There is an ever-present need for reliable yet affordable material testing equipment. In particular, this is true for hardness testing, since accurate measurements of hardness are crucial to determining how durable and strong a material will be in the future. Regardless of whether you are testing metals, plastics, or other materials, the precision and consistency of your hardness tester can have a significant impact on the quality of the results you receive and, as a consequence, your products’ safety and performance.

NextGen Material Testing offers the best Brinell hardness testing systems available in the market today. Our product line includes a number of Brinell solutions for quality control that are affordable for laboratories of all sizes and scopes. We offer advanced Brinell and Universal hardness testing systems, as well as custom solutions to meet our customers’ individual needs. Let us show you our leading testers, so you can choose the most suitable one for your needs.

What is a Brinell Hardness Testing System?

In order to provide you with a better understanding of the importance of these systems, we first need to explain the main functions of Brinell hardness testing systems. A Brinell hardness testing system is a tool for measuring the hardness of materials, particularly metals. The Brinell test method involves pressing a hard ball into the surface of a material with a specific force. The size of the indentation left by the ball is then measured and used to calculate the Brinell Hardness Number (BHN).

Method and Materials

The Brinell test uses a hardened steel or carbide ball indenter, typically 10mm wide. The test force ranges from 500 to 3000 kilograms-force (kgf), depending on the material being tested. This method is particularly suitable for testing materials with a coarse or uneven grain structure, such as castings and forgings, which can present challenges for other hardness testing methods.

Brinell hardness testers can measure many different materials, including:

-

Steel and cast iron

-

Non-ferrous metals such as aluminum, copper, and brass

-

Plastics and polymers

-

Composites and other engineered materials

Advantages and Features

Brinell Hardness Testing Systems offer several advantages:

-

Versatility: Suitable for an array of materials and applications.

-

Accuracy: Provides precise measurements, a requirement for quality control.

-

Simplicity: The method is straightforward and easy to perform.

-

Comprehensive Results: The large indentation size averages out material inconsistencies, providing a more reliable measurement.

Modern Brinell Hardness Testing Systems come equipped with advanced features such as digital readouts, automated test cycles, and integration with computer systems for data analysis and reporting. These advancements increase the accuracy, repeatability, and ease of use of the testing process.

Applications

Brinell hardness testing is used in various industries, including:

-

Automotive: For testing engine blocks, crankshafts, and other components.

-

Aerospace: To maintain structural component quality.

-

Construction: For testing the hardness of building and infrastructure materials.

-

Manufacturing: To maintain consistent material properties in production processes.

Understanding the capabilities and applications of Brinell hardness testing systems is important for selecting the right equipment for your specific needs.

Systems for Testing Brinell Hardness at Reasonable Cost

As a next step, we will discuss four of the most popular hardness testing systems that we offer that may be of interest to you.

UniGen Series – Universal Hardness Tester for Vickers, Rockwell, and Brinell

To begin with, the UniGen Series, also known as the Universal Hardness Tester for Vickers, Rockwell, and Brinell, is a comprehensive all-in-one testing system designed to meet material testing laboratories’ diverse needs. This advanced system is engineered to provide industry-leading user-friendliness combined with robust construction for accurate and repeatable hardness measurements across three major testing methods: Vickers, Rockwell, and Brinell.

To begin with, the UniGen Series, also known as the Universal Hardness Tester for Vickers, Rockwell, and Brinell, is a comprehensive all-in-one testing system designed to meet material testing laboratories’ diverse needs. This advanced system is engineered to provide industry-leading user-friendliness combined with robust construction for accurate and repeatable hardness measurements across three major testing methods: Vickers, Rockwell, and Brinell.

Standards and Compliance

The UniGen Series complies with a number of international standards, guaranteeing its suitability for various industrial and laboratory applications. These standards include:

-

EN ISO 6508

-

JIS Z2245

-

GB/T 230.2

-

JIS Z2243

-

GB/T 231.2

-

JIS Z2244

-

GB/T 4340.2

Ultimate User-Friendliness and Dependability

The UniGen Series is equipped with:

-

An 8″ LCD touch screen

-

CCD Camera

-

State-of-the-art automatic measuring software

The intuitive touch-screen interface simplifies operation, allowing operators to perform tests with minimal training. Automated test force correction and force compensation features guarantee high accuracy and repeatability, eliminating manual adjustments and reducing human error.

Robust and Reliable Design

This Universal Hardness Tester is built to last, with a closed-loop system that uses the highest accuracy load cell, avoiding weight installation. The system’s robust construction allows for reliable performance, even in demanding industrial environments. The modular design of the UniGen Series allows for easy maintenance and long-term reliability, making it a cost-effective solution for laboratories and industrial settings.

Comprehensive Testing Capabilities

The UniGen Series supports Brinell, Rockwell, and Vickers test methods, offering a comprehensive hardness testing solution. It includes an extensive range of test forces and scales for each method:

-

Brinell: Test forces range from 5kgf to 187.5kgf, with multiple scales including HBW1/5, HBW2.5/6.25, HBW1/10, and more.

-

Rockwell: Supports multiple scales (HRA, HRB, HRC, etc.) with test forces of 60kgf, 100kgf, and 150kgf.

-

Vickers: Test forces range from 5kgf to 120kgf, covering scales from HV5 to HV120.

Advanced Features

-

Large touch-screen interface for ease of operation

-

Password protection for setup parameters

-

Ability to save data in Excel format for easy editing and processing

-

Rockwell hardness testing function includes an auto-correct curvature radius

Additionally, the UniGen Series offers a large sample and testing data capacity, further improving its usability.

NIST-Certified Consumables and Lifetime Support

The UniGen Series comes with NIST-certified consumables for all three testing methods, providing a turnkey solution for your hardness testing needs. We

BrinGen Scope – Optically Advanced CCD Brinell Hardness Testing System

The BrinGen Scope – Optically Advanced CCD Brinell Measuring Scope for Manual or Digital Brinell Hardness Testing System, is another innovative and versatile solution designed to optimize Brinell hardness testing accuracy and efficiency. This system integrates smoothly with a computer or laptop, providing real-time results and advanced reporting capabilities to simplify your testing program.

The BrinGen Scope – Optically Advanced CCD Brinell Measuring Scope for Manual or Digital Brinell Hardness Testing System, is another innovative and versatile solution designed to optimize Brinell hardness testing accuracy and efficiency. This system integrates smoothly with a computer or laptop, providing real-time results and advanced reporting capabilities to simplify your testing program.

Advanced Optical System

The BrinGen Scope is equipped with an advanced CCD optical system. Unlike the UniGen Series, which is designed as an all-in-one tester for Vickers, Rockwell, and Brinell, the BrinGen Scope is specifically optimized for Brinell hardness testing. This system supports both manual and automatic measurements, allowing operators to choose the method that best suits their testing needs. The optical system provides high-resolution imaging, making accurate measurements easier.

Ease of Use and Real-Time Results

One of the standout features of the BrinGen Scope is its ease of use. The system performs automatic and accurate hardness measurements at the push of a button. The interface displays auto-measurement results, tolerance values, and other critical information in real-time, allowing immediate analysis and decision-making. Additionally, the BrinGen Scope supports manual measurements for flexibility in testing procedures.

-

Instant Display: The BrinGen Scope provides real-time measurement results, allowing immediate analysis.

-

Conversion Tables: Offers a number of hardness conversion tables, including the ASTM-E140 Scale Conversion Table, to convert hardness values between different test methodologies.

-

Custom Conversion Tables: Operators can create custom conversion tables to suit specific requirements.

-

Statistical Analysis: Real-time statistical results are available, with hardness values displayed in histogram view for easy interpretation.

Comprehensive Reporting

The BrinGen Scope excels at reporting. Operators can generate numerous types of reports, including custom and user-defined reports, documenting inspection results. The system allows easy viewing of basic results, with options to add or remove result columns as needed. Thus, operators are able to customize reports in order to meet their specific needs.

Various Options and Calibration

The BrinGen Scope offers a range of customizable options, including the selection of test type (HBS or HBW), ball diameter, test force, and distance unit (nm, µm, mm). This flexibility allows operators to adapt the system to their specific testing requirements. The system also supports multiple languages. Calibration is straightforward, with options to enter the hardness value of a standard sample or the diameter distance into the calibration window.

Telebrineller Brinell Hardness Testing System

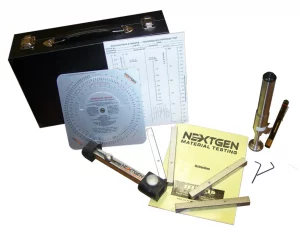

The Telebrineller Brinell Hardness Testing System is engineered for welding crews and other field applications. Drawing on over fifty years of field experience and metallurgical expertise, this system combines portability, ease of use, and a robust design.

The Telebrineller Brinell Hardness Testing System is engineered for welding crews and other field applications. Drawing on over fifty years of field experience and metallurgical expertise, this system combines portability, ease of use, and a robust design.

Portability and Practicality

One of the defining features of the Telebrineller system is its portability. Weighing less than ten pounds and housed in a convenient carrying case, it is designed for easy transport and use in many settings. Whether in a laboratory, on a construction site, or in the field, this system offers unmatched convenience for Brinell hardness testing. The straightforward operation involves a single hammer blow, measurement of the resulting impressions, and basic calculations using the included computer. This makes it accessible to operators without specialized training.

Ease of Operation

The Telebrineller system is engineered for simplicity and efficiency. Its operation can be summarized in a few steps:

-

Select a Test Bar: Choose a test bar with a known Brinell Hardness Number (BHN) that closely matches the expected hardness of the specimen.

-

Position the Instrument: Insert the chosen test bar into the Telebrineller instrument and position it accurately on the specimen.

-

Impact and Measure: Strike the anvil with a two- to five-pound hammer, creating impressions in both the test bar and the specimen. Measure the diameter of these impressions to determine the BHN.

Accuracy and Reliability

The core of the Telebrineller system’s accuracy lies in its test bars, which are calibrated to within ±2% of the labeled BHN. These bars are tested for hardness using equipment compliant with the National Standards Institute. The system’s accuracy allows for reliable hardness measurements, making it a trusted tool in quality assurance processes. When used correctly, the Telebrineller can achieve an accuracy of ±5%, provided the BHN of the test bar is within ±15% of the specimen’s BHN.

Rugged and Weatherproof Design

Built for field use, the Telebrineller system features a weatherproof design with rugged components. This durability allows for accurate measurements in different weather conditions and under rough field circumstances. The robust construction includes a stainless steel and aluminum housing that protects the camera and LED lights.

Components and Accessories

The standard Telebrineller kit includes:

-

A test bar

-

An anvil encased in a soft molded rubber head

-

A steel impression ball

-

A spacing bar

-

Calibration film

-

Software with a protection key

-

A CD with a video user guide

This set of components is designed to work smoothly together, resulting in efficient and precise hardness testing that can be conducted.

BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester

The final product on our list is the BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester. This advanced measurement system is intended to provide precise and repeatable hardness measurements, making it a perfect choice for laboratories, workshops, toolrooms, and inspection laboratories. It complies with ISO 6506 and ASTM E10 standards, thus being suitable for an extensive range of industrial applications.

The final product on our list is the BrinGen – 3000 Series – Digital Brinell and Automatic Brinell Hardness Tester. This advanced measurement system is intended to provide precise and repeatable hardness measurements, making it a perfect choice for laboratories, workshops, toolrooms, and inspection laboratories. It complies with ISO 6506 and ASTM E10 standards, thus being suitable for an extensive range of industrial applications.

Advanced Features for Precision and Accuracy

The BrinGen 3000 Series delivers highly sensitive and accurate readings. It is equipped with a closed-loop system for the highest load control accuracy, which provides precise control of test force applications. The system offers direct digital reading, eliminating human error and providing maximum accuracy.

Ease of Use and Automation

One of the standout features of the BrinGen 3000 Series is its user-friendly interface and automation capabilities. The system is equipped with a large LCD display screen, which clearly shows the indenter, load, and other test information. The test process is fully automatic, including load application, holding, and unloading, which greatly improves test results reproducibility by eliminating operator influence. Additionally, the system allows for test load selection via keyboard and screen, and selectable dwell times can be easily set on the screen.

Versatility in Testing

The BrinGen 3000 Series is flexible, accommodating the full range of test forces and Brinell scales. The test load ranges from 62.5 kgf to 3000 kgf, making it suitable for testing various materials such as unquenched steel, cast iron, non-ferrous metals, and soft-bearing alloys. It includes a 20X optical microscope for measuring Brinell indentations diameter, with a resolution capability of 0.005mm. This high-resolution measurement allows for precise and accurate hardness values.

Technical Specifications

-

Brinell Scale: Supports multiple scales including HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, and more.

-

Test Force: Ranges from 62.5 kgf (612.9 N) to 3000 kgf (29420 N).

-

Test Space: Vertical test space of 230 mm and horizontal space of 155 mm.

-

Measure Resolution: 0.5%.

-

Test Force Accuracy: 62.5-250 kgf ≤ 1%; 500-3000 kgf ≤ 0.5%.

-

Dwell Time: Adjustable from 1 to 60 seconds.

-

Test Range: 8-650 HBW.

-

Microscope: Equipped with a 20X optical microscope.

-

Data Display: LCD touch screen.

-

Power Supply: AC110 V or AC220 ±5%, 50-60Hz.

-

Dimensions: Machine size is 21.6 x7.5 x 29.5 inches; shipping package is 28.7 x17.7 x 38.6 inches.

-

Weight: Net weight is 220 lbs; gross weight is 286 lbs.

Additional Features

The BrinGen 3000 Series also includes a Brinell Hardness Calculator (BHC) to make hardness value calculations easier and more convenient. The system’s weight is 50% less than traditional dead-weight testers, thus increasing its practicality and ease of use in diverse settings.

Who Can Benefit from These Testers?

Brinell hardness testing systems are widely used tools throughout numerous industries due to their ability to measure material hardness accurately and consistently. Among our list of products, each one serves a unique application, benefiting a particular industry or user group. Here is a closer look at who can benefit from the products we offer:

Universal Hardness Tester for Vickers, Rockwell, and Brinell – UniGen Series

UniGen Series benefits engineering and manufacturing sectors. For example, automotive companies use this tester to ensure engine component hardness. Aerospace industries also rely on the UniGen Series to test aircraft materials, making sure that they meet stringent safety and quality standards. The ability to perform multiple hardness tests on one machine makes the UniGen Series a versatile and cost-effective solution for these industries.

BrinGen Scope – Manual or Digital Brinell Hardness Testing System

The BrinGen Scope is particularly useful in academic research and educational institutions. Researchers studying novel materials can make use of the system’s precise optical measurements to gather accurate data on material properties. This is an important consideration in developing new alloys or composites with specific hardness requirements. Additionally, educational institutions benefit from the BrinGen Scope as it provides hands-on learning opportunities for students in material science and engineering programs, allowing them to understand and apply hardness testing techniques effectively.

Telebrineller Brinell Hardness Testing System

Welding crews and field engineers find the Telebrineller system indispensable due to its portability and ease of use. On construction sites or remote locations, the Telebrineller provides a quick and reliable method to assess the hardness of welds and structural materials. This ensures that critical structures meet safety standards, preventing failures. The system’s rugged design and weatherproof features make it ideal for harsh field conditions.

Digital Brinell and Automatic Brinell Hardness Tester – BrinGen – 3000 Series

Manufacturing and quality control departments benefit greatly from the BrinGen 3000 Series. This tester verifies that metal parts and products, such as those used in heavy machinery or infrastructure projects, meet precise hardness specifications. By automating the testing process, the BrinGen 3000 Series minimizes human error and increases throughput. Its precise control and detailed reporting capabilities support stringent quality assurance processes.

Choosing the Right Brinell Hardness Testing System for Your Needs

Generally speaking, we at NextGen are proud to offer a wide variety of Brinell hardness testing systems designed to meet a broad range of industry applications.

The UniGen Series is a versatile universal hardness tester supporting Vickers, Rockwell, and Brinell methods, ideal for comprehensive material testing in the engineering and manufacturing sectors.

As the name implies, BrinGen Scope is an advanced CCD optical system optimized for Brinell hardness testing, providing precise measurements and real-time results, perfect for academic research and educational institutions.

The Telebrineller Brinell Hardness Testing System is a portable and practical solution for field applications, offering ease of use and reliable measurements, especially beneficial for welding crews and field engineers.

The BrinGen – 3000 Series is a digital and automatic Brinell hardness tester ensuring precise and repeatable measurements, ideal for high-volume testing in manufacturing and quality control departments.

NextGen Material Testing are dedicated to providing reliable and affordable equipment for all your material testing needs. Our extensive range of tools covers everything from metal testing to soil and concrete testing. For more information about our equipment, request an online quote or contact us directly. We are here to make sure that you have the most effective tools for accurate and efficient material testing.