A flex tester is a special device that determines the flexibility, endurance, and resistance of materials, particularly when exposed to bending or folding. Such tests are crucial, especially for materials like vulcanized or synthetic elastomers, commonly found in products ranging from automotive components to household items. These elastomers have essential resilience and flexibility, ensuring product functionality and durability.

Another vital assessment performed by flex testers is determining the material’s resistance to cut growth. If an elastomer has an initial imperfection or cut, a flex tester can analyze how this flaw might expand with continued flexing. This measure plays a crucial role across various industries. Understanding a material’s vulnerability to cut growth can highlight potential weak points and predict its long-term performance.

The combination of a temperature chamber with a flex tester elevates the testing process. The chamber simulates cold environments, providing insights into how materials behave at such temperatures. For products designed for colder regions, this test becomes indispensable. A material that is flexible and durable at room temperature might turn rigid when exposed to cold, potentially leading to premature failure. With a temperature chamber, industries can ensure product reliability and performance in diverse environmental conditions.

The purpose of this article is to provide an overview of the GenRoss-CH – a Ross Flex Tester with a Low-Temperature Chamber. This equipment represents advanced technology in material testing. Throughout this blog, we’ll discuss GenRoss-CH’s distinctive features and capabilities, aiming to give readers a thorough insight into its functionalities and specifications.

The Usefulness of Ross Flex Testers and Their Applications

As a result of the high value placed on material properties in multiple industries, which place a high value on durability and quality, flex testers, including the GenRoss-CH Ross Flex Tester with a Low-Temperature Chamber, are extremely useful tools for material testing. As we further explore understanding flex testers and their functionalities, it becomes clear how important they are in determining product standards and innovation.

Industry Utilization of Flex Testers

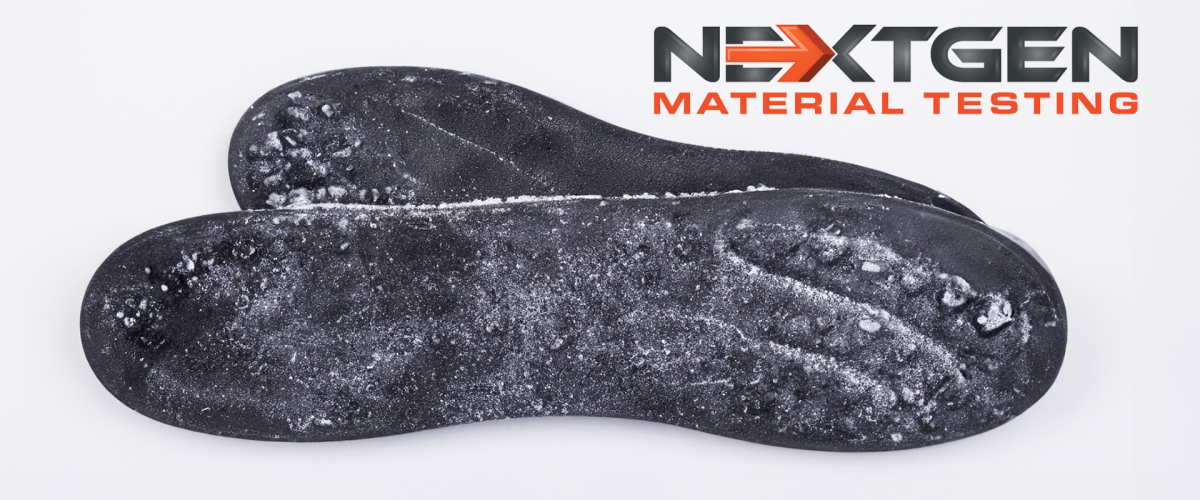

Footwear Industry

Flex testers are instrumental in the footwear industry, offering insights into shoe materials’ flexibility and cold resistance. It’s crucial to understand how materials, like those in winter boots or daily shoes, perform under repetitive stresses, particularly in cold environments.

Automotive Sector

In automotive manufacturing, elastomers used in components like seals, gaskets, and belts are subject to varying temperatures, especially in colder regions. Flex testers forecast these materials’ longevity and efficiency, guaranteeing optimal performance. The GenRoss-CH, with its Low-Temperature Chamber, is especially effective at these evaluations.

Aerospace

In the aerospace field, where high-altitude conditions involve extreme cold, material testing becomes vital. Flex testers ensure aircraft components withstand these demanding conditions, maintaining function and durability.

Outdoor Gear

Manufacturers of outdoor gear, including tents and sleeping bags, turn to flex testers to ensure their products are durable and functional. This is especially true when exposed to cold. These tests determine if materials maintain their flexibility and resilience under such conditions, factors the GenRoss-CH excels at evaluating.

Packaging

Flex testers play a role in the packaging sector too, helping determine how various materials react to low temperatures. This ensures the products inside are protected and unharmed. Given the varied packaging material options, from plastics to bio-polymers, such tests are extremely important.

Assessing Material Diversity with Ross Flex Testers

Flex testers, including the GenRoss-CH, have the capability to analyze a broad range of materials:

Vulcanized Elastomers: Resulting from rubber vulcanization, these materials have heightened elasticity and strength.

Synthetic Elastomers: Acting as alternatives to natural rubber, synthetic elastomers, with their distinct properties, especially resistance to specific chemicals and oils, are vital across many sectors.

Shoe Materials: Flex testers, including the GenRoss-CH, can assess various footwear materials, from natural leather to cutting-edge polymer blends.

General Polymers and Plastics: These testers are capable of testing a wide variety of polymers and plastics, understanding their distinct behaviors at different temperatures.

For research or testing labs, investing in a proficient flex tester, such as the GenRoss-CH, can be invaluable. Such tools echo the ongoing industry emphasis on thorough and precise material testing, demonstrating that products perform as expected in real-world environments.

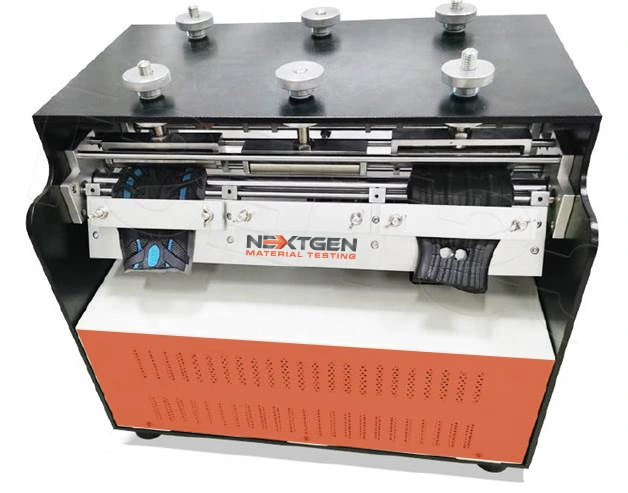

Introduction to the GenRoss-CH Ross Flex Tester

The GenRoss-CH from NextGen Material Testing Inc. is an advanced flex tester equipped to handle both cold resistance and folding endurance assessments. Its primary function is to understand materials’ behavior in cold conditions, gauging their adaptability and performance.

With its internal structure made of durable stainless steel and an efficient temperature controller, the GenRoss-CH prioritizes both accuracy and ease of use. The external design has a coating from DuPont, indicating durability, while its compressor, sourced from Taikang, emphasizes the machine’s dependable nature.

Differentiating itself from conventional flex testers, the GenRoss-CH showcases enhanced features and precise control mechanisms. Further details on its applications and technical specifications will be discussed in the sections that follow.

About Standards

The GenRoss-CH Ross Flex Tester is approved by international standards, ensuring that the tests it performs are both accurate and consistent with globally recognized benchmarks. These standards underline the tester’s credibility but also its compatibility with diverse industries worldwide. Here’s a closer look at these standards:

ASTM D1052

This standard, established by the American Society for Testing and Materials, details the method for determining the resistance of vulcanized rubbers to cut growth using repeated flexing.

ISO 5423

This International Organization for Standardization standard pertains to whole shoe testing, specifically looking at flexing performance in cold climates. ISO 5423 is especially significant for the footwear industry, helping manufacturers determine shoe longevity and reliability in cold environments.

SATRA TM60

A standard developed by SATRA, an international technical organization, TM60 concerns the flexing resistance of light leathers and their surface finishes. It’s crucial in assessing materials used in lightweight footwear and other related products.

SATRA TM92

Another SATRA standard, TM92, is designed for testing the cold flex properties of sole materials. This is vital for understanding how shoe soles perform and endure in freezing conditions.

HG/T 2411

This standard focuses on the methods for testing rubber products’ flexibility, making it applicable to a wide range of rubber products, not just footwear.

The adoption of these standards by GenRoss-CH ensures that its assessments are in line with global expectations. For industries, this means additional assurance in the reliability of test results, and for end-users, a guarantee of product quality.

Features of the GenRoss-CH Flex Tester

The GenRoss-CH Ross Flex Tester is a testament to innovation and precision in material testing. Its design and functionality reflect a deep understanding of industry demands and accurate results.

One of the standout aspects is its body surface treatment. The instrument’s body is coated with US-manufactured DuPont powder through an electrostatic spray painting process. Once coated, it undergoes curing at 200 ℃, ensuring the longevity of its vibrant color. This ensures the usual wear and tear of consistent use.

Ensuring durability and ease of maintenance, the tester has a high-quality inner liner made of stainless steel. This liner, with its semi-circular four-corner design, facilitates the cleaning process, making it straightforward and efficient.

The device’s commitment to delivering consistent results is evident in its air circulation and temperature uniformity system. Thanks to the well-designed air ducts and circulation systems, the testing chamber temperature remains uniform. This is further enhanced by the air convection and breeze devices, armed with high-performance motors and blades. These systems work in harmony, ensuring fresh air circulates continuously within the chamber, maintaining a stable environment.

In its quest to optimize performance, the tester employs nanostructured materials in its door seals and insulation components. This innovation substantially enhances the machine’s efficiency. Complementing this is the sturdy shell construction, made from cold-rolled steel plates, then coated with plastic using an advanced electrostatic spraying technique.

Underpinning its reliability is the Taikang compressor, which is well known for its robustness. Keeping the device insulated from external temperature variations is the high-temperature-resistant insulation material, a thick layer of rigid polyurethane foam.

For heating, the device makes no compromises. It utilizes a stainless steel-finned tube-shaped electric heater for efficient heat dissipation. Moreover, the cold and heat exchange device uses a high-efficiency SWEP design, ensuring seamless exchange between temperature elements.

Finally, at the heart of its operations is the temperature controller: the Taiwan Weilun TH7010. This touchable intelligent programmable device assures precision and offers an intuitive user interface, making testing accurate and user-friendly.

GenRoss-CH Technical Specifications

Unlike similar systems on the market, the GenRoss-CH stands out for its exceptional technical specifications. Below are some of this cutting-edge machine’s best technical specifications.

System & Temperature Control

GenRoss-CH’s core functionality is driven by its balanced temperature regulator wet control system. The device demonstrates a broad temperature range from -20 ℃ to +150 ℃. Accuracy is paramount in testing equipment, and this machine has a 0.5 °C temperature fluctuation. Furthermore, temperature uniformity is tightly controlled within 2 ℃, and precision is affirmed with 0.2 °C measurement accuracy.

Heating & Cooling Dynamics

The temperature transition capabilities of the GenRoss-CH are noteworthy. Heating dynamics allow for a shift from +25 ℃ to +85 ℃ within 30 minutes when unloaded. On the cooling front, the system efficiently transitions from +25 ℃ to -40 ℃ in about 50 minutes, also unloaded. These transitions are facilitated by average rates of 3-5 ℃/min for heating and 0.7~1 ℃/min for cooling, ensuring efficient throughput in testing cycles.

Physical Design Features

Its viewing window, constructed from 3-layer vacuum tempered glass, spans 12.60 x 16.53 x 1.57 inches. The use of a high-quality SUS #304 hinge ensures longevity and smooth door operation. Internally, an energy-saving LED illuminates the chamber, and a φ 150mm lead hole with a rubber plug enhances the device’s adaptability to varied testing requirements.

Dimensions & Power

Space considerations are integral to laboratory equipment. The GenRoss-CH’s inner chamber measures 15.75 x 19.68 x 15.75 inches, while its external dimensions measure 41.34 x 78.74 x 45.28 inches. It’s optimized for power efficiency, requiring an AC220V source at 50/60 Hz frequency.

Standard Configuration of the GenRoss-CH Ross Flex Tester

When it comes to the standard configuration of the GenRoss-CH, its Ross Flex Tester chamber is specifically designed to cater to a range of testing needs. Here’s a breakdown of its configurations:

- Test Piece Size: A moderate dimension of 152 x 25mm ensures that the test pieces fit comfortably within the chamber, allowing for comprehensive and consistent testing across various materials.

- Bending Angle: With a 90° bending angle, this machine can simulate rigorous wear and tear in real-world applications.

- Number of Test Pieces: The chamber can simultaneously accommodate up to 6 sets of test pieces, offering efficiency without compromising the accuracy of results.

- Twist Speed: Ranging from 0 to 100, with an adjustable variance of ±5cpm, this feature ensures that different materials can be tested under varying conditions to provide nuanced insights.

- Diameter of the Winding Shaft: At 10mm, this diameter ensures that the winding process is consistent and reliable, eliminating potential discrepancies in the test results.

- Cutting Edge: A precision-cut 2.5mm edge enables accurate and consistent interactions with test materials.

- Counter: The state-of-the-art LCD counter offers a vast range, counting from 0 up to 9,999,999. This ensures that extensive tests can be run without frequent resets or interventions.

These configurations ensure that the GenRoss-CH Ross Flex Tester is able to provide consistent, reliable, and insightful results for a wide range of testing scenarios when combined together.

Ross Flex Tester – The Best Equipment for Rubber Testing

In the lineage of precise testing equipment that includes the GenRoss-CH, the Ross Flex Tester emerges as an industry benchmark specifically in the realm of rubber and elastomer testing. This series offers advanced cold resistance testing solutions, and the Ross Flex Tester provides detailed insights into elastomers’ durability and resistance when subjected to repetitive bending stresses.

Operational Dynamics and Objective

At its core, the Ross Flex Tester is engineered to rigorously evaluate vulcanized or synthetic elastomers’ resistance to cut growth. This operation is executed by subjecting the elastomers to a consistent 90° bending process. The digital architecture of this instrument, replete with memory functionality, allows it to cater to diverse materials. This includes PU, PVC, and TPR foams. Such versatility is particularly invaluable in industries like footwear, where shoe soles are crafted from flexible sheet materials, and where the importance of flexibility cannot be overstated. Following the testing, a detailed analysis is undertaken to assess the magnitude of damage, if any, and the appearance of cracks on the tested specimen.

Technical Attributes

- Model Designation: NG-ROSS, a testament to its advanced engineering.

- Testing Capacity: A distinguishing feature is its 12-chamber system. This provision allows it to test up to 12 specimens concurrently, optimizing efficiency.

- Bending Specifications: The tester achieves a bending angle accuracy of 90° +/- 20 and operates at an operating speed of 100±3 CPM, ensuring consistent and standardized results.

- Physical Dimensions and Weight: It is designed with a footprint of 19.7x24x21.6″ (500 x 610 x 550 mm) and has a substantial weight of 231 lbs (105 kgs), indicative of its robust construction.

- Power Configuration: It functions on a 110V/60Hz/1Ph power supply, which meets standard industrial requirements.

- Vacuum Capabilities: The system’s vacuum pressure is 65mm-Hg, which enhances its operational effectiveness.

What Comes in the Flex Tester Package

Every purchase of the Ross Flex Tester ensures the user receives:

- The principal unit encapsulates all pivotal functionalities.

- An industry-standard die mold facilitates various tests.

- A hole puncher integrated into the machine is crucial for preparing specimens.

- A detailed system manual, providing step-by-step guidance for optimal utilization.

Endorsements and Support Mechanisms

Similar to the renowned GenRoss-CH, the Ross Flex Tester is not just a product but a commitment to quality. The emphasis on ultimate user-friendliness ensures that even novice users can harness its capabilities easily. The reliability is further enhanced by NIST Certified Consumables. Additionally, as part of the company’s unyielding commitment to its customers, after-sales technical support is readily available. The lifetime product support advantage ensures that users are never left stranded and always have access to expert guidance.

What Makes NextGen’s Ross Flex Tester the Best for Labs?

Throughout the world, laboratories are constantly searching for equipment that is the definition of precision, innovation, and adaptability when it comes to material testing.

The first thing that strikes anyone who is familiar with the GenRoss-CH is its brilliantly designed compact design. With every square inch of lab space being valued, the GenRoss-CH’s dimensions are nothing short of revolutionary. This technology ensures that labs, regardless of their space constraints, do not have to compromise on the scope and scale of their testing activities. NextGen demonstrates that world-class testing capabilities do not necessarily require sprawling setups, by creatively optimizing space.

Aside from its physical dimensions, the GenRoss-CH’s commitment to upholding the highest industry standards is evident in its features and functionality. In addition to adhering to global benchmarks, this tester often exceeds them with its NIST Certified Consumables. It is not just about complying with current standards but also setting new ones, and it is an indispensable ally in this endeavor to have the GenRoss-CH at hand.

What is the significance of all of this? In the broader context of material testing, complying with international standards and the ability to fit a variety of laboratory environments translate into consistent, reliable results. And for industries that rely on these results – be it in manufacturing, research, or quality control – the assurance of accuracy can have far-reaching implications, affecting everything from product quality to consumer safety.

The GenRoss-CH Ross Flex Tester from NextGen isn’t just another piece of lab equipment. It’s a fundamental change in how labs envision material testing. It’s about maximizing potential within limited spaces, adhering to the strictest standards, and delivering results that industries can trust in. For modern labs, choosing NextGen’s Ross Flex Testers is not just a decision; it’s an investment in the future of material testing.

Choosing NextGen’s Ross Flex Tester

Globally, labs are looking for greater accuracy in material testing. During this quest, NextGen’s Ross Flex Testers stand out as symbols of reliability and innovation.

Imagine this: A compact yet powerful machine, the GenRoss-CH, sits in a bustling lab. Its compact design is a tribute to modern labs understanding space value, yet its capabilities are far from constrained. Instead, with every cycle, it delivers results with an impressive temperature control range, showcasing the machine’s finesse. It’s not just about the figures, ranging from -20℃ to +150℃, but the rapid transition between these temperatures. Imagine the efficiency gained when a machine shifts dynamics in 30 minutes. It’s a time-saver, an asset every high-paced lab would like to have.

But NextGen’s capability isn’t limited to swift dynamics. As one explores the GenRoss-CH, one finds an array of features that make it stand out. Industry-leading viewing window, efficient LED chamber illumination, and adaptability to varied testing requirements mark its superior design.

Of course, in a world driven by standards and benchmarks, GenRoss-CH’s adherence to global standards, reflected in its NIST Certified Consumables, is a significant feather in its cap. This isn’t about meeting benchmarks; it’s a bold statement of intent, a commitment to lead and redefine norms.

One might ask, what about post-purchase? It is here as well that NextGen stands out. With a strong focus on supporting their products, they offer:

- Lifetime product support;

- Robust after-sales technical assistance;

- A promise of forging lasting partnerships with labs;

A unique piece of lab equipment, the GenRoss-CH Ross Flex Tester with Low-Temperature Chamber by NextGen stands out from the rest. It’s a model for the future of material testing that shows how labs can go beyond traditional limitations.

If you are looking for just a Ross Flex Tester without the Low Temperature, we also have it available.

For those considering the integration of this leading-edge technology into their workflows, we encourage you to connect with our team. Contact us for detailed insights, and if desired, request a quote specific to your needs and requirements.