Charpy impact tests are becoming increasingly popular in material testing due to their ability to provide valuable data on materials’ toughness and fracture resistance under high strain rates. Having a good understanding of material behavior during impacts is key to preventing catastrophic failures and increasing the reliability of products.

With the growing reliance on Charpy impact tests, there has been a corresponding increase in the need for specifically prepared test specimens, such as V-notched or U-notched specimens. However, not all broaching machines on the market can deliver the necessary precision and efficiency for such specialized preparation.

This is why we at NextGen Material Testing are pleased to introduce our product, the GenNotch 4000 Series – Specimen Notching/Broaching Machine. Our blog will cover 12 reasons why investing in the GenNotch 4000 Series is beneficial for your testing requirements and how this investment can yield significant returns in precision and efficiency.

The Importance of Notched Specimens in Charpy Impact Testing

In addition to the GenNotch 4000 Series’ specific advantages, it is also important to understand why Charpy impact tests require notched specimens.

Charpy impact tests use notched specimens to measure the energy absorbed by a material during fracture, providing data on its toughness and fracture resistance. The inclusion of a notch in the specimen acts as a stress concentrator. This makes it easier to initiate and propagate cracks under impact loading. This setup is designed to simulate real-world conditions where materials might encounter sudden stresses that could lead to catastrophic failures.

The specimens have standardized notches in shape and size, such as V-notched or U-notched configurations. This standardization provides assurance that the test results are consistent and comparable with different materials and test setups. The specific geometry of the notch affects the fracture behavior of the material being tested, with the shape and dimensions of the notch influencing the stress concentration at the tip of the notch. This setup helps in determining the ductile to brittle transition temperature of materials, which indicates at what temperature a material may fail when subjected to rapid impact loads.

12 Reasons to Invest in the GenNotch 4000 Series

Having understood the basics of notched specimens, here are compelling reasons why investing in the GenNotch 4000 Series can significantly benefit the efficiency and quality of your material testing procedures.

Outstanding Accuracy

In terms of Charpy impact testing, the GenNotch 4000 Series offers the highest level of accuracy. In recent years, precision in machining test specimens has reached new heights, enabling the creation of notches as fine as one-third the width of a human hair, a significant improvement over past capabilities. This level of precision guarantees that the machine can meet and exceed the rigorous demands of modern industry standards like ASTM E23 and ISO 148-1, which dictate the dimensions and geometry of test specimens to provide consistent and reliable results.

Accuracy is not just a benefit. It is a requirement in contemporary material testing, where even the smallest deviation can lead to significantly different outcomes in tests designed to simulate real-world stresses. For properties such as ductile to brittle transition temperature and overall material toughness, the GenNotch 4000 Series uses state-of-the-art technology to guarantee that each notch meets precise specifications.

Superb Versatility

The GenNotch 4000 Series offers versatility in specimen preparation, making it ideal for diverse testing requirements when testing different materials. This machine’s ability to precisely cut different kinds of notch types makes it exceptionally useful for a wide range of materials, from metals to polymers like PMMA and soda-lime glass, which are often used in impact testing to assess material behavior under stress.

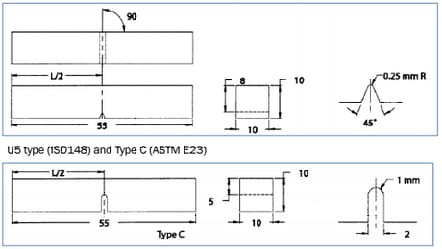

The types of notches that the GenNotch 4000 Series can handle include:

-

V type: Depth of 2mm, angle of 45°±2°, and radius of 0.25mm±0.025mm.

-

U2 type: Depth of 2mm, width of 2mm, and radius of 1mm±0.05mm.

-

U3 type: Depth of 3mm, width of 2mm, and radius of 1mm±0.05mm.

-

U5 type: Depth of 5mm, width of 2mm, and radius of 1mm±0.05mm.

3. A Low-Maintenance Design

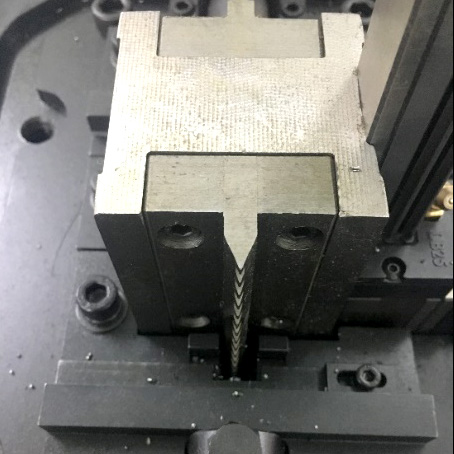

The GenNotch 4000 Series is engineered to simplify operations and increase productivity without sacrificing quality. One of the standout features of this notching and broaching machine is its low-maintenance design. Equipped with an internal lubricating oil circulation system, this machine reduces the need for frequent maintenance checks and manual lubrication, allowing it to operate smoothly over extended periods with minimal intervention.

Furthermore, the design cleverly addresses the issue of debris and shavings, which are inevitable byproducts of notching. These particles accumulate on the top of the machine, strategically positioned to be easily removable with simple cleaning tools such as a brush or a magnet. Besides simplifying maintenance, this thoughtful design element ensures that the machine remains clean and functional, optimizing its lifespan and reliability.

4. Exceptional Durability

The GenNotch 4000 Series is built with durability, designed to withstand continuous laboratory use. This notch broaching machine is constructed using high-quality materials that provide longevity and wear resistance. Engineered to operate efficiently for decades, our tool is an investment in reliability and enduring performance.

In addition to its robust construction, NextGen Material Testing fully supports GenNotch with a comprehensive after-sales service commitment. This support includes everything from routine maintenance to more complex service needs, keeping each GenNotch system performing at its best.

5. Compliance with Key Regulatory Standards

Your facility will be well-equipped to meet these rigorous standards with the GenNotch 4000 Series. Keeping your testing procedures in compliance with recognized international and regional standards not only adds credibility to your procedures but also guarantees that the results of your tests will be accepted by many organizations.

Your facility will be well-equipped to meet these rigorous standards with the GenNotch 4000 Series. Keeping your testing procedures in compliance with recognized international and regional standards not only adds credibility to your procedures but also guarantees that the results of your tests will be accepted by many organizations.

The GenNotch 4000 Series complies with several key regulatory standards, including:

-

ISO 148 – specifies the Charpy pendulum impact test method for metallic materials, a test to determine notch toughness and the energy absorbed in an impact test.

-

EN 10045 – the European standard for metallic materials’ impact test (Charpy), aligned with ISO 148.

-

ASTM E23 – recognized widely in the United States, this standard outlines procedures for notch bar impact testing of metallic materials.

- DIN 50115 – a German standard governing the testing methods for impact tests on metallic materials, making sure your operations meet international and European standards.

6. Excellent Adaptability

The GenNotch 4000 Series stands out for its adaptability, a feature that accommodates material testing laboratories’ varied needs. This versatility is particularly helpful as it enables the machine to handle both regular and sub-size specimens, which are often required under diverse industry standards. Unlike many other machines limited to standard specimen sizes, GenNotch can easily adapt to smaller or non-standard sample sizes with simple modifications.

This adaptability is key for laboratories that work with different types of materials and applications so that they can conduct Charpy and Izod impact tests without multiple machines. As a result of the ability to toggle between different specimen sizes, the GenNotch 4000 Series expands its utility while also improving its efficiency and throughput.

7. Simple Power Requirements

The GenNotch 4000 Series is designed for ease of integration into any laboratory setting, thanks to its power requirements. The machine operates efficiently with a power consumption of just 350W and requires a 3-phase, 5-line AC 220V±10% connection at 50Hz. This makes it adaptable and easy to install in various global settings without complex electrical modifications or special power setups.

This simple approach to power requirements means that facilities around the world can use GenNotch without incurring additional costs for power adaptability. This allows the machine to easily integrate into existing power systems, facilitating an easy setup process that lets users quickly benefit from its capabilities.

8. Reliable Results

To make informed decisions, sample preparations must be reliable in order to make sure that test results accurately reflect real conditions. The GenNotch 4000 Series offers delivering consistent and reliable results, like those produced by a milling machine. This is known for its precision in material removal and shaping. The consistency of test results is crucial for mapping them to real-world applications as closely as possible, despite the complexity of sample preparation.

9. Space-saving Design

Investing in the GenNotch 4000 Series also offers the advantage of its compact and space-efficient design, which is especially beneficial in laboratories with limited space. Unlike many other specimen broaching machines, which can be bulky and require significant floor space, the GenNotch is a floor-standing unit with dimensions that make it highly conducive to smaller environments. The updated measurements are 22.85″ wide, 15.75″ deep, and 44.90″ tall (equivalent to 58 cm x 40 cm x 114 cm), making it one of the more compact models available today.

Weighing 440lbs (200 kg) and featuring a 20-litre oil volume, the GenNotch combines robust functionality with a design that minimizes its footprint. Its efficient usage of space does not compromise the machine’s performance, but rather enhances its suitability for a number of settings, making it easier to integrate into existing lab layouts.

10. A Comprehensive Warranty

As part of NextGen Material Testing’s commitment to customer satisfaction, we offer a comprehensive warranty on the GenNotch 4000 Series. Manufacturer’s warranties cover the entire machine, except for consumables, allowing users to rely on their investment long after purchase. Customers can have peace of mind knowing that their GenNotch is covered against potential defects in materials and workmanship for a minimum of one year.

We offer this extensive warranty not only to reflect our confidence in the quality and durability of our products but also to align with their goal of providing a positive purchasing experience. GenNotch’s robust warranty fosters trust and reliability, both factors highly valued in the laboratory equipment marketplace.

11. Easy to Purchase

Purchasing the GenNotch 4000 Series is meant to be straightforward and hassle-free. The NextGen Material Testing team has simplified the process, enabling customers to request an online quote quickly and effortlessly. Typically, responses to these requests are provided within 24 hours, allowing potential buyers to make informed decisions. For those needing immediate assistance, a knowledgeable company representative is just a phone call away at 1-888-332-3582.

In addition to accommodating a number of payment options such as bank wire transfer, cash, and credit card, we may also accept purchase orders from customers who meet specific credit requirements. For added convenience, interested parties can easily access further information and contact details by visiting the ‘Contact Us’ page. They can also request an online quote.

12. Trusted Product Support

NextGen Material Testing Inc. is renowned for its dependable, user-friendly machines like the GenNotch 4000 Series but also for its comprehensive support services. Backed by a dedicated team of skilled professionals, we offer extensive support for all aspects of machine operation, from routine inquiries to complex troubleshooting.

For over half a decade, NextGen Material Testing has developed industry-leading sample preparation machines. Our specialists provide customized support that meets your specific needs and budgetary requirements. Beyond just technical support, we provide a full range of services including maintenance, servicing of material testing equipment, and supplying consumables.

Achieving the Full Potential with the GenNotch 4000 Series

Investing in the GenNotch 4000 Series offers a multitude of benefits that increase both the efficiency and accuracy of material testing in any lab setting. From its outstanding precision that meets rigorous industry standards to its versatility in handling different types of specimens, our broaching machine sets itself apart. Its design maximizes productivity while minimizing maintenance efforts, and its robust construction guarantees longevity and durability. Compliance with key regulatory standards ensures that your testing processes are globally recognized. The adaptability to a range of specimen sizes means you can handle all kinds of testing requirements with a single machine.

Investing in the GenNotch 4000 Series offers a multitude of benefits that increase both the efficiency and accuracy of material testing in any lab setting. From its outstanding precision that meets rigorous industry standards to its versatility in handling different types of specimens, our broaching machine sets itself apart. Its design maximizes productivity while minimizing maintenance efforts, and its robust construction guarantees longevity and durability. Compliance with key regulatory standards ensures that your testing processes are globally recognized. The adaptability to a range of specimen sizes means you can handle all kinds of testing requirements with a single machine.

Moreover, the GenNotch 4000 Series is designed with practical considerations in mind, such as its space-saving dimensions and simple power requirements, which make it suitable for labs of all sizes and configurations. The reliability of the results it produces guarantees that you can trust its performance to reflect true material behaviors under impact stresses. Each unit comes with a comprehensive warranty, simplifying the purchasing process and providing extensive after-sales support, minimizing the risk of potential problems.

To learn more about the GenNotch 4000 Series, visit the product page on our website. You can also contact us directly or request an online quote. Our dedicated team is ready to assist you with all your material testing needs so that you have the support and resources to achieve the highest standards of testing accuracy and reliability.