Testing hardness can be a time-consuming process. Imagine being in the field and a piece of metal has to be measured for hardness. The nearest laboratory is miles away. That can really eat up time and slow down progress in a project.

A Telebrineller hardness tester makes things more convenient. It is a portable hardness tester that’s easy to operate. It can be used in the field. It can also be used in the laboratory. It’s smaller than conventional hardness testers. It saves some precious lab space and it is easy to bring along to project locations.

Uses

This hardness tester can be used to determine the strength of a metal sample. It can be used for testing the strength of unknown metals, which can help in identification purposes. It can be used to gather more data for research purposes about a specific sample.

This equipment can also be used to determine the load bearing capabilities of a sample. This is important if the metal component of the sample is part of an overall system. One example is testing the load bearing capacities of a section of a train track.

It can also be used to assess and verify structural integrity. This is an important data for assessing safety of certain structures and equipment. It can also be used for determining the weld quality.

Hence, this tester can also be applied in other industries that work with and around metals for quality assurance and safety assessment.

This is a very helpful tool for people working with metals. It has many key benefits that makes any metal-related project much easier.

Benefits

This is a handy tool that helps test hardness of metals anytime, anywhere. It’s easy to carry around and gives reliable results.

-

Accuracy

The Telebrineller system for portable Brinelle measurements is developed following strict quality control. Every factor and element were checked and re-checked against the standard in order to ensure accuracy.

This system is widely considered as a major achievement in the industry. This is a result of using metallurgical knowledge backed by more than 50 years’ worth of research and field experience.

The microscope used by measuring the indentations on the test bars is made by Leica. This is a leading company in manufacturing accurate and reliable microscopes for industry use. This microscope is highly accurate and can provide readings within 0.05 millimeters. This measurement range makes each reading more accurate, providing a greater detail to assessing the hardness of the sample metal.

All parts of this portable hardness tester are built to be able to perform well under rugged conditions. This helps the tester to perform well and provide accurate measurements even in extreme conditions. It has no delicate parts that might get damaged and affect measurements. It also has no sensitive elements that might not function well under certain extreme conditions. Everything is solid to provide accurate data anywhere, under any type of working environment.

The parts are also has steel crystal structure to minimize errors.

-

Portable

This tester is lightweight. It only weighs less than 10 pounds. It can be easily carried from one location to another, as the need arises. It is easy to bring right to the project site for on the spot, immediate measurement.

It is also compact and takes up little space in the equipment cargo. It has its own carrying kit that keeps all the components organized and easy to bring along.

Moreover, it is weather-proof. It can be brought along to any kind of terrain and used in any kind of climate. It has no fragile parts or delicate elements that require special adjustments. All the parts of the tester are manufactured to handle rugged conditions well.

-

Comes standard with certification

Testing equipment should come with standards certification to ascertain their reliability and quality. This portable tester is made according to the standard set by the industry’s regulating authority. The parts are all made according to standards specifications to assure quality, reliability and most importantly, accuracy.

The tester system also comes with certification of calibration. This assures accuracy of measurements with each use.

-

Comes standard with Telebrineller test blocks

The kit comes with standard test bars. These bars are critical to the testing process. The standard Telebrineller test bars have uniform hardness. These have +/- (plus or minus) 3% of BHN. This information is etched on the bars’ edge.

Each of these bars were certified by an equipment verified by the National Standards Institute as completely traceable. That means that each test block can be verified for testing from the original test lab with ease.

-

Excellent for testing on large specimen

The system is simple and very straightforward to use. It can be used on large specimen. The hammer is large enough to make a significant indentation size on larger metal surfaces.

-

Readily available for virtually next-day shipment

This product is available online. Upon checkout and filling in of the requisites for payment and shipping, it will be shipped immediately. It will be delivered at the customer’s address the next day.

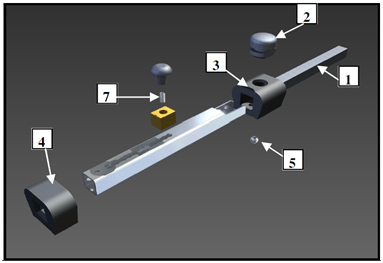

Components of the system

The tester is made up of different parts. There are the test bars, which are key to making accurate hardness measurements. A microscope is also included in the kit, as well as a computer, a bar holder and a calculation pad. Al these are neatly organized in a light metal carrying case. Each of the parts has its own holder inside the case to keep things in their proper place and not rattling around while it is carried from one location to the next.

The test bars are at the core of this tester system. These come in different hardness based on known physical references. The measurements are not affected by certain factors that may cause inaccuracies such as thickness, alloy, position and geometry. Even rust and paint do not have a huge impact on the accuracy of the measurements.

The microscope is used for measuring the indentations made on the sample and on the test bar.

The calculation pad and the computer is used for computing the hardness of the sample. The bar holder keeps the test bar and the sample in place as the indentations are made.

All of these are included in the kit of the portable Brinelle hardness tester. Price is very affordable.

How does a Telebrineller tester work?

A portable Brinell tester works by comparing the hardness of a sample to the standard indentation of a steel ball on a standardized bar.

Using this portable Brinell hardness tester is easy. It’s a one-hammer blow and does not require any special skills or training to operate the tester.

First, the metal type of the sample is determined. A test bar that matches the sample’s type is then selected. This will be used as reference on which the calculations will be based upon.

An indentation is made on the surface of both the sample and the test bar. The Telebrineller system will simultaneously indent the surfaces of the test bar and the sample. Place the Telebrineller instrument on the sample. Strike the anvil with a hammer.

The test bar and sample are then placed under the microscope to measure the indentations, specifically the its diameters. The measurements are then entered into calculation pad to determine the values. Next, these values are entered into the computer where the equations are tweaked to match the type of sample being used.

The computer will make the calculations and give the BHN of the sample.

This can also be applied to unknown metal samples. For this, a test bar with average BHN will be used from the kit.

Learn more by contact us today or submitting your quote request.