Having trouble achieving consistent surface finishes on your tensile or fatigue specimens? Even the most precise machining can leave subtle marks and residual stresses that influence test results. When every micron matters, surface preparation becomes more than just a step — it defines the reliability of your data.

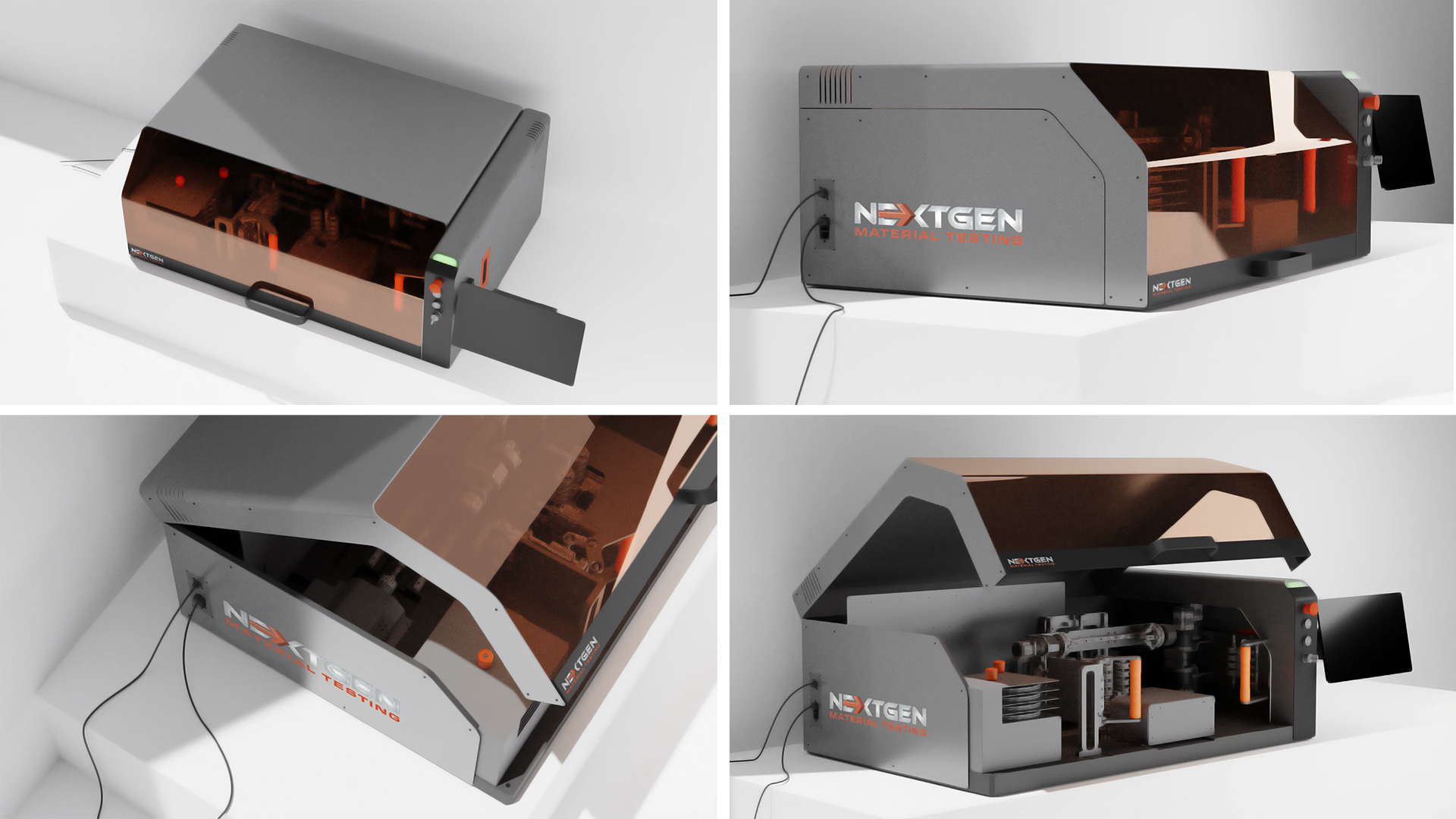

That’s where NG-AutoPol comes in. This automatic longitudinal polisher system brings precision, repeatability, and ease of use into one complete solution. Designed for both cylindrical and flat tensile specimens, it minimizes residual stress and provides a uniform finish for accurate tensile and fatigue testing.

In this article, we’ll take you through everything you need to know about the NG-AutoPol — what longitudinal polishing systems are, why they matter, how this model operates, and who can benefit most from it. By the end, you’ll know exactly how NG-AutoPol can streamline your specimen preparation and whether it fits your laboratory’s workflow.

Longitudinal Polishing Systems and Why They Matter

To begin, let’s see why longitudinal polishing systems matter and what can go wrong when this process is skipped.

After turning or milling, a specimen’s surface may still contain fine scratches, local deformation, and hidden residual stress. These imperfections might look minor, yet they directly influence how the specimen behaves under cyclic or tensile loading. Even a slight irregularity can change how stress is distributed during testing, and that affects the accuracy and repeatability of your data.

Longitudinal polishing solves this problem through a controlled linear motion of the abrasive along the specimen’s longitudinal axis, in the same direction as the applied test load. This process removes machining marks, aligns the surface structure, and minimizes stress concentrations. The result is a uniform surface finish that allows the specimen to perform consistently during tensile and fatigue testing.

In fatigue applications, the surface condition is critical. Studies show that machining methods and residual stress can shift fatigue strength values by noticeable margins, sometimes altering the S–N curve entirely. That is why international standards such as ASTM E466 (constant amplitude axial fatigue), ASTM E606/E606M (strain-controlled fatigue), and EN 6072 (constant amplitude fatigue testing of metals) emphasize precise surface preparation and stable geometry.

Introducing the NG-AutoPol System

The NG-AutoPol is built to take the uncertainty out of specimen preparation. It replaces manual adjustments and inconsistent polishing with a precise, fully automated process that keeps every variable under control. The system was engineered to minimize grinding stress and residual surface tension that often remain after machining operations such as turning or milling.

The NG-AutoPol is built to take the uncertainty out of specimen preparation. It replaces manual adjustments and inconsistent polishing with a precise, fully automated process that keeps every variable under control. The system was engineered to minimize grinding stress and residual surface tension that often remain after machining operations such as turning or milling.

The result is a reliable automatic longitudinal polisher system for both cylindrical and flat tensile specimens. Motion, pressure, and contact are all managed digitally, which means that each specimen receives a consistent surface finish aligned with its testing axis. This is achieved through single-contact polishing, where each section of abrasive interacts with the specimen only once. The method prevents overheating, avoids re-cutting, and extends abrasive life while maintaining an even finish across the entire sample.

The NG-AutoPol creates a smoother, low-stress surface that directly improves test repeatability. Residual stress and microscopic surface irregularities are significantly reduced, helping laboratories achieve stable results across multiple batches of specimens.

Its compact footprint and intuitive touchscreen interface make the system suitable for laboratories of all sizes. Operators can quickly set polishing parameters such as force, linear speed, and active length, without requiring prior CNC experience. The automated cycle frees staff to focus on other tasks while maintaining consistent preparation quality.

Features of the NG-AutoPol

The NG-AutoPol was developed to bring order and consistency to the polishing process through a set of practical, precisely engineered features. Each function focuses on control, repeatability, and simplicity, allowing laboratories to achieve uniform results without added complexity.

The automatic longitudinal polishing function delivers stable and repeatable surface quality through single-contact motion, where each section of abrasive interacts with the specimen only once. This controlled approach prevents overheating, avoids over-polishing, and preserves the specimen’s geometry.

From the touchscreen interface, operators can adjust key parameters like polishing force, linear speed, rotation, and active length, tailoring the process to specific specimen dimensions or material types. These adjustable settings create a flexible workflow that fits both research and production environments.

A multi-grit switching system automatically changes up to four abrasive grades in a single run, enabling a complete polishing sequence without manual intervention. The integrated cleaning mechanism maintains optimal abrasive performance, keeping debris away from the contact zone and extending the life of the polishing media.

The process memory function stores polishing configurations for repeat testing. Laboratories that perform standardized specimen preparation can recall the same settings at any time, ensuring consistent results across different batches.

Through interchangeable specimen fixtures, the NG-AutoPol adapts to a range of sample types — from cylindrical and flat specimens to non-standard geometries. Its rigid mechanical structure distributes pressure evenly across each surface, maintaining balance and stability throughout operation. For aerospace and other precision-focused facilities, a NADCAP-ready configuration is available, aligning the system with demanding industry requirements.

Model Configurations to Match Sample Geometry

One machine platform, several configurations: the NG-AutoPol was created to adapt to different specimen shapes and dimensions with precision. Each model variation provides the same polishing accuracy while addressing specific preparation needs. The system is available in the following configurations:

- SCS – Standard Cylindrical Specimen: for common round tensile samples of regular size and length.

- ESCS – Extremely Small Cylindrical Specimen: for micro-scale specimens requiring fine control and delicate surface finishing.

- ELCS – Extremely Large Cylindrical Specimen: for oversized samples that demand stable pressure and extended polishing length.

- FS – Flat Specimen: for flat tensile specimens where longitudinal uniformity across the entire surface is essential.

- C – Customized Configuration: tailored solutions for unique geometries or non-standard testing applications.

Technical Specifications and System Configuration

The NG-AutoPol is built with precision at its core. Every technical element serves a clear function: to keep the polishing process stable, consistent, and adaptable to different specimen types. Below are the main technical specifications of this longitudinal specimen polisher:

- Adjustable polishing force: 5 – 50 N for controlled contact pressure across different materials.

- Linear speed range: 10 – 100 mm/s, adjustable in 10 mm/s increments.

- Active polishing length: 5 – 280 mm to accommodate short and extended specimens.

- Supported abrasive grits: 200, 400, 600, 800, with automatic switching between up to four grades in one cycle.

- Process control: All parameters managed through a touchscreen interface with real-time visualization.

- Optional functions: Data logging and calibration modes for advanced workflow tracking.

- Polishing motion: Single-contact process—each abrasive section touches the specimen once to prevent over-polishing.

Standards Compliance and Global Testing Methodology

Quality testing systems are only meaningful when they align with recognized international standards. Consistency in preparation and testing allows laboratories across the world to compare data with confidence and accuracy. For this reason, the NG-AutoPol system complies with a range of global material testing standards. The main standards include:

- ASTM E466 – Defines the procedure for force-controlled, constant-amplitude axial fatigue testing of metallic materials. It specifies how specimen geometry, surface finish, and load control affect fatigue life and repeatability.

- ASTM E606/E606M – Covers strain-controlled fatigue testing of metallic materials, where deformation rather than stress is the primary control variable. It is used to study cyclic plasticity, low-cycle fatigue, and the effect of surface condition on fatigue performance.

- EN 6072 – Establishes the European method for constant-amplitude fatigue testing of metallic materials (S-N method). It maintains alignment in specimen design, stress application, and data interpretation across international laboratories.

- NADCAP (Materials Testing Accreditation Program) – A global accreditation framework used in aerospace and high-precision industries to verify the quality, traceability, and audit readiness of laboratory processes.

Who Can Benefit from the NG-AutoPol System

The NG-AutoPol can be integrated into any laboratory or testing facility where tensile and fatigue specimens are regularly prepared. It serves as a practical addition to workflows that require accurate surface finishing, stable stress distribution, and repeatable specimen quality.

Let’s look at several professional fields where such a system becomes essential:

Metallurgical and Alloy Development Laboratories

These laboratories constantly work with new material compositions and heat-treated metals, studying how microstructural changes influence mechanical strength. The NG-AutoPol allows engineers to prepare perfectly uniform specimens for tensile and fatigue testing, ensuring that observed performance differences come from the material itself rather than preparation inconsistencies.

Aerospace and High-Precision Engineering Facilities

In environments where certification and traceability are mandatory, such as aerospace or defense materials testing, specimen preparation must meet strict audit requirements. The NG-AutoPol provides the repeatability and documentation consistency expected under NADCAP and similar programs. By reducing operator influence and maintaining linear stress alignment during polishing it helps laboratories achieve data suitable for design validation, component qualification, and material certification.

Research Institutions and Universities

Academic and research laboratories use the NG-AutoPol for standardized specimen preparation in teaching and experimental work. Students and researchers can replicate surface conditions across different sample types, including cylindrical, flat, or custom geometries, without a complex setup. This makes the system ideal for fatigue analysis, comparative studies, and method validation in engineering education or material science programs.

Quality Assurance and Production Control Facilities

In production settings, the NG-AutoPol helps maintain process consistency by preparing specimens for ongoing tensile and fatigue checks. Its automated cycle allows rapid turnaround and minimal manual handling, providing reliable data for quality verification without slowing down operations. The system fits naturally into high-volume inspection workflows where reproducibility and time efficiency are equally important.

Advanced Manufacturing and Industrial R&D Centers

Facilities developing components for transportation, renewable energy, or heavy machinery benefit from precise specimen polishing when testing welds, coatings, or new metal composites. The NG-AutoPol supports these R&D applications by offering standardized surface conditions that allow accurate evaluation of stress behavior and fatigue limits under real working loads.

Closing Summary on the NG-AutoPol System

You have now seen how the NG-AutoPol system improves the preparation of tensile and fatigue specimens. It brings control, precision, and simplicity to a stage that often defines the quality of every test result. With automated longitudinal polishing, adjustable parameters, and support for global standards, this system helps laboratories achieve clean, stable surfaces without unnecessary setup or manual work.

If your work involves testing metallic materials, developing new alloys, or maintaining quality control in production, the NG-AutoPol can become a key part of your process. It fits into both research and industrial environments, supporting the accuracy and reliability that modern testing demands.

If you are looking for a tensile specimen preparation system that saves time and provides dependable results, reach out to us. You can request a quote or contact our team directly to learn more about configurations, pricing, and setup options. We are ready to help you find the best solution for your laboratory.