If your laboratory has been looking for a dependable Elmendorf tearing tester for films, paper, textiles, nonwovens, or thin foils, we have important news. Our equipment line has expanded with a system built to measure tear resistance for both research and daily quality control.

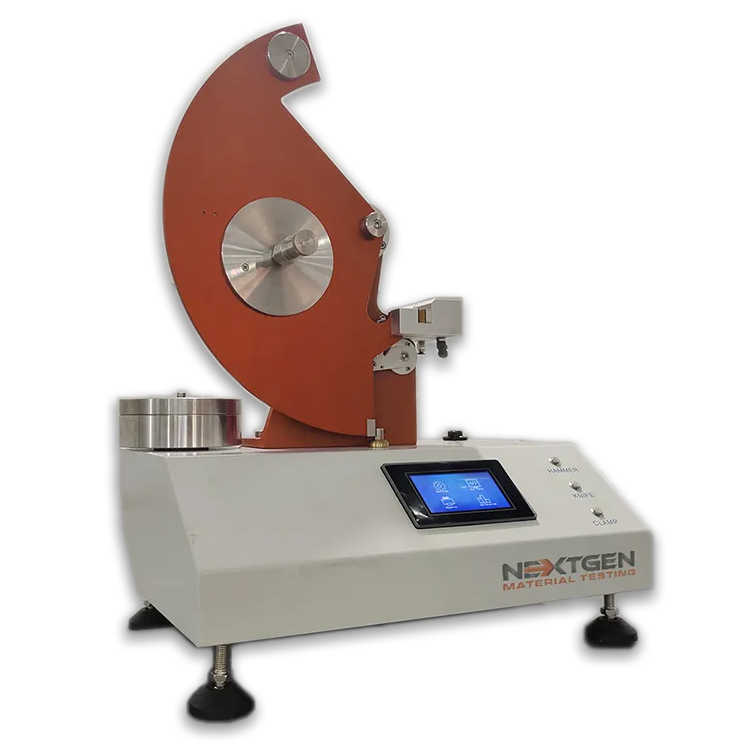

We are introducing the GenElm Series Elmendorf Tearing Tester, available in 64 N and 128 N models. This instrument meets international testing standards and provides the technical capabilities that modern laboratories require.

This overview looks at the GenElm Series from several sides: how the Elmendorf method works, what the system offers in features and specifications, and the materials and standards it is designed to work with.

What The Elmendorf Method Measures

The Elmendorf method is a pendulum-based tear test. A specimen with a precise slit is clamped between two jaws. When released, the pendulum swings through the sample and propagates the tear. The energy lost by the pendulum corresponds to the force needed to continue the tear.

This method gauges tear propagation resistance—how much force is required to extend a slit under controlled geometry. Because the clamp gap, slit length, and tear path are fixed, results are comparable between samples and laboratories.

Materials such as paper, plastic films, textiles, and nonwovens are typical subjects. The test is useful when a material might tear after an initial cut, and you want to quantify how “resistant” it is to that tear’s progression.

Because the method measures the energy (or force) required for the tear to propagate over a fixed distance, it provides a consistent metric for comparing materials under similar conditions. The key value reported is often in Newtons or grams-force.

Meet The GenElm Series – Elmendorf Tearing Tester

The GenElm Series Elmendorf Tearing Tester is part of our laboratory line for material evaluation. It works on the pendulum principle, a reliable method for studying how a tear develops once it begins. Each test produces direct data that laboratories can use for research or quality control. The system follows ASTM, ISO, and DIN procedures.

The GenElm Series Elmendorf Tearing Tester is part of our laboratory line for material evaluation. It works on the pendulum principle, a reliable method for studying how a tear develops once it begins. Each test produces direct data that laboratories can use for research or quality control. The system follows ASTM, ISO, and DIN procedures.

Both versions share the same structure, accuracy, and geometry. The 64 N model covers films, paper, and light fabrics, while the 128 N model handles stronger or reinforced materials. The range gives laboratories the flexibility to test samples of different thickness and strength without changing the setup.

A precise pendulum, pneumatic clamping, and automatic cutting keep every test consistent. The touchscreen interface allows quick setup and data review. A built-in microcomputer records the measurements and calculates statistics such as average, minimum, and maximum values.

Features That Speed Up Routine Testing

The GenElm Series is built for laboratories that run tests every day. Its design focuses on speed, clarity, and accuracy without adding extra steps to the process.

The touchscreen panel gives direct access to settings, test runs, and reports. All calculations are performed automatically, leaving no need for manual data handling. Pneumatic clamping keeps each specimen fixed in place, while the pendulum release starts the test under identical conditions every time.

The touchscreen panel gives direct access to settings, test runs, and reports. All calculations are performed automatically, leaving no need for manual data handling. Pneumatic clamping keeps each specimen fixed in place, while the pendulum release starts the test under identical conditions every time.

Automatic cutting prepares each sample with the same shape and slit length. Interchangeable pendulums cover the full testing range from 16 to 128 newtons, allowing work with light films or tougher fabrics on the same system.

The tester calculates statistical values on the spot, including mean, minimum, maximum, standard deviation, and coefficient of variation. Results can be exported through an RS232 port for printing or data archiving.

The interface supports several languages and comes with calibration documentation. Each unit is supplied with inspection certificates confirming that it meets laboratory testing requirements.

Compliance With International Standards

Our Elmendorf tearing testers comply with a range of global standards, from ASTM and ISO to APPITA, BS, and JIS. These documents define how tear resistance should be measured across materials such as paper, film, and textiles. Below is a short list of the core standards that the GenElm Series supports.

Our Elmendorf tearing testers comply with a range of global standards, from ASTM and ISO to APPITA, BS, and JIS. These documents define how tear resistance should be measured across materials such as paper, film, and textiles. Below is a short list of the core standards that the GenElm Series supports.

- ASTM D1424 – Defines the method for measuring the tearing strength of woven fabrics using a falling pendulum. It specifies sample dimensions, slit length, and clamp setup to keep conditions uniform.

- ASTM D1922 – Describes how to evaluate the tear resistance of plastic films and thin sheets. The test measures the energy required to propagate a tear after an initial slit. It is widely used in packaging and polymer quality control.

- ASTM D689 – Establishes the Elmendorf method for paper and board. The pendulum swing measures the force needed for a tear to extend through the sheet.

- ISO 1974 – Covers paper and cardboard tear testing using the Elmendorf method. It defines the geometry of clamps and tear path to maintain comparability between laboratories.

- ISO 6383-2 – Specifies tear resistance testing for plastic film and sheeting by the Elmendorf method. It is applied to thin polymer materials used in packaging and industrial applications.

- ISO 4674-2 – Applies to coated fabrics such as rubberized or laminated textiles. The test helps determine durability under stress conditions and repeated bending.

- DIN 53862 – Details how to test the tear strength of textiles using a pendulum apparatus. It focuses on precision in clamping and specimen alignment to avoid measurement deviation.

- DIN 53128 – Describes the method for determining the tearing resistance of paper and cardboard. It is often used alongside ISO 1974 for comparative testing in European laboratories.

- EN ISO 13937-1 – Defines a trouser-shaped tear test for woven fabrics. It helps measure how a tear propagates under tension, giving insight into fabric structure and weave performance.

- JIS K 7128-2 – Outlines Japan’s Elmendorf method for plastic films and sheets. It mirrors the international approach while including parameters for locally used polymer materials.

- JIS L0849 – Covers tear testing of woven fabrics by the Elmendorf method. It remains a key standard for textile manufacturers in Asia.

- BS 4468 – Specifies the British procedure for measuring the tear strength of paper and board. It defines calibration checks and sample conditioning to maintain result accuracy.

- CSA D9 – Represents the Canadian standard for tear testing of paper. It aligns closely with ASTM and ISO methods but reflects regional material types and testing climates.

- APPITA P 400 – Used by the pulp and paper industries in Australia and New Zealand. It details how to determine tear resistance in both sheeted and pulp-based products.

Technical Specifications

The GenElm Series comes in two versions for different testing ranges. The 64 N model works within 0–16 N, 0–32 N, and 0–64 N limits, suited for films, textiles, and paper. The 128 N model expands capacity to 128 N for reinforced and technical materials. Both use the same pendulum mechanism and geometry for consistent measurement.

The GenElm Series comes in two versions for different testing ranges. The 64 N model works within 0–16 N, 0–32 N, and 0–64 N limits, suited for films, textiles, and paper. The 128 N model expands capacity to 128 N for reinforced and technical materials. Both use the same pendulum mechanism and geometry for consistent measurement.

Each tester has a clamp gap of 7.0 ± 0.25 mm, a slit length of 20 ± 0.2 mm, and a tear travel of 43 ± 0.15 mm. The structure keeps all results comparable between instruments.

Both versions keep the same frame, electronics, and operating flow. The only difference is capacity, letting laboratories match the model to the strength range of their materials.

- Measuring Range:

64 N model – 0–16 N, 0–32 N, 0–64 N

128 N model – 0–16 N, 0–32 N, 0–64 N, 0–128 N - Accuracy: ±0.2% F.S.

- Clamp Gap: 7.0 ± 0.25 mm

- Slit Length: 20 ± 0.2 mm

- Tear Travel: 43 ± 0.15 mm

- Dimensions: 19.7 × 15.7 × 24.4 in (500 × 400 × 620 mm)

- Weight: 110–128 lbs (50–58 kg)

- Power Supply: AC220V, 50Hz, 100W

- Control System: LCD touchscreen with microcomputer

- Sample Clamping: Pneumatic with automatic pendulum release

- Specimen Cutting: Automatic and uniform

- Data Output: RS232 connection to PC or printer

Reliable Tear Testing For Paper, Film, And Fabric

The GenElm Series represents the next step in how laboratories approach tear strength testing. It delivers accuracy that stays consistent, whether you work with paper, film, or textile materials. Both models, 64 N and 128 N, maintain identical geometry, giving laboratories the freedom to test different materials without changing instruments.

Every detail in the system was created with laboratory work in mind. Automatic cutting and pneumatic clamping shorten preparation time. The touchscreen control makes operation clear, while built-in data processing keeps results organized and traceable. Together, these features form a workflow that feels natural and reliable, even during daily testing routines.

For laboratories interested in upgrading their current setup or adding Elmendorf tear testing to their capabilities, the GenElm Series offers a complete and practical solution. You can request a quote or contact our team directly for more information.