Looking for a reliable electromechanical universal testing machine that fits your lab’s needs – whether compact and precise or built for heavy-duty performance? At NextGen Material Testing, we’ve just relaunched our NG-EML Series – a refined family of electromechanical UTMs designed to support everything from everyday quality control to advanced materials research.

The updated NG-EML lineup brings better control, wider force ranges, improved user safety, and smarter software integration — all in one cohesive platform. In this article, we’ll walk you through what’s new, what each model offers, and how these systems can support your team’s testing workflow. If you’re curious about what’s possible with our newest generation of UTMs, keep reading.

What’s New in the NG-EML Electromechanical UTM Series

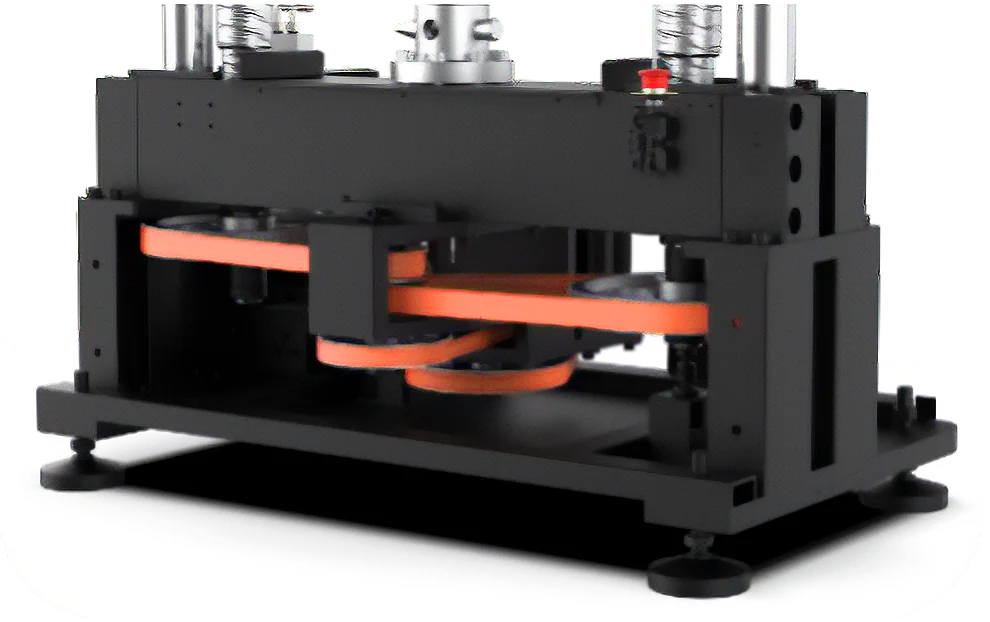

The NG-EML Series represents a new generation of electromechanical universal testing machines designed to meet the evolving needs of modern material testing. These systems are built for flexibility — capable of performing tensile, compression, flexural, and cyclic tests on an array of materials including metals, polymers, composites, rubbers, and thin films.

Designed to handle test forces from as low as 50 N up to 1000 kN, the NG-EML Series is suited for everything from delicate micro-specimens to heavy industrial samples. Built for both industrial and laboratory settings, the NG-EML Series offers stable, precise testing for a variety of applications.

The lineup includes four core models:

- A Series – compact, single-column bench-top system for low-force testing (50 N to 5 kN); ideal for small components and space-constrained labs.

- B Series – dual-column bench-top machine with a mid-force range (10 N to 20 kN); perfect for versatile, everyday testing.

- C Series – available as bench-top or floor-standing, this model handles medium-to-high force applications (5 kN to 50 kN) and offers installation flexibility.

- D Series – a floor-standing system with a high capacity that is specifically engineered for heavy-duty testing (50 kN to 1000 kN); a strong fit for demanding industrial environments.

While each model serves a unique purpose, they all share the same refined engineering, reinforced frame structures, and updated hardware. The latest generation introduces greater stiffness, smoother motion control, and improved load accuracy across the board. Whether you’re testing soft elastomers or ultra-high-strength alloys, each machine in the NG-EML Series is built to produce reliable and consistent outcomes.

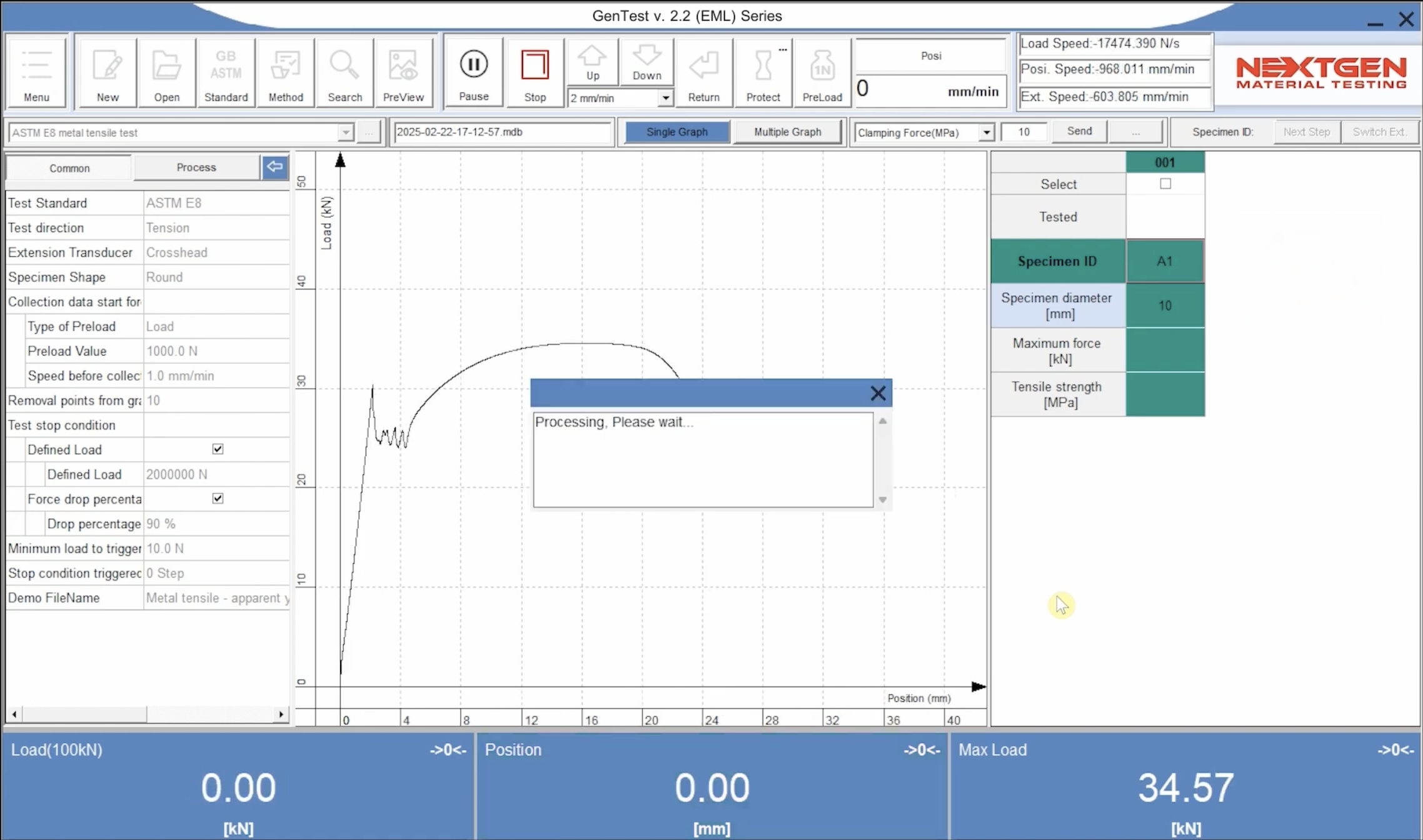

All systems are powered by GenTest™, our intuitive and powerful testing software that simplifies test setup and data management. With real-time visualization, ready-to-use standards-based methods, and flexible configuration tools, our software gives your team full control without the learning curve.

Explore the NG-EML Electromechanical UTM Models

Now that you’re familiar with the NG-EML Series as a whole, it’s time to take a closer look at the four individual systems that make up this lineup. Every model, from high-capacity floor units to compact bench-top machines, was created with the specific testing requirements in mind.

In the following sections, we’ll explore the key features, technical capabilities, and ideal applications of the A, B, C, and D Series. Whether you’re evaluating speed, frame stiffness, footprint, or force range, this breakdown will help you understand which system fits your lab or production floor best.

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A is the most compact model in the lineup, designed for low-force material testing in space-conscious environments. This system provides precision and control for delicate specimens without sacrificing stability, thanks to its single-column frame and force capacity of 50 N to 5 kN.

Despite its small footprint, the Series A offers a high-speed, low-vibration drive system with crosshead speeds up to 2400 mm/min and a return speed of 3000 mm/min, helping labs maintain efficiency during high-throughput workflows.

The rigid frame is supported by dual linear guide rails and pre-loaded precision ball screws that guarantee accurate, coaxial motion across the full travel range. Combined with a high-resolution optical encoder (0.0133 μm), the system offers excellent positioning accuracy — a necessity for tests that require microdisplacement control.

Series A is especially well-suited for testing:

- Plastics, rubbers, thin films, wires, foams, paper, and packaging

- Fine components such as medical sutures, adhesives, and microelectronics

- Specimens requiring minimal preload or controlled low-speed movement

In addition to its mechanical performance, the Series A includes:

- A 24-bit closed-loop digital control system (sampling at 1200 Hz)

- Real-time safety logic with overload, travel, and temperature monitoring

- A compact, ergonomic remote handset with touchscreen and rotary dial for local control

- Optional PC-mounted touchscreen interface for fully independent operation

The machine is compatible with a broad array of manual and pneumatic grips, extensometers, temperature chambers, and test accessories. Modular integration allows quick setup changes without manual recalibration.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

Stepping up from the compact A Series, the NG-EML Series B offers a more robust dual-column bench-top design with enhanced stiffness, expanded test space, and a higher force capacity of 100 N to 10 kN. It’s an excellent fit for labs and research centers that require extra stability and broader material compatibility without committing to a full floor-standing system.

Compared to its single-column counterpart, the B Series features reinforced dual guidance columns, providing greater lateral stability and axial alignment — especially useful when working with thicker specimens or those requiring higher test loads. Despite the added strength, it remains compact enough for a bench setup and is optimized for both flexibility and precision.

Compared to its single-column counterpart, the B Series features reinforced dual guidance columns, providing greater lateral stability and axial alignment — especially useful when working with thicker specimens or those requiring higher test loads. Despite the added strength, it remains compact enough for a bench setup and is optimized for both flexibility and precision.

The drive system includes a maintenance-free direct-drive servo motor with a high-rigidity synchronous belt, delivering test speeds up to 2000 mm/min and ultra-smooth control for both fast and ultra-slow procedures. Combined with a position resolution of 0.011 µm, this makes the system suitable for everything from high-speed throughput to delicate strain-rate-sensitive testing.

Materials and test types commonly handled by Series B include:

- Reinforced plastics, elastomers, and foams

- Soft metals, thin sheets, solder joints

- Flexible electronics, adhesives, textiles, and packaging

- Biocompatible materials and environmental test specimens

The B Series also introduces additional data processing power with six synchronized analog input channels and real-time acquisition at 1200 Hz, making it an optimal choice for advanced test procedures, including cyclic, ramped, or temperature-conditioned tests.

Control flexibility is another key strength. Operators can choose between a handheld 3.5” touchscreen controller and an optional PC-mounted industrial touchscreen with full GenTest™ software integration. Voice prompts, real-time test visualization, quick method loading, and auto-recognition of accessories (via TEDS) make daily use simple and efficient.

NG-EML Series C – Dual Column Floor Standing UTM (500 N – 50 kN)

The NG-EML Series C marks the transition from bench-top to full floor-standing power, offering a serious upgrade in both test force and physical capacity. With a working range of 500 N to 50 kN, this dual-column model is designed for labs that require dependable throughput, rock-solid frame stiffness, and enough vertical travel for long or bulky specimens.

Unlike Series B, which balances compactness with versatility, Series C is built to handle heavier-duty tasks — from standard metal tension tests to high-elasticity polymer compression and flexural testing. The larger frame offers expanded space between columns and a longer vertical stroke, making it a go-to solution for users working with rigid or oversized materials.

The system includes the same precision servo-driven drive and pre-loaded ball screws used in other models, but housed in a reinforced frame structure for added mechanical integrity during high-force operations. It supports test speeds up to 1000 mm/min, making it ideal for both static and dynamic test scenarios.

Common applications for the Series C include:

- Structural plastics, metals, alloys, and carbon-fiber composites

- Standardized tensile tests for ASTM D638, ISO 527, and related methods

- Flexural, peel, shear, and puncture tests on rigid or semi-rigid specimens

- Automotive component validation, aerospace materials testing, and R&D

With the larger test envelope comes more room for specialty grips, extended extensometers, and temperature/environmental enclosures — all plug-and-play thanks to the universal mounting system and GenTest™’s smart accessory recognition.

NG-EML Series D – High-Capacity Floor Standing UTM (50 kN – 1000 kN)

At the top end of the NG-EML product family stands the Series D — a powerful line of floor-mounted universal testing machines engineered for demanding, high-load applications. This series is well-suited for testing numerous component types, including anchor systems, large-scale assemblies, and structural metals, with force capacities between 50 kN and 1000 kN.

The machines are equipped with heavy-duty dual-space frames, precision-grade actuator control, and full compliance with ASTM and ISO testing protocols. Built for precision and reliability, Series D enables accurate tensile, compression, bending, and flexural testing, even under extreme mechanical stress.

The machines are equipped with heavy-duty dual-space frames, precision-grade actuator control, and full compliance with ASTM and ISO testing protocols. Built for precision and reliability, Series D enables accurate tensile, compression, bending, and flexural testing, even under extreme mechanical stress.

The Series D lineup includes four models:

- NG-EML 50–100 – Entry-level high-force machine offering 50 kN or 100 kN options, with fast return speed (1200 mm/min) and outstanding 0.0095 μm resolution. Ideal for strong plastics, smaller metal samples, and moderate-force structural elements.

- NG-EML 200–300 – Versatile mid-range system available in 200 kN and 300 kN force levels, with enhanced frame stiffness (380 kN/mm) and high-speed testing up to 600 mm/min. Designed for metals, polymers, and composites in R&D and QC labs.

- NG-EML 500–600 – Robust industrial-grade model with 500 kN and 600 kN options. High load-bearing capacity (900 kN/mm frame stiffness) and ultra-precise 0.011 μm resolution make it suitable for structural-grade steels, rebar, and pressure components.

- NG-EML 1000 – The flagship 1000 kN model offers maximum force capacity, the highest frame stiffness (1300 kN/mm), and stability for full-scale materials testing in civil, aerospace, and heavy manufacturing environments.

Every model in the Series D family comes with built-in safety protocols, reliable dual-zone operation, and a durable design meant to withstand years of rigorous use. Additionally, they are fully compatible with our GenTest™ software, providing the same level of control and smooth testing experience as the rest of the NG-EML Series.

GenTest™ Software – Smart Control for Every Operator

All NG-EML Series machines come equipped with GenTest™, our advanced data acquisition software created to simplify even the most complex mechanical testing tasks. Whether you’re working in a high-volume lab or using a universal testing machine for the first time, GenTest™ delivers a clean, intuitive interface that makes setup, execution, and reporting fast and straightforward.

Operators can choose from a wide library of pre-configured test methods compliant with ASTM, ISO, DIN, EN, and BS standards. Real-time data capture, built-in analysis tools, and customizable reports help users—from beginners to experienced engineers—get accurate results without the learning curve.

GenTest™ is optimized for tensile, compression, flexural, and fatigue testing, and it’s fully integrated with every model in the NG-EML lineup. No additional configuration needed—just clear results, faster decisions, and greater confidence in every test.

Complete Range of Grips and Fixtures – Built for Every Application

To unlock the full potential of your NG-EML Series Universal Testing Machine, NextGen offers a comprehensive catalog of high-performance grips and fixtures. These accessories are engineered to comply with ASTM, ISO, and other international standards, guaranteeing secure specimen alignment, consistent loading, and precise, repeatable outcomes for all testing modes.

Whether your test involves tensile, compression, flexural, peel, puncture, or shear forces, NextGen’s grip solutions cover virtually every material and geometry. For metals and composites, wedge-action grips provide high-capacity, self-tightening performance under heavy loads. Pneumatic grips offer quick, consistent clamping for rubber, plastics, and textiles. Side-action and self-tightening grips accommodate soft or deformable specimens, while snubbing grips and threaded holders are available for wire, cable, and fastener testing. Specialized bending fixtures, including 3-point and 4-point setups, support rigorous flexural testing of plastics, wood, and structural components.

Whether your test involves tensile, compression, flexural, peel, puncture, or shear forces, NextGen’s grip solutions cover virtually every material and geometry. For metals and composites, wedge-action grips provide high-capacity, self-tightening performance under heavy loads. Pneumatic grips offer quick, consistent clamping for rubber, plastics, and textiles. Side-action and self-tightening grips accommodate soft or deformable specimens, while snubbing grips and threaded holders are available for wire, cable, and fastener testing. Specialized bending fixtures, including 3-point and 4-point setups, support rigorous flexural testing of plastics, wood, and structural components.

From R&D and quality control labs to demanding industrial environments, NextGen’s grips and fixtures are engineered to perform—precisely, reliably, and safely. Our solutions are tailored to support virtually any test standard, helping your lab adapt to new requirements without the need for third-party components.

Integrated directly with the NG-EML Series frames and GenTest™ software, these accessories complete your universal testing system—a turnkey platform with everything you need to execute professional-grade testing from day one.

Frequently Asked Questions About the NG-EML Series Universal Testing Machines

Over the years, we’ve worked closely with clients exploring our electromechanical universal testing machines, including the NG-EML models. Throughout these conversations, certain questions come up again and again. To help you make a confident and informed decision, we’ve outlined clear, detailed answers to the most common questions below.

1. Are NG-EML Series Machines Compatible With International Testing Standards?

Yes, NG-EML Series Universal Testing Machines are fully compatible with a broad range of international standards for tensile, compression, and flexural testing. Each model in the series can be configured to meet the requirements of globally accepted protocols, making them suitable for use in accredited laboratories, production control, and advanced research environments.

Yes, NG-EML Series Universal Testing Machines are fully compatible with a broad range of international standards for tensile, compression, and flexural testing. Each model in the series can be configured to meet the requirements of globally accepted protocols, making them suitable for use in accredited laboratories, production control, and advanced research environments.

Below is a list of the key standards supported by NG-EML Series UTMs:

- ASTM E8 – Tension testing of metallic materials

- ASTM E4 – Force verification for universal testing machines

- ASTM D638 – Tensile properties of plastic specimens

- ASTM D790 – Flexural properties of plastics and composites

- ASTM D412 – Tensile testing of rubber and elastomers

- ASTM E21 – Tension testing of metallic materials at elevated temperatures

- ASTM E1012 – Verification of testing frame alignment

- ISO 7500-1 – Verification of static uniaxial testing machines

- ISO 6892 / ISO 6892-1 – Tensile testing of metallic materials at room temperature

- ISO 527 – Determination of tensile properties of plastics

- ISO 604 – Compression testing of plastics

- ISO 178 – Flexural properties of plastics

- ISO 37 – Tensile stress-strain testing of rubber

- ISO 1184 – Tensile testing of plastic films

- ISO 2439 – Indentation testing of flexible cellular materials

- GB/T 228 & GB/T 16825.1 – Standards for metal tension and force calibration

- NADCAP & NASM 1312B – Aerospace testing and alignment standards

These machines are not only capable of meeting the above standards, but can also be delivered with full traceable calibration, alignment verification, and documentation packages to help testing facilities maintain certification and audit readiness at all times.

2. Do You Offer Professional Calibration Services for NG‑EML Series Systems?

Yes. NextGen provides certified calibration services for all NG‑EML Series models to help maintain accuracy and compliance with relevant testing standards.

Calibration services include:

- Force verification – ASTM E4, ISO 7500-1

- Displacement and extensometer verification – ASTM E83, ISO 9513

- Load frame alignment – ASTM E1012

- Traceable calibration procedures – ISO/IEC 17025:2017, ANSI/NCSL Z540-1-1994

Calibrations are carried out on-site or during commissioning and include validation of the system’s load cells, extensometers, encoders, and software integration. A traceable calibration certificate is provided after each procedure.

Additional services:

- Diagnostic checks of system performance

- Operator training for up to 3 users on calibration use and result interpretation

- Documentation for audit preparation, including NADCAP-related cases

Annual calibration is recommended to support testing accuracy, regulatory compliance, and audit readiness.

3. Do You Offer Professional Calibration Services for NG‑EML Series Systems?

Yes. NG‑EML Series systems are supported by a comprehensive stock program to ensure uninterrupted operation and fast maintenance turnaround.

Key highlights include:

- Wide inventory of grips, extensometer accessories, seals, load cells, and other wear components

- NIST-traceable, pre-calibrated parts ready for immediate dispatch

- Bulk ordering options for high-use items like seal kits and jaw faces

- Plug-and-play compatibility with GenTest™ software and NG‑EML hardware

- Regional warehouses for fast global delivery

- Expedited sourcing for rare or custom components

All spare parts are designed to support uptime and reduce dependency on service technician visits.

4. What Support and Service Options Do You Provide After Purchase?

Each NG‑EML Series UTM is covered by NextGen’s Lifetime Product Support Advantage — from installation through years of operation.

Support options include:

- Remote assistance for over 95% of service inquiries, minimizing downtime

- Certified local partners coordinated by our technical team for on-site support

- Global service coverage with standardized system design for easy servicing

- Optional training sessions and system checks during calibration or installation

- Full documentation support for audits, validations, and accreditations

NextGen’s support model is built for flexibility — whether you require a quick fix, annual system calibration, or long-term service planning.

5. Can NG‑EML Systems Be Customized to Specific Testing Needs?

Yes. NG‑EML Series Universal Testing Machines are modular by design and can be tailored to meet the technical requirements of diverse material testing applications.

Customization options include:

- Load frame configuration: Single- or dual-column models, custom crosshead travel ranges, and reinforced frames for high-capacity applications.

- Load cells: Interchangeable load cells ranging from sub-kilonewton capacities for thin films to 300kN+ for structural metals testing.

- Grips and fixtures: A wide selection of compatible fixtures, including wedge, pneumatic, hydraulic, flexural, and peel grips to support industry-specific standards.

- Extensometers: Options include clip-on, automatic, non-contact (video-based), and high-elongation extensometers based on material type and strain range.

- Software modules: GenTest™ software includes optional modules for cyclic testing, stress relaxation, creep, modulus analysis, and custom reporting formats.

- Electronics and control interfaces: Machines can be delivered with PC-controlled or stand-alone touch interface systems depending on the lab’s workflow.

These configurations allow users to match the machine setup to the specimen type, test frequency, industry regulations, and throughput requirements — from basic R&D to high-volume QC labs.

6. Do You Offer Support for Laboratory Accreditation and Documentation?

Yes. NG‑EML systems are designed to support compliance with a wide range of international standards and can assist laboratories preparing for audits or accreditation processes.

Support includes:

- Traceable calibration certificates for load cells, extensometers, and displacement sensors, aligned with ISO/IEC 17025:2017.

- Documentation packages that include technical drawings, system validation reports, user manuals, maintenance logs, and compliance statements.

- Standard compliance: NG‑EML systems meet ASTM E4, ISO 7500-1, ISO 6892, ASTM D638, ISO 527, and other common testing standards across different industries.

- Alignment verification protocols (ASTM E1012) available for labs seeking NADCAP approval or equivalent aerospace/defense validation.

- Remote or on-site audit preparation support, available upon request, including documentation review and guidance on system verification procedures.

This infrastructure helps reduce audit preparation time and allows labs to meet accreditation requirements more efficiently, whether working with ISO, ASTM, or sector-specific schemes.

7. How Do You Guarantee Short Lead Times for Urgent Lab Requirements?

NextGen maintains an integrated logistics and inventory model designed to fulfill standard NG‑EML Series orders quickly, even under tight timelines.

Key factors that enable fast delivery:

- Pre-configured models: Popular NG‑EML configurations and accessories are stocked and partially assembled at regional distribution centers.

- Modular architecture: The NG‑EML system’s modular build allows for rapid assembly and final calibration without long fabrication delays.

- Spare part availability: All commonly required components — grips, load cells, actuators, electronics — are maintained in inventory, reducing delays from component sourcing.

- Dedicated production slots: For urgent or large-scale projects, production can be prioritized through dedicated manufacturing timelines.

- Regional shipping hubs: Machines and spare parts are shipped from warehouses for shorter transit time.

In most cases, NG‑EML Series UTMs can be shipped within 2–4 weeks depending on the configuration, with express service available for urgent testing needs.

Electromechanical Testing Systems for All Force Ranges

The NG-EML Series brings together precision, adaptability, and control across its full lineup—from compact bench-top models to high-capacity floor-standing systems.

Whether you’re operating in a fast-paced production environment or a research-driven materials lab, the NG-EML Series delivers consistent performance and full compatibility with a broad range of testing accessories and standards.

If you’re looking to upgrade your testing capabilities with a dependable, scalable solution—this is the series built to meet your goals.

Explore the NG-EML models, contact our team directly, or request a quote online—we’ll guide you toward the best fit for your application.