How much energy can your material absorb before it snaps? That simple question sits at the heart of impact testing. Charpy and Izod are the two classic pendulum methods used to measure impact strength (toughness) by striking a notched specimen and recording the energy absorbed at break. While both techniques use a swinging hammer, they differ in how the sample is held and where the blow is delivered—differences that matter when you choose a method for metals or plastics, set up a procedure, and report results.

This article explains Charpy vs. Izod in plain terms, shows how specimen orientation and notch geometry affect readings, clarifies reporting units across common standards, and outlines what to consider when selecting a pendulum tester and accessories.

By the end, you’ll know how to: compare Charpy and Izod setups, prepare and condition samples correctly, interpret results for metals and polymers, and pick equipment that fits your energy range and workflow.

Charpy vs Izod – Core Differences in Test Setup

Before diving into sub-sections, here’s the big picture: both are pendulum impact testing methods using a notched specimen, but Charpy treats the sample like a simply supported beam (horizontal), while Izod clamps it as a cantilever (vertical). That single choice, cantilever vs simply supported, drives how the blow is applied and how the notch is oriented, which in turn affects measured toughness.

Before diving into sub-sections, here’s the big picture: both are pendulum impact testing methods using a notched specimen, but Charpy treats the sample like a simply supported beam (horizontal), while Izod clamps it as a cantilever (vertical). That single choice, cantilever vs simply supported, drives how the blow is applied and how the notch is oriented, which in turn affects measured toughness.

Specimen Orientation & Support

Charpy: the bar sits horizontally on two anvils (simply supported). The striker hits the center span.

Izod: the bar stands vertically and is rigidly clamped at one end (cantilever). The striker hits near the free end.

Notch Direction & Impact Point

Charpy: the pendulum strikes the face opposite the notch; the notch is on the tension side during bending.

Izod: the pendulum strikes on the same side as the notch; the notch directly faces the striker.

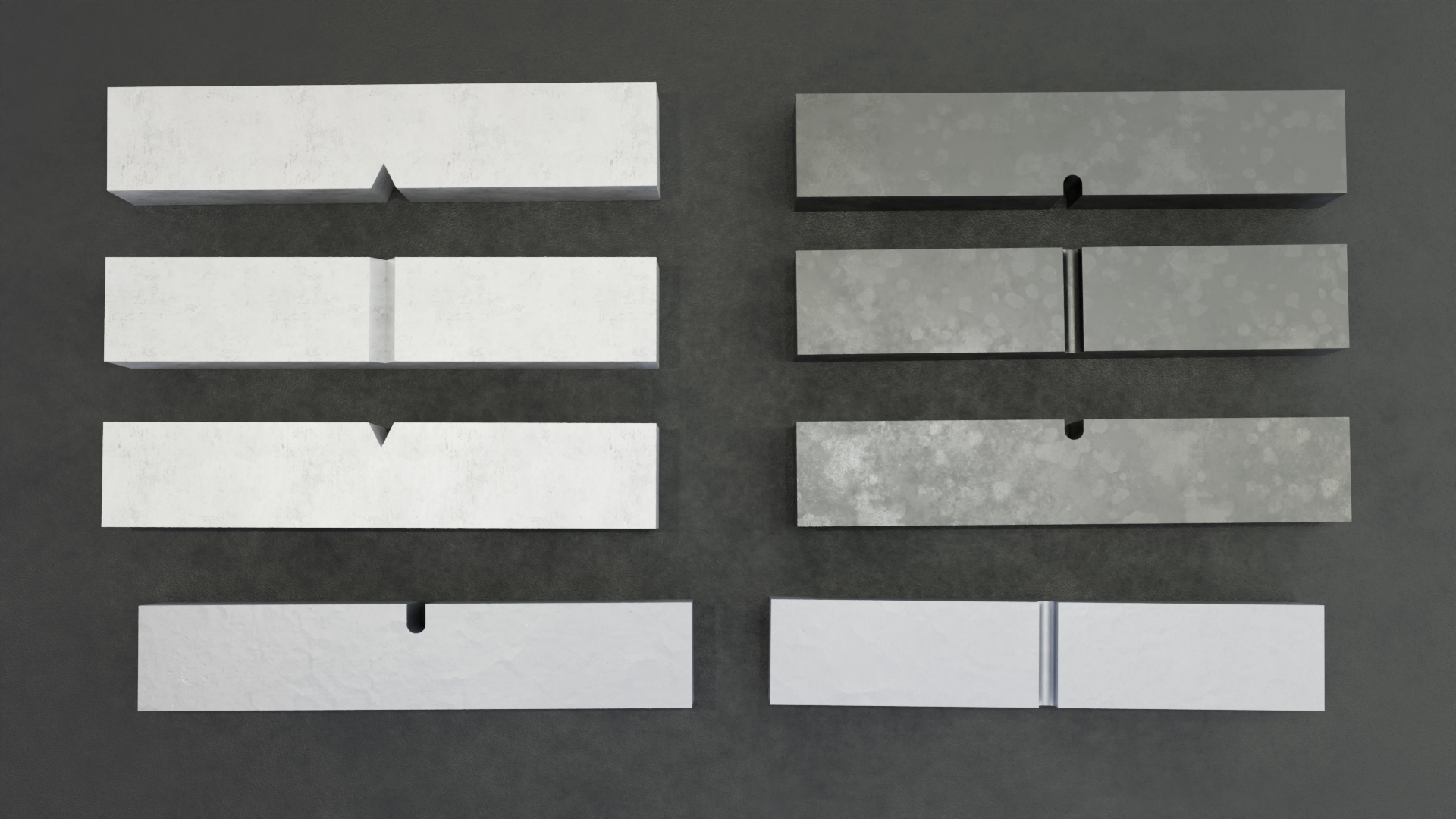

Specimen Types & Notches

Both methods use a single standardized notch per specimen (V or U depending on material/standard). Dimensions, notch radius, and surface finish are tightly controlled because they strongly influence energy absorption.

Result Sensitivity & Typical Use

Charpy setups are common for metals; Izod is widely used for plastics (though both methods appear in each domain under the right standards). Because fixture geometry differs, results are not interchangeable; comparisons should stay within one method and specimen type.

Standards and Reporting for Metals and Plastics

Impact data means little without the right rulebook. Here are the current core standards, what each covers, and how results are reported:

Impact data means little without the right rulebook. Here are the current core standards, what each covers, and how results are reported:

- ASTM E23 — Standard Test Methods for Notched Bar Impact Testing of Metallic Materials (current: ASTM E23-25). Covers Charpy (simply supported) and Izod (cantilever) methods for metals. Defines specimens, procedures, reports, machine requirements and Charpy machine verification (annexes), plus guidance on fracture appearance. Use it when qualifying metallic lots, comparing heats, or setting low-temperature toughness criteria.

- ISO 148-1:2016 — Metallic Materials — Charpy Pendulum Impact Test — Part 1: Test Method. Specifies V-notch and U-notch Charpy testing for metals; instrumented impact is handled separately in ISO 14556. Choose this when your specification references ISO practice, especially for international supply chains. Report absorbed energy (J) and any required ancillary observations (e.g., fracture appearance) per the standard.

- ASTM D256-23e1 — Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. The go-to Izod spec for plastics. Defines notched/unnotched configurations, specimen geometry, and conditioning references. Results are usually expressed as energy per thickness (e.g., J/m or ft·lb/in). Use when ranking polymer grades or comparing molding conditions under ASTM methodology.

- ISO 180:2023 — Plastics — Determination of Izod Impact Strength. ISO counterpart to D256 with multiple specimen types and notches defined; reporting is typically in kJ/m² (area at the notch). Select when an ISO route is required or when you need the ISO family’s specimen options.

- ASTM D6110-18 — Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. Charpy method for plastics; the specimen is a notched bar supported as a beam and struck mid-span. Results are energy per area or per thickness as specified. Apply when your polymer program or customer spec calls for Charpy under ASTM.

- ISO 179-1:2023 — Plastics — Determination of Charpy Impact Properties — Part 1: Non-Instrumented Impact. Broad specimen/configuration coverage for plastics; the ISO 179 series notes wider applicability than ISO 180 for certain materials (e.g., those prone to interlaminar shear fracture). Reporting is typically in kJ/m². Use for ISO-aligned polymer testing and when you need the ISO 179 configurations.

- ISO 13802:2025 — Plastics — Verification of Pendulum Impact-Testing Machines — Charpy, Izod, and Tensile Impact. Defines how often and how to verify pendulum machines (geometry, alignment, energy range) used with ISO 179-1, ISO 180, and ISO 8256. Use it to schedule verification and keep instruments within tolerance; this underpins data traceability.

Reporting units and conversions:

- Metals (ASTM E23, ISO 148-1): report absorbed energy in joules (J). Additional metrics like fracture appearance percentage may be specified by the governing document.

- Plastics (ASTM vs ISO): ASTM methods commonly normalize by thickness (J/m or ft·lb/in); ISO methods typically normalize by area at the notch (kJ/m²). Keep methods separate—do not compare Izod values from D256 directly to ISO 180 numbers, or Charpy values from D6110 directly to ISO 179-1.

Machine verification:

For plastics testing under ISO routes, reference ISO 13802:2025 for verification frequency and procedures. For metals under ASTM E23, follow the annexed verification requirements for Charpy machines. Verified energy capacity, striker geometry, anvil spacing, and alignment directly affect toughness values and comparability across labs.

Specimen Preparation and Test Conditions

Getting specimens and conditions right is the foundation of reliable impact data. The geometry you cut, the notch you machine, and the climate you test in will shift results as much as the pendulum energy itself. Below is a clear, practice-driven guide without fluff.

Metals: Geometry and Notch

For metallic programs, use the rectangular bar sizes defined by the governing method and stick to the specified tolerances. Charpy work typically uses V-notch specimens (with U-notch variants where allowed). The notch angle, depth, and root radius must be held tightly; a slightly rounded root or a chatter mark at the root will raise absorbed energy and mask brittleness. Cut notches with the proper tool, then verify on a projector or gauge rather than by eye. If you are running Izod on metals, follow the metallic method’s single V-notch geometry and report exactly which sub-size you used, since thickness reductions alter the measured energy.

Plastics: Geometry and Notch

Polymer bars follow their own dimensions and notch details under the plastics standards. Izod for plastics relies on one standardized notch per specimen; Charpy for plastics does the same with configurations set by the method family. Thickness control matters more than many teams expect: a small drift in thickness or notch depth can reorder a ranking of grades. Keep surfaces smooth at the notch, maintain the specified notch radius, and avoid heat-affected zones from poor machining that can toughen the root.

Orientation, Clamping, and Strike

Charpy mounts the bar horizontally on two anvils and strikes mid-span on the face opposite the notch, placing the notch on the tension side during bending. Izod clamps the bar vertically as a cantilever and strikes near the free end on the notch side. Treat anvil spacing, striker radius, and pendulum energy as set-points, not suggestions. Check vise alignment and clamping torque for Izod so the bar doesn’t slip, and confirm anvil wear and level on Charpy so the blow lands where the standard expects. Do not mix elements of the two setups; a Charpy anvil span combined with an Izod clamp will give numbers that look precise and mean little.

Conditioning and Test Environment

Plastics should be conditioned to the specified temperature and relative humidity before testing, then tested at the stated climate. Moisture and temperature shift polymer toughness markedly, so record both conditioning and test conditions in the report. For metals, low-temperature evaluations require a proper soak at the target temperature and a quick transfer to the machine to avoid warm-up. In all cases, log the test temperature, striker ID and radius, and any deviations from the prescribed procedure.

Typical Errors and How to Avoid Them

Most bad datasets trace back to a handful of issues: notch geometry out of tolerance, rough finish at the root, the notch facing the wrong way at setup, worn or wrong striker radius, anvil spacing off-spec, or skipped conditioning for plastics. Fix the notch with the correct cutter and re-measure, double-check orientation before every run, replace or re-dress strikers on a schedule, verify anvil spacing and level, and stabilize plastics to the required climate before you start. Document each of these controls alongside the absorbed energy so future comparisons across lots, grades, or labs stay meaningful.

Equipment Considerations: What to Look for in an Impact Tester

Selecting a pendulum impact tester is about matching your method (Charpy or Izod), material family, and reporting route to hardware that produces stable, traceable data. Use the points below as a practical checklist before you shortlist models.

Energy Range and Pendulum Options

Start with the absorbed-energy window you expect. Metals often need higher capacities; many polymer programs sit lower. Look for multiple pendulum arms or interchangeable weights to cover several joule ranges without sacrificing resolution. Adjustable release angles and a reliable brake help with repeatable pre-positioning and safe recovery.

Striker Geometry and Anvils

Charpy and Izod use different striker noses and support hardware. Verify that the system offers the correct striker radius options and anvil spans for your standards, plus positive identification of each part (markings or IDs in software). Quick, tool-assisted swaps reduce setup errors and downtime.

Charpy/Izod Changeover

If you plan to run both methods on one frame, evaluate the changeover sequence. A good design uses keyed fixtures, hard stops, and stored presets so orientation, span, and height cannot be mis-set. Clear on-screen prompts and photos reduce operator mistakes on shift changes.

Safety and Guarding

A full enclosure with interlocks prevents a release when the door is open and contains fragments at break. Remote release, emergency stop, and automatic pendulum catch are not “nice to have” features—they protect people and samples.

Instrumented Impact Capability

Instrumented options add a force–time (and force–deflection) trace alongside absorbed energy. This enables peak force, crack initiation energy, and partitioning of total energy. Check sampling rate, signal conditioning, and calibration workflow. If you need this now or later, confirm the path to retrofit and the supported standards.

Temperature Control and Transfer

For sub-ambient or elevated testing, look for compatible baths or environmental chambers with specimen racks that match your bar dimensions. The system should support timed soaks and a short, consistent transfer to the strike position; accessories like insulated tongs and staging fixtures help keep temperature within tolerance.

Automation and Software

Well-designed software reduces variability: guided workflows per standard, barcode/QR sample ID, automatic unit handling (J, J/m, kJ/m²), and templated reports. Useful extras include batch queues, audit logs, role permissions, and exports (CSV/PDF/LIMS). If you run both ASTM and ISO routes, confirm that reporting formats switch cleanly.

Verification, Calibration, and Upkeep

Impact numbers drift when striker noses wear, anvil edges round, or alignment shifts. Look for built-in verification routines, compatibility with certified reference specimens, and clear counters for maintenance tasks. Availability of spare strikers, anvils, and bearings matters for uptime.

Specimen Preparation and Metrology

Repeatable notches drive repeatable energy. Consider paired equipment: notch broaching/milling machines, gauges, and an optical projector to check notch depth and root radius. Keeping prep and verification in the same ecosystem cuts scrap and rework.

Fit for Your Lab

Check footprint, mass, and floor requirements; power and air (if any); operator training materials; and service coverage. Simple, labeled fixtures and an intuitive HMI shorten onboarding for new technicians.

Systems That Fit Real Lab Requirements

Impact programs rarely look the same from one lab to the next. Materials, methods, and reporting routes change, and the hardware has to follow.

As a supplier of material testing equipment, NextGen offers a broad range of pendulum impact solutions. If you are currently evaluating Charpy and Izod machines, allow us to introduce two top-sellers that cover plastics on one side and high-energy metals on the other.

Class J — Charpy & Izod Automatic Impact Testing System (1 J–50 J)

Class J is tailored for polymers and other light-gauge materials where non-instrumented Izod and Charpy are the daily workflow. Out of the box it supports Izod to ASTM D256 and ISO 180, Charpy to ASTM D6110 and ISO 179, and adds tensile-impact per ASTM D1822 and ISO 8256. Verification follows ISO 13802, so machine setup and periodic checks align with common ISO practice.

Class J is tailored for polymers and other light-gauge materials where non-instrumented Izod and Charpy are the daily workflow. Out of the box it supports Izod to ASTM D256 and ISO 180, Charpy to ASTM D6110 and ISO 179, and adds tensile-impact per ASTM D1822 and ISO 8256. Verification follows ISO 13802, so machine setup and periodic checks align with common ISO practice.

Interchangeable pendulums cover 1–50 J for Charpy and up to 22 J for Izod. A shaftless encoder delivers fine angle resolution, while the touchscreen guides specimen dimensions, pendulum selection, units, and calibration entries. The single-column frame leaves ample working space and makes changeovers straightforward when moving between bars, pipe segments, or tensile-impact fixtures.

Safety and day-to-day handling are built in: a guarded test area, electromagnetic release, and a control flow that keeps operators on the correct setup for the method at hand.

Class G — Single-Column Charpy & Izod Impact Tester (Up To 750 J)

Class G targets metallic programs that require higher energies and tight repeatability. It covers Charpy and Izod for metals under ASTM E23, ISO 148, and EN 10045. An instrumented option is available to capture force–time traces in line with ASTM E2298 and ISO 14556 when you need more than absorbed energy.

Class G targets metallic programs that require higher energies and tight repeatability. It covers Charpy and Izod for metals under ASTM E23, ISO 148, and EN 10045. An instrumented option is available to capture force–time traces in line with ASTM E2298 and ISO 14556 when you need more than absorbed energy.

Capacity scales from 150 J through 300, 450, and 600 J up to 750 J. The system pairs an analog dial with a digital readout and can connect to a PC for analysis and batch reporting. A motorized raise with auto-return, quick striker swaps between ASTM and ISO noses, and a fully enclosed test space support repeatable work at speed.

For environmental control, an optional cooling package enables sub-ambient testing down to −180 °C. Automation paths include specimen feeding and debris collection that clears the strike path and routes fragments to separate bins for high-throughput workflows.

Bringing It All Together

Picking between Charpy and Izod starts with your material and the standard you follow. Metals programs often point to Charpy or Izod under ASTM E23 or ISO 148, while plastics work leans on Izod (ASTM D256, ISO 180) and Charpy (ASTM D6110, ISO 179-1). Staying inside one method family keeps results comparable and reporting clear.

Good data comes from more than the pendulum. Specimen geometry, notch quality, climate control, striker radius, anvil span, and verification routines all move the needle. Treat these as fixed set-points, document them in the report, and you’ll get trendable numbers across lots, grades, and labs.

If you’re evaluating equipment, match energy range and fixtures to your test route, decide whether you need instrumented impact now or later, and check that changeovers between Charpy and Izod are fast and fool-proof. That combination saves time and keeps variability down.

If you need help selecting impact testing equipment or want to compare configurations for your standards and energy window, please request a quote or contact us directly. We’re here to help you set up a clean, compliant impact workflow.