The West Cerchar Abrasivity Index Tester is a tool used mainly in mining and construction. Its main job is to measure how abrasive rock materials are. This is similar to a scale that indicates how rough a rock can be on machinery and equipment. This data is essential because when companies know how abrasive the rock is, they can choose the right equipment and techniques for their projects, avoiding damage and saving money.

In the mining industry, as well as in construction, especially underground work, the type of rock and its roughness can impact efficiency and safety. For instance, if a rock is too abrasive, it might wear out machinery faster or make drilling more challenging. This is why rock abrasivity parameters are so crucial.

West Cerchar Abrasivity Index Tester

In this blog, we’ll explore the West Cerchar Abrasivity Index Tester from NextGen Material Testing Inc. in detail. We will discuss how it works, why it is important, and who can benefit from its use. Whether you are involved in the industry or just curious about how such tools are used in large projects, this article will provide you with a better understanding of this essential device.

The Key Role of the Abrasivity Index Tester in Many Industries

Abrasiveness, in simple terms, relates to the wear and tear capability of one material over another. Understanding this property, especially in rock materials, is of fundamental importance in a wide range of industries. Let’s review the industries that require devices like the West Cerchar Abrasivity Index Tester:

Mining Industry

The mining industry is filled with machinery that continuously interacts with different rock formations. An oversight in estimating the abrasiveness of these rocks can result in increased equipment maintenance costs. According to a study by the International Journal of Mining Science and Technology, knowledge of rock abrasiveness can lead to a potential 15-20% extension of mining equipment life.

Moreover, as mining projects drill deeper into the Earth’s surface, encountering unexpected rock types becomes more common. Proper abrasiveness testing can reduce machine downtimes and unexpected project delays. Additionally, by understanding the rock’s abrasiveness, mining operators can strategically plan their excavation, ensuring optimal machinery usage and reduced wear. With the rise of environmentally conscious mining, predicting equipment wear also plays a role in minimizing the carbon footprint by minimizing frequent equipment replacements.

Construction and Infrastructure

Tunneling and underground construction rely heavily on machinery that drills through rock. The abrasiveness of the rock is directly related to project speed and efficiency. In recent times, as cities look to expand their underground transport networks, there has been an increase in the frequency of excavations. This has made rock wear analysis even more critical. Projects can be slowed down by unexpected rock abrasiveness, leading to increased operation costs.

Moreover, unplanned downtime for equipment maintenance or replacement can cause significant delays in the completion of projects. Additionally, understanding rock abrasiveness better equips project managers to develop effective excavation plans. This ensures machinery is used optimally and safely throughout the project lifecycle.

Geological Studies

For geologists, the tester is not just a tool but an opportunity to better understand Earth’s history. Rock formations, their composition, and their abrasiveness can provide insights into past geological events. By comparing the abrasiveness of different rock samples, geologists can identify regions that have undergone similar geological transformations.

Research & Development

Universities and research institutions that specialize in geotechnical engineering and geological sciences often utilize the West Cerchar Abrasivity Index Tester in their labs. In addition, it is helpful in experimental studies, allowing students and researchers to gain practical experience and knowledge.

Among the many industries and sectors that interact with the world of rocks and geology, the West Cerchar Abrasivity Index Tester is an invaluable tool. Its precise measurements, reliability, and ease of use make it a top choice for professionals searching for efficiency, accuracy, and reliability in their operations.

Understanding the Cerchar Abrasivity Index (CAI)

The Cerchar Abrasivity Index (CAI) is a metric specifically developed to evaluate rock samples’ abrasiveness. This numerical value, often used in industries like mining and construction, measures a rock’s potential to cause wear and tear on machinery and tools during drilling or excavation processes. The West Cerchar Abrasivity Index Tester is specifically designed to determine this CAI value.

CAI was created to address the need for determining the wear potential of different rock types. Given that machinery and drilling equipment are significant investments in industries, understanding the abrasiveness of the rocks they interact with is of primary importance. A higher CAI indicates a more abrasive rock. This suggests that the machinery will undergo more wear when working with that rock, potentially leading to faster degradation and increased maintenance costs.

The measurement process for CAI is generally standardized. A rock sample is subjected to a specific test, usually involving a pin or stylus being moved across its surface under controlled conditions. The resulting wear on the pin or stylus, when quantified and calibrated, gives the CAI value. The CAI offers a scale, generally ranging from 0 (least abrasive) to over 6 (highly abrasive), assisting industries in making informed decisions about the equipment and procedures they should employ.

Operational Mechanism of The West Cerchar Abrasivity Index Tester

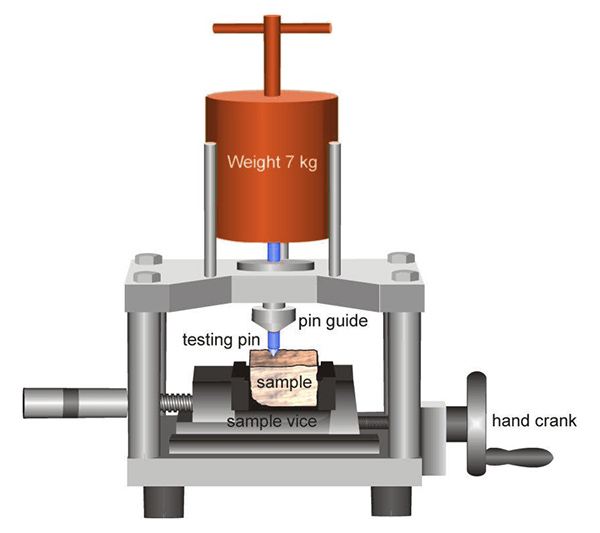

The West Cerchar Abrasivity Index Tester is a composite of meticulously engineered parts ensuring precision and functionality. At its core lies a stationary stylus, weighted down by a 70N deadweight. This combination guarantees ideal pressure during testing. Its design includes a robust load frame and a specialized vice. These vices ensure the rock sample remains firmly clamped during the test. The inclusion of a cross table with two adjustable axes ensures the sample aligns perfectly in both horizontal dimensions. A standout feature of this tester is the graduated knob, enabling scratch distance adjustments with an accuracy of 0.01 mm.

Its indenter visualization system is one of its most notable features. Equipped with a digital camera and dedicated software, this system quantifies wear, a metric directly tied to the CAI. To maintain optimal functionality, a sharpening tool accompanies the tester, priming a dulled stylus for the ensuing tests.

The Importance of the ASTM D7625-10 Standard

An integral aspect of the West Cerchar Abrasivity Index Tester conforms to the ASTM D7625-10 standard. ASTM standards serve as benchmarks in various industries, setting the industry standard for quality and reliability. Specifically, the D7625-10 standard focuses on rock abrasivity testing protocols and prerequisites. The compliance of the tester with this standard not only underscores its precision but also provides support for its credibility on a global scale.

Benefits of the Cerchar Abrasivity Index Tester System

Navigating rock abrasiveness assessment requires scientifically rigorous and user-centric tools. The Cerchar Abrasivity Index Tester offers a combination of both, becoming a vital asset for industries dealing with rock formations. Let’s explore the distinctive advantages that set this system apart:

- ASTM D7625-10 Compliance: The tester meets ASTM D7625-10 standard. ASTM standards are globally recognized for ensuring quality, safety, and efficiency.

- User-centric Design: Ease of use often becomes the basis of tool frequent application. The Cerchar Tester’s design emphasizes user-friendly manual handling, ensuring that even novices can navigate its features with minimal difficulty. This focus on user experience significantly reduces the learning curve and accelerates operational readiness.

- Precision Slide Mechanism: One of the most important features of the tester is the precision slide that allows smooth movement. This feature ensures that the rock glides seamlessly over the required scratch distance, maintaining the test’s integrity and delivering consistently reliable results.

- Adaptable Daylight Adjustment: The height of the rock samples tested may differ significantly. Recognizing this variability, the tester has an adjustment feature. This ensures that irrespective of the specimen’s height, the testing process remains constant and accurate.

Understanding the Testing Method

Using the Cerchar Abrasivity Index Tester, rock abrasiveness can be assessed in a scientifically rigorous manner. In addition to optimizing equipment longevity and operational efficiency, such assessments are based on precise measurements and evaluations. The West Cerchar Abrasivity Index Tester uses a precise method to measure rock abrasiveness. Let’s take a closer look.

Test Methodology

-

Initial Examination: A rock sample undergoes detailed analysis to determine the optimal scratch location and direction. Such a process is vital, especially for rocks exhibiting significant anisotropy. Selecting a scratch direction that best reflects the rock’s predominant mineralogical and textural characteristics is the goal.

-

Precise Positioning: Following the initial examination, the sample is fixed in a vice. The stylus, a crucial component, is then meticulously aligned orthogonal to the rock surface, ensuring precision at every step.

-

The Scratch Test: With the setup ready, a standardized scratch, 10.0 mm long, is executed for 10 seconds. It’s essential to maintain uninterrupted contact between the stylus and the rock throughout this duration.

-

Post-Scratch Evaluation: After the scratch, the stylus is examined under a microscope, typically at a minimum magnification of 25x. This allows for the measurement of ‘wear flat,’ essentially quantifying the wear endured by the stylus.

Calculating the CAI

From the measured wear, a dimension known as ‘d’ is derived. The CAI is then computed as CAI=d×10. To ensure the robustness of the data, the test is replicated a minimum of five times, each instance with a fresh or re-sharpened stylus. The final CAI value is an arithmetic mean of these tests, factoring in the standard deviation.

Exploring the Optional Accessories of the West Cerchar Index Tester

For those engaged in rock abrasivity testing, the effectiveness of the equipment and its additional tools often determine the results’ precision and reliability. Take a closer look at the optional accessories provided by the West Cerchar Index Tester to understand their utility:

- West Cerchar Specialty Indenters: The West Cerchar tester comes equipped with 100 sharp steel indenters, each with a 90° conical angle. This ensures uniform testing, minimizing potential errors. Such a requirement eliminates the need for additional indenters and ensures each test is conducted under standardized conditions.

- Digital Microscope: Assessing results post-testing is vital to gain valuable insights from abrasivity tests. The West Cerchar tester offers an advanced digital microscope for this purpose. This microscope isn’t just a visualization tool; it comes integrated with an indenter holder equipped with digital micrometers and an XY stage. Such features ensure accurate positioning and measurement of stylus tip wear. Additionally, the inclusion of a video camera and dedicated software provides a platform to both view and quantify wear, enabling users to derive the Cerchar Abrasivity Index (CAI) with precision.

- Steel Indenter Sharpening Tool: Continued testing can wear out the indenters. To address this, the West Cerchar Index Tester comes with specialized a sharpening tool. This tool is specifically designed to re-sharpen the stylus, maintaining its 90° cone angle. Such a feature ensures that the tester is always ready for future tests without affecting the quality of the results.

Broader Implications of Rock Abrasiveness

Understanding rocks’ abrasiveness and machinery interactions is not merely about protecting equipment. The repercussions extend to various sectors of our economy, the environment, and human well-being. Now let’s take a closer look at some broader implications.

Economic Ramifications

- Operational Costs: As previously mentioned, abrasive rocks can significantly increase operational costs. But it’s not just about machinery. Projects can experience delays, which result in compensation or extended labor costs. Strategic planning, based on rock abrasiveness, ensures financial viability and cost-effectiveness.

- Resource Conservation: Being equipped with rock abrasiveness knowledge allows industries to allocate resources wisely. This includes choosing machinery that’s apt for the task, thereby reducing unnecessary expenditure on equipment repair or replacement.

Environmental Considerations

- Energy Consumption: Machinery that wears out rapidly due to abrasive rocks often becomes less efficient over time, requiring more energy for the same output. This higher energy usage contributes to a larger carbon footprint.

- Lifecycle of Machinery: The constant need to replace worn-out machinery components has economic and environmental implications. The production, transport, and recycling of these parts add to the environmental impact in terms of resource use and waste production.

Safety Concerns

- Equipment Malfunctions: As mentioned, equipment that interacts with highly abrasive rocks can fail. This is especially critical in environments like mines, where equipment failure can result in catastrophic consequences, including life-threatening situations.

- Preventive Measures: By measuring rocks’ abrasiveness accurately, industries can anticipate potential issues and take proactive safety measures. This might involve routine checks, additional safety equipment, or alternative excavation techniques to ensure worker safety.

Skill Development and Specialized Training

- Maximizing Tool Efficiency: For industries to truly benefit from tools like the West Cerchar Abrasivity Index Tester, they must ensure that operators are well-versed in their use. Inaccurate measurements can lead to incorrect decisions with far-reaching implications.

- Ongoing Training: As technology evolves, so do the methods and details of using such tools. Continuous training programs ensure personnel are always equipped with the latest knowledge and best practices.

Due to rock abrasiveness complexity, precise measurements are essential. That’s why using the West Cerchar Abrasivity Index Tester ensures accurate assessments of rock interactions. This device will help industries in mitigating economic, environmental, and safety risks, serving as a critical tool for informed decision-making and optimal resource utilization.

The West Cerchar Abrasivity Index Tester – A Vital Tool for Assessing Rock Abrasiveness

Understanding rock abrasiveness and its complexities is essential for industries that frequently interact with geological formations. The West Cerchar Abrasivity Index Tester emerges as a critical instrument, ensuring precise and reliable measurements of this property. In addition to its use in the mining and construction sectors, its relevance extends to infrastructure, geological studies, and academic research.

From an economic perspective, the tester helps industries predict operational costs, ensure optimal equipment use, and minimize unexpected downtimes. These aspects contribute directly to resource conservation and project success. In terms of the environment, knowing the abrasiveness of rocks is helpful in reducing energy usage and increasing machinery life. This leads to reduced carbon footprints and waste production. Furthermore, from a safety perspective, the West Cerchar Abrasivity Index Tester equips industries to prevent equipment malfunctions and implement proactive safety measures.

Considering the broad implications of rock abrasiveness, accurate measurements are essential. Tools like the West Cerchar Tester are essential for industries that strive for sustainability, safety, and economic viability. Moreover, with the growing emphasis on environmentally conscious practices and the ever-present demand for infrastructure development, this tester’s significance is only bound to increase.

The West Cerchar Abrasivity Index Tester from NextGen Material Testing Inc. demonstrates the importance of combining technological innovation with industry requirements. Its precision, ease of use, and alignment with globally recognized standards make it a valuable tool in today’s geotechnical sector. For industries looking to navigate the challenges posed by diverse rock formations, the West Cerchar Tester provides crucial support in their efforts to become more efficient and sustainable.