Metallography is ever-evolving, and with it, comes the demand for advanced tools that ensure precision with minimal manual intervention. Hence, we have the GenGrind FA-IC, a state-of-the-art automatic grinder & polisher from NextGen Material Testing. Rather than being just another tool, the GenGrind FA-IC is a testament to technological advancements in metal testing equipment. This grinder and polisher seamlessly merges functionality with user-friendliness, providing not only excellent results but also an exceptional user experience. In this blog, we’ll explore what makes this product unique in the industry.

What is a Fully Automatic Grinder and Polisher System

An automatic grinder and polisher system prepare smooth surfaces on metal samples so that their true structure can be viewed under a microscope. It’s an essential tool for studying metal structures’ tiny details.

This machinery, being “automatic,” is particularly favored for its ability to operate without human intervention. It provides consistent and repeatable results, minimizing human-induced variables that might otherwise lead to errors in sample preparation. Given its precise nature, the machine is useful for a range of professionals, including metallurgists, industrial researchers, quality assurance experts, and those engaged in metal manufacturing processes.

Application and Usage of Automatic Grinder & Polisher

The automatic grinder & polisher is a key tool in today’s materials science and engineering world. Devices like the GenGrind FA-IC have made a notable impact, offering both efficiency and precision. Their primary role extends beyond just refining surfaces. These machines have a widespread impact across a range of industries.

This critical role showcases how crucial such machines are in connecting raw materials to conclusive research. As different industries evolve, GenGrind FA-IC and similar devices become increasingly important. Let’s look at the wide range of applications and value these machines contribute to various industries.

Semiconductor Manufacturing

As microelectronics demand surges, the semiconductor industry requires grinders and polishers to achieve ultra-smooth wafer surfaces. The GenGrind FA-IC, with its customizable settings, ensures wafer surfaces are free from microscopic irregularities, essential for integrated circuits.

Biomedical Engineering

Advanced materials, especially biocompatible metals and ceramics, are now an integral part of medical devices and implants. The surface finish of these materials affects cellular responses and, in the case of implants, integration with body tissues. Therefore, a consistent and reliable grinding and polishing process becomes flawless.

Forensic Laboratories

Forensic metallurgy often involves the examination of fractured metal surfaces to determine the cause of failure. A reliable grinder and polisher help prepare the specimen to microscopic levels. This enables analysts to determine whether the failure was due to material defects, external factors, or intentional manipulation.

Archaeometallurgy

This scientific field focuses on the study of metal production and use in ancient times. An automatic grinder and polisher like GenGrind FA-IC can assist archaeologists in preparing specimens from ancient artifacts, allowing them to study the metallurgical practices of bygone eras without harming precious samples.

Jewelry and Watchmaking

The high-end jewelry and luxury watch industries demand impeccable surface finishes for aesthetic and functional reasons. The GenGrind FA-IC ensures precious metals and gems are polished to their best without removing excessive material.

Geology and Petrography

Studying the earth’s crust and its various compositions requires thin sections of rocks and minerals. A reliable grinder & polisher ensures that these thin sections are prepared with precision, enabling geologists to study the mineralogy and texture under microscopes.

Nanotechnology Research

As we explore the nanoscale, the need for ultra-precise grinding and polishing becomes evident. Whether it’s for studying nanowires, quantum dots, or other nanostructures, having a good grinder and polisher becomes increasingly important.

Renewable Energy

With a growing emphasis on sustainable energy, research into materials for solar cells, fuel cells, and advanced batteries continues to grow. The quality and efficiency of these materials can be greatly affected by their surface topology. Thus, a precise grinder & polisher ensures optimal performance.

Introduction to GenGrind FA-IC – Dual Wheel Fully Automatic Grinder & Polisher

GenGrind FA-IC represents the pinnacle of precision engineering, integrating the latest in single-chip microcomputer control to redefine grinding and polishing standards. Built with a robust ABS material shell, the machine is compact and has commendable resistance to corrosion. These are crucial factors in ensuring longevity in lab environments. This material choice is a testament to the manufacturer’s commitment to durability, reinforcing its position in an industry where equipment reliability is important.

At the core of GenGrind FA-IC is its versatility. It features step-less speed control, enabling operators to fine-tune grinding or polishing speed to each sample’s specific needs. This ensures optimal results for every specimen, regardless of the specimen’s characteristics. Further, the reversible rotational direction offers adaptability to processes, allowing for a wide range of sample requirements. The grinding head’s dual-method approach—offering both individual and central pressure—allows for increased flexibility in sample preparation, marking a change from traditional, rigid systems.

While many machines in the industry promise efficiency, the GenGrind FA-IC – dual wheel fully automatic grinder and polisher delivers on this promise by reducing the amount of labor-intensive manual grinding and polishing processes. This reduction is not just in terms of time but also in consistency. Manually prepared samples can vary depending on the technician’s skill and fatigue levels. By automating this process, the machine guarantees consistent, high-quality sample preparation that is essential for accurate metallographic analysis.

Furthermore, the GenGrind FA-IC underscores its commitment to users through its support features. NIST Certified Consumables ensure equipment adheres to stringent industry standards, ensuring reliability. In addition, the ready availability of stocked consumables and spares minimizes downtime, while the trusted after-sales technical support and lifetime product support advantage reflect a brand that stands firmly behind its product. All these elements come together to make the GenGrind FA-IC the perfect tool for any establishment seeking excellence in metallographic sample preparation.

A Closer Look at the GenGrind FA-IC Dual Wheel Features

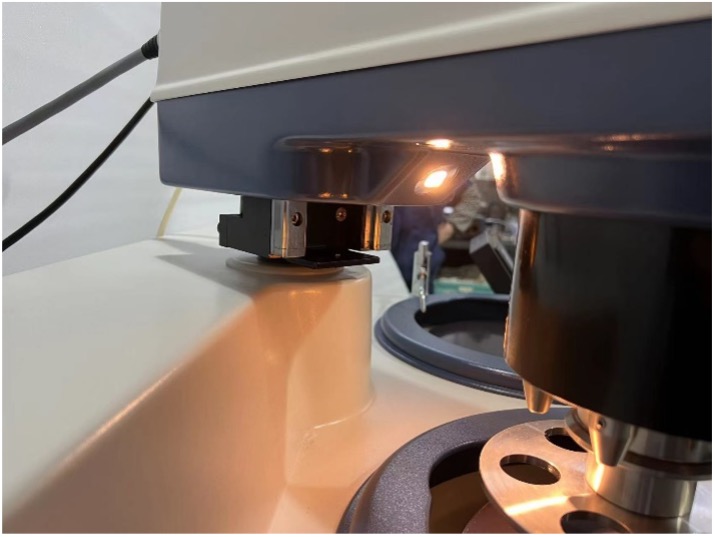

One of the standout features of the GenGrind FA-IC is its high-definition LCD touchscreen. This isn’t just a technological novelty, it’s a game-changer in grinding and polishing. Operators can manage the entire process with a touch, eliminating manual adjustments. It provides a clear, intuitive display that streamlines operations, reducing the learning curve for novice users and improving efficiency for experienced operators.

The heart of the machine, however, is its automatic grinding and polishing system. Traditional metallographic sample preparation required careful manual oversight, with operators adjusting time, speed, and water flow as needed. The GenGrind FA-IC – dual wheel fully automatic grinder & polisher is automated in all of these aspects. Its customizable settings mean samples can be prepared under highly controlled conditions, ensuring consistency across batches. The system’s unique self-adaptive grinding disc design is especially noteworthy. Achieving an ideal fit with the sample ensures uniform grinding surfaces, crucial for accurate microscopic examinations. This adaptability solves many issues related to generic grinding machines, which may not account for diverse samples processed in labs.

The design prioritizes safety and convenience. The grinding head’s automatic locking function exemplifies this commitment. This ensures that the machine operates safely, reducing potential hazards associated with unsecured grinding heads. Furthermore, the magnetic grinding disc design simplifies the disc replacement process—a feature highly appreciated by any operator who has difficulty with manual replacements. The Teflon-coated disc surface promotes cleanliness, resisting material build-up which could compromise subsequent grinding and polishing sessions.

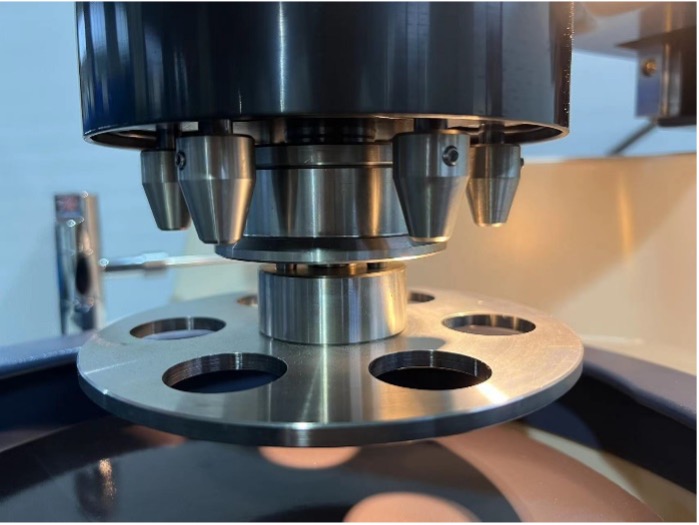

GenGrind FA-IC’s dual wheel design showcases its advanced engineering. It eliminates constant paper/pad changes, significantly speeding up the process. This dual system allows for in-sync grinding and polishing, an efficiency rarely seen in the industry. The inclusion of a DC brushless motor further testifies to the machine’s premium build quality. Not only does it ensure a prolonged service life, but it also reduces operational noise—an important factor in lab environments—while delivering powerful grinding and polishing performance.

A notable highlight is its built-in memory capabilities, allowing storage of up to ten different grinding and polishing procedures. This feature may appear simple, but it’s revolutionary for laboratories that deal with a wide range of samples. The ability to switch between different parameter settings ensures versatility and convenience.

Also, the GenGrind incorporates a highly advanced load cell system, optimized for its pneumatic polisher and grinder unit. Unlike traditional spring force systems, the pneumatic approach provides a more consistent force load across the specimen. This stability, as captured by the load cell’s precision feedback, ensures that each grind or polish delivers superior surface quality. As a result, the GenGrind – dual wheel fully automatic grinder & polisher stands out for its ability to achieve exceptional consistency and reliability in metallographic preparation.

Lastly, the GenGrind FA-IC’s design focuses on longevity and precision. The robust support design assures precision rotary balance, ensuring consistent performance. Meanwhile, the leak-proof spindle design offers additional protection to the machine’s internal bearings, protecting them against potential damage and extending the equipment’s lifespan.

Specifications of the Dual Wheel Automatic Grinder & Polisher – GenGrind FA-IC

Certainly, when exploring the GenGrind FA-IC models, it’s important to understand their differences in order to determine their appropriateness for various applications. There are two primary models: the FA-IC 250 Dual and the FA-IC 300 Dual. The FA-IC 250 Dual is designed with a more compact disc diameter of 250mm, making it ideal for labs or industries where space is limited but performance can’t be ignored. On the other hand, the FA-IC 300 Dual, with its 300mm disc diameter, is more suitable for applications requiring a larger surface area for grinding and polishing.

Both models come with stepless speed control, ranging between 50-100 rpm, which allows fine-tuning the machine’s operation to achieve the desired results. The ability to change the rotational direction of the disc from clockwise to counterclockwise adds another layer of versatility, allowing different types of grinding and polishing actions. When it comes to the electromotor that powers the disc, both models have a DC brushless motor, operating at 110V and providing 1.2 kW of power. According to industry sources, DC brushless motors are known for their high efficiency and reliability. This makes them ideal for applications where long operational life and reduced noise levels are critical.

Moving on to the power head motor, it also employs a DC brushless motor, but with a power output of 750W, providing the muscle needed for rigorous grinding and polishing. Its head speed is adjustable between 20-120 rpm, ensuring that the machine can adapt to different hardness and compositions of metallic specimens. For holding samples, both machines come standard with a capacity for six pieces 30mm in diameter. However, for those needing different sizes, there are options ranging from Φ25mm to Φ40mm or custom sizes upon request, showcasing the equipment’s adaptability.

Pressure control is critical to accurate and reliable metallography results. GenGrind FA-IC models offer individual or central pressure control methods. While individual pressures range from 0-50N, central pressure goes up to 160N. This flexibility in pressure application is particularly critical for ensuring that specimens meet the exacting standards set by organizations like ISO.

User interface and control are facilitated by a 7-inch LCD touchscreen, which is intuitive and easy to navigate. In terms of safety, an emergency stop button is integrated into the machine, offering immediate cessation of all operations in case of an emergency. Lastly, the robust build measures 1200 x 800 x 760mm and weighs 134kg, indicative of its sturdy construction designed for heavy-duty use.

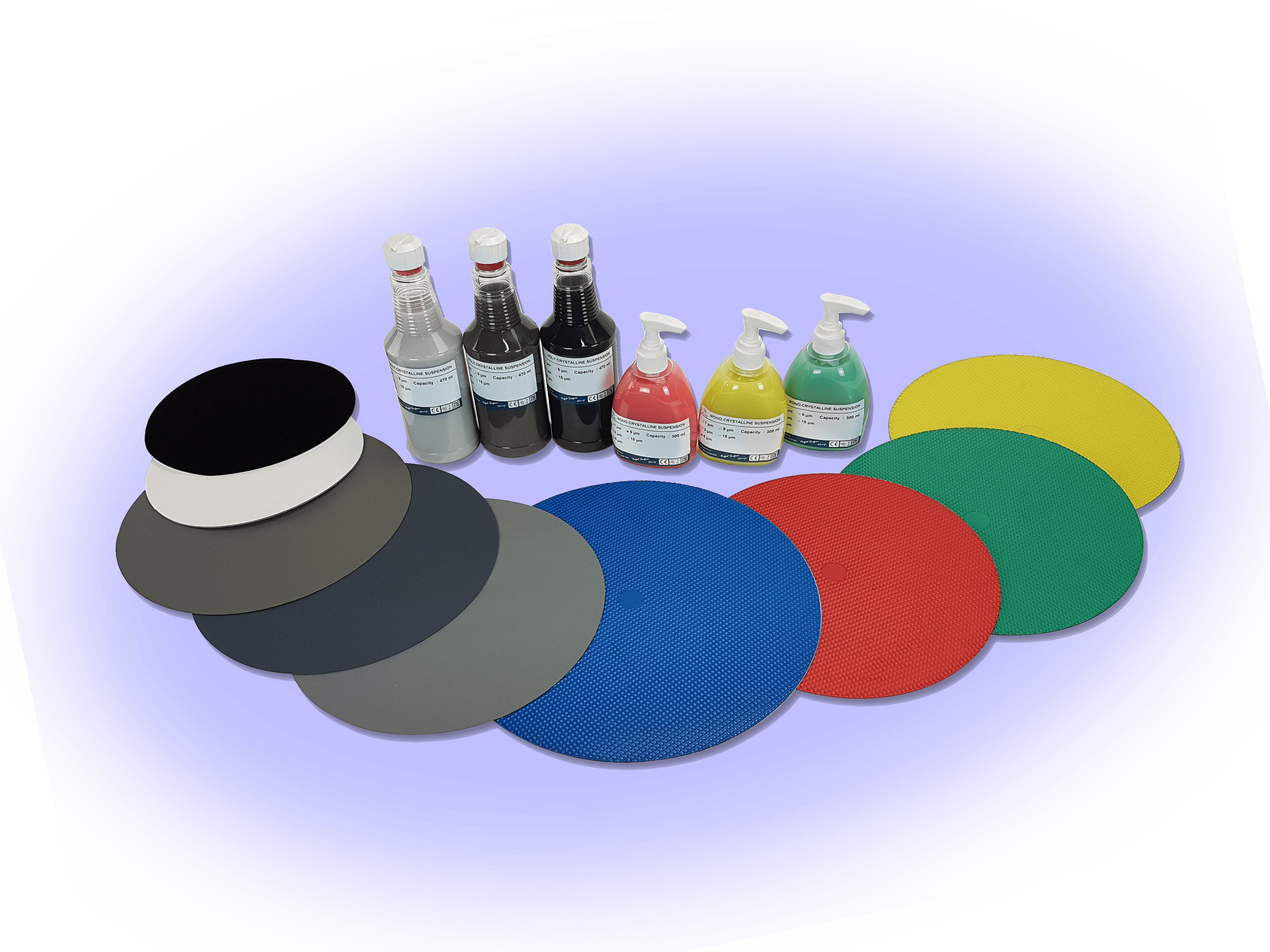

GenGrind FA-IC Dual Wheel Standard Configuration

The GenGrind FA-IC is a comprehensive system designed to cater to metallurgical needs. The standard configuration of this model ensures that the user has all the necessary tools and components right out of the box to begin sample preparation.

The main component of this configuration is the dual wheel GenGrind FA-IC. Designed with both individual and central force control, this machine provides users with the flexibility to handle a wide range of sample sizes and types, ensuring precise grinding and polishing.

To assist with grinding and polishing, an automatic power head is included. This power head minimizes manual interventions and ensures consistency in sample preparation.

A vital component of any grinding and polishing system is water flow. The GenGrind FA-IC comes equipped with a specialized water pipe. This ensures that the specimen remains cool during grinding, preventing overheating and potential damage to the sample’s microstructure.

Safety and cleanliness are of the highest importance. The splash cover included in the standard configuration ensures that the surrounding workspace remains clean and free from water and abrasive residues.

For the actual grinding process, the GenGrind FA-IC offers an aluminum grinding platen, complemented by an O-ring. This combination ensures uniform pressure distribution and effective grinding. Similarly, for polishing, an aluminum polishing plate is provided. This platen guarantees a smooth and even polishing surface.

To hold the specimens securely during grinding and polishing, a quick-release sample holder adapter is included in the configuration. This adapter simplifies the process of switching between samples, making the process efficient.

To get users started, the GenGrind FA-IC dual standard configuration includes 4x silicon carbide papers and 2x abrasive polishing cloths. These consumables are essential for initiating the grinding and polishing processes.

Lastly, to ensure users can make the most of their GenGrind FA-IC Dual, an operational manual is provided. This manual is a comprehensive guide, detailing machine operations, maintenance protocols, and troubleshooting tips.

In summary, GenGrind FA-IC dual standard configuration is a complete package, designed with convenience and efficiency in mind. Whether you are a seasoned metallurgist or just starting out in the field, this configuration ensures you have everything you need to produce high-quality metallographic samples.

Why Choose GenGrind FA-IC Dual Wheel Fully Automatic Grinder & Polisher?

When it comes to advanced metallography equipment, the GenGrind FA-IC emerges as a notable choice, and here’s why. This machine is designed to meet the increasing need for consistent and automated sample preparation in metallography. One of its most remarkable features is the high-definition LCD touchscreen, which provides operators with an intuitive interface, significantly reducing the learning curve and simplifying adjustments.

At its core, GenGrind FA-IC’s automatic grinding and polishing system differentiates itself from traditional methodologies. It ensures that metal samples are prepared under controlled conditions, enabling consistency that is difficult to achieve manually. The dual-wheel design further enhances its efficiency, allowing both grinding and polishing, which expedites the process and reduces possible differences between samples.

Safety is another critical aspect where the GenGrind FA-IC stands out. The automatic locking function of the grinding head ensures operations are secure, mitigating risks. Moreover, its pneumatic load cell system provides an edge over traditional spring force systems. Ensuring a more consistent force load guarantees higher surface grinding and polishing quality.

Lastly, its built-in memory capabilities, allowing storage of up to ten different procedures, signify its versatility. This feature is especially beneficial for laboratories dealing with different samples, facilitating a seamless switch between multiple parameter settings. All in all, the GenGrind FA-IC from NextGen. combines technology, safety, and efficiency, making it a preferred choice for modern metallography labs.

NextGen Material Testing Inc. guarantees the high-quality performance of the GenGrind FA-IC – dual wheel fully automatic grinder and polisher, as well as the accuracy of the results in metallographic sample preparation.

For more detailed information about the GenGrind FA-IC – fully automatic grinder and polisher, make a request on our website, and we will answer all your questions.