When testing metal hardness, many professionals face the same challenge: inconsistent results caused by manual testing errors, limited load control, or outdated equipment. These issues lead to unreliable data, failed quality checks, and costly delays in production or certification. In industries where precision matters, even a small measurement error can affect the entire outcome of a project.

NextGen Material Testing knows the value of accurate and repeatable Brinell hardness testing. We are proud to introduce the BrinGen-3000 Series, our advanced digital and automatic Brinell hardness tester with a closed-loop system. This device fulfills modern standards and laboratory needs with complete automation, high accuracy, and simple operation, even for rough metal surfaces that traditional testers cannot handle.

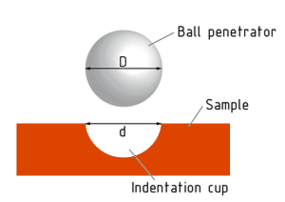

The BrinGen-3000 Series combines digital efficiency and mechanical reliability. After applying a fixed load to the test surface, it measures the indentation diameter to calculate hardness. All loading, holding, and unloading are automated. This guarantees accurate, repeatable results without operator error. This tester gives metal testing confidence and consistency in quality control labs, manufacturing workshops, and research facilities.

In the following sections, we examine how BrinGen’s digital features and closed-loop control improve accuracy and reliability in Brinell hardness testing.

Advanced Digital Testing with Closed-Loop Accuracy

The BrinGen – 3000 Series was developed to make sure that Brinell hardness testing is as precise and consistent as possible. A closed-loop control mechanism is the key element of the system. This feature guarantees that the force applied to each specimen is precisely controlled, repeatable, and stable. The closed-loop system actively monitors and adjusts the test load throughout the entire cycle instead of relying on older deadweight systems that can drift or fluctuate over time.

This level of control can be especially critical when working with an array of metals. The BrinGen tester is capable of applying test forces ranging from 62.5 kgf to 3000 kgf, making it suitable for a broad selection of materials, including hardened steel and soft bearing alloys. Each examination is executed automatically. The machine applies the load, which then holds it for a predetermined dwell time and releases it without the operator’s involvement.

The automation of this process not only increases efficiency but also prevents human error. This is crucial in situations where a large number of samples must be tested in a short amount of time. The results of manual testing may differ depending on the operator. With BrinGen, the process remains consistent, no matter the test cycle or load applied.

The testing process is further made easier by the integrated Brinell Hardness Calculator (BHC), which instantly calculates hardness values based on the indentation diameter. Users can simply select load values, establish dwell times, and view results when combined with a straightforward control interface and a large LCD touchscreen.

Optical Measurement and Automation Integration

To obtain accurate hardness readings, the BrinGen – 3000 Series is equipped with a 20X optical microscope with a resolution of 0.005 mm. This microscope helps users to precisely measure the diameter of the Brinell indentation, a critical component of determining dependable hardness values. The fine resolution guarantees that even minor variations in indentation size are readily discernible and quantifiable.

The system can be upgraded with the NG-Scope, an optional automatic image analysis system, for users who require even greater speed and efficiency. This upgrade removes the necessity for manual measurements by using advanced software to directly measure the indentation from a captured image. The outcome is a reduction in the likelihood of human error and a faster reporting process, particularly when managing large test volumes.

The integration of automation and optical tools enables users to operate with assurance. It also reduces operator fatigue, since repetitive measuring tasks are handled digitally. This makes this piece of equipment suitable for both experienced technicians and teams with varying levels of training.

Certified Compliance with Global Standards

The BrinGen – 3000 Series is fully compliant with the main Brinell hardness testing standards that are used throughout different regions and industries. Below are the key standards supported by our system:

ASTM E10 – Standard Test Method for Brinell Hardness of Metallic Materials

ASTM E10 defines the procedure for applying a standard test force using a hardened ball and measuring the resulting indentation to determine hardness. It is widely accepted in North America and internationally. The BrinGen system supports all required parameters, including force application, dwell time, and precise measurement.

ISO 6506 – Metallic Materials — Brinell Hardness Test

The method for testing metallic materials using Brinell hardness techniques is delineated in this international standard. It sets measurement criteria, indenter specifications, and load ranges. BrinGen is fully compatible with ISO 6506, making it suitable for ISO-certified environments.

BS EN ISO 6506 – European Standard for Brinell Hardness Testing

This standard is implemented in the United Kingdom and EU member states as the European adaptation of ISO 6506. The BrinGen – 3000 Series’ test results are valid for trade, certification, and industrial documentation within Europe due to their compliance with BS EN ISO 6506.

GB/T 231 – Brinell Hardness Test Method for Metallic Materials

GB/T 231 is a standard that is commonly accepted for Brinell hardness testing. It is frequently implemented in large-scale manufacturing and export-oriented industries and shares technical similarities with ISO 6506. This standard is fully supported by the our product, which provides flexibility in a number of production environments.

Material Compatibility and Hardness Range

As previously mentioned, the BrinGen – 3000 Series was built to evaluate a diverse array of metallic materials. It is particularly effective for surfaces that are too rough for other testing methods. Common applications include unquenched steel, cast iron, aluminum, copper, soft bearing alloys, and non-ferrous metals.

The system supports a hardness range from 8 to 650 HBW, covering both soft and hard metals. Example values include:

- Mild steel: approximately 120 HB

- 304 stainless steel (annealed): approximately 200 HB

- Hardened tool steel: up to approximately 900 HB

- Pure aluminum: approximately 15 HB

- Copper: approximately 35 HB

Technical Overview and System Specifications

Our BrinGen – 3000 Series offers an extensive set of technical capabilities that facilitate precise and consistent Brinell hardness testing in contemporary production environments and laboratories.

Let us now examine them in greater detail:

Supported Brinell Scales:

HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW5/125, HBW5/250, HBW5/750, HBW10/100, HBW10/250, HBW10/500, HBW10/1000, HBW10/1500, HBW10/3000

Test Force Range:

- From 62.5 kgf (612.9 N) to 3000 kgf (29,420 N)

Accuracy:

- Test force accuracy:

• ±1% for 62.5–250 kgf

• ±0.5% for 500–3000 kgf - Measuring resolution: 0.5%

Test Parameters:

- Hardness range: 8 to 650 HBW

- Dwell time: adjustable from 1 to 60 seconds

- Test space (H × D): 9.1 × 6.1 in (230 × 155 mm)

User Interface:

- LCD touchscreen display

- Test load and dwell time selection via screen and keyboard

- Real-time display of all test parameters

Optical System:

- Built-in 20X microscope

- Resolution: 0.005 mm

Power Supply:

- AC110 V or AC220 V ±5%

- Frequency: 50–60 Hz

Dimensions and Weight:

- Machine size: 21.3 × 7.5 × 29.5 in (540 × 190 × 750 mm)

- Shipping size: 28.7 × 17.7 × 38.6 in (730 × 450 × 980 mm)

- Net weight: 220 lbs (100 kg)

- Gross weight: 286 lbs (130 kg)

Engineered for Consistency. Supported for the Long Term.

To support continued performance, the BrinGen – 3000 Series is backed by a complete range of services and resources. We provide:

- Stocked consumables and spare parts for immediate replacement and minimal downtime

- NIST-certified accessories to maintain measurement reliability

- Trusted after-sales technical support for assistance with setup, operation, or troubleshooting

- Lifetime product support to guarantee continuing performance and peace of mind

The BrinGen – 3000 Series is an excellent option for modern Brinell hardness testing due to its full compliance with international standards, precise force control, modern digital automation, and optical measuring capabilities. It is well-suited for environments that necessitate reliability, efficiency, and accuracy on a daily basis.

Please do not hesitate to request a quote or reach out to us directly if you have any inquiries regarding this product. We are available to assist you with your material testing.