines to assess the durability and quality of materials under stress.

As it relates to industries like packaging and textiles, the implementation of ISO 2759 means that the GenBurst tester provides consistent, internationally recognized results, making certain that materials meet durability requirements for reliable use. By complying with these standards, GenBurst provides a valuable tool for testing and evaluating the structural integrity of materials, contributing to the safety and longevity of products.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Burst Strength Tester for Fabric (GenBurst) is developed to comply with ASTM D2210, a standard that establishes methods for measuring textile bursting strength. This standard outlines the procedures to test a material's resistance to rupture under hydraulic pressure, making certain that fabric materials meet specific durability requirements.

Compliance with ASTM D2210 is vital in industries such as textiles, leather, and packaging, where the material’s capacity to endure pressure directly impacts product quality and reliability. By following ASTM D2210 guidelines, GenBurst provides accurate, standardized results that manufacturers can trust, enabling them to evaluate the resilience of their materials consistently for an array of end-use applications.

Click here to learn more about the product or here to receive a personalized quote.

The Burst Strength Tester for Fabric (GenBurst) operates by measuring the resistance of various materials, such as fabric, leather, and paper, to bursting under pressure. This machine uses a hydraulic diaphragm bursting system, which applies controlled hydraulic pressure to the specimen through a flexible diaphragm. As the pressure builds, it tests the material's durability by simulating conditions where it would be subjected to high stress.

Once the pressure reaches the material’s rupture point, the tester records the exact pressure at which bursting occurs. This allows manufacturers to understand the material's strength threshold. With options like manual and automatic control, GenBurst provides both LED and PLC touchscreen displays for monitoring results. This process not only offers precise data on burst resistance but also aids in comparing different materials under standardized conditions, meeting international standards like ISO 2759 and ASTM D2210.

Click here to learn more about the product or here to receive a personalized quote.

Both the GenBurst-AD and GenBurst-A models of the Burst Strength Tester for Fabric are equipped with pressure transducers as their primary sensors. These transducers measure the pressure applied to the specimen with high accuracy, allowing for the precise determination of the material’s burst strength.

Pressure transducers are critical in making sure that both models maintain consistent and reliable measurements, capturing the exact pressure levels needed to evaluate material durability. This sensor type is well-suited to assessing burst strength across a variety of materials like fabric, leather, and paper, providing dependable performance in both models, whether manually or automatically controlled.

Click here to learn more about the product or here to receive a personalized quote.

The GenBurst-AD model of the Burst Strength Tester for Fabric uses an LED display, providing a simple and straightforward interface for viewing test results and settings. This display mode is effective for basic operations, delivering clear readings without complex interaction.

In contrast, the GenBurst-A model features a PLC touchscreen display. This advanced display allows for a more interactive experience, enabling users to control and adjust settings directly on the screen with ease. The touchscreen also offers greater functionality, making it suitable for more complex testing requirements and a smoother user experience. The choice between an LED display and a PLC touchscreen display provides flexibility, catering to different testing environments and user preferences.

Click here to learn more about the product or here to receive a personalized quote.

The GenBurst-AD model of the Burst Strength Tester has a load resolution of 1/20,000, which allows it to provide precise measurements suited to general testing needs. This level of resolution is effective for accurate readings, ensuring dependable results for material burst strength tests.

The GenBurst-A model offers a higher load resolution of 1/50,000, providing even finer measurement detail. This higher resolution is advantageous for applications requiring increased sensitivity and precision, making it an ideal choice for high-precision testing environments. The two models offer flexibility, allowing users to select the load resolution that ideally fits their testing requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenBurst-AD model of the Burst Strength Tester for Fabric operates with a manual clutch control system. This control mode requires the user to engage and adjust the machine manually, offering hands-on control over the testing process, which can be beneficial in applications where fine manual adjustments are preferred.

In contrast, the GenBurst-A model features an automatic measure and return control mode. This automated system allows the machine to handle testing operations independently, measuring and resetting itself after each test. This mode is ideal for high-throughput environments, as it reduces operator intervention, making testing more efficient and user-friendly.

Click here to learn more about the product or here to receive a personalized quote.

The GenBurst-A model of the Burst Strength Tester for Fabric includes a micro-printer for direct test results printing. This feature allows users to quickly document and record measurements, making it convenient for applications that require a physical record of each test. The integrated micro-printer streamlines the documentation process, which is notably useful in quality control environments where maintaining detailed records is an important requirement.

The GenBurst-AD model, however, does not include print functionality. This model is suited to applications where on-the-spot printouts are not necessary, providing a simpler setup for users who prefer digital recording or external documentation methods. This difference in functionality allows each model to cater to varying user needs in testing environments.

Click here to learn more about the product or here to receive a personalized quote.

The GenBurst-AD model has dimensions of approximately 17.7 x 21.7 x 20.5 inches (45 x 55 x 52 cm), which makes it suitable for smaller laboratory spaces that require efficient space utilization.

The GenBurst-A model is slightly larger, with dimensions of 21.7 x 19.7 x 21.7 inches (55 x 50 x 55 cm). This additional size accommodates features like the PLC touchscreen and micro-printer, allowing the PLC to provide enhanced functionality while still maintaining a manageable footprint within the laboratory environment.

Click here to learn more about the product or here to receive a personalized quote.

The GenBurst-AD and GenBurst-A models of the Burst Strength Tester for Fabric differ in a number of key aspects, each designed to suit specific testing needs.

- Display and Control: The GenBurst-AD model is equipped with an LED display and uses manual clutch control, making it straightforward and ideal for users who prefer simple manual operation. In contrast, the GenBurst-A model features a PLC touch screen with automatic measure and return control, allowing for a more interactive and automated experience, useful in high-throughput environments.

- Print Functionality: Only the GenBurst-A includes a micro-printer for direct printing of test results, allowing immediate documentation. GenBurst-AD lacks a print function, which simplifies its design for labs that do not require on-the-spot printouts.

- Load Resolution: The GenBurst-AD offers a load resolution of 1/20,000, while the GenBurst-A provides a finer 1/50,000 resolution, perfect for applications needing higher sensitivity and precision.

As a result of these distinctions, the GenBurst-AD can be used for basic manual testing applications, whereas the GenBurst-A is designed for advanced, automated use, thereby improving accuracy and operational efficiency.

Click here to learn more about the product or here to receive a personalized quote.

The Burst Strength Tester for Fabric, available in the GenBurst-AD and GenBurst-A models, is valuable for a range of industries that rely on material durability. Textile manufacturers can use this tester to assess fabric strength under pressure, assuring high-quality standards in products like clothing, upholstery, and technical textiles. By determining burst resistance, manufacturers can verify that their materials meet the durability and safety requirements for a range of applications.

This tester is also beneficial for leather goods and packaging manufacturers, where strength and resistance to pressure are necessary for product longevity and reliability. Quality control labs and research centers can also benefit, as the device meets international standards like ISO 2759 and ASTM D2210, allowing them to conduct consistent, compliant testing.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

ICI / Mace Snag Tester

Discover the Fabric Textile ICI / Mace Snag Tester, a reliable tool for assessing fabric snagging under normal wear conditions.

Moving Die Rheometer (MDR)

Introducing the NG-MDR Moving Die Rheometer, your solution for accurately assessing the curing and processing characteristics of vulcanized rubber compounds. Designed for precision, this state-of-the-art rheometer captures the characteristic curve and parameters of rubber vulcanization by measuring the torque applied to the oscillating die.

Aging Oven – High-Temperature Chamber – NG-AGOV-ADV

The NG-AGOV-ADV Aging Oven is designed for high-temperature testing of rubber, plastics, and insulating materials. It features programmable PID control, uniform airflow, and forced convection for stable and repeatable aging cycles. This system supports global testing standards including ISO 188, ASTM D573, and IEC 60216-4-1. With its durable stainless-steel chamber and user-friendly interface, it’s ideal for R&D, quality control, and certification labs.

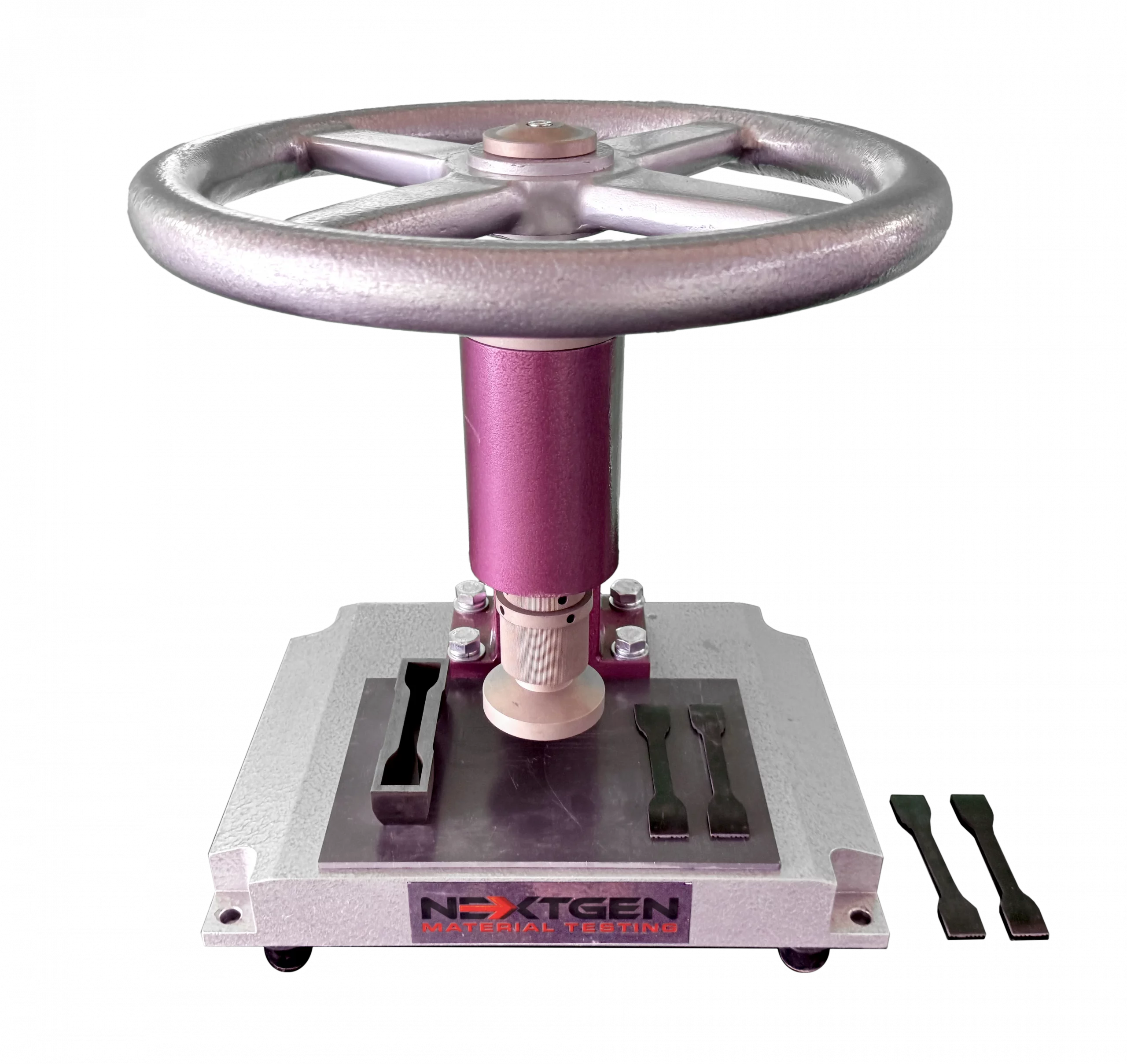

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

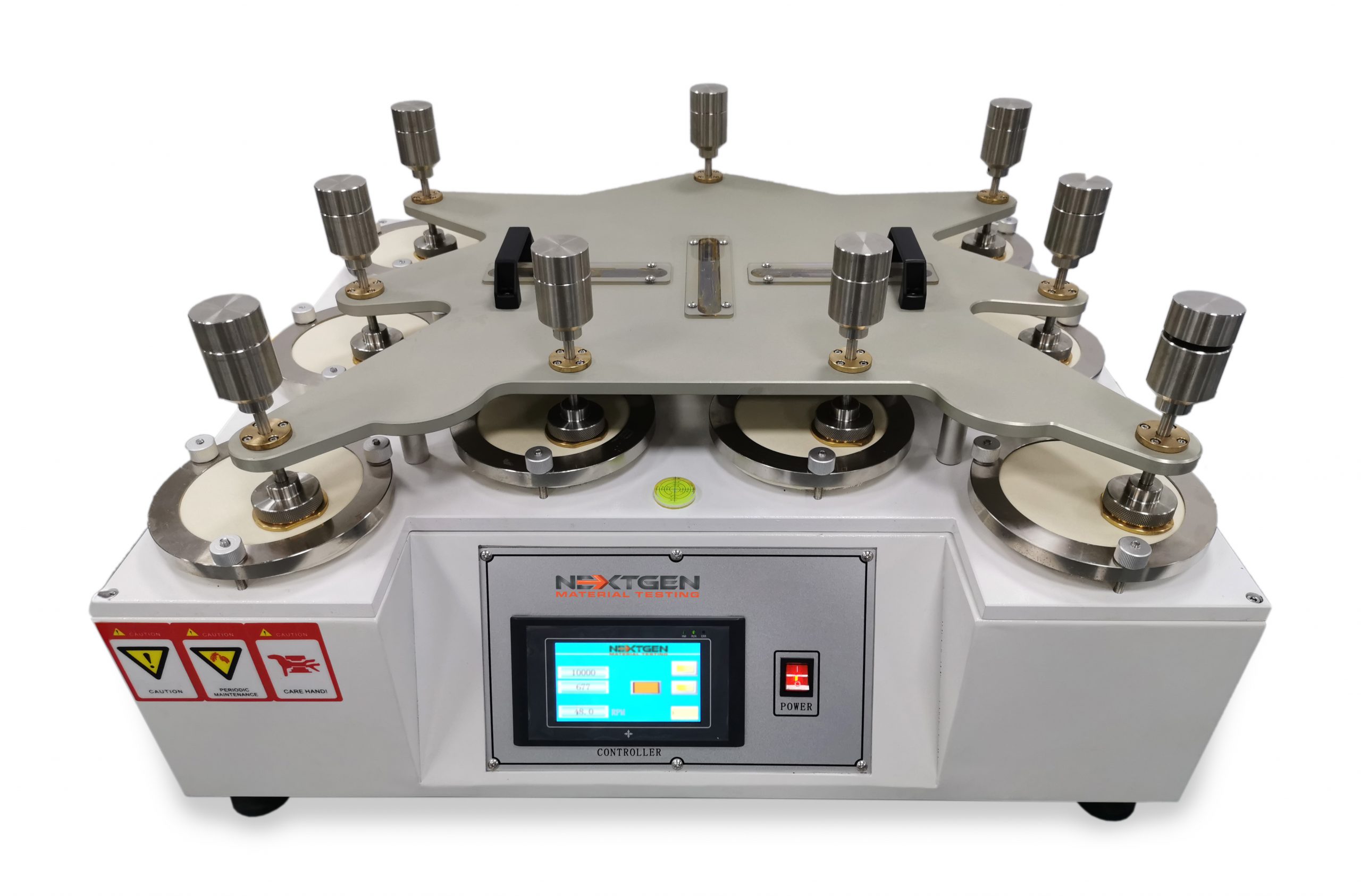

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.