Unreliable equipment, uncertified testers, lack of compliance with international standards — these are common problems in hardness testing workflows. Inconsistent results, limited testing range, and manual errors often lead to delays, wasted materials, and failed audits. If you’re involved in rubber or plastic quality control, this may sound all too familiar.

That’s why we’re introducing the Digi Test II, a fully automatic Shore, IRHD, and VLRH hardness testing system that gives accurate, repeatable results with little input from the operator. It meets standards like ASTM D2240 and DIN ISO 48, so it is built for accuracy, traceability, and efficiency.

In this article, we’re going to show you what Digi Test II can do, how it works, and why it’s an important tool for modern QA teams, engineers, manufacturers, and material testing labs.

Understanding Modern Shore, IRHD, and VLRH Hardness Testing Systems

Hardness testing is very important for assessing the quality and performance of rubber, plastic, and foam materials. But not all methods for testing are the same. There are three standardized methods called Shore, IRHD, and VLRH, each of which is meant to test a different type of material or condition.

Hardness testing is very important for assessing the quality and performance of rubber, plastic, and foam materials. But not all methods for testing are the same. There are three standardized methods called Shore, IRHD, and VLRH, each of which is meant to test a different type of material or condition.

People often use Shore hardness testing on elastomers and thermoplastics. The Shore A and D scales cover materials that are soft to hard. IRHD (International Rubber Hardness Degrees) is great for rubber parts that are small or have complicated shapes because it gives you high repeatability without changing the shape of the sample. VLRH (Very Low Rubber Hardness) lets you measure very soft materials like foam rubber and silicone.

Older testers often need to be set up and handled by hand, but newer systems like the Digi Test II do everything automatically. They make sure that the force is applied consistently, the measurement time can be programmed, and the readings are accurate on all supported scales. This change from manual to automatic operation gets rid of variability, makes things more efficient, and makes sure that global standards like ASTM D2240, ISO 48, and DIN EN ISO 868 are always followed.

Introducing Digi Test II: The Automatic Shore, IRHD and VLRH Hardness Testing System

The Digi Test II is a fully automatic hardness testing system that can measure Shore, IRHD, and VLRH with excellent precision. It is used for quality control in testing rubber, plastic, foam, and elastomers, and it gives consistent, traceable results for many types of materials and shapes.

The Digi Test II is a fully automatic hardness testing system that can measure Shore, IRHD, and VLRH with excellent precision. It is used for quality control in testing rubber, plastic, foam, and elastomers, and it gives consistent, traceable results for many types of materials and shapes.

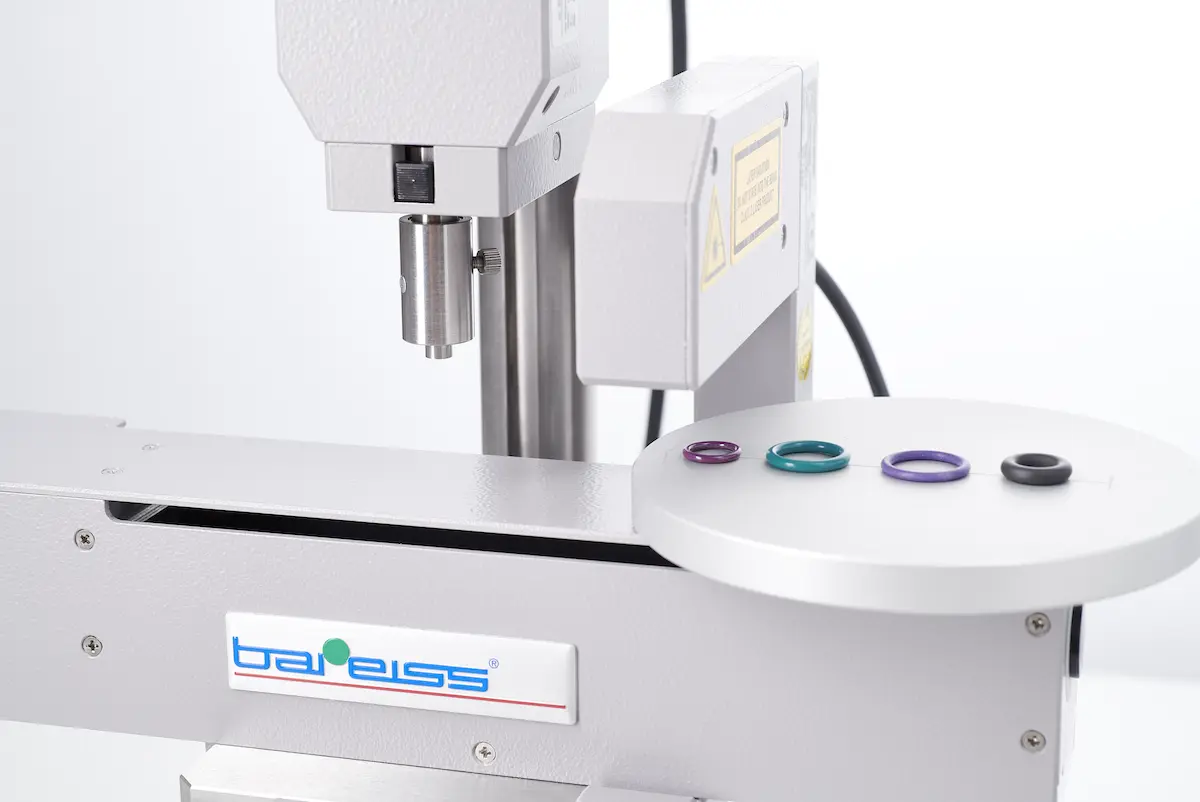

This modular system includes four main components:

- Electronic unit – serves as the intelligent control center, managing settings, method selection, and measurement time

- Loading module (pick-up bracket) – applies precise test forces

- Motorized test stand – makes sure that the position is stable and can be repeated.

- Interchangeable measuring heads – support all relevant hardness methods (Shore A/B/C/D/00/000, IRHD N/H/L/M, VLRH)

The tester automatically determines the measurement head and test method that are already installed. It is easy to set up and doesn’t need to be calibrated by hand. The system can handle even the hardest samples because it can program test times (1 to 99 seconds), find surfaces on its own, and work with concave, convex, and irregular surfaces.

Digi Test II is flexible and reliable enough for both routine quality control and more complicated research and development tasks. You can use it to measure the hardness of foam rubber, soft silicone, thermoplastics, composite tubes, O-rings, or thin-walled rubber seals.

Barofix and Centrofix are two additional tools that make it easy to quickly and automatically position samples, especially O-rings, hoses, and seals. The system also works with special software that lets you fully control tests, analyze results, and make reports.

Key Features of the Digi Test II Hardness Testing System

The Digi Test II has been created to provide you with a hardness test that is fully automated, accurate, and can be done repeatedly. It has smart software, modular hardware, and a user-friendly interface that make even the most complicated testing situations intuitive for operators of all levels. It can be used alone or as part of a production line.

- High Accuracy and Repeatability: The system gives measurements with a Shore value of 0.1, which is the highest level of accuracy that the industry expects for hardness testing. Automation reduces the influence of the operator, which guarantees that the results are the same for all test cycles.

- Programmable Measurement Timing: Users can set the measurement time from 1 to 99 seconds, giving them full control over the test parameters to meet different standards and material behaviors.

- Full Compliance with International Standards: This system meets the testing needs of many countries, such as ASTM D2240, DIN ISO 7619, and DIN EN ISO 868.

- Smart Electronic Control Unit: The built-in control panel has a clear display, easy-to-use navigation, and feedback, including real-time guidance if readings go outside the expected range. This helps you pick the right measuring unit and makes sure the test is accurate.

- Modular and Flexible System Architecture: The system can test Shore, IRHD, and VLRH all on one platform because the measuring units can be switched out. The measuring head is automatically recognized, and the right settings are applied right away, so you don’t have to do anything by hand.

- USB Data Output and Software Integration: You can export test results for reporting, archiving, or analysis using the built-in USB interface. The system also works with special software, which lets you do everything digitally, from testing to making reports.

- Production-Ready Design: Digi Test II can be used in automated testing environments, which makes it perfect for operations with a lot of work where consistency and traceability are very important.

- Hysteresis Function for Elastic Materials: The system has a hysteresis mode that lets you look closely at viscoelastic materials where rebound or time-dependent deformation needs to be taken into account.

ASTM and ISO-Compliant Shore, IRHD, and VLRH Hardness Tester

The Digi Test II is a good choice for regulated environments and global quality assurance workflows. It meets a lot of different testing standards, such as:

- ASTM D2240

- ASTM D1415

- DIN ISO 7619

- DIN ISO 48

- DIN EN ISO 868 / NF EN ISO 868

- DIN ISO 27588

- 903 Part A26

- NF T 46-003

This broad range of compliance means that both Shore and IRHD/VLRH hardness testing methods work with an extensive selection of materials and industries.

All exchangeable measuring units come with official DAkkS (formerly DKD) certificates proving that they have been calibrated and verified for quality. This confirms that metrological standards are met and documentation remains audit-ready.

Who Can Benefit from the Digi Test II Hardness Testing System?

The Digi Test II offers exceptional value for both experienced professionals and newcomers. Its broad scope of coverage (Shore, IRHD, VLRH), modular design, and automation make it useful in many fields:

- Rubber and Plastics Manufacturers: Great for testing O-rings, seals, hoses, gaskets, pressure rollers, and molded parts. The system enables uniform hardness measurement throughout production, enhancing quality control during both intermediate and final inspections.

- Quality Assurance and Material Testing Labs: This system gives you traceable, audit-ready results that meet all ASTM and ISO standards and can also get DAkkS certification if you want it. It works well in labs that deal with an assortment of sample types because it can handle micro and ultra-soft materials.

- Automotive, Aerospace, and Defense Industries: Used to test the hardness of parts that operate under stress, temperature fluctuations, and mechanical load. Digi Test II helps make sure that rubber and plastic parts used in engines, aircraft systems, and military-grade equipment work as they should and meet safety standards.

- R&D and Product Development Teams: This lets them accurately characterize materials and test the performance of new elastomers, foams, and advanced polymers. The programmable measuring time and hysteresis function give you a lot of information about viscoelastic behavior and deformation that changes over time.

- Pharmaceutical and Medical Device Manufacturers: This is good for testing the hardness of silicone tubing, gel components, soft plastics, and other medical-grade materials where safety and compliance depend on accuracy and consistency.

- Consumer Goods and Soft Material Applications: Allows for in-depth testing of soft foams, silicone grips, flexible soles, and other materials with low hardness. VLRH and Shore 00/000 capabilities give useful results when regular durometers don’t work.

Why Digi Test II Is the Right Choice for Hardness Testing

Having the right tools for hardness testing can make a big difference. The Digi Test II is an easy-to-use system that combines smart automation, certified accuracy, and an extensive list of testing options. It helps you get consistent, reliable results every time, whether you’re working with soft silicones, hard plastics, or complicated rubber parts.

Digi Test II is an excellent option for quality control labs, manufacturers, and engineering teams that need a platform that meets international standards and can be used for many different things.

If you want to know more about this product or need help picking the right one for your specific needs, you can reach out to us or fill out an online form. We are here to help you with all of your material testing needs.