A digital densimeter is a laboratory instrument that measures the density of materials using advanced electronic technology. It is used in industries such as pharmaceuticals, petrochemicals, and materials science to ensure that products meet specific standards and function as intended. This article provides a comprehensive overview of the digital densimeters of the NG-DM-A Series from NextGen Material Testing Inc., emphasizing their significance and application in modern industries.

The Important Role of Digital Densimeters in Modern Industries

Densimeter efficiency is best demonstrated in its compatibility with a wide range of materials. From rubber to plastics, its significance is undeniable. In the tire industry, for instance, rubber consistency and its other basic materials are of high importance. The densimeter ensures that tires, a critical safety component in automobiles, are of high quality, displaying the required properties vital for optimal performance.

Furthermore, the footwear sector, which relies heavily on materials such as shoe materials, macromolecules, and composite materials, greatly benefits from digital densimeter precision. The consistency and quality of these materials directly influence footwear comfort, durability, and overall performance. By taking accurate measurements, manufacturers can determine the right balance of materials, ensuring the production of top-quality footwear.

Another significant industry that utilizes the digital densimeter’s capabilities is the production of conveyor belts, transmission belts, and other elastic materials. These products, which are foundational to numerous industrial operations, need to comply with the highest quality and safety standards. Even a slight difference in density could translate to quality issues or even safety risks. Hence, the digital densimeter system becomes an essential part of quality assurance in these industries.

What truly underscores the digital densimeter’s versatility is its ability to work with both soft synthetic leather and traditional leather. In the world of fashion and interior design, where leather’s feel, look, and durability are crucial, the digital densimeter ensures that these materials maintain consistent quality. This ensures that these materials resonate with discerning customers’ expectations.

How Standards Guide Digital Densimeter Performance

Leading standards, such as those set forth by ASTM and ISO, establish a uniform approach to quality assessment. Take ASTM D792 or ISO 2781, for instance. These standards outline rigorous protocols for determining plastic density and specific gravity in solid forms. Similarly, ISO 1183, GB/T 1033, and GB/T 2951, among others, have set benchmarks for assessing various materials’ densities.

Without compliance with standards, the results can be unreliable. Variability or differences can cause problems, leading to potential disagreements and, in some cases, disastrous outcomes. In critical industries, such as aviation, the risks are incredibly high. Aircraft components, especially those made of composite materials, need specific properties to ensure they can withstand stresses during flight. A minor error in assessing the density of these materials can lead to significant effects, compromising aircraft structural integrity and risking the lives of people.

Composite materials in the aviation sector are meticulously designed to be lightweight yet extremely durable. These materials often combine different elements and the density measurements can define their performance. Using a densimeter compliant with standards like JIS K 6268, GB/T 208, GB/T 5163, and GB/T 1933 ensures that these materials meet the required manufacturing specifications.

All of the mentioned standards are incorporated into our densimeter. This compliance isn’t just an assertion but a verified truth, guaranteeing that our product will produce correct data. As a consequence, the precision and genuineness of results obtained using NG-DM-A are assured, guaranteeing trust and consistency in every measurement.

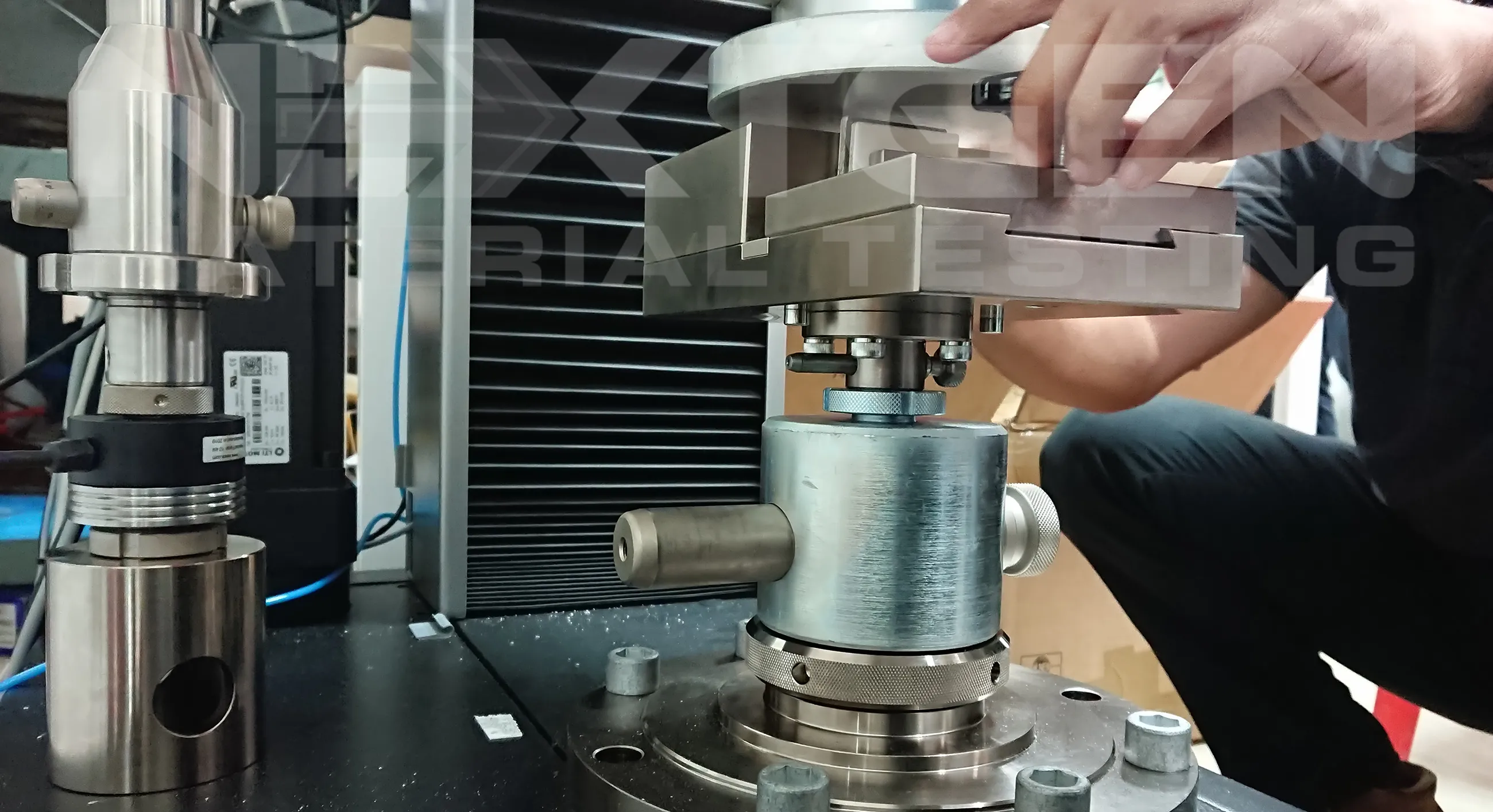

Overview of the NG-DM-A Series Digital Densimeter Systems

NG-DM-A series of digital densimeters represents an advanced generation of digital densimeters, specifically designed to meet diverse material testing needs. These systems, while being highly compact, offer a broad capacity range from 150g to 3000g, ensuring precision measurements with accuracy spanning from 0.001g/cm³ to a fine 0.0002g/cm³.

NG-DM-A can analyze plastics, tires, shoe materials, macromolecular compounds, composites, elastic substances, conveyer belts, transmission belts, soft synthetic leather, genuine leather, and much more in addition to rubber.

NextGen’s digital densimeter offers multifunctional density measurement capabilities. In addition to providing instant density readings, it can also determine abrasion loss of relative volume according to DIN, AHRI, and AKRON standards. The system displays detailed metrics such as expansion rates, quality metrics, and volume changes.

Additionally, the NG-DM-A series’ versatility makes it an ideal instrument for a variety of industries and applications, with its primary application in automotive and aerospace industries.

Core Benefits

As the material testing industry continues to evolve, the NG-DM-A series stands out as an example of technological innovation. A true asset for professionals, this series ensures precision and comprehensive functionality.

- User-Friendly Design: Engineered with precision, they provide an intuitive operational experience. Both novice and expert users will find its interface streamlined and instructions clear, ensuring efficient utilization without unnecessary complexity.

- Dependability and Reliability: The densimeters are engineered with a robust construction to ensure they withstand varied testing conditions. They consistently offer accurate density measurements, highlighting their emphasis on durability and sustained performance across multiple uses.

- NIST Certified Consumables: All consumables for this machine are certified by the National Institute of Standards and Technology (NIST). This certification ensures that they comply with industry standards, providing users with confidence in the accuracy and reliability of the data.

- Stocked Consumables and Spares: Operational efficiency is vital. By ensuring that consumables and spare parts are readily available, users can avoid unnecessary downtime. With the NG-DM-A series, quick replacements and minimal disruptions guarantee an uninterrupted testing process.

- Trusted After Sales Technical Support & Lifetime Product Support: The purchase is just the beginning of a long-term partnership. Our technical support team is available to assist with troubleshooting, maintenance, or advanced operations guidance. We are sure of the longevity of our product and are committed to satisfying our users with lifetime product support.

Overall, the NG-DM-A Series is more than just equipment; it represents a comprehensive solution that addresses the intricate needs of material testing.

Digital Densimeter Systems Features & Functions

Precision Beyond Comparison

The accuracy of the results is of high importance when it comes to material testing. With its precision calibration, the system offers density measurement accuracy of either 0.001 grams per cm3 or 0.0001 grams per cm3. In addition to fostering confidence, such accuracy levels ensure that the probability of errors, which can be costly in many industries, is minimized.

Adaptive and User-centric Design

With its user-centric features, the NG-DM-A demonstrates the comprehensive approach taken in its design. In addition to delivering results, it enhances the user experience. The comprehensive display allows users to view all critical metrics, including apparent density, volume, and mixture ratios, as well as the rate at which density and volume change over time.

Another noteworthy aspect is its adaptability to global operational environments. Densimeters’ power systems are versatile, compatible with electrical standards in North America and Europe, spanning AC 100V-240V and being able to run at both 50HZ and 60HZ frequencies. In this way, users receive a consistent level of service regardless of their geographic location.

Elevating Connectivity and Data Management

At a time when data reigns supreme, the NG-DM-A series is at the forefront of data processing. Featuring an in-built RS-232 port, it enables seamless and efficient connectivity. Whether it’s linking up with PCs for data analysis or connecting to printers for instant hard copies, this densimeter caters to all needs. Furthermore, the ability to store up to ten sets of data enhances its data management capabilities, enabling users to seamlessly track and analyze results over time.

Versatility in Operation

While many digital densimeters on the market offer basic features, the NG-DM-A series goes a step further. This isn’t just a tool, but a comprehensive solution as well. This device’s versatility can be observed in the fact that it can be used with a wide variety of liquid mediums, which include water and other specialized liquids. NextGen’s digital densimeters have customizable settings, including temperature adjustments and density specifications.

Benchmarking Against Conventional Densimeters

NG-DM-A system is a fusion of innovation, user-centric design, and precision where standard devices might offer basic measurements. Due to its large tank design, high-capacity injection molded PC water tank, and precise suspension wires, every measurement taken is free from external interference and inaccuracy. It is not only desirable, but essential to maintain such precision in an industry where even the smallest error can have serious impacts.

The DM-A series of digital densimeters represents the perfect balance of technology and precision. As a user-friendly, precise, and versatile tool, it is setting new standards in the field of material testing.

Technical Specifications of the Digital Systems from NextGen

A variety of models are available in the NG-DM-A series, which addresses a variety of technical requirements. Beginning with the NG-DM-A300, it’s designed to handle weights up to 300g. This model, with a reliable density precision of 0.001g/cm^3, is adept at general laboratory applications. For more demanding applications, the NG-DM-A600 can handle up to 600 g while maintaining the same level of precision, which makes it ideal for more demanding tasks. NG-DM-A1200 is designed for intensive research and commercial applications. It can handle samples weighing up to 1200 grams. In order to handle large volumes without compromising accuracy, the NG-DM-A3000, which supports up to 3000g, is the best choice. As a final point, although the NG-DM-A150 is significantly lighter at 150g, it has the advantage of ultra-high precision and can be used to satisfy specific industrial needs that demand the highest degrees of accuracy.

| Model | NG-DM-A300 | NG-DM-A600 | NG-DM-A1200 | NG-DM-A3000 | NG-DM-A150 | |

| The maximum weight(g) | 300g | 600g | 1200g | 3000g | 150g | |

| Density precision(g/cm3) | 0.001g/cm3 | 0.0002g/cm3 | ||||

| Repeatability accuracy | ±0.001g/cm3 | ±0.0003g/cm3 | ||||

NextGen Material Testing densimeters are capable of measuring a wide range of parameters, including density, specific gravity, mixing ratio, and volume. These instruments are able to analyze a variety of samples, whether they are solids, pellets, films, or floating samples. The series’ capacity to measure densities above and below 1 ensures its relevance across a wide range of industries.

The operational modes of the series further enhance the functionality of the series. Densimeters are excellent at evaluating parameters of solids and granules when used in Solid Mode. When switched to Mixing Ratio Mode, they become indispensable tools for measuring the mixture ratio of materials with known densities.

Each of these densimeters has settings tailored to a variety of testing environments. Through its advanced temperature and solution compensation settings, which allow adjustment up to a density of 19.999, as well as seamless integration with external systems via RS-232C output mode, the series is highly flexible. It is possible to operate these devices effectively within a broad temperature range, ranging from -18°C to a comfortable 45°C, and at relative humidity levels up to 80%.

To conclude, these digital densimeters have a compact design while maintaining high functionality. It has been strategically chosen to ensure minimal space occupancy in professional setups, with the aim of delivering both robust and precise performance.

Calculation and Determination of Results in the NG-DM-A Series Digital Densimeter Systems

The core of the NG-DM-A series digital densimeter system’s operation lies in its computational ability to determine the density of a given sample. Understanding how this determination is made can provide useful knowledge about the accuracy and reliability of the results the equipment provides.

Archimedes’ Principle

At its core, the digital densimeter system relies on Archimedes’ principle. This ancient Greek principle states that an object submerged in a fluid experiences an upward force equal to the weight of the fluid it displaces. It’s this principle that allows a densimeter to accurately measure the density of a given sample.

Calculations

The densimeter essentially measures the mass of the sample in air and then measures the apparent mass of the sample when it’s submerged in a fluid (typically a calibrated liquid). The difference between these measurements gives the displaced fluid volume. Using a special formula, the sample density can be determined.

Operational Steps:

- Weigh in Air: The sample’s weight in the air is measured using the densimeter’s precision scale.

- Weigh in Liquid: The sample is then submerged in the calibrated liquid, and its apparent weight is measured.

- Compute Density: Using the difference in weight (from air to liquid), the sample volume is determined. The densimeter then calculates the density using the above formula.

Factors to Consider

There are several factors that can influence the accuracy and precision of density measurements:

- Temperature of the Liquid: Liquid density changes with temperature. It’s essential that the temperature is consistent and known, as the densimeter often compensates for temperature variations.

- Calibrated Liquid: The calibration liquid density (often distilled water) must be known and consistent. Some advanced densimeters, including those in the NG-DM-A series, allow other specialized liquids for specific applications.

- Sample Geometry: While the densimeter is designed to handle a variety of sample shapes and sizes, ensuring that the sample is completely submerged and free from air bubbles will provide more accurate results.

The NG-DM-A series digital densimeter systems employ advanced technology to simplify density determination while ensuring high accuracy. By using a fundamental principle from ancient times and combining it with modern computational methods, these densimeters provide reliable, fast, and precise density measurements critical to numerous industries today.

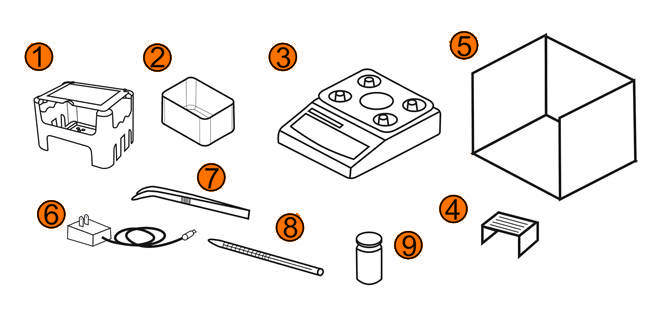

Standard Accessories

The NG-DM-A series is complemented by its standard accessories, which are specifically designed to enhance its functionality. Its core component is the measuring platform, which is essential to obtaining precise measurements. The setup includes a robust water tank that ensures consistent measurements in liquid environments.

-

Measuring platform

-

Water tank

-

Main-body

-

Anti-floating frame

-

Windshield (Optional Configuration)

-

AC adapter

-

Tweezers

-

Thermometer

-

Calibration weight

Designed to withstand rigorous testing scenarios, the main body of the system is robustly constructed. The anti-floating frame enhances the precision of measurements by ensuring samples remain submerged during testing. Although the windshield is an optional configuration, it plays a crucial role in environments where external factors may affect measurements.

Powering the system is an AC adapter that meets European standards, ensuring seamless operation. In addition, there are essential accessories such as tweezers that facilitate the handling of samples, and a thermometer that helps in maintaining the desired temperature for accurate results.

Why Choose the NG-DM-A Series Digital Densimeter Systems

NG-DM-A series digital densimeter systems offer the highest precision and a suite of features that make it a leader in its field.

First and foremost, these densimeters deliver the highest accuracy. With the ever-increasing demand for precision in various industries, from aerospace to pharmaceuticals, having a tool that can provide meticulous measurements is invaluable. The smallest differences in density can dictate the performance, safety, and quality of products.

Beyond just accuracy, the DM-A series is an example of reliability. Equipment in laboratories and industrial settings is frequently subjected to rigorous use. The durability of the NG-DM-A ensures that it not only withstands such usage but continues to deliver optimal performance. Long-term dependability means fewer interruptions, reduced downtime, and consistent outputs, which, in turn, can translate to cost savings and increased productivity for businesses.

Innovation is another feather in its cap. The world is rapidly evolving, and so are the challenges faced by industries. This series doesn’t just respond to these challenges; it predicts them. Its cutting-edge features are designed keeping in mind both current and future needs, ensuring that users are always a step ahead in their material testing tasks.

As a final note, choosing the NG-DM-A digital densimeters is about aligning with a vision of excellence. NextGen Material Testing Inc. has a reputation for being at the forefront of technological advancements, and by opting for their products, one aligns with a commitment to quality, innovation, and progress.