A mounting press, such as a Fully Automatic Mounting Press (will be referred to MFA or GenPress MFA from now on), is a special tool designed to encapsulate samples, typically for microscopy, ensuring they are preserved, supported, and sized appropriately. Its core function is to make a sample—often a sliver of metal or material—more manageable for subsequent processes like grinding, polishing, and microscopic inspection. In industries such as aerospace, automotive, and metallurgy, these presses are highly valuable. They facilitate the process of examining materials’ microstructure, which provides information about properties like grain boundaries, phase distribution, and defects.

Mounting presses are essential for the preparation of metal samples. Metallography, the study of metal’s physical structure and components, often requires samples to undergo rigorous preparation to be studied under a microscope. A mounting press ensures sample integrity, making it easier to handle and prepare for high-resolution microscopic analysis.

In this blog, we will look at the MFA Series Presses for Metallographic Sample Preparation by NextGen Material Testing. Each of these presses will be detailed reviewed to furnish readers with insights into their primary characteristics and specific applications.

The Importance of Mounting Presses

The use of mounting presses is not limited to metallurgy. They find applications in various industries, serving a wide range of functions. Research labs, quality control departments in manufacturing facilities, and educational institutions use them a lot.

In the aerospace industry, for instance, materials reliability is a top priority. A mounting press assists researchers in preparing samples of aerospace components. This enables them to study and ensure that these materials can withstand extreme conditions.

The automotive industry also heavily uses these tools. With a focus on lightweight and durable materials for better fuel efficiency and safety, researchers employ mounting presses to study various metal alloys and composites.

Recent research underscores the importance of mounting presses in advancing material science. A 2019 study published in the Journal of Material Science and Technology highlighted the critical role of sample preparation, particularly using mounting presses, in obtaining clear, high-definition microscopic images. Clarity is key to reaching accurate conclusions about material properties.

How Mounting Presses Work

Mounting presses operate based on a systematic process that is essential for the preparation of solid samples. This process ensures that materials are not just visible under the microscope but also maintained in their original form for accurate analysis.

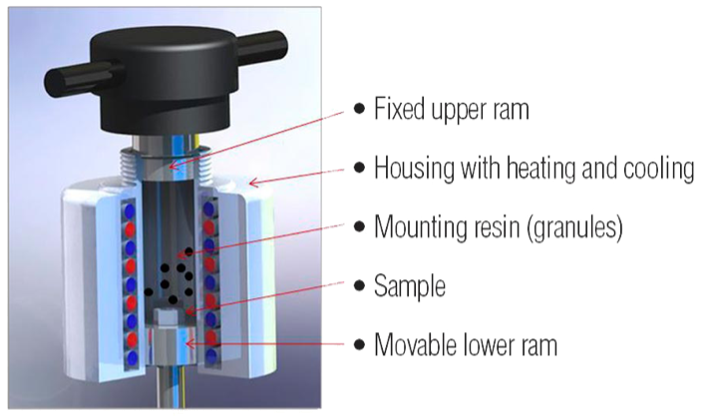

- Sample Placement: The process begins with the sample being placed in a mold. The mold’s size and shape depend on the sample’s dimensions and microscopic specifications.

- Resin Introduction: Once the sample is set, it is often encapsulated using resin or other mounting substance. This medium holds the sample securely and provides a clear, polished surface for viewing. The type of material (whether thermosetting or thermoplastic) is chosen based on the sample’s properties and finish requirements.

- Heating and Compression: The sample, now within its mold and surrounded by resin, is subjected to heat and pressure. This combination allows the resin to flow, envelop, and solidify around the sample, creating a stable mount. The exact temperature and pressure parameters can differ, depending on the resin type and sample characteristics.

- Cooling Phase: After the resin envelopes the sample, the assembly is cooled. Cooling can be rapid or gradual, depending on the mounting press model and the resin’s properties. This phase solidifies the resin, ensuring the sample remains stable.

- Ejection and Polishing: Once cooled and solidified, the mounted sample is ejected from the mold. The sample’s surface is then polished, rendering it smooth and clear for microscopic examination.

Mounting press efficiency depends on its precision in regulating heat, pressure, and cooling phases. Modern presses, like those in the MFA series, often incorporate automation and programmability, ensuring consistent and high-quality sample preparation across different materials and industries.

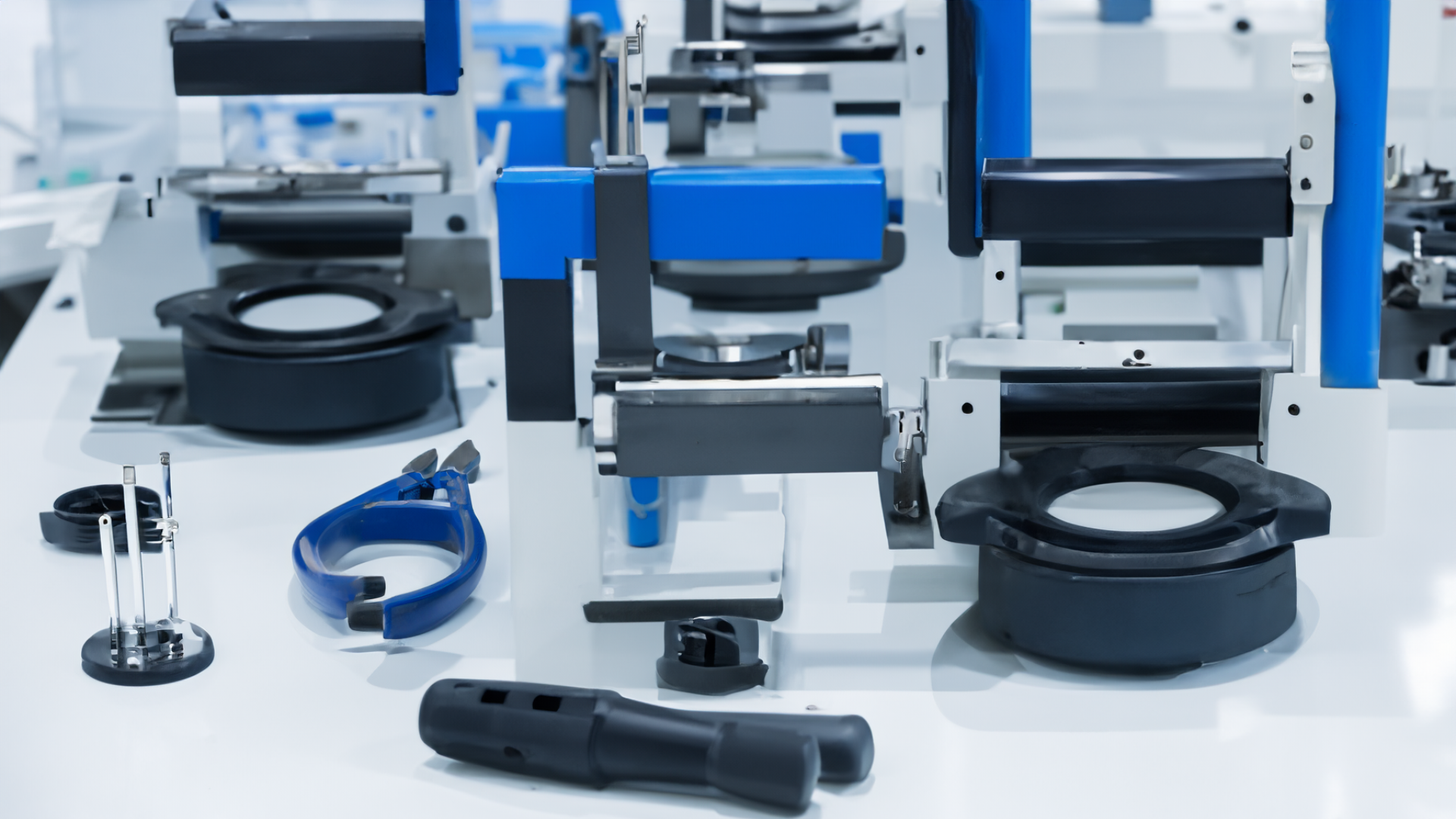

Introducing the MFA Series Fully Automatic Mounting Presses

The MFA Series of Fully Automatic Mounting Presses feature precision engineering designed specifically for metallographic sample preparation. Each press in this series is equipped with a 7-inch touchscreen interface. The interface provides operators with high-resolution visualization and easy navigation, allowing them to easily adjust heating, cooling, and timing settings.

The MFA series’ advanced programmability sets it apart from conventional mounting presses. Not only can operators save up to 100 customized programs, but data storage also reduces the possibility of errors. With each saved program, the system can repeatedly perform sample preparations, adapting to both routine and unique metallurgical requirements.

Within the MFA Series, the integrated compression system is a remarkable example of technical integration. Whether the model employs a motorized mechanism or a hydraulic system, the objective remains the same: ensuring samples are compressed as efficiently as possible. This precision ensures that each sample is prepared under conditions best suited to its specific type and size.

Automation, in the context of the MFA Series of Fully Automatic Mounting Presses, is more than just machine operation without human intervention. After setting the desired parameters, the presses perform the entire cycle automatically, resulting in reproducible conditions for each sample. Furthermore, operators can remain informed without constant monitoring, thanks to an efficient notification system that sounds an alert upon each preparation cycle.

Versatility is a defining feature of the MFA Series. It’s designed to accommodate a wide range of sample sizes, evident from its compatibility with mold diameters spanning from 25mm (approximately 1″) to 50mm (2″). This flexibility ensures that the presses are equally effective for smaller, softer samples as for larger, robust ones.

As mentioned above, the MFA Series also includes an integrated alarm system. This allows lab personnel to manage other tasks while the press operates. Upon cycle completion, a distinct alarm signal, optimizing workflow and ensuring timely sample retrieval.

Lastly, the structural integrity of MFA presses must be taken into consideration. Constructed with a high-quality ABS shell, these presses offer durability and ease of maintenance. The material is resistant to laboratory chemicals, ensuring longevity. Additionally, the integrated cooling system is a vital component of these systems, designed to speed up the cooling phase, thus reducing overall sample preparation times.

As we continue, we’ll break down the individual systems of the MFA Series, focusing on their specific characteristics and functionalities. This detailed exploration will provide clarity on the technical details and practical applications of each system in the context of metallographic sample preparation.

GenPress MFA Dual HYD – Fully Automatic Dual Hydraulic Mounting Press

The MFA Dual HYD is a distinctive addition to the GenPress lineup, characterized by its ‘dual’ capability. This feature enables the processing of two metal samples concurrently, which is advantageous in bustling professional environments, particularly in contemporary metallurgical labs.

This system is suitable for metallurgy, material testing labs, and educational sectors. Its efficiency and reliability cater to both routine tasks and innovative research. Industrial settings seeking high output and educational labs focusing on hands-on learning will find it especially beneficial.

Key Features

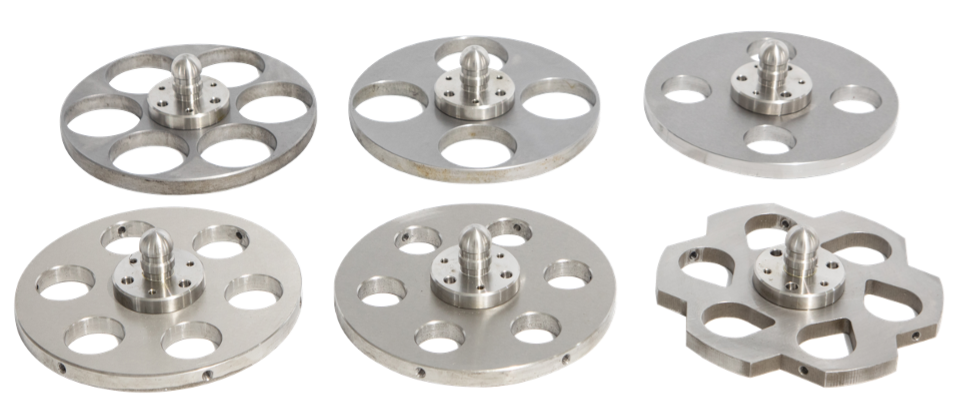

- Sample Handling: The ability to produce up to 4 samples in one cycle makes it highly efficient. The MFA series accommodates various sample sizes, ranging from 1” to 2″ and their metric counterparts from 25mm to 50mm. With optional sample spacers, you can prepare one or two samples concurrently.

- Operational Modes: Depending on the need, users can swing between manual and automatic operation.

Technical Specifications

- Pressure: It operates within a 0-300Bar range with customization options from 0-60Bar.

- Heating: A 4KW heater ensures temperatures from 0 – 200 ℃ are attainable.

- Timing: Adjustable settings for both mounting and cooling span 0-99 minutes.

- Cooling System: A primary water-based mechanism is at play, with an advanced chiller option for those desiring rapid cooling.

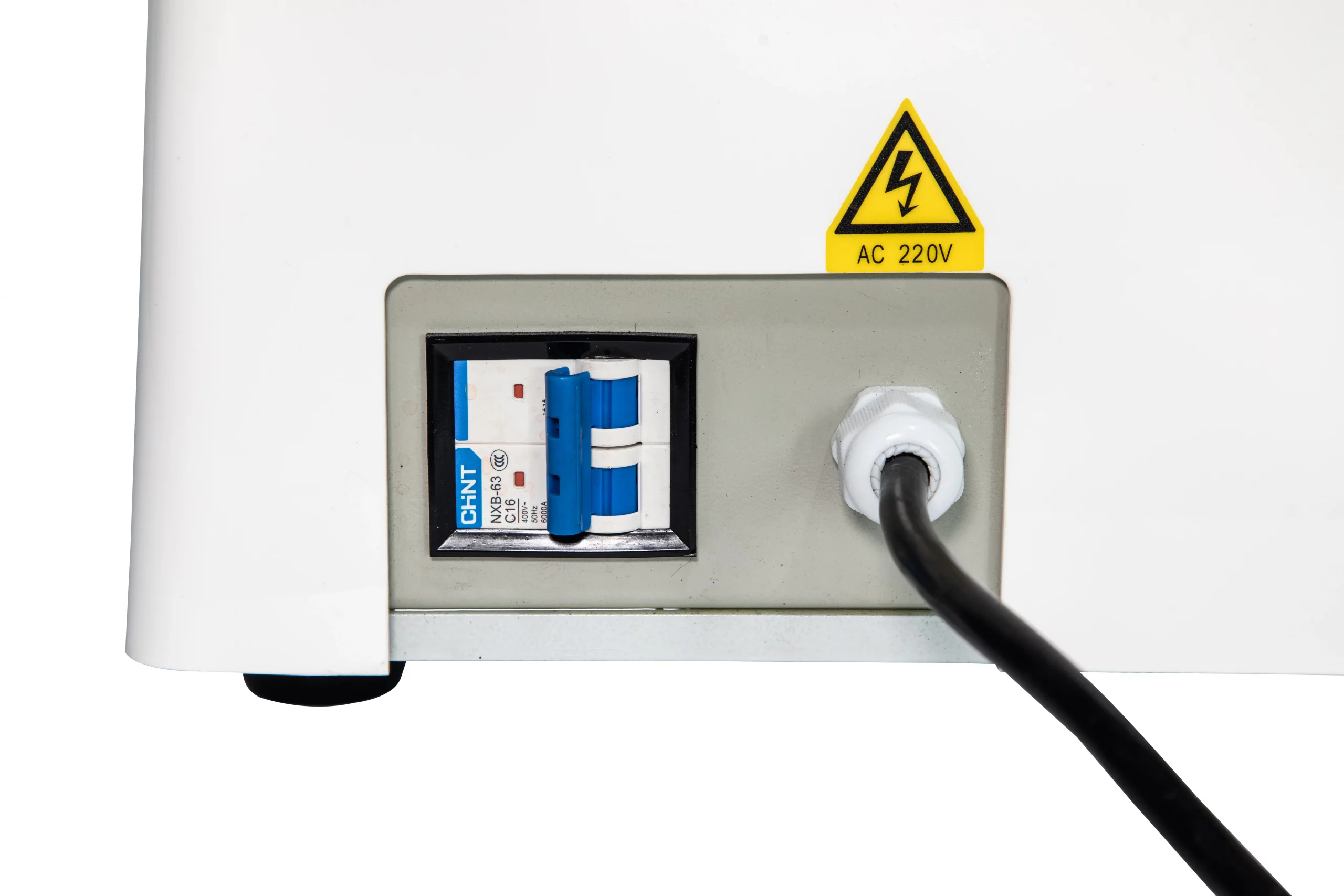

- Power Specs: Draws 4.5KW with an AC220V 50/60 Hz power requirement.

- Physical Footprint: Dimensions are 760 x 580 x 550mm with a 95kg weight. In imperial measurements, it measures 30” x 23” x 22” and tips the scales at 209 lbs.

Additional Components: The press ships with a range of accessories: the mounting press, specified mold assembly, powder spoon, funnel, water inlet and drain pipes, cleaning brush, 2 dual spacers, and an instruction manual.

GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press

As opposed to the previous system, the ‘Dual’ variant, the MFA HYD focuses on singular processing. Its compact design, emphasizing reduced weight and dimensions, makes it the best choice for small laboratories and facilities with limited space.

Perfectly tailored for metallurgy, materials testing, and educational scenarios, the MFA HYD seamlessly blends into any workflow, be it standard procedures or groundbreaking research. Small educational facilities aiming for a comprehensive hands-on experience or compact industrial units where every inch of space counts will find the MFA HYD invaluable.

Key Features

- Single Sample Focus: While it processes only one sample at a time compared to its dual counterpart, this feature ensures careful attention to detail for each specimen. It accepts samples ranging from 1” to 2″, as well as metric measurements from 25mm to 50mm.

- Versatile Operational Modes: Adapt to any situation with the ability to switch between manual and automatic operation effortlessly.

Technical Specifications

- Pressure Handling: The MFA HYD boasts a broad operational pressure range of 0-300 bar, allowing settings adjustable from 0-60 bar.

- Temperature Control: Armed with a 2KW heater, it provides a temperature range from 0 – 200℃, ensuring optimal heat treatment.

- Power Management: It operates at 2.2KW and is powered by an AC220V 50/60Hz supply.

- Compact Dimensions: The unit measures 460 x 600 x 500mm and weighs 65kg. For those more familiar with imperial metrics, it’s 18” x 24” x 20” with a weight of 143 lbs.

Package includes: Each MFA HYD unit comes bundled with essential accessories such as the mounting press, chosen mold assembly, powder spoon, funnel, water inlet and drain pipes, cleaning brush, a dual spacer, and a comprehensive operation manual.

GenPress MFA MOT – Fully Automatic Motorized Mounting Press

The GenPress MFA MOT, a model of the MFA series, is notable for its motorized control system. This system not only offers a high degree of precision but also provides a seamless operational experience for users.

Designed for metallurgy, material testing labs, and educational institutions, the MFA MOT seamlessly balances routine operations with research demands. Its motorized mechanism ensures a steady, consistent application of pressure. This results in quicker response times and reduced wear and tear, compared to certain hydraulic systems.

Key Features

- Motorized Control System: One of the few in the MFA series to boast motorized controls, this system ensures a consistent and efficient mounting process, offering impeccable results every time.

- Sample Flexibility: The press is adept at handling a myriad of sample sizes, from 1” to 2″, and metric counterparts from 25mm to 50mm. With optional sample spacers, it’s capable of preparing one to two samples simultaneously.

- Operational Modes: Flexibility is key, with the ability to switch between manual and automatic operation based on user requirements.

Technical Specifications

- Pressure Dynamics: The MFA MOT operates within a 0-300Bar spectrum, with adjustable settings ranging from 0-60Bar.

- Heating Capabilities: A robust 2KW heating element facilitates a temperature spectrum of 0 – 200℃.

- Timing: Both mounting and cooling durations can be customized between 0-99 minutes.

- Power Metrics: Operating at 2.2KW, it’s supported by an AC220V 50/60Hz power source.

- Dimensions: Compact yet sturdy, it stands at 460 x 600 x 500mm, weighing 60kg. In imperial terms, this translates to 18” x 24” x 20” with a weight of 132 lbs.

Included Accessories: Each unit is equipped with a selection of tools, including the mounting press, designated mold assembly, powder spoon, funnel, water inlet and drain pipes, cleaning brush, dual spacer, and a comprehensive user manual.

Utilizing GenGrind in Combination with GenPress MFA Processes

After the preparation of samples using the GenPress MFA series mounting presses, the next step in the metallographic sample preparation process is grinding and polishing. GenGrind’s FA-IC 10″ Dual Wheel Fully Automatic Grinder & Polisher suits this purpose.

GenGrind FA-IC: Integration with GenPress MFA Series

The GenGrind 10” FA-IC is a modern grinding and polishing machine, controlled by a single-chip microcomputer. Designed with precision in mind, it perfectly complements samples prepared using the GenPress MFA series.

Constructed with a durable ABS material shell, the GenGrind FA-IC ensures resistance to corrosion, making it a durable choice for any laboratory environment. Furthermore, its stepless speed control and reversible rotational direction provide versatile grinding and polishing options, catering to a wide range of metallographic sample requirements.

Offering both individual and central pressure grinding methods, the GenGrind FA-IC replaces manual grinding and polishing, reducing labor-intensive tasks. By integrating it with the GenPress MFA series, laboratories can streamline their sample preparation process, ensuring consistent, high-quality results at every phase.

The Importance of High-Quality Results in Metallographic Sample Preparation

An accurate material analysis begins with the preparation of metallographic samples. Its importance extends across industries and research domains, underpinning countless applications’ reliability and safety.

Consider the construction industry. In this domain, materials lay the foundation for towering skyscrapers and other massive infrastructures. A single defect in a steel beam or inconsistency in concrete could undermine an entire building’s structural integrity. Failures in this sector have significant financial implications but also put lives at risk. Consequently, meticulous metallographic analysis, underpinned by exemplary sample preparation, is indispensable in certifying construction materials’ dependability.

Beyond immediate safety concerns, incorrect metallographic analysis has significant economic implications. A mistake in material characteristics could lead to poor material selection or processing decisions. This might, in turn, result in product recalls, warranties, or even lawsuits. Moreover, trust, once lost to consumers and partners due to material failures, is difficult to regain.

In academia and research, the reputation of institutions depends on the accuracy of their findings. When researchers share their results, it expands the scientific community’s collective understanding. However, if their metallographic investigations rely on poorly prepared samples, the conclusions drawn may be incorrect. These mistakes aren’t confined to just one publication; they spread through the scientific community, potentially leading subsequent researchers astray and misallocating resources and funding.

A study in the International Journal of Metallography clearly underlines the growing demands for specialized material properties. It also illustrates how they emphasize the need for precise metallographic analysis. Properly characterizing these metals ensures they meet the rigorous standards necessary for their wide-ranging applications.

Why the GenPress MFA Series Mounting Presses is the Best Choice

The GenPress MFA Series Fully Automatic Mounting Presses from NextGen Material Testing Inc. represent the ideal combination of engineering precision and cutting-edge technology. Designed specifically for metallographic sample preparation, these devices stand out for their comprehensive approach to optimal sample integrity. Users benefit from advanced programming capabilities, allowing them to easily save and manage a variety of custom processes.

Constructed with great attention to detail, the series ensures precision during the heating, compression, and cooling stages. The goal is clear: to maintain the highest quality of samples without compromise. The resilient design, marked by a robust ABS shell, is crafted not just for longevity but also for resisting common laboratory chemical interactions.

Its core functionality is centered around a 7” touchscreen controller, streamlining parameter adjustments for heating, cooling, and timing. With storage capacity for 100 custom programs, it simplifies repetitive tasks. Its automation allows lab technicians to focus on other tasks, signaling once the cycle is complete.

The series boasts a motorized compression system, a compact design adaptable to various settings, and flexibility in sample sizes from 1” to 2”, including metric sizes. Moreover, with optional spacers, it can prepare two samples in one cycle, marking the MFA Series as a cost-effective metallography solution.

For everyone, there’s a solution that’s right for them:

GenPress MFA Dual HYD – Fully Automatic Dual Hydraulic Mounting Press – For those who demand speed and comprehensive research capabilities without compromising quality.

GenPress MFA MOT – Fully Automatic Motorized Mounting Press – A great choice for those who prefer motorized control over hydraulics.

GenPress MFA HYD – Fully Automatic Hydraulic Mounting Press – Designed for those working in compact laboratory spaces.

Some more benefits of the MFA Series:

- Ultimate User-Friendliness: A 7-inch touchscreen interface graces every MFA Series model. This innovation simplifies tasks, from adjusting settings to saving custom programs and reducing setup durations.

- Leading Dependability and Reliability: Commitment to excellence is evident in performance consistency and precision, a feature invaluable in both research and industrial environments.

Diversity Tailored for Every Need: The series doesn’t adopt a one-size-fits-all approach. Instead, it diversifies with models that offer dual processing, compact forms, and motorized controls, catering to varied lab requirements.

Diversity Tailored for Every Need: The series doesn’t adopt a one-size-fits-all approach. Instead, it diversifies with models that offer dual processing, compact forms, and motorized controls, catering to varied lab requirements.- Strict Compliance with Industry Standards: Compliance isn’t just theoretical. Each system meets rigorous industry benchmarks.

- NIST Certified Consumables: The significance of accurate results can’t be overstated. Hence, the inclusion of consumables that adhere to NIST certification standards.

- Stocked Consumables and Spares: Maintaining operational continuity is crucial. With a ready stock of consumables and spares, there is never a chance of disruption.

- Trusted After Sales Technical Support: Beyond the purchase, users are guaranteed exceptional technical support, indicative of NextGen’s commitment.

- Lifetime Product Support Advantage: A long-term commitment to partnership, ensuring every system operates at its optimal level throughout its operational span.

Don’t delay! If you require a fully automatic mounting press system for metallographic sample preparation or have additional questions, please contact us for a quote.