Cement & Concrete Testing Equipment

Standards

Certified

Description

The Blaine apparatus is used to determine the fineness of cement (and other powdery products) in terms of specific surface in cm2g-1

The digital Automated BlaineGenPLUS model is manufactured according to specifications of the following standards:

- EN196-6 Methods of testing cement Determination of fineness.

- ASTM C 204 "Fineness of Hydraulic Cement by Air Permeametry Method".

In this test, cement is compressed under conditions defined by standard, taking a certain amount of air through the powder compacted.

The resistance to air flow is directly proportional to the fineness of grain, as long as the same testing conditions are respected.

The determination of specific surface serves to control the uniformity of the milling process in the cement plant, but can also be applied to control the particle size of other powder materials. Learn more about the full scope of Blaine Apparatus methods and operational instructions here.

Unique Features

No Computer is Required

The Automated Blaine Apparatus works as a stand-alone system. Alternatively,

operator may connect the equipment to PC and manage results, export data,

generate reports via the supplied software WinPerm64.

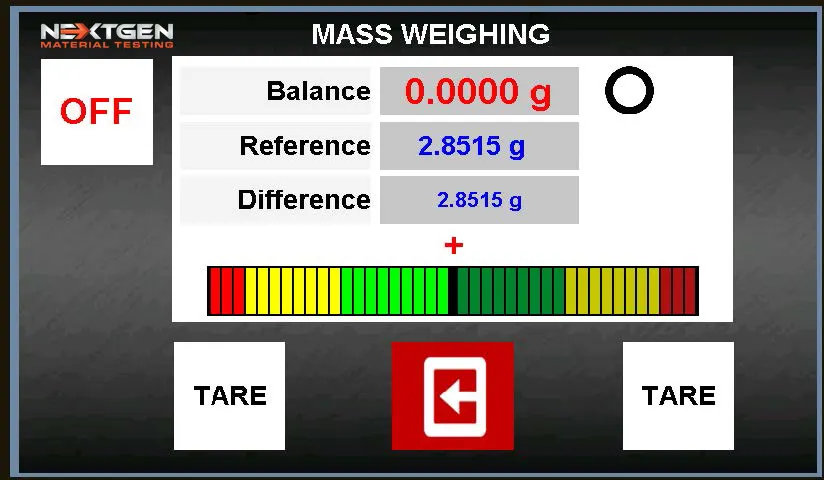

Integration with Analytical Balance

The system can measure the mass directly through the equipment.

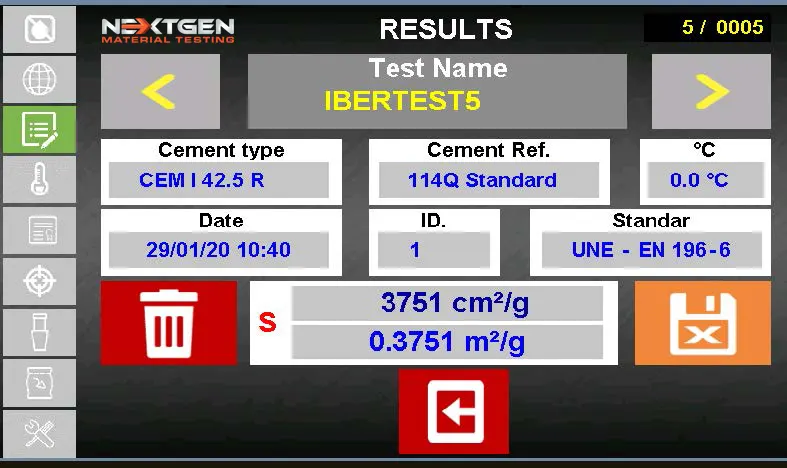

Ergonomic Visualization of Tests Results

This is achieved thanks the standard 7" LCD touch screen display with IP65

protection.

4 Level Sensors

Designed to detect the correct manometric fluid level before the test and to

determine when the oil has dropped completely between measurements, optimizing

operating cycle times.

Automation

The operation of BLAINEGENPLUS is automatic in as concerns to:

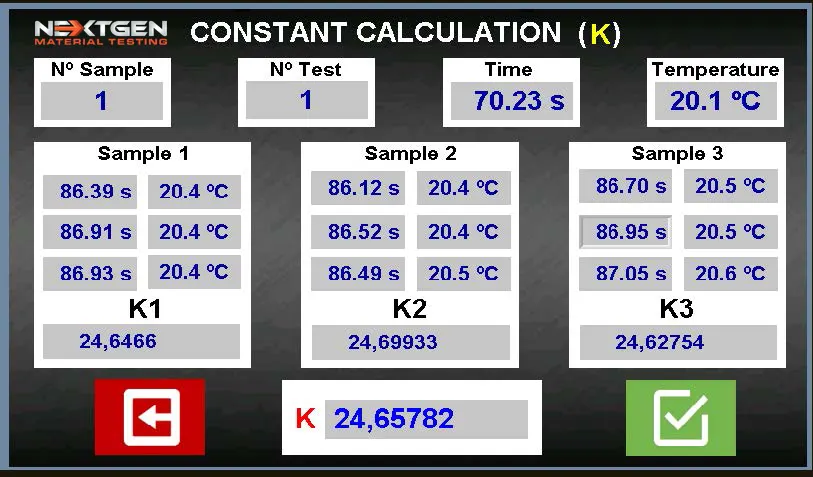

- Automatic calibration with calculation of the K constant of the equipment according to EN and/or ASTM.

- Test performing: fluid aspiration, timing of the fall and detecting pass between the glass tube marks.

- Making all calculations, showing the test results in the screen.

- Automatic storage of all test data results.

Validation of the Apparatus

The BLAINEGENPLUS fulfills the requirements of validation demanded to the automatic methods for the determination of the refinement Blaine, and described in standard ASTM C 204-07, chapter 12.

The performance of the BLAINEGENPLUS overcomes in accuracy and precision to the manual method, because the errors in the measurements of time are much lower.

Calibration of the equipment must be done using a cement surface standard reference, as for example the standard reference material NIST 114q.

For optimum results testing should be carried out in a room with controlled temperature.

New Modern and Intuitive Interface

The AUTOBLAINE PREMIUM device incorporates a renewed interface which which provides the user an improved experience in terms of:

- Simplicity and intuitivity, thanks to the new design of the buttons and menus which provides the user a faster operation and quick access to all functions.

- Modern design, ergonomic and attractive.

- Display of menus and results, thanks to the new 7" screen with dust and splash resistance.

Standard Configurations Include

- Blaine manometric tube, made of glass, U-shape.

- Stainless steel Blaine cell, with plunger and perforated disc and certificate of volume as per EN 196-6a nd ASTM C204.

- Support made in stainless steel, to keep the cell in vertical position and to facilitate the introduction of the cement specimen.

- Extractor for the permeability cell (to extract the tested cement and the perforated disc).

- Manometric liquid. 50 mL.

- Paper filters Ø 12,7 mm. 1000 pcs. Filtration grade medium.

- Clamps for handling filters discs.

- Stainless steel spatula with curved double ends.

- Brush and paintbrush cleaning.

- Stylus (provided with LED flashlight and pen).

- Plastic funnel for filling the cell.

- Rubber stopper for leak testing.

- Pasteur plastic pipette.

- Syringe and suction tube for manometric liquid.

- Reference Portland Cement. 3 units x 5 g.

- Calibration certificate IBERTEST with NIST standard Portland cement.

Accesories and Spare Parts

STANDARD MATERIAL REFERENCE NIST SRM 46h

Ref. 210-104705

Certified Portland cement. Box of 10 pcs of 5g.

PERMEABILITY CELL COMPLETE SET (BLAINE)

Ref. 210-103564

Stainless steel Blaine cell, with plunger and perforated disc.

VERIFICATION OF BLAINE CELL VOLUME

Ref. 510-100015

Performed by the IBERTEST metrology Laboratory, with certificate according to EN 196-6.

FILTER PAPER DISCS. Ø 12,7 MM FOR BLAINE TEST.

Ref. 210-100464

Box of 1000 units

MANOMETRIC BLAINE TUBE

Ref. 210-100018

Glass made, U shaped, with stopcock

MANOMETER LIQUID. 100 ML FLASK

Ref. 210-100154

Technical Specifications

| BlaineGenPLUS | |

|---|---|

| Screen | Color LCD 5,7” touch screen |

| Level detectors | Precision photodiodes for detecting upper and lower levels and additional safety level detector. To in-crease accuracy, comprises backlight in red by means of a LED. |

| Time resolution | 0.01 s |

| Isolation | Detachable protective screen, made in polycarbonate, with stainless steel frame |

| Temperature resolution | 0.1 °C |

| Manometric liquid | Light mineral oil with optimal viscosity. Non-toxic (safety datasheet is comprised) |

| Rise of fluid |

Automatic compression pump Compression avoids the risk of liquid get into the pump |

| Predefined testing methods |

On-screen wizard to perform the tests, including specific protocols for

conducting the test according to EN 196-6 or ASTM C 204. The wizard calculates automatically the weight of cement to test according to the measured density, desired porosity and verified volume (cement bed) of the Blaine cell. |

| Test development | Real time displaying of temperature, constant K, passing time and other parameters |

| Calibration standards | Up to 5 reference cements as standards in each testing methods EN 196-6 or ASTM C 204 |

| Cement types |

Up to 20 different types of cement can be memorized. (more cements on

request) Independent calculation methods for each cement type |

| Blaine cells |

Up to 5 Blaine cells can be selected for calculations. User can change and memorize the cement bed volume of all his Blaine cells |

| Test data storage |

Up to 1000 complete data test can be memorized in a non-volatile memory.

When 1000 tests are performed, the equipment shows a calibration advice warning. |

| PC link | USB 2.0 output. Allows to export the memorized data to a Windows Excel file. |

| Selectable Languages | Spanish, English and French (others on request) |

| Weight | 13.5 kg |

| Dimensions | 270 x 400 x 410 mm (width x depth x height) |

| Power supply | 115V / 60 Hz / 1Ph or 230V / 50 Hz / 1 Ph |

| Visual alarms |

The computer displays a warning if the temperature measured by the probe

is outside the range imposed by the Testing Standard. The temperature sensor is adjustable to match with an external certified thermometer. (requires pas-sword) |

FAQs

The main purpose of the Automated Blaine Apparatus – BlaineGen Plus is to determine the fineness of cement and other powdery materials in terms of their specific surface area, measured in cm²/g. This measurement is crucial for assessing the quality and uniformity of milling processes in cement plants, making sure that the particle size distribution meets the required standards for construction applications.

By using the air permeability method, the apparatus evaluates the resistance of compacted powder to airflow, which is directly related to the material's fineness. The BlaineGen Plus simplifies this testing process through automated features, including calibration, data collection, and results display. It also offers increased accuracy and repeatability than manual methods, which minimizes potential errors. With its compliance with international standards such as EN 196-6 and ASTM C204, the BlaineGen Plus is a valuable tool for laboratories and manufacturing facilities aiming to maintain consistent cement quality and optimize performance in construction materials.

Click here to learn more about the product or here to receive a personalized quote

Yes, the Automated Blaine Apparatus – BlaineGen Plus complies with EN 196-6 standard. This standard specifies the methods for determining cement fineness using air permeability techniques, assuring accurate and reliable measurements of specific surface area in cm²/g.

Compliance with EN 196-6 guarantees that the BlaineGen Plus delivers results that meet international cement testing benchmarks. This requirement provides consistent and repeatable measurements, vital for controlling milling processes uniformity in cement manufacturing. By following this standard, the device provides confidence to laboratories and manufacturers, enabling them to maintain product quality and meet regulatory requirements in construction applications. The BlaineGen Plus offers automated processes, reducing human error while meeting EN 196-6 protocols, thereby becoming one of the most useful tools used for cement testing in the modern era.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automated Blaine Apparatus – BlaineGen Plus complies with ASTM C204 standard. This standard outlines the procedure for determining the fineness of hydraulic cement using the air permeability method, which measures the specific surface area in cm²/g of a compacted cement sample.

In compliance with ASTM C204, the BlaineGen Plus provides reliable and accurate results, aligning with cement quality assessment requirements. This compliance is critical for manufacturers and laboratories that need to evaluate cement particle size consistency for construction purposes. The automated features of BlaineGen Plus, including fluid aspiration, timing, and calculation, reduce human error and improve efficiency, making it a superior choice for testing compared to manual methods.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automated Blaine Apparatus – BlaineGen Plus is able to operate as a fully stand-alone system, which is highly convenient for laboratories and testing environments that may not have access to a dedicated computer. The apparatus features an integrated 7-inch LCD touchscreen, allowing users to perform tests, view results, and manage data directly on the device.

For additional functionality, the device can also be connected to a computer via USB. This connection allows operators to use the supplied WinPerm64 software to manage results, export data, and generate detailed reports. This dual operational capability provides flexibility, enabling users to work independently or integrate the system into more comprehensive data management workflows. Whether operating standalone or connected to a PC, the BlaineGen Plus guarantees accuracy and efficiency in cement fineness testing.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automated Blaine Apparatus – BlaineGen Plus integrates easily with an analytical balance, allowing the system to directly measure the cement sample mass. This feature eliminates the need for separate weighing equipment, simplifying the testing process and reducing errors during sample preparation.

The integration improves efficiency by automating the mass measurement step, providing precise and consistent results. This capability is particularly beneficial for laboratories requiring high accuracy and repeatability in their fineness testing processes. By combining sample weighing with automated testing functions, the BlaineGen Plus provides a comprehensive solution for determining the specific surface area of cement and other powders, meeting the highest standards for precision and reliability.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is equipped with 4 precision-level sensors that allow for accurate and efficient testing. These sensors are designed to detect the correct level of the manometric fluid before a test begins so that the fluid is at the optimal level required by the testing standards.

Additionally, the sensors monitor when the liquid has completely dropped between measurements, allowing the system to automatically proceed to the next step. This automation optimizes operating cycle times, reducing manual interventions and assuring consistency across tests. By maintaining precise control over fluid levels, the 4 level sensors contribute to the apparatus’s ability to deliver accurate and repeatable results, resulting in a highly reliable tool for cement fineness testing in compliance with ASTM and EN standards.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus offers advanced automation features that simplify the entire cement fineness testing process. Automated functions increase precision, reduce human error, and improve overall efficiency.

Key automated operations include automatic calibration, where the equipment calculates the K constant according to EN and ASTM standards. This calibration guarantees consistent accuracy and compliance with testing protocols. During testing, the device automates critical steps such as fluid aspiration, timing fluid fall, and detecting its passage between glass tube marks. All calculations are performed automatically, with the results displayed clearly on the screen for immediate review.

Additionally, the system automatically stores all test data, providing a comprehensive record for future analysis or reporting. This level of automation simplifies operation and guarantees repeatable, high-quality results.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is validated according to the requirements described in ASTM C 204-07, Chapter 12, which governs the automatic methods for determining Blaine fineness. This validation verifies that the system meets stringent industry standards for precision and reliability.

The BlaineGen Plus provides superior accuracy than manual methods, as it significantly reduces errors in timing measurements. This performance improvement enables consistent and dependable results for every test. Calibration of the apparatus is performed using certified cement surface standards, such as the NIST 114q reference material, to maintain compliance with the required protocols.

For optimal results, it is recommended to conduct testing in a temperature-controlled environment. This helps eliminate external variables that may affect the measurement process, further improving the accuracy and repeatability of the BlaineGen Plus.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus features a modern and intuitive interface intended to improve the user experience. Its renewed design simplifies operations and improves accessibility, making testing more efficient and user-friendly.

The interface includes redesigned buttons and menus that allow for faster operation and quick access to all functions, reducing the time needed to set up and execute tests. The 7-inch color LCD touchscreen offers a clear and vibrant display of menus and results so that critical information is easily visible. Additionally, the screen is equipped with dust and splash resistance, making it suitable for use in laboratories.

The ergonomic and attractive design of the interface improves usability and makes it easy for users to perform tests. The combination of functionality and modern aesthetics makes the BlaineGen Plus a cutting-edge solution for testing cement fineness.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is supplied with a comprehensive set of standard configurations to provide optimal functionality and compliance with testing standards. These include:

-

Blaine Manometric Tube: Made of U-shaped glass for precision airflow measurement.

-

Stainless Steel Blaine Cell: Comes with a plunger, perforated disc, and a certified volume in accordance with EN 196-6 and ASTM C204.

-

Support Stand: Stainless steel construction to maintain the Blaine cell in a vertical position, simplifying sample preparation.

-

Extractor for Permeability Cell: For removing tested cement and perforated disc efficiently.

-

Manometric Liquid: 50 mL of light mineral oil for accurate manometric readings.

-

Paper Filters: Ø 12.7 mm, 1000 pieces with medium filtration grade.

-

Clamps: For safe and precise filter disc handling.

-

Accessories for Sample Preparation and Cleaning: Includes a stainless steel spatula with curved ends, brush and paintbrush for cleaning, and a plastic funnel.

-

Additional Tools: Stylus with LED flashlight and pen, Pasteur pipette, syringe, and suction tube for handling manometric liquids.

-

Reference Portland Cement: 3 units x 5 g for calibration.

-

Calibration Certificate: Issued by IBERTEST, guaranteeing accuracy with NIST standard Portland cement.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is supported by an extensive range of accessories and spare parts to optimize its functionality and guarantee long-term reliability. These include:

-

Standard Material Reference NIST SRM 46h: Certified Portland cement, available in a box of 10 pieces (5 g each), ideal for calibration.

-

Permeability Cell Complete Set (Blaine): Includes a stainless steel Blaine cell with a plunger and perforated disc for efficient testing (Ref. 210-103564).

-

Verification of Blaine Cell Volume: Performed by the IBERTEST metrology laboratory, complete with a certificate in compliance with EN 196-6 standards (Ref. 510-100015).

-

Filter Paper Discs: Ø 12.7 mm, supplied in a box of 1000 units for use in Blaine tests (Ref. 210-100464).

-

Manometric Blaine Tube: U-shaped glass tube with a stopcock for precise manometric fluid handling (Ref. 210-100018).

-

Manometer Liquid: 100 mL flask of light mineral oil, designed for safe and accurate manometric measurements (Ref. 210-100154).

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is equipped with precision photodiode-level detectors that are integral in guaranteeing the accuracy and safety of the testing process. These detectors monitor both the upper and lower levels of the manometric fluid, making sure that it is in the correct position before and during tests.

An additional safety level detector is included to provide an extra layer of security, reducing the risk of errors caused by improper fluid levels. To increase visibility and precision, the detectors feature a red LED backlight, which allows for clear detection of fluid positions even in challenging lighting conditions.

This advanced-level detection system increases the accuracy of the device and ensures consistent and reliable results in cement fineness testing, meeting the rigorous standards required for high-quality laboratory equipment.

Click here to learn more about the product or here to receive a personalized quote.

The time resolution of the Automated Blaine Apparatus – BlaineGen Plus is 0.01 seconds, allowing for precise time measurement during the testing process. This high resolution is critical for accurately capturing the time it takes for the manometric fluid to pass through the compacted cement bed, a key parameter in determining cement fineness.

Such precision minimizes potential errors and provides repeatability in results, making the apparatus highly reliable for laboratories and cement manufacturers. By providing detailed time measurements, the BlaineGen Plus increases the overall accuracy of fineness testing, aligning with the strict requirements of EN 196-6 and ASTM C204 standards. In terms of cement quality control, this feature makes it an indispensable tool.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is equipped with a detachable protective screen made of durable polycarbonate and supported by a stainless steel frame. This design provides excellent isolation, safeguarding both the operator and the apparatus during testing.

The protective screen prevents external contaminants such as dust or debris from interfering with the test, ensuring accurate and reliable results. Additionally, it offers a barrier against accidental contact with sensitive components, enhancing safety in laboratory environments. The detachable feature allows for easy maintenance and cleaning, ensuring long-term functionality and hygiene. This thoughtful isolation design underscores BlaineGen Plus's commitment to providing a safe, efficient, and user-friendly testing experience.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus has a temperature resolution of 0.1 °C, allowing for precise monitoring and control of temperature during cement fineness testing. This high resolution makes certain that even small temperature variations are detected and accounted for, which is crucial for maintaining test results' accuracy and consistency.

Temperature is a key factor in the air permeability method, as deviations can impact the flow of air through the compacted cement bed and ultimately affect the measured fineness. By providing such precise temperature readings, the BlaineGen Plus meets the rigorous requirements of standards like EN 196-6 and ASTM C204, assuring that the device delivers reliable and repeatable results under controlled laboratory conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus uses light mineral oil as its monometric liquid. This oil is specifically selected for its optimal viscosity, resulting in smooth and accurate flow during testing. As a result of its properties, it is designed to maintain precision and consistency when measuring air permeability for the purpose of determining cement fineness.

In addition to its technical advantages, the manometric liquid is non-toxic, making it safe for use in laboratory environments. Safety datasheets are provided to assist in proper handling and storage. This choice of manometric liquid increases the reliability of the device while prioritizing safety and ease of use for operators conducting cement quality assessments.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus utilizes an automatic compression pump to control fluid rise during testing. This advanced feature provides consistent and precise fluid movement, which is necessary for accurate air permeability measurements used in determining cement fineness.

The pump design includes safeguards to prevent manometric liquid from entering the pump mechanism, reducing the risk of contamination or damage. This improves the reliability and longevity of the apparatus while maintaining the integrity of the testing process. By automating fluid compression, the BlaineGen Plus eliminates manual adjustments, improving efficiency and minimizing potential errors. This feature illustrates the apparatus's focus on precision, user-friendliness, and long-term durability in cement quality testing.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus supports efficient test development by providing real-time displays of critical parameters during testing. These parameters include temperature, the K constant, the passing time of the manometric fluid, and other key metrics that directly influence cement fineness measurement accuracy.

This real-time feedback allows operators to monitor the test progress and make any necessary adjustments promptly. By displaying these parameters clearly on its intuitive touch screen, the BlaineGen Plus offers transparency and precision throughout the testing process. The ability to track multiple factors together not only improves accuracy but also helps users maintain compliance with standards like EN 196-6 and ASTM C204.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is built to process up to 20 different types of cement, with the option to expand further upon request. This adaptability makes it ideal for laboratories and manufacturers working with different types of cement compositions and specifications.

For each type of cement, the system employs independent calculation methods, resulting in accurate and customized measurements based on the specific properties of the material. This customization allows the BlaineGen Plus to deliver precise fineness results, regardless of variations in density, porosity, or particle size distribution among different cement types.

By supporting multiple cement profiles and providing dedicated calculation protocols, BlaineGen Plus increases efficiency and adaptability, making it a valuable instrument for ensuring cement quality control in a variety of production and testing environments.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is capable of managing up to 5 Blaine cells for calculations, providing flexibility for laboratories that work with different setups or test configurations. This feature allows operators to select the appropriate Blaine cell for each test, optimizing accuracy and efficiency.

Users can also customize and memorize the cement bed volume for each Blaine cell, resulting in precise calculations tailored to the individual specifications of the cell. This capability enables smooth switching between cells without repeated manual adjustments, simplifying testing.

By supporting multiple Blaine cells and allowing easy customization, the BlaineGen Plus enhances its flexibility, providing a valuable tool for laboratories conducting different types of cement fineness tests with different configurations and requirements.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus features non-volatile memory capable of storing up to 1000 complete test data sets. This guarantees that all test results are securely saved, even in the event of a power interruption, allowing users to maintain a comprehensive record of their testing history.

Once the storage capacity reaches 1000 tests, the device automatically displays a calibration advice warning, prompting the operator to recalibrate the device for continued accuracy. This proactive feature makes certain that the equipment remains precise and reliable over extended use.

By providing ample data storage and automatic calibration reminders, the BlaineGen Plus simplifies laboratory workflows, optimizes data management, and guarantees long-term consistency in cement fineness testing.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus offers a multilingual interface with Spanish, English, and French as default language options. Consequently, the system can be used efficiently by operators in a broad range of geographical areas due to its flexibility.

Additionally, the system allows customization, with other languages available upon request. This adaptability makes the BlaineGen Plus a globally accessible tool, catering to laboratories and manufacturing facilities worldwide. By providing language options, the apparatus enhances user experience and usability, providing a smooth operation regardless of the operator’s preferred language.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus weighs 29.8 lbs (13.5 kg), providing a practical balance between portability and stability. Its moderate weight makes it easy to relocate within laboratory environments without compromising the precision and reliability needed for accurate cement fineness testing.

This manageable weight is particularly advantageous for laboratories with space constraints or flexible equipment setups. Despite its lightweight design, the device is constructed from durable materials to provide long-lasting performance and consistent results. The robust build provides stability necessary for precise measurements, even during repeated use. By combining portability, durability, and precision, the BlaineGen Plus is an ideal solution for laboratories and facilities aiming for efficient and accurate testing in a compact and versatile package.

Click here to learn more about the product or here to receive a personalized quote.

The dimensions of the Automated Blaine Apparatus – BlaineGen Plus are 10.6 x 15.7 x 16.1 inches (width x depth x height) or 270 x 400 x 410 mm. This compact size makes the instrument suitable for laboratories with limited workspaces while still providing all the necessary features for accurate cement fineness testing.

Its manageable dimensions fit easily into most laboratory setups without excessive space. The thoughtful design ensures ease of use and accessibility, enabling operators to conduct tests efficiently. Despite its compact footprint, the BlaineGen Plus is robustly built to deliver reliable and consistent performance, providing a valuable addition to any testing facility.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus operates on a dual power supply option, supporting 115V / 60 Hz / 1Ph for American standards and 230V / 50 Hz / 1Ph for international standards. This flexibility means that the apparatus can be used in laboratories and facilities worldwide without additional power conversion equipment.

The dual power supply capability increases the BlaineGen Plus' flexibility, resulting in a convenient choice for global operations. Its compatibility with different electrical systems guarantees reliable performance regardless of location, allowing laboratories to integrate the apparatus easily into their existing setups. This feature underscores BlaineGen Plus’s adaptability and usability in diverse testing environments.

Click here to learn more about the product or here to receive a personalized quote.

The Automated Blaine Apparatus – BlaineGen Plus is equipped with a visual alarm system to verify testing accuracy and compliance with standards. The system displays a warning if the temperature measured by the probe falls outside the range required by the relevant testing standard, such as EN 196-6 or ASTM C204. This feature helps maintain test results reliability by alerting operators to potential temperature inconsistencies.

Additionally, the temperature sensor can be adjusted to match readings from an external certified thermometer, further improving measurement accuracy. This adjustment process is secured by a password to prevent unauthorized changes, assuring consistent calibration. As a result of these visual alarms and adjustable settings, the BlaineGen Plus is a reliable and precise tool for testing cement fineness, supporting strict compliance with industry standards.

Click here to learn more about the product or here to receive a personalized quote.

The Blaine apparatus must comply with AASHTO T153 and ASTM C204.

According to IS: 3031 (Part I), 1996, good quality cement must have a fineness value smaller than 10% of the weight of cement particles that are bigger than 90 microns.

For one, Portland cement is among the lowest-cost materials and most widely preferred for use over the past century. This is because the materials used to produce Portland cement including shales, limestone, and various other naturally occurring materials are cheap and widely available. the concrete produced by Portland cement is among the most versatile construction materials in the world.

A common type of cement for general use, Portland cement is the most widely-used basic ingredient in concrete, stucco, mortar, and non-specialty grout all over the world.

Both the automatic and semi-automatic Blaine apparatus versions offer better precision and more accuracy than those offered by the manual iteration of the Blaine apparatus. A cement sample reference like the NIST 114q is used to calibrate the unit. To get the most accurate results possible, the test must be done in an environment with a controlled temperature.

The air-permeability Blaine apparatus is primarily a means to draw a specific amount of air through a ready cement bed with definite porosity. It works by drawing in a specific amount of air through a cement bed with a definitive porosity measurement. The size and number of pores in a pre-set bed with an absolute porosity value. It is a particle size function and determines the airflow rate through the bed. The procedure is outlined as Method A in ASTM C204 and AASHTO T153.

Typically expressed in sq2 /g of surface area, there are 2 kinds of Blaine apparatus testing methods: test methods A and B. Test method A, the reference test method, involves the manual operation of the standard Blaine apparatus. On the other hand, Test method B allows using an automated apparatus that has proven the ability to come up with acceptable performance.

The fluid called MA13 Blaine Air Permeability Manometer is a non-mercury fluid indicator (red spirit) used together with the MA10 Blaine Air Permeability Apparatus to determine the Portland cement fineness. 8 oz or 240 ml bottles are available as refills. Features include its use for testing based on standards set by the ASTM and AASHTo.

A Blaine number is the surface area-based parameter that is quantified with the use of the air permeability method. The technique is well-established in the cement industry. However, it has several widely recognized and important limitations. These include 2 types of cement of the same Blaine number exhibiting different characteristics in terms of performance.

Measuring cement fineness involves filtering the material on standard strainers. This way, you determine the cement proportion where the grain size is bigger than the specified size of the mesh. The cement fineness measurement is expressed as a specific surface. A bigger specific surface means finer cement will be produced.

Determining the Portland cement fineness value involves using the Blaine Air Permeability Apparatus. It measures the particular fine materials' surface area in sq2 cm / g of the test sample. With the use of the apparatus, an amount of air is drawn via a bed with pre-defined porosity.

Measuring the fineness value of Portland cement involves the use of the Blaine Fineness Apparatus. The test is performed according to standards set by the AASHTO and ASTM. The fineness measurement is based on the specific cement area, which is expressed as the total surface area in cm2 / g (square centimeters per gram).

The average Blaine fineness value in modern cement varies anywhere between 3,000 and 5,000 cm2 / g (or 300 – 500 m2/kg). The company says that the vertical roller mills housed in the complex make achieving the maximum disintegration level possible by grinding down the material down to 4,500 - 6,000 Blaine fineness. This ensures the hardening rate and cement strength.

BlaineGen PLUS, Automatic Blaine Apparatus, perfectly meets the standard EN 196-6 and ASTM C 204. This essential, considering, most other systems do not comply with this criteria.

It is also important to note that the specimen dimensions are in accordance with the standard. The operator does not required to use bigger sample sizes than the standard bed of cement.

Accuracy and repeatability combined with exceptional user-friendly interface is what gives the end user the ultimate advantage with the Automatic Blaine system.

Contact us today to learn more!

- The automatic system has much better repeatability and precision due to the human error factor elimination during the measurement process.

- The automatic system offers automatic calculation of the specific surface of cement.

- After placing the cement sample in the apparatus, our TEST PROCEDURE is much easier, user-friendly and fully automatic. Due to the integrated touch screen panel (full colour) and intuitive software interface adapted to any user.

- The automatic system is a 100% stand-alone equipment. Is not mandatory to use a PC for handling and tests storage in the memory.

- The automatic Blaine system can be connected to a PC for management through WinPerm64 software, export and integration with other applications.

- The results after the automatic calculations are displayed on the screen.

- Automatic recalibration process of the apparatus, guided process as defined by the testing standards.

- Temperature sensor is included in the system and it tells you if the temperature is correct for the test.

- The automatic Blaine apparatus has 4 Optical Switches for an accurate liquid detection. In every test the BlaineGen PLUS verifies the correct level of the manometer liquid.

- Auto adjustment of compressor flow to adapt to the different conditions of atmospheric pressure.

Contact us today to learn more!

Related Products

Digital Blaine Apparatus – BlaineGen Classic

BlaineGen Classic is a digital Blaine apparatus for routine determination of cement fineness and specific surface area. The instrument applies the Blaine air permeability method and reports Blaine values directly on the display. It is manufactured in line with EN 196-6, ASTM C204, GB/T 8074 and NF P15-403, with correlation to ISO 9277 for specific surface area evaluation. The workflow follows the classic Blaine cell concept with digital timing and calculation.