GenVac MP Series: Vacuum Impregnation System that is Leading Amid Competition.

One of the wonders of material science engineering, vacuum impregnation systems plays an important role in manufacturing and maintenance of porous and composite materials like circuit boards, ceramics, minerals and even rocks.

Vacuum impregnation refers to the process of fixing leaks that may have been a result of leaks in powdered metal parts and metal castings. It is therefore important for manufacturers to find the best vacuum impregnator available in the market today.

GenVac MP2 – Vacuum Impregnator is often touted to be among the most precise impregnator commercially available. Differentiating the GenVac MP2 series from other similar equipment is its user-friendliness, process-orientation, re-usability of consumables, strong structure, and superior quality.

The equipment has been getting consistent good reviews from experts at vacuum impregnation metallography.

User Friendly

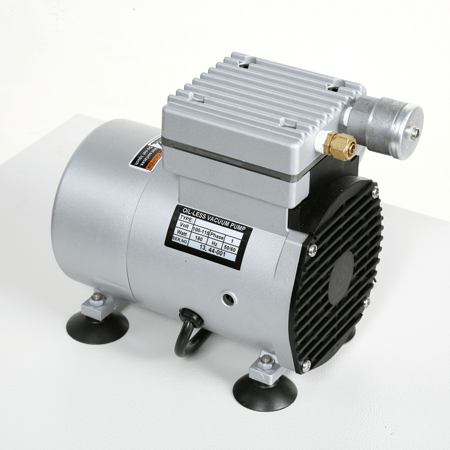

Unlike its contemporaries, the GenVac series system has a separate vacuum pump that can be activated using a friendly user interface. The GenVac Cold mounting press includes a cup holder for disposable samples required to achieve optimal sample impregnation.

The 16-cm diameter transparent cover allows user to get a clear view of the sample impregnation process. The cover can be removed to reveal the vacuum chamber bed. Users are afforded better vantage point to observe the impregnation process. This allows the user to adjust how they handle and position samples.

Since the disposable inlet tube is attached to the chamber covers, users will find it easy to refill the mounting caps placed inside the chamber. Having a clear view of the chamber interior and an apparatus that allows additional materials to be sent to the mounting cups can prevent the loss material integrity required for impregnation.

The control panel in front of the unit only has a few control levers allowing users to get easily acquainted in operating the equipment.

First-time user will find the GenVac very easy to use compared to its contemporary. This however does not compromise their functionality and depth of use. Experienced users will find the equipment a delight to use because of its process oriented design. The manufacturers were thorough in designing the equipment to suit a variety of users ranging from the inexperienced users to professionals such as material science engineers.

Process-Oriented

Unlike its competitors, the GenVac has an excellent understanding of its purpose and its process. GenVac incorporates a metallographic specimen mounting press to rid off air and other impurities from the material. This process removes the gaps between the resin and the specimen crucial in maintaining the integrity of the sample.

Samples with highly-porous properties are the most difficult material to handle. The GenVac has a firm understanding of how to handle mineralogical samples that necessitate epoxy mounting in a vacuum. These samples have cracks and cavities that must be pressed together to produce optimal samples.

The GenVac MP2 series maybe a user-friendly impregnation system but its design considered both the process and the usage making the work of laboratory technicians easier.

Reusable Parts and Consumables

Parts and consumables are all widely-available. Since GenVac does not use proprietary parts and consumables, these materials can be purchased not just from the Next Gen Material Testing company but also from local suppliers. This means, users can source these materials anywhere anytime especially if the plan is to use the equipment overseas and on a long-term basis.

In terms of compatibility, consumables and reusable parts available commercially or from local providers are a perfect fit to the GenVac. While the manufacturers recommend sourcing these parts from Next Gen, they acknowledge that using locally-sourced parts produce results with minimal variability.

Strong Structure

The materials used to create the GenVac is built for long-term operations. Even the tubes that are considered consumables are made up of high-quality material for repeated use. The high-quality epoxy resin used in these tubes prolong their lifespan. The resin has an average curing time of 24 hours at room temperature. Substandard curing epoxy solidify faster resulting to a blocked tube. Blocked tube can no longer be used for vacuum impregnation.

Makers of GenVac made sure that the equipment is built from high-quality materials. NextGen understands that purchasing the GenVac is an investment for metallographic analysts. Like any investments, users will want to make the most out of it in terms of functionality and length of use.

Superior Quality

The GenVac equipment was born of advancements in technology achieved through years and years of research by the Next Gen company. The MP series is a plug-and-play equipment that can be used by simply reading the instruction manual. Unlike its more complicated peers, the GenVac does not require formal training for installation and usage.

Manufacturers of the GenVac has instructional videos available online. These videos contain graphics and narrations that explains how to easily set-up and use the machine.

The GenVac system assures its users that the vacuum impregnation equipment helps prepare high quality samples required to make reliable metallographic analysis.

Technical Support

The best thing about the GenVac is not only the equipment but the amount of support supplied by its makers. As in all their products, NextGen Materials provide lifetime support guarantee. This means they are always available to answer questions pertaining to the product. The support representatives will guide users into the proper usage of the GenVac for long-term use.

NextGen invested a lot in making sure that the GenVac users will not have hard time using their equipment. They have an engaged team prepared to make user experience a breeze.

Purchasing the GenVac

Interested user can easily request a quotation for the GenVac metallographic cold mounting press through the Next Gen website. The company’s support team will be in touch with interested purchaser on the same day. Upon confirmation of purchase, the equipment will be delivered within two weeks.

For consumables and spare parts, users can simply contact the number that comes with the packaging of the GenVac equipment. These parts are likewise available from local suppliers since GenVac does not use proprietary parts to ensure long-term use.

About Vacuum Impregnation

The technology behind vacuum impregnation is designed to solve common problems in material science engineering such as fungus growth and corrosion. The impregnation process produces pressure tightness that seals permanently micro and macro-porous voids. The resins used in the process prolongs tool life by removing machine friction.

Casting impregnation is important to improve the quality of the materials made up of casting metals. Tiny defects found in these materials are close to impossible to avoid. These defects can range from noticeable incursions, to less-noticeable imperfections such as small bubbles and porosity on the surface.

These defects are the reason why users must invest only in high-quality vacuum impregnation system. It is imperative to purchase only from the best name in the market. Without a doubt, Next Gen Testing Laboratory provides the best equipment available in the market today.

GenVac bests its peers because it is user-friendly due to its uncomplicated design. The equipment is process oriented because of the makers’ good understanding of the equipment’s purpose. Its consumable parts are reusable because of its high-quality resin. The equipment is of superior quality mainly due to its robust structure. Best of all, the makers assembled a tech support who are always willing to assist users in setting up and using the GenVac.

Submit your quotation request today to benefit from our Main and Economical line of equipment today.