An extensometer is an accessory to a tensile strength tester and is extensively used in materials testing. This instrument places a sample under stress, which causes it to physically deform. These deformities can be almost invisible to the eye or they can be clearly visible. Extensometry is the practice of measuring these differences.

These devices are used in the Tensile Preparation ASTM E8 test along with tensile testers. ASTM E8 method is the most common test for tensile strength of metals in any form. The tests are conducted at an ambient temperature range of 50 – 100 degrees Fahrenheit (10 – 38 degrees Celsius).

Although the ATSM E8 tensile test is designed to measure a range of different properties, the following are the most common:

- Yield strength measures how much stress a material can bear before it is permanently deformed

- Reduction of area measures a material’s ductility

- Tensile strength measures the maximum stress a material is capable of sustaining

- Yield point elongation determines the stage during which a material changes to plastic behavior from elastic behavior

The information gathered using ASTM E8 is essential for comparing materials as well as in processes such as creating alloys. Testing the tensile strength of steel preparation can help improve safety in settings where they are used. For instance, it ensures that steel used in construction will be able to bear the stresses they are typically subject to without failing.

Extensometers are generally used in industries where manufacturers need to test tensile strength of the materials they use, to determine if they can withstand the amount of strain typically put on them. Extensometers are also used in field settings, such as mines. Geotechnical engineers use them to test if there is a risk of structures in the area collapsing.

There are two types of tensile testing machines – those that require contact with the sample to conduct tensile testing and those that do not. The earliest extensometers were contact instruments that were originally developed in the nineteenth century.

However, the need to be in physical contact with the sample meant that the results may be skewed. Using this instrument might also be impractical for certain types of testing. Thus, extensometers were developed that did not require contact to perform a tensile stress test.

How Tensile Test Machines Work

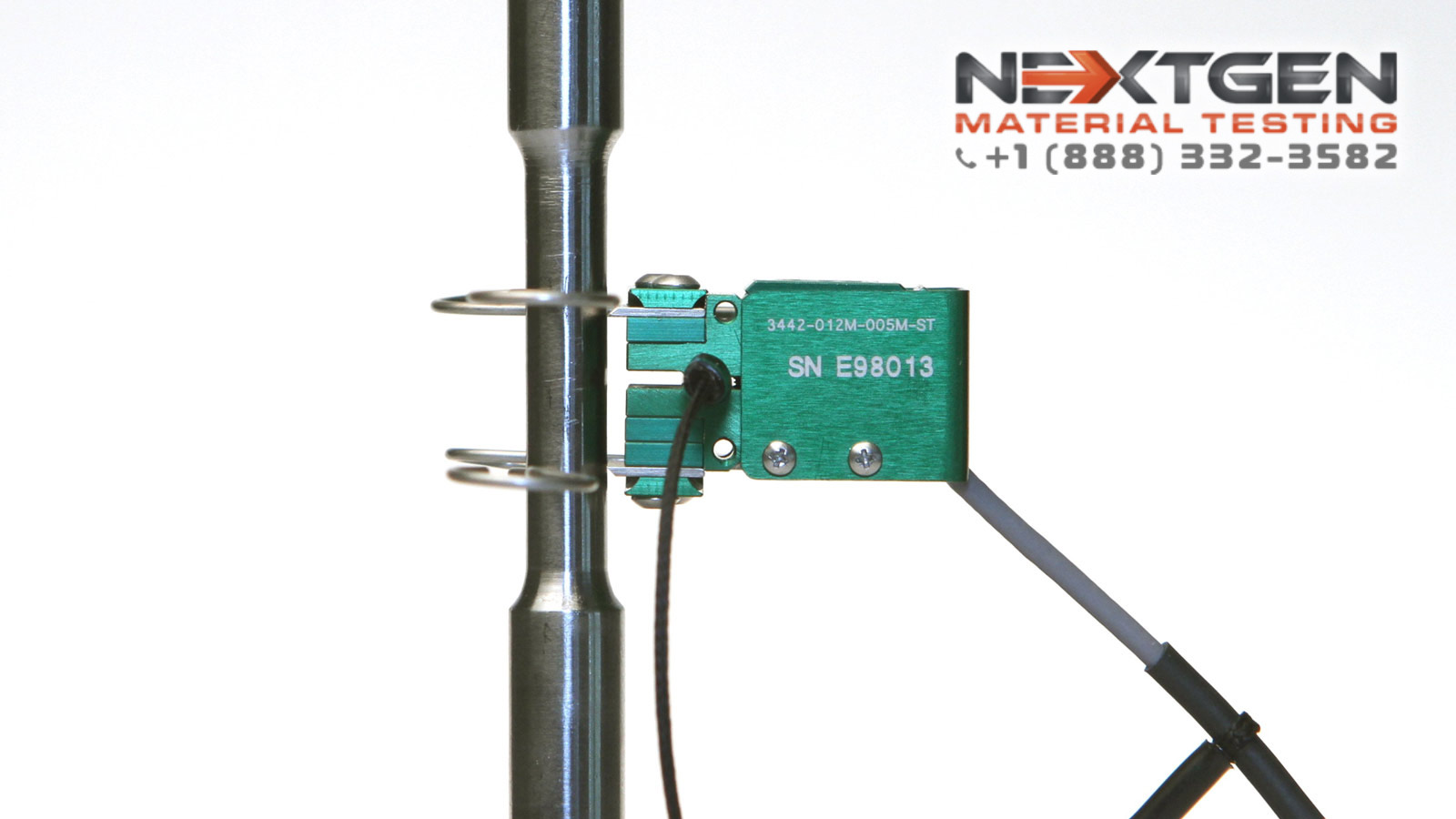

Contact extensometers are generally of the ‘clip-on’ variety, where a knife-edge or other object is physically placed on the tensile test specimen. These instruments are used where high precision measurements are needed. They are also cost-effective.

The knife-edge has only a very small contact with the specimen surface, resulting in a microscopic indentation. This indentation forms a precisely positioned contact point that helps ensure the high accuracy of the measurements, as well as the measured values only being within a small scatter bandwidth.

The tensile test sample is normally applied and removed from the instrument manually by the operator. However, setting errors may affect the results. To offset this, motorized application and removal systems were installed in certain models.

Clip-on extensometers normally have a limit of a few millimeters, and loads are directly applied to the tensile testing samples. However, there may be superimposed bending stresses, and to compensate for these, extensometers with double-sided measuring systems and counter-balance weight may be used.

However, traditional contact extensometers may not be suitable when delicate or small samples are being tested. Thus, newer products were developed that used a digital sensor or ‘feeler’ arm. These models had features that made up for the weaknesses of the older models.

For instance, they compensated for bending stresses by having the feeler arms be in contact with both sides of the sample. The more precise designs ensured that only a minimum load was applied to the specimen.

These instruments are also ideal for automated tensile strength testing since a motorized system applies the sensor arm automatically to the specimen, providing more replicable results than clip-on devices.

One major disadvantage of contact extensometers is the risk of the test instrument being damaged if the sample reaches its breaking point and exhibits whiplash. For instance, if a material with high elasticity is being tested and it breaks, it may ‘snap back’. This may result in damage to the tensile test apparatus.

Non-contact extensometers avoid this problem by using video or lasers to conduct tensile testing. This avoids the risk of damage even when the sample reaches breaking point.

Laser extensometers work by illuminating the sample with a laser after it has been loaded in a tensile test machine. Reflections from the specimen are captured using a CCTV camera, and analyzed using a complicated algorithm. There is also no need to make test marks on the sample, which saves a lot of time when conducting tests.

Video extensometers capture images of the test specimen while it is under stress, using digital video cameras or frame grab software. As part of the tensile testing preparation process, the specimen has to be cut in a specific shape and test marks placed on it using markers or special stickers. As the sample is stretched or compressed, the video tracks the pixel distance between the marks to measure strain.

However, these marks may be a source of error in the measurements. As the sample deforms, they may become indistinct and difficult to read, or fall off. Placing measurement marks also adds another stage to the testing process, increasing costs, as well as the risk of inaccurate results.

Still, noncontact extensometers are the ideal solution for applications that require high accuracy. In fact, for certain tests, they may even be superior to other extensometer types since they can measure strain on the sample over a great range.

To ensure accurate measurements, extensometers have to be periodically calibrated. This can be done in facilities that specialize in calibration activities or which have a calibration kit.

In addition, extensometers are sensitive devices that need to be kept in a secure place where they are not exposed to shocks. Being jarred may affect the accuracy of the instrument. They should also be stored in the protective cases or coverings that they came with when not in use.

Choosing Tensile Testing Equipment

One of the main criteria is the tensile test samples whose properties are to be checked. The considerations include the shape and dimensions of the sample, the test requirements, and the formal standards that need to be met. These define the accuracy of the test results, the environmental conditions under which they are to be conducted, and the test sequence. You may learn more about tensile sample preparation equipment to identify how an accurate dog bone is prepared every time.

Aside from the material properties of the sample, you also have to consider what type of extensometer would be best for testing it. For instance, can the instrument be physically attached to the sample without damaging it or affecting the load measurement? If the specimen is small, such as a wire, does it have enough surface area to allow for accurate non-contact measurements?

And, of course, how will the tensile tester be affected if the specimen fails? We have already discussed how specimens that break and exhibit whiplash can damage extensometers. This is particularly true with flexible or high extension samples, such as steel rope that can even destroy instruments due to de-lamination or splintering.

Thus, it is particularly important that the right tensile tester be used for a particular sample. In the example above, for instance, a non-contact instrument should be used in order to ensure accurate measurements.

Avoidance measures can also be taken. For instance, adding swiveling knife-edges to contact extensometers can help mitigate the risk of damage, even with specimens that have particularly rough surfaces.

Other considerations for choosing a tensile tester machine include:

The ergonomics of the instrument. If series testing is conducted, the operator may suffer from repetitive movement injuries, which can affect the accuracy of the results. Thus, a tensile strength machine that is easy to use and can be programmed to automate routine procedures can ensure the quality and accuracy of the results you are getting.

The economics of acquisition. While the initial costs of getting an extensometer may be costly, you have to consider if you can amortize them over the long term. For instance, can you use the machine for many different applications?

You also have to consider the ongoing costs of ownership. For instance, how much will your maintenance costs be? How long will it take to prepare specimens for testing, as well as to configure the device before use?

Conclusion

To summarize, contact extensometers are cost-effective and provide highly accurate results for conducting a tensile strength test. But they require more manual intervention from an operator, which increases the risk of test results scatter if they are not careful. However, this risk can be mitigated using feeder arm extensometers.

Non-contact extensometers are ideal for testing specimens that may break under stress or which are sensitive to knife-edges. But they are relatively more expensive and take more time to set up and calibrate, particularly when you are testing different types of materials.

When choosing a tensile machine, it is important to keep in mind that there is no one extensometer that fits all requirements. Thus, before buying, you have to consider what applications it will be used for, and choose the extensometer based on these needs. You may even need more than one extensometer to meet all your testing requirements. Request quotation for a tensile testing system that is the right fit for you.