In this blog post, we’ll learn how abrasion testing improves product quality and introduce the Linear Taber Abrasion Tester from NextGen Material Testing, Inc.

Abrasion Tester Introduction

Everyday use of household items inevitably leaves traces of this use on them. These are scuffs, scratches, discoloration. Such changes make things unattractive and can also interfere with their functionality. Market laws dictate that manufacturers need to improve the durability of their products. Therefore, abrasion and scratch resistance tests are used to evaluate the ability of materials or coatings of products to withstand wear and tear and to withstand mechanical damage. These tests help manufacturers evaluate the quality and durability of materials and products ranging from textiles and leather goods, furniture and floor coverings, cell phones, computers, to automobiles and airplanes.

Everyday use of household items inevitably leaves traces of this use on them. These are scuffs, scratches, discoloration. Such changes make things unattractive and can also interfere with their functionality. Market laws dictate that manufacturers need to improve the durability of their products. Therefore, abrasion and scratch resistance tests are used to evaluate the ability of materials or coatings of products to withstand wear and tear and to withstand mechanical damage. These tests help manufacturers evaluate the quality and durability of materials and products ranging from textiles and leather goods, furniture and floor coverings, cell phones, computers, to automobiles and airplanes.

Wear and abrasion testing is a test for wear and abrasion resistance, which usually involves treating the surface of a material with mechanical friction. The goal is to determine how quickly it will wear off or how many layers of material can be destroyed in a certain amount of time. This test helps to establish how long a material or product has a service life before signs of abrasion appear.

Scratch testing evaluates the ability of a material or coating to withstand damage that can occur from scratches or abrasions. During this test, scratches are applied to the surface using special tips to determine how resistant the material is to such damage.

The use of these tests helps manufacturers improve products and ensure greater durability and longevity of materials in various industries.

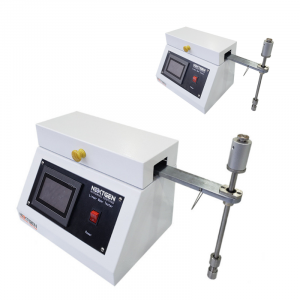

Linear Taber Abrasion Tester from NextGen – used to determine the abrasion resistance, scratch resistance, and colour loss of products. Both dry and wet abrasion tests can be performed.

Methods used to determine the resistance to wear, abrasion, and scratching

- Abrasion Testing: This method involves the use of abrasive materials that are applied to the surface of the material and subjected to mechanical movement to cause wear. Parameters such as weight loss or depth of wear are then measured to evaluate the material’s resistance to wear.

- The Taber Abrasion Test uses a rotating platform with attached abrasive wheels or disks that apply a specific load to the surface of the material or product under test. The material is subjected to rotational and sliding movements and the resulting wear – weight loss and depth of damage – is measured. The Taber test is a widely used method for evaluating the abrasion resistance of materials. These testers are also called Taber abraser or Taber abrader.

- Scratch Testing evaluates the resistance of a material to scratches and surface damage. Various test methods can be used, such as using a stylus or indenter with known hardness to apply a controlled force to the surface of the material. Scratch depth, weight loss, and visual damage assessment are used to evaluate the scratch resistance of a material.

A special mention should be made of The Linear Taber Abrasion Test.

The Linear Taber Test: Both Abrasion and Scratch Resistance

The Linear Taber Abrasion Test can be considered more versatile compared to the standard Taber Abrasion Test in terms of evaluating both abrasion resistance and scratch resistance. While the standard Taber Abrasion Test primarily focuses on evaluating the material’s resistance to rotational and sliding abrasion, the linear variant incorporates linear or back-and-forth motion, which allows for a wider range of wear and damage to be assessed.

By utilizing linear motion, the Linear Taber Abrasion Test can simulate various types of wear and friction that materials may encounter in real-world applications, including both abrasive forces and scratches. This makes it suitable for evaluating material performance in situations where linear wear or scratching is an issue.

The test results, weight loss, scratch depth and/or colour fastness are evaluated against each other or against standard samples. In this way, the quality of the products is maintained at the proper level during routine quality control, or improved during tests aimed at selecting a more suitable material for the application.

It is important to note that while the Taber linear abrasion test provides valuable information about abrasion and scratch resistance, specialized scratch test methods that specifically focus on scratch phenomena can provide more detailed and accurate results for scratch resistance assessment. Nevertheless, the versatility of the Linear Taber abrasion test makes it a valuable tool for evaluating the durability and wear resistance of materials in a variety of applications.

Utility of NextGen Linear Taber Abrasion Tester

The tester is small (26 x 28 x 32 cm / 10.25″ x 11″ x 12.625″) and weighs 35 kg / 77 lbs, so a small part of the workbench surface is sufficient for installation. It is operated via a touch screen with an intuitive interface. It is supplied with all the attachments that may be required to perform various tests. The interchangeable nozzles provide testing versatility. The possibility of supplying special custom-made nozzles can be discussed by contacting NextGen directly.

Designed to test both contoured and flat surfaces, making it ideal for evaluating finished products of all sizes. To extend the versatility of this instrument, the linear abrasive can be configured with optional test attachments to perform different types of abrasion tests. It can be used for both wet and dry testing.

Designed to test samples of virtually any size or shape, the linear abrasive is ideal for testing the mechanical properties of materials, profiled surfaces, and finished products. The versatility of the tester lies in its ability to evaluate wear resistance as well as scratch resistance in a single or multiple pass. This method of scratch resistance assessment can also be used to determine the colour fastness of a surface, paint or coating. It can test samples of any size and shape and is ideal for abrasion testing of products with embossed and polished surfaces (e.g., computer mouse). It is commonly used to test materials and products made of plastic, rubber, leather, and textiles for testing inks, printing and other products.

The arm of the device is securely attached to the mechanism of the device, which performs back and forth movements with a specified frequency from 2 to 60 movements per minute. In the case of non-flat surfaces, when the arm makes a linear movement, the working head follows the contours of the sample, whether curved or flat. The selected parameters of stroke length, stroke frequency, and load are saved.

Summary

To accurately replicate real-world conditions and to standardize testing, it is possible to customize all the necessary test parameters that are optimal for each type of test specimen.

If you are considering whether to purchase a Linear Taber Abrasion Tester for your laboratory or have any questions about its use, configuration, or pricing, please contact NextGen directly.