In the field of material testing, there are thousands of standards, each of which has been developed for a particular material type, testing method, or application. These standards are more than just guidelines—they establish strict technical requirements that must be met for a material or product to achieve compliance. The reliability and clarity of certain of these standards have resulted in their widespread recognition and frequent use in laboratories and industries worldwide.

The same applies to impact testing. Although there are many standards present on a global scale, only some of them are consistently referenced and used in practical applications. These standards are the foundation for the assessment of impact resistance in materials and components throughout an extensive spectrum of industries.

This article presents the most common and widely accepted standards related to the three principal types of impact testing: Charpy, Izod, and drop weight testing. Whether working in a testing laboratory, overseeing quality assurance processes, or managing materials in production environments, understanding these standards is a requirement for accurate, consistent, and compliant testing.

What is Impact Testing?

To gain an in-depth understanding of the standards, it is necessary to first comprehend the purpose and nature of the testing. Impact testing is a technique used to assess the behavior of a material in response to a sudden force or shock. It aids in the assessment of a material’s toughness, which is its capacity to absorb energy during a fracture without breaking. This property matters in safety-critical applications, where materials must operate consistently in the face of unforeseen impact conditions.

There are several methods of impact testing, but three stand out as the most widely used due to their reliability and standardization: Charpy, Izod, and drop weight impact testing. Each of these methods involves a specific specimen or

ientation, testing setup, and energy measurement approach, which are strictly defined by international standards.

Below is a brief overview of these three primary methods:

- Charpy impact testing involves a notched specimen supported horizontally and struck behind the notch by a swinging pendulum. It is often used with metals and assists in the determination of the energy absorbed during fracture.

- Izod impact testing is similar in concept but differs in setup. The specimen is struck on the same side as the notch and clamped vertically as a cantilever beam. This method is frequently applied to plastics and polymers.

- Drop weight impact testing uses a free-falling weight that strikes the specimen from a specified height. This method is commonly used to assess the ductile-to-brittle transition behavior or puncture resistance of materials such as steels, composites, and plastic films.

Key Standards for Charpy Impact Tests

We will begin with Charpy impact testing standards, as this is the most commonly used method of impact testing. The following are the most recognized and applied standards:

ASTM E23 – Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

ASTM E23 is the primary United States standard that outlines the procedures for conducting Charpy impact testing on metals. It also includes provisions for the Izod method. The standard specifies key technical parameters such as specimen dimensions (typically 10 mm × 10 mm × 55 mm with a V-notch or U-notch) and detailed procedures for measuring absorbed energy. It is extensively used throughout North America for testing steels and other metallic materials.

ISO 148-1 – Metallic Materials – Charpy Pendulum Impact Test – Part 1: Test Method

ISO 148-1 is the internationally recognized standard for Charpy impact testing of metallic materials. It includes both V-notch and U-notch methods. This standard has replaced the earlier EN 10045-1, which is now withdrawn. Although ISO 148-1 is largely equivalent to ASTM E23, it allows for different striker geometries (such as an 8 mm striker in addition to the 2 mm radius striker defined in ASTM), which can result in slight differences in absorbed energy measurements for tougher materials.

ASTM A370 – Standard Test Methods and Definitions for Mechanical Testing of Steel Products

ASTM A370 is a broad standard covering various mechanical testing procedures for steel products, including tension, hardness, bend, and impact tests. It incorporates Charpy V-notch impact testing as part of its methodology, referencing ASTM E23 for detailed procedures. In practice, this standard is often used for testing steel components such as structural steel and pressure vessels, providing acceptance criteria while maintaining consistency with ASTM E23.

Charpy Impact Testing Standards for Plastics

While primarily associated with metals, Charpy impact testing is also applied to plastics. Two key standards in this area are ASTM D6110 and ISO 179.

- ASTM D6110 – Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics defines procedures for testing plastic specimens using a pendulum impact method.

- ISO 179 – Plastics – Determination of Charpy Impact Strength similarly defines methods for assessing the impact resistance of plastic materials.

These standards are conceptually similar to those used for metals but specify different specimen dimensions (for example, 80 × 10 × 4 mm in ISO tests) and testing conditions tailored to the behavior of polymer-based materials.

Most Used Standards for Izod Impact Testing

Izod testing, while less commonly used for metals today, remains a standard method for assessing the impact resistance of plastics and polymer composites. Below are the most frequently referenced standards for Izod testing:

ASTM E23 (Izod for metals) – Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

ASTM E23 covers both Charpy and Izod methods for testing metallic materials. Although Charpy testing is more prevalent for metals, the standard does include specifications for conducting Izod impact tests, with specimen dimensions such as 75 mm length for Izod compared to 55 mm for Charpy. Izod testing of metals was historically applied in some industries, and it may still appear in older specifications or in certain regional requirements.

BS 131: Part 1 (Izod for metals) – Izod Impact Test on Metals

British Standard 131-1:1961 was the classic United Kingdom standard detailing the Izod impact test for both ferrous and non-ferrous metals. It specified test conditions, specimen geometry, and procedures. Although largely superseded in Europe by Charpy-based standards such as EN 10045 and ISO 148, BS 131 is still occasionally referenced in older documentation or legacy testing protocols. Part 2 of this standard addressed Charpy testing separately.

ASTM D256 – Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

ASTM D256 is the most widely used standard for Izod testing of plastics. It outlines the procedure for notched Izod impact testing of rigid plastic specimens, typically with dimensions of 63.5 × 12.7 × 3.2 mm. The absorbed energy is measured and reported per unit specimen width (e.g., ft·lb/in or J/m) or per cross-sectional area. ASTM D256 is extensively used in plastic materials datasheets and quality control processes, particularly in North America.

ISO 180 – Plastics – Determination of Izod Impact Strength

ISO 180 is the international counterpart to ASTM D256, used broadly in Europe and other regions. It follows the same principle but applies different specimen dimensions and reports results as energy per unit area (J/m²). Although both ISO 180 and ASTM D256 serve the same purpose, their methodologies are not fully interchangeable, and laboratories typically select the appropriate standard based on client or material specifications.

Most Common Drop Weight Impact Test Standards

The third and final group in our overview is drop weight impact testing standards. Among the many available standards, the following five are among the most commonly referenced and applied in laboratories and industrial settings:

ASTM E208 – Standard Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

This standard defines the drop-weight test used to identify the Nil-Ductility Transition Temperature (NDTT) of ferritic steel specimens. A specimen with a machined notch is struck in a three-point bending setup. The test is repeated at increasing temperatures until ductile behavior is observed. ASTM E208 is regularly referenced for materials such as pressure vessel steels and ship plate, helping confirm that they maintain ductile behavior under service conditions.

ASTM E436 – Standard Test Method for Drop-Weight Tear Tests of Ferritic Steels

ASTM E436 outlines the drop-weight tear test (DWTT), which evaluates fracture behavior of full-thickness steel specimens. A notched sample is impacted, and the resulting fracture surface is analyzed to determine the percentage of shear (ductile) versus cleavage (brittle) appearance. This method is particularly important in pipeline applications where crack arrest and ductility at low temperatures are critical.

ASTM D1709 – Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method

ASTM D1709 is a commonly used standard in the plastics industry to evaluate the impact resistance of plastic films. A hemispherical dart is dropped onto a film specimen, and the weight at which 50% of the samples fail is recorded. This test is essential in packaging and flexible film production for assessing durability under impact.

ASTM D2444 – Standard Test Method for Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling Weight)

This standard applies to plastic pipes and fittings, such as those made from PVC or polyethylene. A guided weight (tup) is dropped onto a pipe specimen to determine its resistance to cracking or breakage. ASTM D2444 is used in quality assurance for plastic piping systems, particularly in construction and infrastructure sectors.

Importance of Equipment Compliance with Impact Testing Standards

The reliability and accuracy of impact tests are contingent upon the use of testing equipment that is fully compliant with relevant international standards, as well as on the preparation of well-prepared specimens and the establishment of proper procedures. Whether performing Charpy, Izod, or drop weight tests, laboratories must rely on testing systems that match the dimensional, mechanical, and functional requirements defined by standards such as ASTM E23, ISO 148-1, and ASTM E208.

Non-compliant or outdated equipment can lead to inaccurate readings, invalid test results, and potential safety risks. For instance, the design and maintenance of temperature control systems, pendulum energy range, specimen support configuration, and striker geometry must conform to strict specifications. The comparability and traceability of results can be compromised by any deviation.

Additionally, countless quality assurance programs and audit procedures necessitate documented evidence that testing machines are not only calibrated but also comply with the standards that govern the testing process. It is needed to select certified, standard-compliant equipment in order to guarantee the reliability of materials testing operations, pass audits, and maintain credibility.

NextGen’s Impact Testing Equipment with Full Standards Compliance

At NextGen, we realize the value of dependable material testing equipment and its ability to produce repeatable, precise results. Additionally, we acknowledge that full compliance with international standards is a necessity. Consequently, our product line is engineered to satisfy the precise technical specifications provided by esteemed organizations, including ASTM, ISO, and EN.

We provide a comprehensive selection of impact testing systems to meet the requirements of an array of industries. Our catalog covers an extensive array of specialized equipment, including optical projector systems for dimensional accuracy and notch verification, as well as environmental chambers for specimen conditioning. These are just a few examples—our offerings also cover comprehensive solutions for Charpy, Izod, and other types of impact tests.

If you are considering purchasing impact testing equipment, here are some of our most trusted systems:

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

The Class G impact tester is a single-column system that is designed to meet the requirements of ISO 148, ASTM E23, and EN 10045. It is capable of conducting both Charpy and Izod impact tests with exceptional precision. It is adaptable to both educational laboratories and high-demand industrial environments, and it is available in 450 J and 750 J configurations. The durable and scalable solution for precise and repeatable high-energy pendulum testing is provided by the enclosed safety structure, analog and digital readouts, PC connectivity, and optional automation upgrades, including specimen feeding and cooling systems.

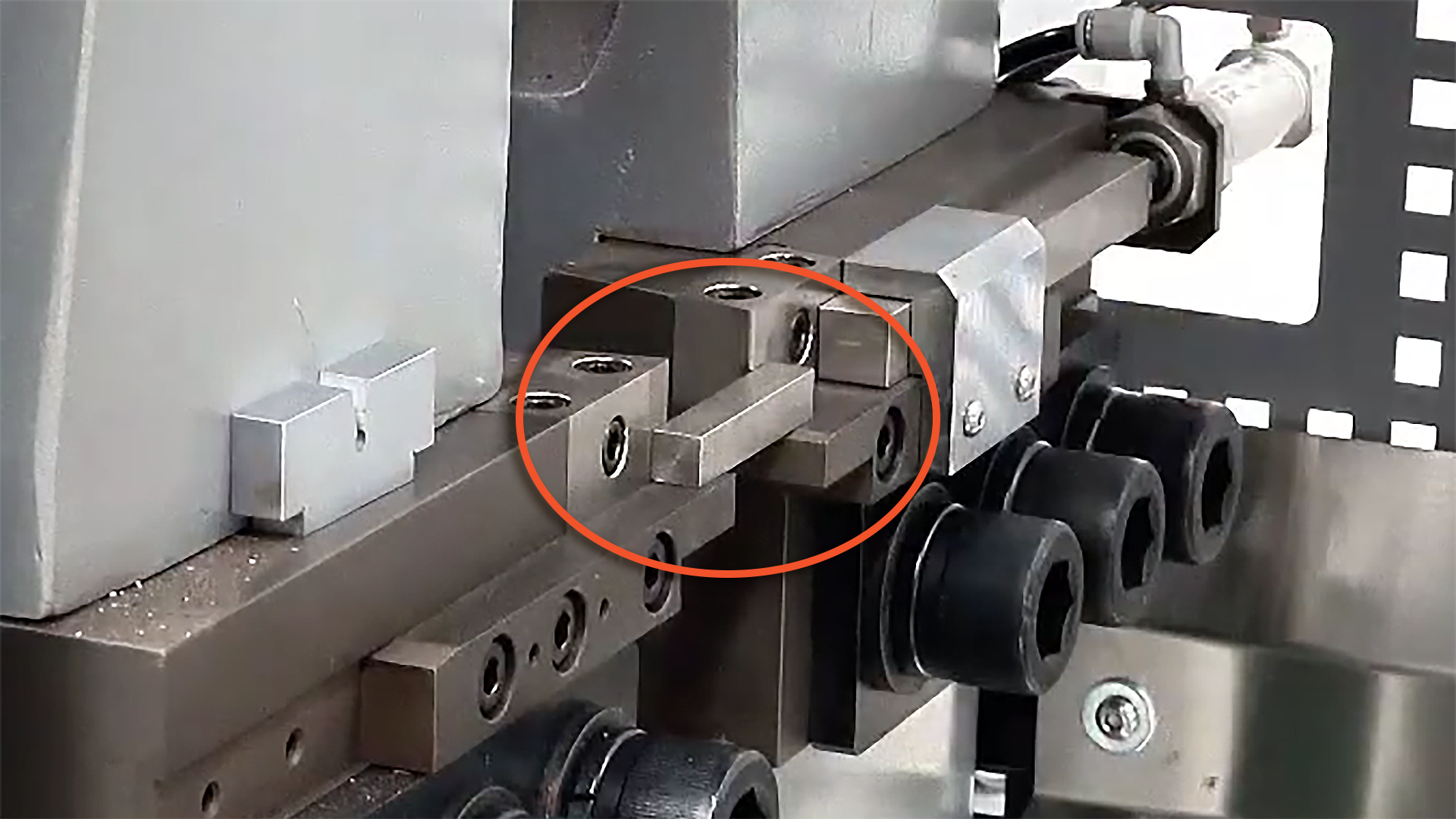

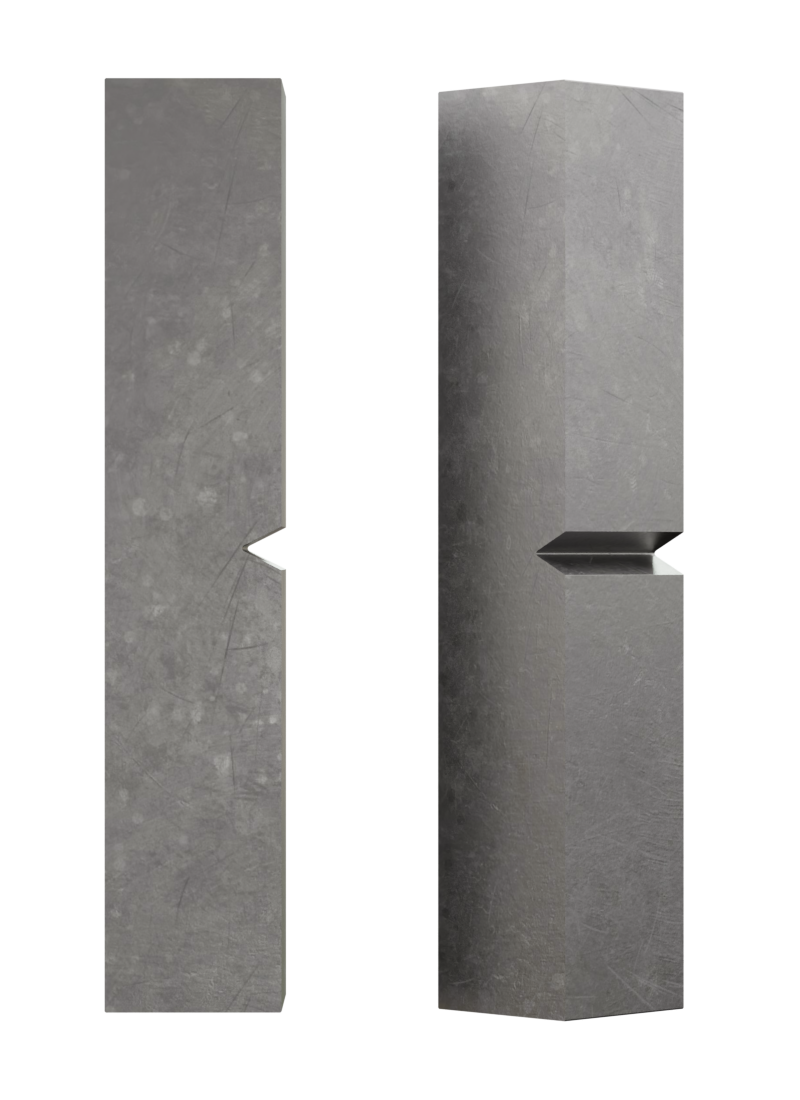

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy notch-making machine that has been created to generate high-quality V-type and U-type notched specimens across three chambers in a single cycle. This unit meets the requirements of ISO 148, ASTM E23, and DIN 50115, guaranteeing that specimen preparation is conducted with precision, repeatability, and speed. It is the optimal choice for laboratories that need minimal operator involvement and demand reliable, standards-compliant notch formation, thanks to its intuitive interface, oil-lubricated cutting system, and compatibility with various notch profiles and material hardness levels.

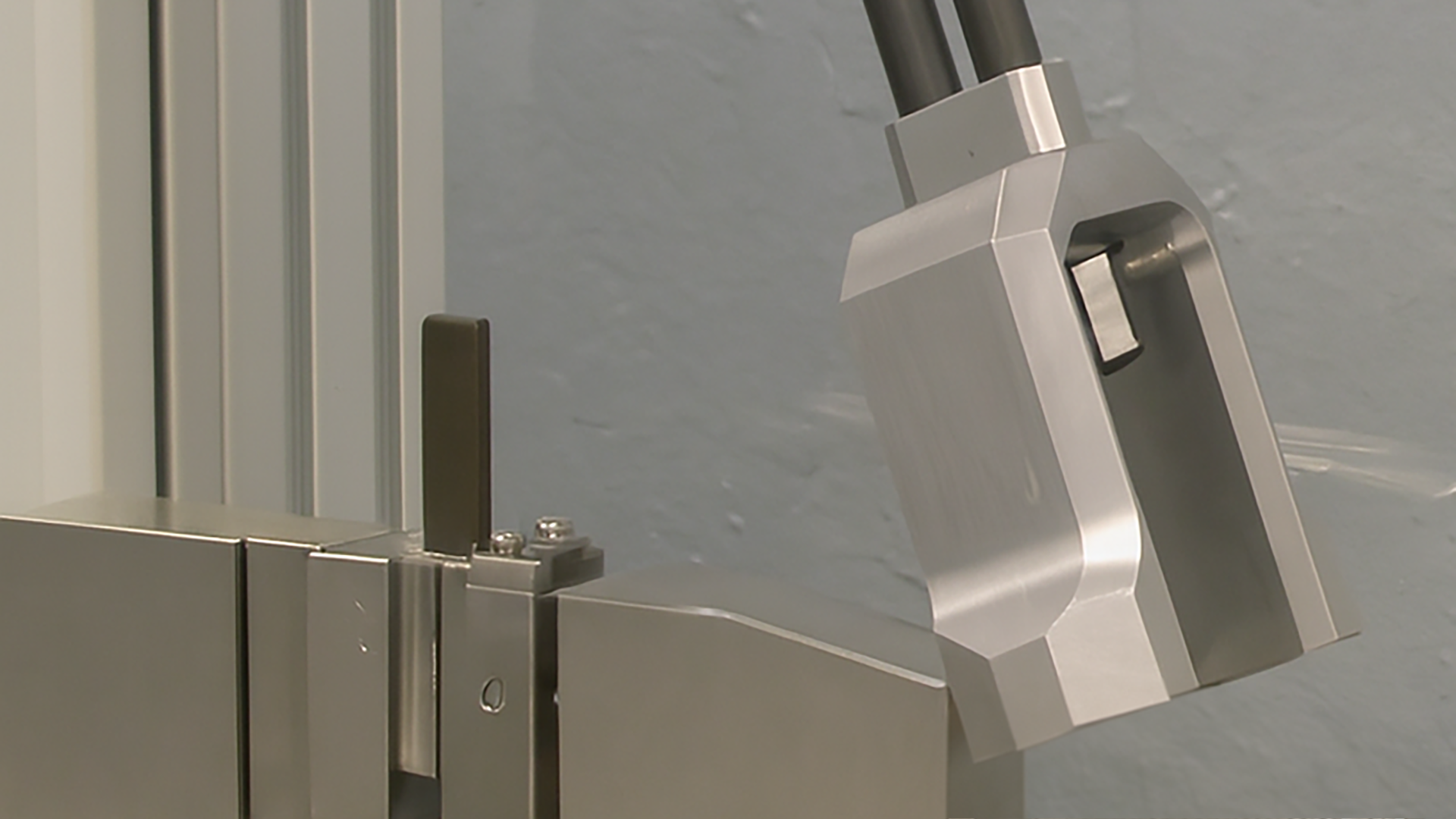

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

The NG-NPS-CIS projector system provides precise optical verification of Charpy and Izod notch geometries using 50× magnification and a Φ200 mm projection screen. It is engineered to ensure precise notch inspection using certified reference templates, real-time digital readout, and advanced table adjustment capabilities, all of which are in full compliance with ASTM E23 and ISO 148. This system is a key tool for laboratories that prioritize specimen verification, notch conformity, and compliance with international standards, as it includes built-in calibration and traceability capabilities that guarantee consistent, audit-ready measurements.

Final Thoughts on Standardized Impact Testing

Understanding and implementing the appropriate testing standards is the initial step toward guaranteeing consistency in material performance evaluation. Each method, whether it be Charpy, Izod, or drop weight testing, has value for evaluating the reliability and durability of materials in the face of sudden impact. The quality and comparability of test results throughout industries are assured by the most commonly used international standards, which provide clear procedures, dimensional requirements, and reporting methods, as demonstrated throughout this guide.

Nevertheless, the delivery of meaningful data is contingent upon the use of fully compliant, properly calibrated equipment, despite the highest standards. This is the reason why it is crucial to choose systems that are built to meet global testing standards.

If you are currently in search of impact testing equipment that suits your technical and compliance requirements, we are here to help. Contact us directly with any questions or request a quote online if you have any inquiries or want to learn more about our solutions.