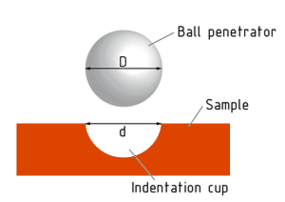

The importance of accurate hardness testing cannot be ignored in industries requiring both strength and durability. When working with very small surface areas, such as a 2.5mm ball indentation in Brinell hardness testing, achieving high accuracy is a key component of the procedure. However, this level of precision can be challenging without the right toolset, often leading to inconsistencies and human errors.

Human error is a common problem in Brinell hardness testing, affecting accuracy and reliability. Imagine the significant impact on your organization’s testing process if you had a tool capable of completely removing these errors. Such a tool would not only increase the reliability of your tests but also increase confidence in your measurements, leading to better quality control and product integrity.

Now, think of a tool that allows you to see these results in real time, reducing waiting time and the potential for errors even further. Additionally, this tool offers these benefits with minimal training required, thanks to its design and built-in ease of use. This means that even operators with less experience can achieve precise and consistent results effortlessly.

Meet the BrinGen 3000 Series, an optically advanced CCD measuring scope specifically designed to eliminate human error in Brinell hardness tests. This innovative tool delivers reliable, accurate, and repeatable results, making it an indispensable addition to your testing equipment. In this article, we will provide you with the necessary information about this tool, the precision and affordable solution you have been looking for.

What is the BrinGen 3000 Series?

The BrinGen 3000 Series is a state-of-the-art digital and automatic Brinell hardness tester, specifically designed to measure metal specimen resistance to indentation. By using a fixed force (load) applied by an indenter, our product determines the material’s hardness based on the size of the indentation – the smaller the indentation, the stronger the specimen. This system is particularly effective on surfaces too rough for other testing methods, aligning with ASTM E-10 standards.

The BrinGen 3000 Series is a state-of-the-art digital and automatic Brinell hardness tester, specifically designed to measure metal specimen resistance to indentation. By using a fixed force (load) applied by an indenter, our product determines the material’s hardness based on the size of the indentation – the smaller the indentation, the stronger the specimen. This system is particularly effective on surfaces too rough for other testing methods, aligning with ASTM E-10 standards.

The BrinGen – Brinell Hardness Tester offers a broad test load range from 62.5kgf to 3000kgf, giving it flexibility in meeting different testing needs. It is equipped with a closed-loop system that guarantees the highest load control accuracy, providing precise control over test force applications. Additionally, these standalone units can be easily upgraded to include the NG-Scope – Brinell Hardness Image Automatic Measuring system, which delivers the most accurate results through advanced optical analysis software.

Key Features of the BrinGen – Brinell Hardness Tester

The BrinGen 3000 Series is full of features designed to maximize hardness testing accuracy and efficiency. The following are some of the key features of this product:

-

High Sensitivity and Accuracy: Engineered to deliver highly sensitive and accurate readings.

-

Direct Digital Reading: Provides immediate digital readings for convenience.

-

Versatile Applications: Ideal for use in laboratories, workshops, tool rooms, and inspection labs.

-

Error Elimination: The test process prevents human error, resulting in maximum accuracy.

-

User-Friendly Interface: Equipped with a large LCD display screen for ease of use.

-

Wide Material Compatibility: Commonly used to test unquenched steel, cast iron, non-ferrous metals, and soft-bearing alloys.

-

Optical Precision: Features a 20X optical microscope to measure Brinell indentations diameter with a resolution of 0.005mm.

-

Lightweight Design: The tester is 50% lighter than traditional dead-weight type testers.

-

Convenient Load Selection: Test loads can be easily selected via the keyboard and displayed on the LCD screen.

-

Fully Automatic Test Cycles: Includes automatic cycles for load application, holding, and unloading, greatly improving reproducibility and minimizing operator influence.

-

Adjustable Dwell Time: Dwell times and other test parameters are clearly displayed on the large LCD screen.

-

Brinell Hardness Calculator (BHC): Simplifies hardness value calculations, making the process easier and easier.

Real-Time Results and Customizable Features

The BrinGen 3000 Series offers test data in real-time, significantly optimizing manual and digital measurements. This feature allows operators to instantly verify results, reducing data processing time and minimizing errors.

Our product offers a highly flexible results table that can be customized to meet specific testing needs:

-

Dynamic Column Management: Users can easily add or remove columns to display essential parameters such as Diameter, HBS or HBW, load, and other relevant data points.

-

Intuitive Histogram Display: The system includes a visual histogram feature that presents hardness values in an easy-to-understand graphical format. This visualization aids in quick data analysis and identifies trends or anomalies in test results.

-

Flexible Report Generation: The BrinGen 3000 Series supports the generation of various types of reports, which can be extensively customized with user-defined parameters. This feature enables the creation of comprehensive documents that cater to specific requirements.

Frequently Asked Questions About the BrinGen 3000 Series

It is possible to speak about the BrinGen tool all night long. Here are some frequently asked questions to help you understand our product information:

Will the BrinGen 3000 Series Test My Material?

Yes, the BrinGen 3000 Series is highly versatile and operates on nearly any metal surface. Its ergonomic design allows for smooth movement and precise positioning, while the operator’s display shows accurate measurements, tolerance values, test results, and other vital information. This makes it suitable for use in labs, workshops, or manufacturing environments, contributing to accuracy and automation for operators of all experience levels.

How is the BrinGen 3000 Series Calibrated?

Calibration for the BrinGen – Brinell Hardness Tester is simple and fast. In the software calibration window, users can choose to input either the hardness value of a standard sample or the distance between the diameters. Thanks to its operator-friendly design, calibration is straightforward and easy, even for beginner engineers.

What Accessories Come With the BrinGen 3000 Series?

The BrinGen 3000 Series comes fully equipped with a camera and LED lights, all secured in stainless steel and aluminum housing. Users also receive a calibration film, software, and an additional CD containing the user guide and video instructions. All these components are packaged in a padded hard shell case, ensuring maximum portability and safety for your device.

Is the BrinGen 3000 An Effective System for Brinell Hardness Testing?

Clearly, the BrinGen 3000 Series, combined with the BrinGen Scope, delivers exceptional accuracy in Brinell hardness testing and can be called an effective system without hesitation. These automatic Brinell scopes are pre-certified and pre-calibrated for ASTM E10 Brinell test requirements, allowing users to customize the system for various methodologies. The intuitive, user-friendly software offers extensive options for customization and data refinement, enabling precise report customization. Additionally, NextGen Material Testing provides a comprehensive range of Brinell product consumables, including indentation balls and test blocks, which are available in stock or can be custom-manufactured within a week to meet specific testing needs.

Upgrade Your Hardness Testing with the BrinGen 3000 Series

The BrinGen 3000 Series is a revolutionary digital and automatic Brinell hardness tester designed to deliver precise and consistent results. Its advanced features, including a closed-loop system for accurate load control, real-time data display, and versatile application on different metal surfaces, make it an essential tool for any testing environment. The system’s ergonomic design and user-friendly interface ensure ease of use and minimal training requirements, making it accessible to operators of all experience levels.

In addition to its high sensitivity and accuracy, the BrinGen – Brinell Hardness Tester offers extensive customization options, from dynamic column management in results tables to flexible report generation. This flexibility, combined with its comprehensive accessory package and robust calibration options, guarantees that this product meets all your hardness testing needs with exceptional efficiency and reliability.

At NextGen Material Testing, we are dedicated to supporting your material testing requirements with top-notch products and services. We offer a wide selection of cutting-edge equipment, like the BrinGen 3000 Series, and provide comprehensive maintenance and support to ensure your operations run smoothly. You can request an online quote or contact us directly to learn more about how we can assist you with your material testing needs.