For years, our team has worked with labs and production facilities that run tensile testing as routine work. The same problems come up again and again. Samples arrive late. Geometry varies from batch to batch. Results get questioned because prep was inconsistent.

That pressure has only grown. Testing schedules are tighter. Materials are more varied. Many shops are also short on experienced machinists. In that environment, specimen preparation can no longer depend on whoever happens to be at the lathe that day.

This article looks at two newer CNC systems we offer with our partner, TensileMill CNC, for round tensile specimen preparation. It explains how each machine fits into a lab workflow, what makes the process repeatable, and where the differences matter when you choose between them.

Why Round Tensile Sample Preparation Shapes Test Results

Round tensile sample preparation sits between raw material and the final data set. If that step slips, the rest of the test follows it. Labs notice the impact first when results start to drift and no one can explain why.

Round specimens show up across the testing world. Quality control teams use them for incoming inspection and batch release. Production sites rely on them to keep heat treatment and forming processes in check. R&D groups use them when they compare alloy options or validate new suppliers. In all of those settings, specimen prep sets the pace and the credibility of the work.

When preparation is slow, the testing line slows with it. Machines sit idle while technicians wait on samples. Reports move later in the day, then later in the week. Those delays ripple into manufacturing schedules and customer commitments.

When preparation is uneven, the damage is harder to see at first. A slight off-center setup can introduce bending. A gauge diameter that varies by a small amount can shift stress calculations. Shoulder transitions that differ from one sample to the next can move where the break happens. Over time, the lab ends up debating the specimen instead of the material.

Outsourcing can solve a capacity problem, but it adds another set of risks. Lead times change without warning. Logistics complicate traceability. Small geometry decisions get made outside the lab’s control. For teams trying to run a stable tensile specimen preparation workflow, that tradeoff is not always worth it.

Even so, round specimens are not “just another shape.” They demand tighter attention to alignment and geometry because the test loads run through an axis. That is why repeatability and turnaround time in round tensile prep are closely tied to the machine, the setup, and the workflow.

Round vs. Flat Tensile Sample Preparation

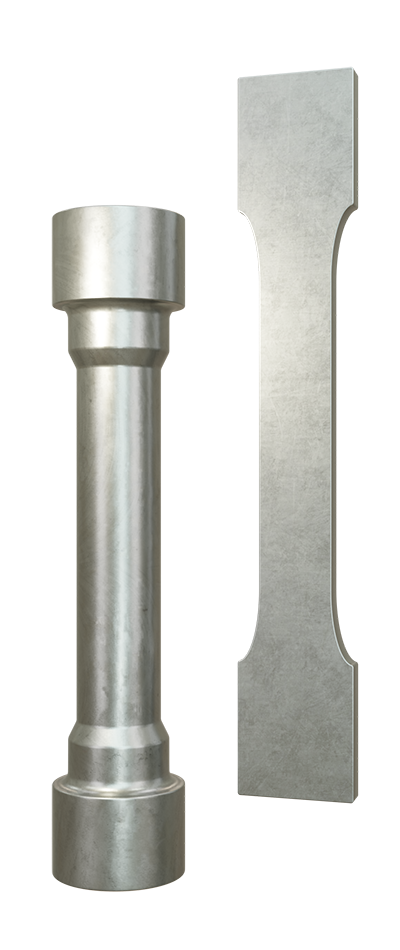

Flat specimens often start with sheet or plate and follow a different path. The work centers on thickness control, edge quality, and avoiding heat or burrs along the sides. Round specimens depend more on centering, gauge diameter control, and smooth transitions into the shoulders. Stock can also vary more. Labs may start from round bar, square bar, or irregular coupons. That mix is one reason round tensile preparation tends to expose workflow problems faster than flat prep.

Our New Round Tensile Sample Preparation Equipment

The market has changed since many labs bought their last specimen-prep lathe. Testing volume has climbed in some sectors. Material mixes have widened in others. At the same time, fewer facilities can count on having a dedicated machinist available on every shift.

That shift is part of why we are now focusing on two newer CNC systems for round tensile specimen preparation. Both are built around guided operation, standards-based geometry libraries, and cycle times that stay steady enough to plan a day’s testing around them.

These machines are aimed at groups that prepare specimens as part of routine work. That includes quality control laboratories that release batches, R&D teams that compare materials, and production sites that treat tensile data as a daily checkpoint. The next sections break down how each model fits into that reality.

TensileTurn CNC Classic Upgrade

The TensileTurn CNC Classic Upgrade is a compact CNC lathe set up for preparing round tensile specimens inside the lab. It supports specimen diameters up to about 45 mm and handles materials up to roughly 55 HRC. For many facilities, that range covers common steels, heat-treated parts, and typical alloy work that still needs frequent tensile checks.

The TensileTurn CNC Classic Upgrade is a compact CNC lathe set up for preparing round tensile specimens inside the lab. It supports specimen diameters up to about 45 mm and handles materials up to roughly 55 HRC. For many facilities, that range covers common steels, heat-treated parts, and typical alloy work that still needs frequent tensile checks.

A central feature is the triple clamping fixture. It allows several samples to be prepared in one setup. That shortens the time spent re-clamping stock and reduces the chances of small alignment shifts between parts. For labs that process repeat batches, the difference shows up in throughput and in how uniform the gauge section looks from sample to sample.

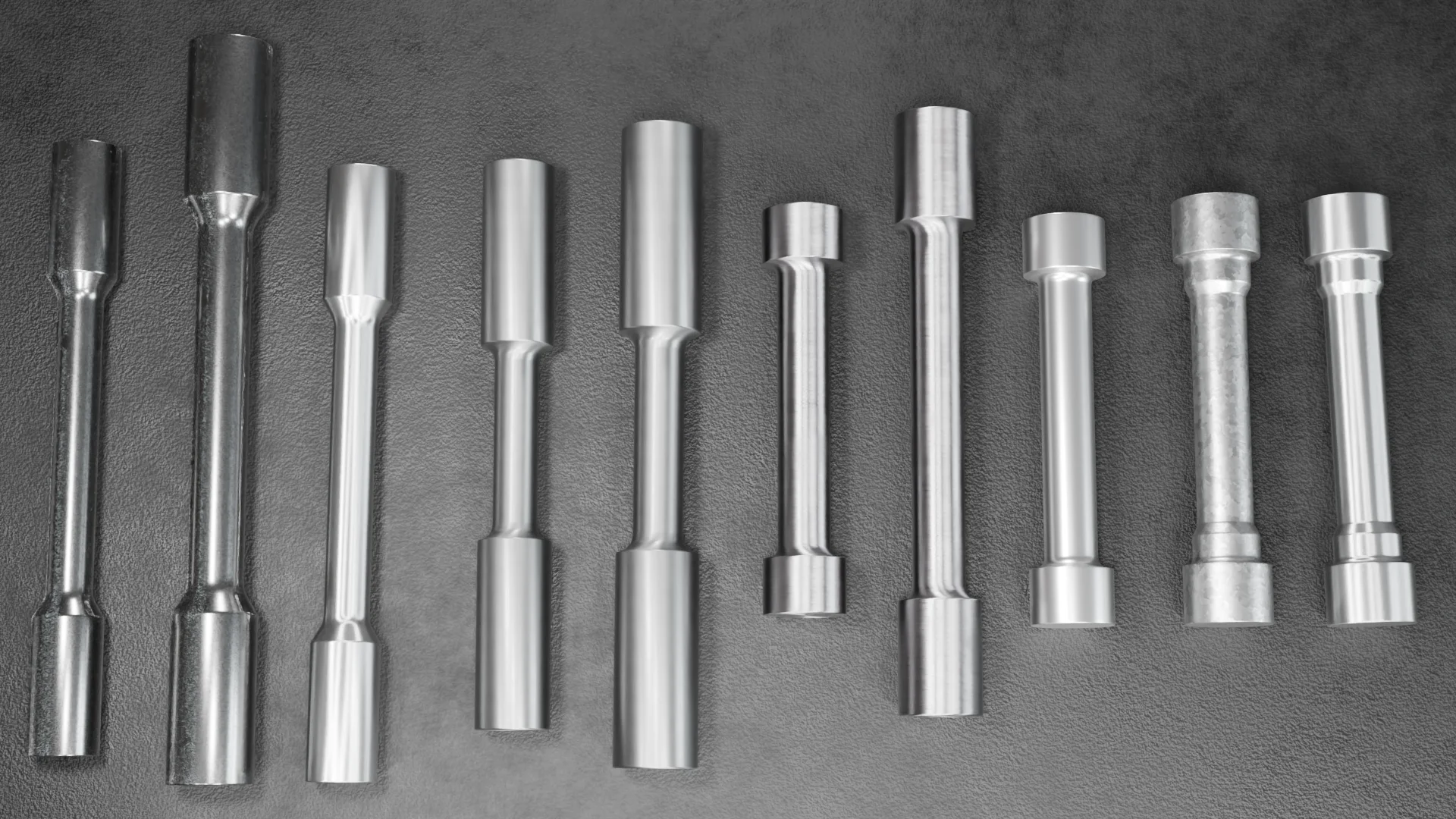

The Classic Upgrade supports standard round tensile specimens, sub-size specimens, threaded-end tensile bars, button-head specimens, and fatigue specimens. It also accepts starting stock that is round, square, or irregular, which matches what many facilities pull from production scrap, cut coupons, or incoming bar.

The workflow is built around a guided sequence. The operator loads the stock, clamps it, selects specimen geometry from a standards library or enters custom dimensions, then starts machining. A typical preparation cycle takes minutes, which helps labs avoid sending coupons to an outside machine shop and waiting for a slot.

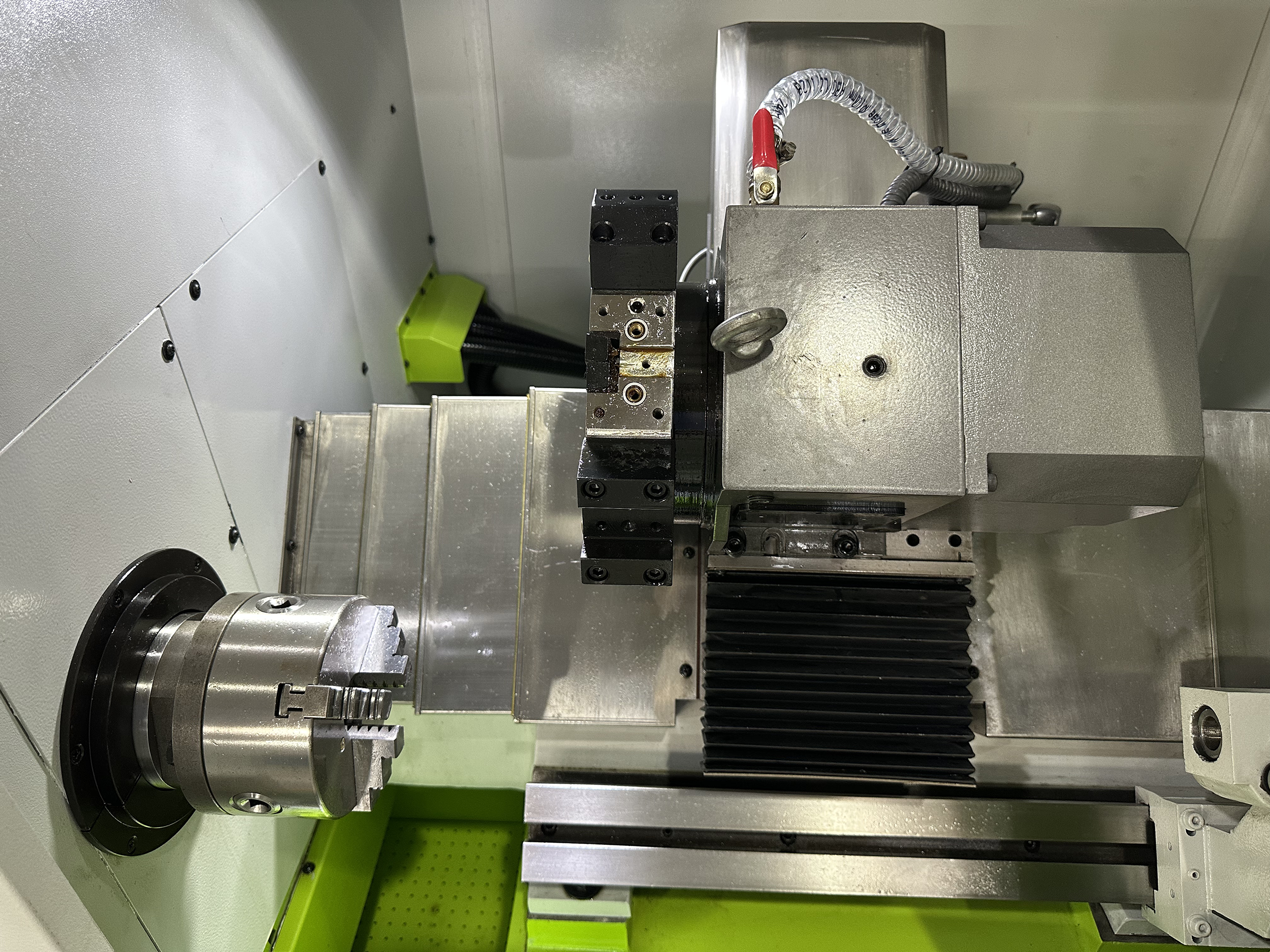

Repeatability comes from practical mechanics. The machine holds the stock centered, keeps tool position stable across cycles, and runs cutting steps under controlled conditions. Those details are what protect gauge diameter and shoulder transitions from drifting over a long series of specimens. Control runs through a 15-inch touchscreen using TensileSoft 2.0, with access to full FANUC CNC functions when a lab needs general turning work beyond specimen profiles.

TensileTurn CNC Industrial Upgrade

The TensileTurn CNC Industrial Upgrade is a compact CNC lathe built for standardized specimen preparation in both laboratory and production settings. We supply it through our partner, TensileMill CNC, and it runs the TensileSoft v2.0 interface on a touchscreen controller. Operators can choose from a library of common specimen geometries tied to ASTM, ISO, and DIN practice, or enter custom parameters for internal drawings.

The TensileTurn CNC Industrial Upgrade is a compact CNC lathe built for standardized specimen preparation in both laboratory and production settings. We supply it through our partner, TensileMill CNC, and it runs the TensileSoft v2.0 interface on a touchscreen controller. Operators can choose from a library of common specimen geometries tied to ASTM, ISO, and DIN practice, or enter custom parameters for internal drawings.

The machine is meant to cut across a broad material range. It is used on common metals and on harder cases such as heat-treated alloys and grades like Inconel. That matters in facilities where the specimen queue changes week to week, and prep work has to keep pace without resetting the entire process each time.

One practical difference in this model is automated center drilling. It standardizes an early alignment step that often varies across operators and shifts. That can be especially useful when starting stock is mixed, or when samples come from square or irregular coupons rather than clean bar.

The Industrial Upgrade prepares the same core specimen families most labs rely on. That includes standard round bars, sub-size specimens, threaded tensile samples, button-head specimens, and fatigue bars. It also accepts round, square, and irregular starting stock, which makes it easier to keep specimen preparation in-house even when incoming material forms change.

Its mechanical platform is built for repeat runs. The system uses a granite base and a precision ballscrew motion system, along with an enclosed structure suited to lab and shop environments. It also uses an eight-position electric turret and FANUC servo drive architecture. In day-to-day work, those features support stable tool motion and predictable geometry across batches, which is the point of a dedicated specimen-prep machine.

Standards Built Into the Workflow

Most labs do not struggle because they lack standards. They struggle because standards get applied unevenly. One technician uses a familiar profile. Another types dimensions from a printout. A third relies on a shop note that is two revisions old. Small differences follow the specimen into the test frame.

Most labs do not struggle because they lack standards. They struggle because standards get applied unevenly. One technician uses a familiar profile. Another types dimensions from a printout. A third relies on a shop note that is two revisions old. Small differences follow the specimen into the test frame.

The standards most facilities run into are well known. ASTM E8 and ASTM A370 cover many steel workflows. ASTM B557 shows up often in aluminum and nonferrous work. ISO 6892-1 is common in international supply chains. DIN 50125 and JIS Z 2241 still appear in specific industries and customer requirements. A lab may only use two of these regularly. The trouble starts when a supplier, customer, or internal program changes the target geometry without warning.

That is where a standards-based geometry library matters. Instead of re-entering dimensions from scratch, an operator starts from a known template and adjusts only what the procedure allows. It reduces transcription mistakes. It also shortens setup time, especially when the day includes several specimen types. Training becomes simpler as well, because new staff can follow a guided path rather than memorizing a long list of dimensions.

Still, the library does not replace lab judgment. The lab has to pick the right standard for the material and the test method. It also has to verify what the procedure requires, including gauge diameter checks, shoulder transitions, and any rules tied to extensometer use. The geometry library can keep the starting point clean. Measurement discipline is what keeps the final result credible.

What These Two Systems Share

By design, these two machines solve the same category of problems. They help labs prepare round tensile specimens without turning specimen prep into a scheduling fight or a skills bottleneck. The details differ between models, but the day-to-day priorities they address tend to be the same.

By design, these two machines solve the same category of problems. They help labs prepare round tensile specimens without turning specimen prep into a scheduling fight or a skills bottleneck. The details differ between models, but the day-to-day priorities they address tend to be the same.

In practice, engineers and QC managers usually judge this kind of equipment on a short set of fundamentals. They want a workflow that is easy to repeat across shifts. They want geometry that stays predictable across batches. They want fewer handoffs to outside shops and fewer surprises in the test queue. They also want support that does not disappear after installation.

Let’s look at the functions these two systems have in common.

- Guided touchscreen workflow with room for expert control. TensileSoft v2 leads operators through specimen setup. At the same time, full CNC functions remain available when a machinist needs them.

- A tight focus on repeatable geometry. Both machines are built to hold the gauge section, shoulder transitions, and key lengths within a controlled cycle, not by manual judgment.

- Preparation stays in-house. Labs can machine specimens when they are needed, rather than waiting for a slot at an outside shop. That shortens lead time and keeps schedule changes from turning into backlogs.

- Flexible starting stock. Both platforms accept round bar, square stock, and irregular material, which matches the mix many facilities handle in real work.

- Built for lab-adjacent operation. Each is compact enough to fit into testing environments and uses an enclosed, controlled cutting area with coolant support, so specimen prep can run without turning the lab into a machine shop.

- Service and supply continuity. These machines are tied to stocked consumables, spare parts planning, and structured technical support, which matters when the goal is steady operation over years.

Key Differences and Selection Guidance

The two systems overlap in purpose, but they do not fit the same facility in the same way. Selection usually comes down to workload patterns. It also depends on how much variety a lab sees in starting stock, specimen types, and material grades. The points below reflect how most teams sort the decision in practice.

Choose the Classic Upgrade if your work is lab-paced and sample-heavy

The Classic Upgrade makes the most sense when specimen preparation runs as a steady lab routine. It suits facilities that need fast turns on standard requests and want to keep the workflow simple for rotating staff.

- You need higher throughput from one setup. The triple clamping fixture supports multi-sample runs with fewer re-clamps.

- Your specimen range centers on larger diameters and harder materials. The model covers specimens up to about 45 mm and works up to roughly 55 HRC.

- You want broad specimen coverage without a complex setup. It supports standard and sub-size rounds, threaded ends, button-head profiles, and fatigue specimens, while keeping the steps familiar for day-to-day lab use.

Choose the Industrial Upgrade if your environment looks more like production

The Industrial Upgrade fits better when specimen prep sits close to manufacturing pressure. It is built for a steady stream of parts and frequent shifts in what comes through the door.

- Your workflow is tied to production demand. The machine is a better match when testing volume moves with output, not with a fixed lab schedule.

- Materials change often, including tougher grades. It handles common metals and also covers heat-treated alloys and materials such as Inconel that show up in higher-demand programs.

- You want center drilling as a standard step. Automated center drilling helps keep early alignment steps uniform across operators and shifts.

- You value a turret and servo architecture built for repeat runs. The tool turret and motion system support stable cycles when the same geometry must be repeated over a long production run.

Reliability Over Time: Maintenance, Software Updates, and Avoiding Delays

Specimen-prep equipment does not usually fail in a dramatic way. Most problems show up as drift. A tool starts leaving a different finish. A setup that used to hold center begins to wander. A shoulder transition changes just enough to raise questions about where the break occurred. By the time a lab notices, the damage is often measured in rework and retests.

Maintenance matters because tensile results are sensitive to small changes in geometry. Wear in moving components can affect positioning. A loosened fixture can shift centering. Tooling that stays in service too long can change gauge diameter or surface condition. None of that looks serious on its own. Together, it can widen data scatter and make trends harder to trust.

Preventive maintenance reduces the chance of those surprises. It also helps facilities avoid the worst kind of downtime, the kind that arrives mid-week when the test queue is already full. When checks are scheduled, parts are replaced on a plan, and alignment is verified on a routine basis, specimen preparation becomes easier to schedule.

Training matters for the same reason. Many labs rotate staff. Some hire technicians who have never run CNC equipment before. A guided interface helps, but it does not replace basic process discipline. Refresher training keeps habits aligned across shifts. It also protects the lab from slowdowns that start when one person becomes the “only operator” who can run the system smoothly.

Software belongs in the same conversation. Geometry libraries, saved parameters, and stored programs are part of the control system, not an extra. Updates can expand or refine standard profiles. Settings backups protect a lab after a hardware change or a controller replacement. Clean file management also prevents the quiet errors that come from running an outdated profile on a new job.

This is where a structured service plan tends to pay for itself. It turns maintenance into a calendar item instead of an emergency. It also gives labs a way to train new staff without losing weeks to trial and error.

Implementation in Real Facilities

In most facilities, specimen preparation succeeds or fails based on where it sits in the day. If it is treated as a side task, it competes with everything else. If it is built into the testing routine, the lab gains control over timing and quality.

Quality control labs tend to use these systems as a bridge between sampling and testing. A coupon comes in from production or receiving. The specimen is prepared and measured. The test follows right away, often the same shift. That flow matters because QC work is rarely flexible. Release decisions wait on tensile numbers, and delays can stall shipments or hold up a batch.

R&D groups use the machines differently. They often work with small lots, nonstandard geometries, or programs where the specimen changes as the project evolves. Custom profiles become part of the routine. The value is speed between iterations. When a change is made to heat treatment or composition, the lab can prepare a new set of specimens without booking time outside the department.

Production sites focus on predictability. The goal is not just speed, but a turnaround time that stays steady enough to plan against. When specimen preparation is done in-house, facilities can compare data across batches with fewer variables introduced by outside handling. That helps when materials, suppliers, or process settings change and the plant needs to know whether the shift is real.

A typical workflow is straightforward. Stock is cut and identified. The operator clamps it, selects a standard profile or enters a custom geometry, and runs the machining cycle. The specimen is measured, then tested. The value is not in complexity. It is in keeping that sequence reliable from one sample to the next.

Closing Notes for Teams Running Round Tensile Specimen Prep In-House

These two CNC systems cover the main scenarios facilities face in round tensile specimen preparation. The Classic Upgrade fits labs that need fast, repeatable specimen cycles and multi-sample setups. The Industrial Upgrade is a strong match for production-driven environments and shifting material mixes, including tougher alloys. In both cases, the goal is the same. Keep specimen preparation inside the lab workflow, reduce delays, and protect the credibility of test results.

If you want more detail, visit the product page for each machine. Those pages include full catalogs, expanded specifications, and FAQs. You can also request a quote or talk with a specialist about your workload and constraints.

For a more targeted recommendation, share the standards you run, the specimen types you prepare, and the material range you machine. We will point you to the setup that best fits your facility.