Rock Mechanics Testing Equipment

Standards

Description

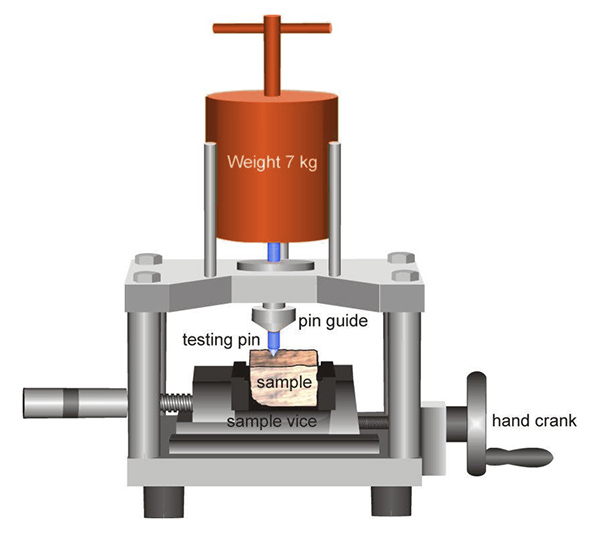

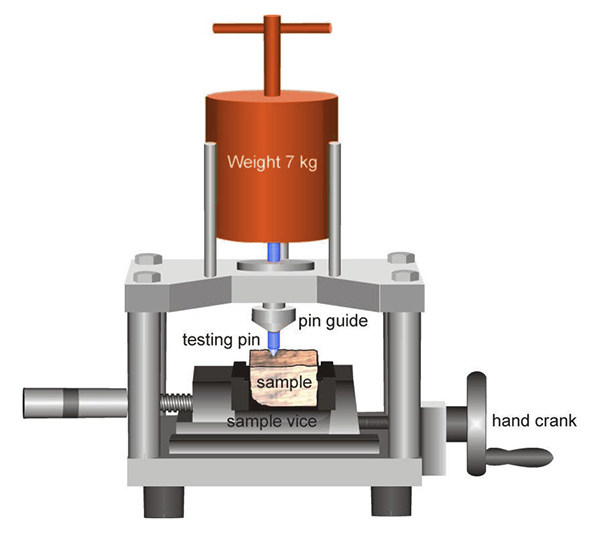

The West Cerchar Abrasivity Index Tester is designed to determine the rock abrasivity index (CAI) for the purpose of quantifying the classification of rock materials abrasivity. This type of test is especially valuable in the mining industries, underground construction and various tunnelling excavation processes. The process of abrasion is the wear and tear of particles from solid surface materials. The apparatus comprises a stationary stylus, a deadweight (70N) placed on top of the stylus, a stiff load frame, a rigid vice to firmly clamp the rock sample and a cross table with 2 adjustable axes for specimen alignment along the two horizontal axes. You can read more in our Mega Blog!

The device comes with a graduated knob for 0.01 mm accurate scratch distance control. Options include an indenter visualization system, spare indenters and a sharpening tool. The former encompasses a digital camera with indenter support and inspection software to reveal the wear amount which is then correlated to the abrasiveness index (CAI). The sharpening tool rapidly sharpens a worn stylus for subsequent scratch tests.

Test Method

First, the sample must be carefully scrutinized to infer the most appropriate scratch location and direction. This is particularly important for rocks exhibiting a high level of anisotropy; that is scratch location and direction should portray the sample’s dominant mineralogy and texture. The sample is then firmly clamped in the vice and the stylus carefully lowered and positioned onto the rock surface so that it is perfectly orthogonal to the rock surface. The standard scratch length and test duration are 10.0 mm and 10 seconds, respectively. During testing, the operator must ensure constant contact between the stylus and rock surface. After testing, the stylus is carefully lifted from the rock surface and removed. Measurements of the tip wear flat are made using a microscope having a minimum magnification of 25x, and are executed by side- or top-view settings.

For each measurement of the wear flat, d, the Cerchar abrasivity index, CAI, is calculated as follows:

CAI = d x 10

A minimum of five test replications are made on a rock surface, each time with a new or re-sharpened stylus. The dimensionless CAI value is reported as the arithmetic mean of five or more replications combined with the standard deviation.

System Benefits

- Compliant with ASTM D7625-10

- User-friendly and easy-to-use manual handling

- Features precision slide for smooth movement of the rock specimen over the required scratch distance

- Easy adjustment of the daylight for different specimen heights

Optional Accessories

West Cerchar Specialty Indenters

West Cerchar Specialty Indenters

The tool includes a set of one hundred (100) sharp steel indenters (i.e. stylus pin). The tip of test pin comprises a conical angle of 90°.

Digital Microscope

After the test, the width of the wear flatness is measured on the stylus tip surface using a digital microscope. The device comprises an indenter holder equipped with digital micrometers, XY stage, a video camera and a dedicated video software (PC not included). The microscope reveals the wear amount which is then correlated to the abrasiveness index (CAI).

Steel Indenter Sharpening Tool

Steel Indenter Sharpening Tool

The sharpening tool rapidly re-sharpens a worn stylus with 90° cone of 1 mm long for subsequent scratch tests.

Technical Specifications

| Standard | ASTM D7625-10 |

| Load | 70 N |

| Maximum specimen height | 150 mm (6 inches) |

| Maximum specimen diameter | 76 mm (3.0 inches) |

| Scratch distance precision | 0.01 mm |

| Steel Stylus | Rockwell Hardness HRC 54/56 |

| Weight | 25 kg |

| Dimensions (WxLxH) | 330 x 500 x 500 mm |

FAQs

Yes, the West Cerchar Abrasivity Index Tester is fully compliant with the ASTM D7625-10 standard, a globally recognized standard issued by ASTM International. This standard specifically outlines the procedures for conducting the Cerchar Abrasion test to accurately determine the abrasivity of rock materials.

By complying with this standard, the West Cerchar Abrasivity Index Tester ensures it follows the prescribed method of testing. This involves the preparation of the rock sample, ensuring constant contact between the stylus and rock surface, and measuring the stylus's tip wear using a microscope with a minimum magnification of 25x. The resulting measurements are then used to calculate the Cerchar Abrasivity Index (CAI), which provides a quantifiable measure of a rock sample's abrasivity.

Furthermore, this compliance ensures that the results generated by the West Cerchar Abrasivity Index Tester are accurate, reliable, and comparable to other tests conducted under the same standard. This allows for consistent classification and understanding of rock abrasivity across various industries, including mining, underground construction, and tunneling excavation. These industries often require a precise understanding of rock abrasivity to make informed decisions about operational strategies and equipment selection, further underlining the importance of compliance with the ASTM D7625-10 standard.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester is specifically designed to ascertain the abrasivity index of rock samples, also known as the Cerchar Abrasivity Index (CAI). This measure is critical for classifying the abrasivity of rock materials, which has substantial implications in industries like mining, tunneling, and underground construction.

The device operates by scratching the surface of a rock sample using a stationary stylus under a set weight. Following the test, the wear on the stylus is meticulously measured, and the extent of this wear indicates the rock's abrasivity. The tester adheres to the ASTM D7625-10 standard, ensuring the reliability and comparability of its results.

By quantifying a rock's abrasivity, the West Cerchar Abrasivity Index Tester provides valuable data that can inform operational strategies, equipment selection, and safety measures in contexts where interactions with rock materials are common. This makes it a powerful tool for engineers, geologists, and other professionals working with rock materials.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester plays a critical role in industries such as mining, underground construction, and tunneling excavation because it accurately measures the abrasivity of rock materials, which is a key factor in these fields.

Rock abrasivity directly impacts the wear and tear on machinery and tools used in these industries. A high abrasivity index indicates that the rock is more likely to cause significant wear on equipment, potentially leading to more frequent maintenance, downtime, and replacement of parts, all of which have cost and operational implications.

By using the West Cerchar Abrasivity Index Tester, these industries can more accurately predict and plan for these challenges. For instance, they can choose the appropriate machinery and tools that can withstand the predicted abrasivity, schedule maintenance activities effectively, and implement strategies to mitigate potential operational challenges.

Moreover, knowing the rock abrasivity also contributes to worker safety. High abrasivity could mean more challenging working conditions, requiring additional protective measures. Hence, the information provided by this tester is invaluable for ensuring both efficiency and safety in these industries.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester offers several additional options that enhance its functionality and usability. These options include:

- Indenter Visualization System: This feature includes a digital camera with indenter support and inspection software. It enables users to visualize the wear on the indenter and thereby determine the abrasiveness index (CAI) more accurately. This system can significantly improve the precision of the tests.

- Spare Indenters: Having spare indenters is useful in maintaining the tester's efficiency. Over time, indenters may wear out due to the abrasion process. Having spare ones readily available ensures that the testing can continue without significant delays.

- Sharpening Tool: The sharpening tool is used to quickly sharpen a worn stylus for subsequent scratch tests. This is essential to keep the stylus in optimal condition, which contributes to the accuracy of the test results.

These additional options enhance the tester's performance, make it more user-friendly, and ensure its longevity.

Click here to learn more about the product or here to receive a personalized quote.

The digital camera, when coupled with the indenter support and inspection software, significantly enhances the functionality of the West Cerchar Abrasivity Index Tester. This indenter visualization system allows for a detailed inspection of the wear amount on the indenter (stylus) post-testing. By capturing high-resolution images of the stylus tip, the digital camera helps accurately quantify the wear. The accompanying inspection software then aids in the analysis of these images.

This wear is directly correlated to the Cerchar Abrasivity Index (CAI), which is the measure of a rock's abrasivity. Thus, the more precise the wear measurement, the more accurate the CAI. The digital camera and software make this measurement process more accurate and less prone to human error, enhancing the tester's overall reliability and precision. This high level of precision is essential in industries such as mining and construction, where accurate knowledge of rock abrasivity significantly impacts operational planning and safety measures.

Click here to learn more about the product or here to receive a personalized quote.

The sharpening tool included with the West Cerchar Abrasivity Index Tester plays a crucial role in maintaining the effectiveness and precision of the tester. During the abrasivity testing process, the stylus, which is used to scratch the rock surface, can become worn. This wear could potentially affect the accuracy of the tests if it is not properly managed.

That's where the sharpening tool comes in. It is designed to quickly and efficiently sharpen a worn stylus, restoring its condition for subsequent scratch tests. By keeping the stylus sharp, the tool ensures consistent and accurate results across all tests. This functionality is particularly valuable when multiple tests are required on a single rock sample or when tests are being conducted on a series of samples, ensuring that the reliability of the tester is maintained throughout the testing process.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester employs a consistent load of 70 Newtons (N) when conducting abrasivity tests on rock samples. This uniform load ensures that the conditions under which the stylus scratches the rock surface remain constant for all samples, creating a standardised environment for testing. This uniformity is crucial as it allows for comparable and consistent results when measuring the Cerchar Abrasivity Index (CAI) across different rock types.

The 70 N load is in line with the requirements stipulated in the ASTM D7625-10 standard, which the West Cerchar Abrasivity Index Tester complies with. This compliance means the tester's procedures align with internationally recognized protocols, lending greater credibility and trust to the results it produces.

By maintaining a consistent load during testing, the West Cerchar Abrasivity Index Tester can produce reliable and accurate measurements of rock abrasivity. These measurements, in turn, provide valuable insights for industries such as mining and construction, where understanding the wear characteristics of rock can significantly impact equipment selection, operational strategies, and safety measures.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester has been designed to accommodate rock specimens with a maximum height of 150 mm, or approximately 6” inches. This provision influences the tester's usability and functionality in several ways.

Firstly, the capability to handle rock samples of this size allows for a more comprehensive and representative analysis of the rock's abrasivity. Larger specimens may provide a more accurate reflection of the rock's characteristics, as they likely contain a broader range of the rock's inherent mineralogical and textural variations.

Secondly, this size accommodation enhances the versatility of the tester. By being able to test specimens of varying sizes, the tester can be applied in a broader range of scenarios and geological settings. This makes the tester a versatile tool, adaptable to different operational needs in industries such as mining, construction, and underground tunnelling.

Finally, the West Cerchar Abrasivity Index Tester ensures its compliance with internationally recognized testing protocols, enhancing the credibility and reliability of the test results. Therefore, this maximum specimen height contributes to both the functionality and the adaptability of the tester.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester is designed to accommodate rock specimens with a maximum diameter of 76 mm, or approximately 3” inches. This specification plays a crucial role in determining the range of rock samples that the tester can handle, influencing its functionality and versatility across various applications.

The ability to accommodate rock samples of this size means that the tester can handle a wide array of rock types, making it a versatile tool for different industrial contexts. Industries such as mining, construction, and tunneling excavation often encounter diverse rock types with varying levels of abrasivity. A tester that can handle larger diameters is beneficial in these scenarios, providing more accurate and representative results.

Larger specimens can offer a more holistic view of a rock's abrasivity, as they can capture more of the potential variations in mineralogical composition and texture within the rock. This leads to a more comprehensive understanding of the rock's abrasivity, informing better decision-making processes in relevant industrial operations.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester provides a high scratch distance precision of 0.01 mm. This precision plays a key role in achieving reliable and accurate testing results. It refers to the degree of control the tester has over the distance that the stylus travels when it scratches the surface of the rock sample. With the ability to measure and control the scratch distance down to hundredths of a millimeter, the tester ensures consistent and repeatable testing conditions.

The importance of this precision lies in its impact on the determination of the Cerchar Abrasivity Index (CAI). The CAI is calculated based on the wear on the stylus after scratching the rock surface. Hence, maintaining a high precision of scratch distance reduces the risk of inaccuracies or inconsistencies in the test results. It ensures that any changes in the CAI can be confidently attributed to the differing abrasivity of the rocks tested, rather than variations in the testing process.

Additionally, the ability to precisely control the scratch distance enables the tester to effectively assess rocks with a wide range of abrasivity levels, enhancing its versatility and applicability across various industries and geological contexts.

Click here to learn more about the product or here to receive a personalized quote.

The steel stylus used in the West Cerchar Abrasivity Index Tester has a Rockwell hardness of HRC 54/56. The Rockwell scale is a standard for measuring the hardness of materials, and the HRC scale specifically measures the hardness of hardened steel. The hardness of the stylus is a crucial aspect of the tester as it directly affects the abrasivity measurements.

A stylus with a hardness of HRC 54/56 is quite hard, which allows it to effectively scratch the rock samples without being easily worn or damaged, thereby ensuring consistent and reliable test results. The hardness of the stylus also plays a role in its durability and longevity, contributing to the overall efficiency and cost-effectiveness of the tester.

Furthermore, the use of a stylus with this specific hardness ensures that the West Cerchar Abrasivity Index Tester can accommodate a wide variety of rock types with different abrasivity levels. This feature enhances the tester's versatility, making it a valuable tool in industries like mining, construction, and tunneling excavation.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester weighs 25 kilograms. This weight plays a role in the tester's stability and mobility. With a weight of 25 kg, the tester is substantial enough to remain stable during testing operations, ensuring that tests are carried out accurately and consistently. The stability offered by this weight prevents any unwanted movement that could potentially interfere with the precision of the tests.

At the same time, at 25 kg, the tester is not overly heavy, which means it can be relatively easily moved or transported as required. This can be particularly beneficial in various industrial contexts such as mining, construction, and underground tunnelling, where the tester may need to be moved between different locations or sites.

Weight of the West Cerchar Abrasivity Index Tester plays a crucial role in balancing the need for stability during testing procedures with the practical considerations of mobility and ease of transportation.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester measures 330 mm in width, 500 mm in length, and 500 mm in height. These dimensions are significant as they impact the tester's footprint and its capacity to accommodate rock samples.

Given its compact size, the tester can be conveniently placed and moved in different working environments without occupying too much space. This makes it particularly suitable for industries such as mining, construction, and underground tunneling, where space can often be at a premium.

Additionally, the dimensions of the tester also define its capacity to hold rock samples for testing. With its height of 500 mm, the tester can comfortably accommodate samples up to 150 mm, allowing for a wide range of rock types to be tested. Furthermore, the dimensions of the tester have been designed to facilitate ease of operation, with the width and length providing a stable and accessible platform for conducting the abrasivity tests.

Click here to learn more about the product or here to receive a personalized quote.

The steel indenter sharpening tool is an integral accessory of the West Cerchar Abrasivity Index Tester. This tool is designed to rapidly sharpen a worn stylus, restoring its tip to a precise 90° cone that is 1 mm long. The sharpening process prepares the stylus for subsequent scratch tests.

The importance of the sharpening tool is twofold. Firstly, it ensures that the stylus maintains its optimal shape and sharpness for accurate and consistent testing. Over time and with repeated testing, the stylus can experience wear and tear, which may affect its performance and the reliability of the test results. By enabling quick and easy sharpening, the tool mitigates these potential issues.

Secondly, the sharpening tool enhances the efficiency of the testing process. Instead of replacing a worn stylus, which could be time-consuming and costly, the user can simply sharpen it and continue with the testing. This increases the lifespan of the stylus and reduces operational downtime, making the tester more cost-effective and efficient for users.

Click here to learn more about the product or here to receive a personalized quote.

The digital microscope is a vital component of the West Cerchar Abrasivity Index Tester. It is used after the testing process to measure the width of the wear flatness on the stylus tip surface. The digital microscope features an indenter holder, digital micrometers, an XY stage, a video camera, and dedicated video software (PC not included).

The central role of the digital microscope is to reveal the amount of wear on the stylus, which is a critical parameter in determining the abrasiveness index, known as the Cerchar Abrasivity Index (CAI). The wear on the stylus is directly proportional to the abrasivity of the rock sample tested. By accurately measuring this wear, the digital microscope allows for a precise calculation of the CAI.

The microscope's capabilities, including its digital micrometers and video camera, ensure high-resolution imaging and precise measurements, contributing to the accuracy and reliability of the testing process. It is, therefore, an indispensable tool in the rock abrasivity testing workflow facilitated by the West Cerchar Abrasivity Index Tester.

Click here to learn more about the product or here to receive a personalized quote.

The optional West Cerchar specialty indenters are a set of additional tools for use with the West Cerchar Abrasivity Index Tester. The set includes one hundred (100) sharp steel indenters, also referred to as stylus pins.

Each indenter features a tip with a conical angle of 90°. These indenters are vital components of the tester, playing a key role in performing the abrasivity test. They are used to scratch the rock sample, and the degree of wear on the indenter's tip after the test provides an indication of the sample's abrasivity.

Having additional indenters at hand can be beneficial for a variety of reasons. For instance, in situations where testing needs to be conducted rapidly or in high volumes, having spare indenters can reduce downtime associated with stylus sharpening. Moreover, in cases where an indenter gets excessively worn or damaged, a replacement can be readily available. Hence, while these specialty indenters are optional, they can significantly enhance the efficiency and convenience of the abrasivity testing process.

Click here to learn more about the product or here to receive a personalized quote.

The West Cerchar Abrasivity Index Tester provides several key system benefits that make it an ideal choice for testing rock abrasivity.

- Compliance with ASTM D7625-10: The tester complies with the ASTM D7625-10 standard, ensuring the reliability and accuracy of the abrasivity index measurements. This standard is widely recognized, so compliance ensures the test results are valid and comparable with other compliant equipment.

- User-friendly and Easy-to-use Manual Handling: The tester is designed for simple, user-friendly manual handling. This makes it accessible to operators with different levels of experience and ensures straightforward operation, reducing the potential for errors.

- Precision Slide for Smooth Movement: The tester features a precision slide that allows for smooth movement of the rock specimen over the required scratch distance. This feature ensures that the scratch test is performed accurately and consistently, providing reliable results.

- Easy Adjustment of the Daylight for Different Specimen Heights: The tester allows for easy adjustment of the daylight - the gap between the testing stylus and the rock specimen - to accommodate different specimen heights. This feature enhances the versatility of the tester, enabling it to handle a range of rock sample sizes with ease.

Click here to learn more about the product or here to receive a personalized quote.

The testing method utilized by the West Cerchar Abrasivity Index Tester involves a specific sequence of steps to accurately assess the abrasivity of rock samples.

- Scrutinize the Sample: Initially, the rock sample is carefully scrutinized to identify the most appropriate scratch location and direction, especially for rocks exhibiting a high level of anisotropy. The chosen scratch location and direction should best represent the sample’s dominant mineralogy and texture.

- Clamp and Position the Stylus: Next, the sample is firmly clamped in the vice, and the stylus is carefully lowered and positioned onto the rock surface, ensuring it is perfectly orthogonal to it.

- Scratch Test: The standard scratch test is performed, involving a scratch length of 10.0 mm and a duration of 10 seconds. The operator ensures constant contact between the stylus and rock surface during this phase.

- Post-Test Procedures: After the test, the stylus is carefully lifted from the rock surface and removed.

- Measure the Wear: Lastly, measurements of the stylus tip's wear flat are made using a microscope with a minimum magnification of 25x, with measurements conducted via side- or top-view settings.

Click here to learn more about the product or here to receive a personalized quote.

The Cerchar Abrasivity Index (CAI) is a measure used to classify and quantify the abrasivity of rock materials. This is an essential parameter in industries such as mining, construction, and tunneling, where understanding the wear and tear on machinery from rock materials can influence operational efficiency and equipment lifespan.

The CAI is calculated using the West Cerchar Abrasivity Index Tester following a specific procedure. After a rock sample has been scratched with the stylus for a specific distance and duration, the stylus is removed and the wear flat, i.e., the worn area on the stylus tip, is measured using a microscope.

The width of this wear flat (denoted as 'd') is then used in the calculation of the CAI. The formula for the calculation is straightforward: CAI = d x 10. This yields a dimensionless value, which is reported as the arithmetic mean of five or more test replications, combined with the standard deviation.

Click here to learn more about the product or here to receive a personalized quote.

The precision slide feature is a significant component of the West Cerchar Abrasivity Index Tester, contributing directly to its performance and the accuracy of the results it generates.

In the process of determining the rock abrasivity index (CAI), the rock specimen needs to move smoothly over a prescribed scratch distance under the stylus. Any irregular or inconsistent movements could potentially affect the validity of the test results.

The precision slide feature ensures this smooth movement of the rock specimen over the required scratch distance. It provides a consistent, controlled environment for the stylus to make accurate, repeatable scratches on the rock specimen. This, in turn, results in more reliable measurements of the wear flat on the stylus tip, which forms the basis of the CAI calculation.

Precision slide feature greatly enhances the tester's performance, ensuring it can reliably and accurately quantify the abrasivity of various rock materials.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Semi-Automatic Core Grinding Machine - NG-CoreGrind 1000

Our Semi-Automatic Core Grinding Machine (also known as Coregrinder or Core Grinder) is the preferred alternative to the traditional rubber / sulfur capping methods used by Quality Labs

Rock Core Cutter and Masonry Saw

Our Rock Core Cutter and Masonry Saw designed for preparing concrete, rock, or natural stone cores and test specimens.

Rock Shear Box Apparatus

This apparatus was originally developed at Imperial College, London, by Professor E. Hoek. It is a simple and practical method of determining the strength and slope stability of rock, both in the field and in the laboratory.

Rock Strength Index Apparatus

The apparatus consists of a load frame 60 kN cap. with a hydraulic loading ram actuated by a hand pump. The frame is adjustable for testing samples up to 102 mm dia.

Core Trimmer and Cut-Off Machine - NG-CoreTrim

NG-CoreTrim is used to obtain rock samples perfectly machined (cube, prisms, etc) from irregular rock or core pieces. It is supplied complete with a proper vice to hold irregular pieces firmly in place up to 7x14

Laboratory Coring Machine and Bits

This machine is specifically used in the laboratory for cutting core samples from hard materials such as rock and concrete.

Double Faced Rock Core Grinder Machine NG-CoreGrind 2000

CoreGrind Double faced core grinder machine is designed to grind and polish the end surfaces of concrete & rock cube and cylinder specimens.